Halogen-free low-smoke flame-retardant TPE cable material

A low-smoke flame retardant and cable material technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor compatibility, lower mechanical properties and processing properties of materials, and achieve both flame retardant and mechanical properties good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

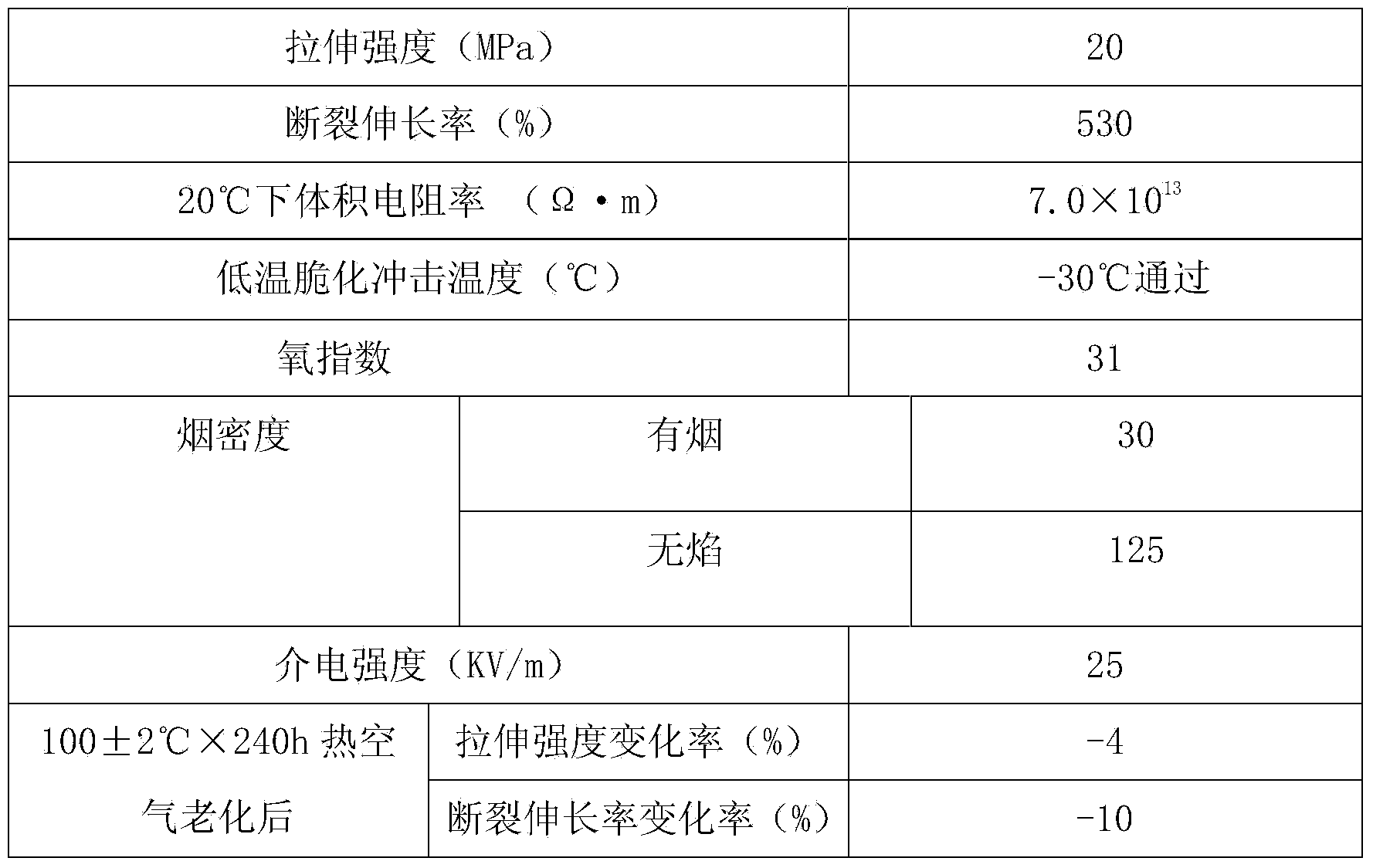

[0017] A halogen-free low-smoke flame-retardant TPE cable material, prepared from the following component raw materials in weight (kg):

[0018] Polyurethane thermoplastic elastomer 45, POE elastomer 15, polypropylene resin 35, PE wax 8, aluminum hypophosphite 18, zinc borate 9, ammonium molybdate 11, ethylene-octene copolymer grafted maleic anhydride copolymer 8, anti- Oxygen agent 1024 0.2, antioxidant 1035 0.4, epoxy butyl oleate 11, dioctyl phthalate 11, dioctyl maleate 6, carbon black N220 5, light calcium carbonate 8, zinc oxide 2 , wollastonite powder 8, carbon fiber 11,

[0019] Nano boron carbide 9, modified filler 17,

[0020] Wherein, the preparation method of the modified filler is as follows: a. Take the following raw materials in parts by weight: kaolin 185, medical stone 33, nano-carbon 1, ascorbic acid 2, coix seed oil 1, aluminum nitride powder 1, zinc gluconate 2, jade Powder 2, polyisobutylene 2, aluminate coupling agent DL-411 1, stearic acid 2, antioxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com