Oil-resistant acrylic rubber sealing pad for transformer and preparation method thereof

A rubber gasket and acrylate technology, applied in the field of gaskets, can solve the problems of aging and cracking of gaskets, poor oil resistance, oil leakage of transformers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

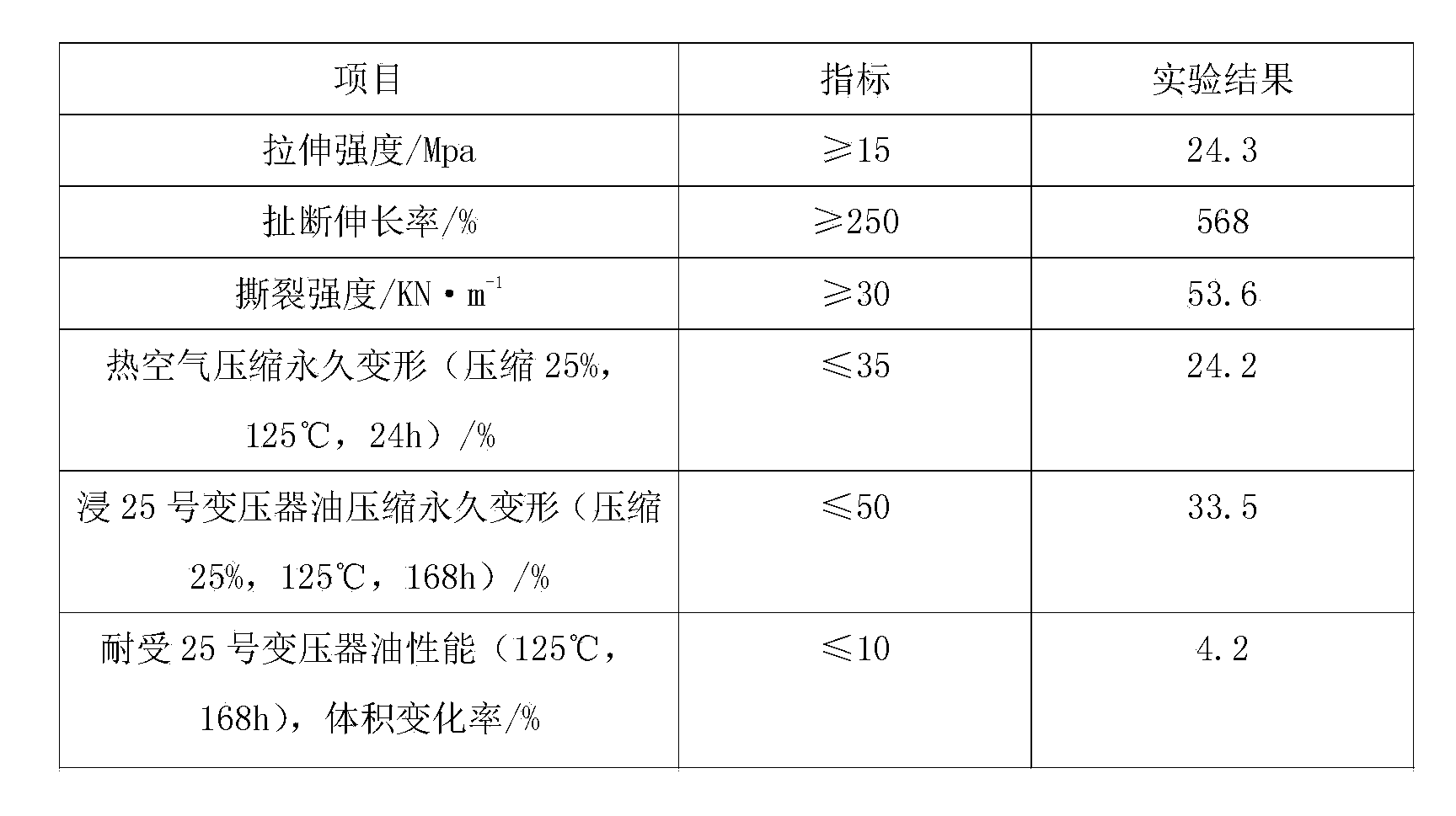

Examples

Embodiment Construction

[0014] An oil-resistant acrylic rubber gasket for transformers, made of the following raw materials (kg): acrylic rubber (AR-200) 50, chloroether rubber (C-55) 18, fluororubber (246) 10, modified Sepiolite powder 8, zinc borate 4, antimony trioxide 3, 2-hydroxyimidazoline 2, chlorinated paraffin 3, magnesium oxide 1, organic bentonite 10, calcined loess 4, ethylene bisoleic acid amide 1.5, calcium zinc Stabilizer 1.5, sulfur 3, dioctyl maleate 4, trioctyl trimellitate 2, antioxidant ODA 1, antioxidant TPPD 2, accelerator CZ 2, accelerator ZDC 2.

[0015] The modified sepiolite powder is prepared by the following method: soak the sepiolite in 0.5mol / L sulfuric acid solution for 2 hours, wash it, dry it at 130°C for 12h, then calcinate it at 350°C for 4h, take it out, and cool it , crushed and finely ground; then add dolomite powder equivalent to 8% of sepiolite weight, 4% magnesium silicate, 2% precipitated white carbon black, 3% polyisobutylene, 5% calcium lignosulfonate, mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com