Microporous rubber base plate and preparation process thereof

A technology of microporous rubber and backing plate, applied in the field of microporous rubber, can solve the problems of reducing the tensile strength of the material, reducing the density of the rubber material, high temperature dependence, etc., so as to maintain the deformation recovery ability, prolong the service life, and reduce the viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

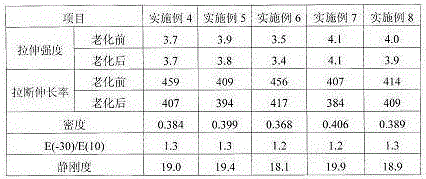

Embodiment 1

[0053] The preparation technology of microporous rubber backing plate of the present invention comprises the following steps:

[0054] The first step mixing

[0055] Put 100 parts by weight of EPDM rubber on the open mill and put it into the internal mixer 15 times, and then put in 5 parts by weight of active agent, 60 parts by weight of filling material and 30 parts by weight of paraffin oil, and mix for 10 minutes. The rotation speed is 15r / min, the debinding temperature is 130°C, after cooling to room temperature, it is thinly passed on the mill for 4 times, and 6 parts by weight of polyethylene glycol mixture, 6 parts by weight of foaming agent, 2.5 parts by weight of vulcanizing agent and 2 parts by weight of vulcanizing agent are added successively. part accelerator, mixed evenly to obtain rubber compound;

[0056] Step 2 Foaming and vulcanization

[0057] Vulcanize on a plate vulcanizer at 155°C for 25min, with a vulcanization pressure of 4MPa.

Embodiment 2

[0059] The preparation technology of microporous rubber backing plate of the present invention comprises the following steps:

[0060] The first step mixing

[0061] Put 100 parts by weight of EPDM rubber on the open mill for 15 times into the internal mixer, and then put in 7 parts by weight of active agent, 80 parts by weight of filler material and 45 parts by weight of paraffin oil, and mix for 12 minutes. The rotation speed is 20r / min, the degumming temperature is 140°C, after cooling to room temperature, it is thinly passed on the open mill for 5 times, and 12 parts by weight of polyethylene glycol mixture, 8 parts by weight of foaming agent, 4 parts by weight of vulcanizing agent and 3.75 parts by weight of foaming agent are added in sequence. part accelerator, mixed evenly to obtain rubber compound;

[0062] Step 2 Foaming and vulcanization

[0063] Vulcanize on a flat vulcanizer at 155°C for 32.5min with a vulcanization pressure of 6MPa.

Embodiment 3

[0065] The preparation technology of microporous rubber backing plate of the present invention comprises the following steps:

[0066] The first step mixing

[0067] Put 100 parts by weight of EPDM rubber on the open mill for 15 times into the internal mixer, and then put in 9 parts by weight of active agent, 100 parts by weight of filler material and 60 parts by weight of paraffin oil, and mix for 14 minutes. The rotation speed is 25r / min, the degumming temperature is 150°C, after cooling to room temperature, it is thinly passed on the open mill for 6 times, and 18 parts by weight of polyethylene glycol mixture, 12 parts by weight of foaming agent, 5.5 parts by weight of vulcanizing agent and 5.5 parts by weight of foaming agent are added successively. part accelerator, mixed evenly to obtain rubber compound;

[0068] Step 2 Foaming and vulcanization

[0069] Vulcanize on a plate vulcanizer at 155°C for 40min, and the vulcanization pressure is 8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com