Synthetic method of biphenyl compounds

A synthesis method and compound technology, which is applied in the field of synthesis of biphenyl compounds, can solve problems such as unreported and harsh reaction conditions, and achieve the effects of simple operation, high reaction efficiency, and a wide range of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

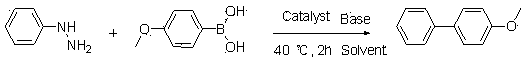

[0022] Embodiment 1: the synthesis of p-methoxybiphenyl

[0023]

[0024] Phenylhydrazine ( 1 ) (0.03 mmol), p-methoxyphenylboronic acid ( 2 ) (0.06 mmol), tetrakistriphenylphosphopalladium (0.0009mmol), sodium carbonate (0.06mmol) and toluene (1 ml) mixed solvent, stirred at 40 ℃ for 2 hours. After the reaction was completed, filtered, the organic phase was combined, Concentrated crude product. The crude product was subjected to column separation with ethyl acetate / petroleum ether=1:10 as the eluent to obtain the desired product. The yield is 91%.

[0025] 1 H NMR (400 MHz, CDCl 3 ) δ 7.54 (t, J = 8.2 Hz,4H), 7.42 (t, J = 7.6 Hz, 2H), 7.30 (t, J = 7.4 Hz, 1H), 6.98 (d, J = 8.7 Hz, 2H), 3.85 (s, 3H).

Embodiment 2

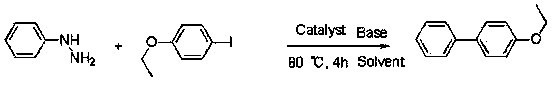

[0026] Embodiment 2: the synthesis of 3-methoxybiphenyl

[0027]

[0028] Phenylhydrazine ( 1 ) (0.03 mmol), 3-methoxyphenylboronic acid ( 2 ) (0.06 mmol), tetrakistriphenylphosphopalladium (0.0009mmol), sodium carbonate (0.06mmol) and toluene (1 ml) mixed solvent, stirred at 40 ℃ for 2 hours. After the reaction was completed, filtered, the organic phase was combined, Concentrated crude product. The crude product was subjected to column separation with ethyl acetate / petroleum ether=1:10 as the eluent to obtain the desired product. The yield is 92%.

[0029] 1 H NMR (400 MHz, CDCl3) δ 7.59 (d, J = 7.2 Hz, 2H), 7.44 (t, J = 7.5 Hz, 2H), 7.39 – 7.32 (m, 2H), 7.18 (d, J= 7.8 Hz, 1H), 7.13 (d, J = 1.9 Hz, 1H), 6.90 (dd, J = 8.2, 1.9 Hz, 1H), 3.87 (s, 3H).

Embodiment 3

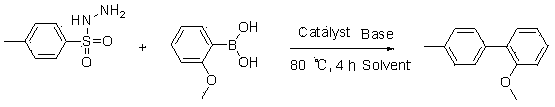

[0030] Embodiment 3: the synthesis of 2-methoxybiphenyl

[0031]

[0032] Phenylhydrazine ( 1 ) (0.03 mmol), 2-methoxyphenylboronic acid ( 2 ) (0.06 mmol), tetrakistriphenylphosphopalladium (0.0009mmol), sodium carbonate (0.06mmol) and toluene (1 ml) mixed solvent, stirred at 40 ℃ for 2 hours. After the reaction was completed, filtered, the organic phase was combined, Concentrated crude product. The crude product was subjected to column separation with ethyl acetate / petroleum ether=1:10 as the eluent to obtain the desired product. Yield 86%.

[0033] 1 H NMR (400 MHz, CDCl3) δ 7.53 (d, J = 7.2 Hz, 2H), 7.41 (t, J = 7.5 Hz, 2H), 7.33 (ddd, J = 6.8, 4.3, 2.4 Hz, 3H), 7.08 – 6.95 (m, 2H), 3.82 (s, 3H).

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com