Multilayer plastic-wood composite board and preparation method thereof

A technology for wood-plastic composite materials and boards, which is applied in the fields of structural materials and their preparation, multi-layer wood-plastic composite materials and their production fields, and can solve the problem of low nail holding force of foamed porous plastic-wood composite materials and solid plastic-wood composite materials. Cumbersome, inconvenient transportation, installation and other problems, to achieve the effect of strong anchoring force, high rigidity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

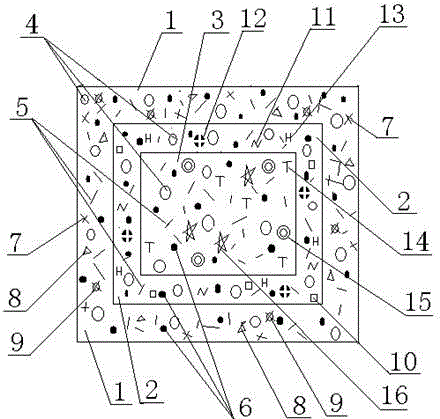

Image

Examples

Embodiment 1

[0085] Example 1: A multi-layer plastic-wood composite material board and a preparation method thereof, the preparation process is:

[0086] (1) Weigh benzene and ethanol at a mass ratio of 1:1 to prepare a mixed solvent. Use the mixed solvent to extract the wood flour at 90°C for 8 hours to remove the wax in the wood flour, and then rinse the wood flour with tap water for 45 minutes. After drying to absolute dryness, modified wood powder is obtained;

[0087] (2) Mix polyethylene, modified wood powder (120 mesh), maleic anhydride grafted polyethylene, ultraviolet absorber, nano silicon dioxide (30nm), and glyceryl stearate in the following parts by weight, then use The extruder extrudes the molten material flow on the surface of the solid wood plastic composite material, the extrusion temperature is 170℃:

[0088] Polyethylene 25

[0089] Modified wood flour 100

[0090] Maleic anhydride grafted polyethylene 4

[0091] UV absorber 0.09

[0092] Nano silica 0.4

[0093] Glyceryl stearate...

Embodiment 2

[0110] Embodiment 2: A multi-layer plastic-wood composite material board and its preparation method and its preparation method, the preparation process is:

[0111] (1) Weigh benzene and ethanol at a mass ratio of 1:1 to prepare a mixed solvent. Use the mixed solvent to extract the wood flour at 85°C for 6 hours to remove the wax in the wood flour, and then rinse the wood flour with tap water for 30 minutes. After drying to absolute dryness, modified wood powder is obtained;

[0112] (2) Mix polyethylene, modified wood powder (80 mesh), maleic anhydride grafted polyethylene, ultraviolet absorber, nano silicon dioxide (20nm), and glyceryl stearate in the following parts by weight before use The extruder extrudes the molten material flow on the surface of the solid wood plastic composite material, the extrusion temperature is 160℃:

[0113] Polyethylene 20

[0114] Modified wood flour 100

[0115] Maleic anhydride grafted polyethylene 2

[0116] UV absorber 0.06

[0117] Nano silica 0.2

...

Embodiment 3

[0135] Embodiment 3: A multi-layer plastic-wood composite material board and its preparation method and its preparation method, the preparation process is:

[0136] (1) Weigh benzene and ethanol at a mass ratio of 1:1 to prepare a mixed solvent. Use the mixed solvent to extract the wood flour at 95°C for 10 hours to remove the wax in the wood flour, and then rinse the wood flour with tap water for 60 minutes. After drying to absolute dryness, modified wood powder is obtained;

[0137] (2) Mix polyethylene, modified wood powder (160 mesh), maleic anhydride grafted polyethylene, ultraviolet absorber, nano silicon dioxide (40nm), and glyceryl stearate in the following parts by weight before use The extruder extrudes the molten material flow on the surface of the solid wood plastic composite material, the extrusion temperature is 180℃:

[0138] Polyethylene 30

[0139] Modified wood flour 100

[0140] Maleic anhydride grafted polyethylene 6

[0141] UV absorber 0.12

[0142] Nano silica 0.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com