Foamed shoe sole material and preparation method thereof

A technology of sole material and natural rubber, applied in the field of foamed soles, can solve the problems of water resistance, poor elongation, reduced wear resistance and the like, and achieve the effects of weight reduction, high wear resistance and high wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

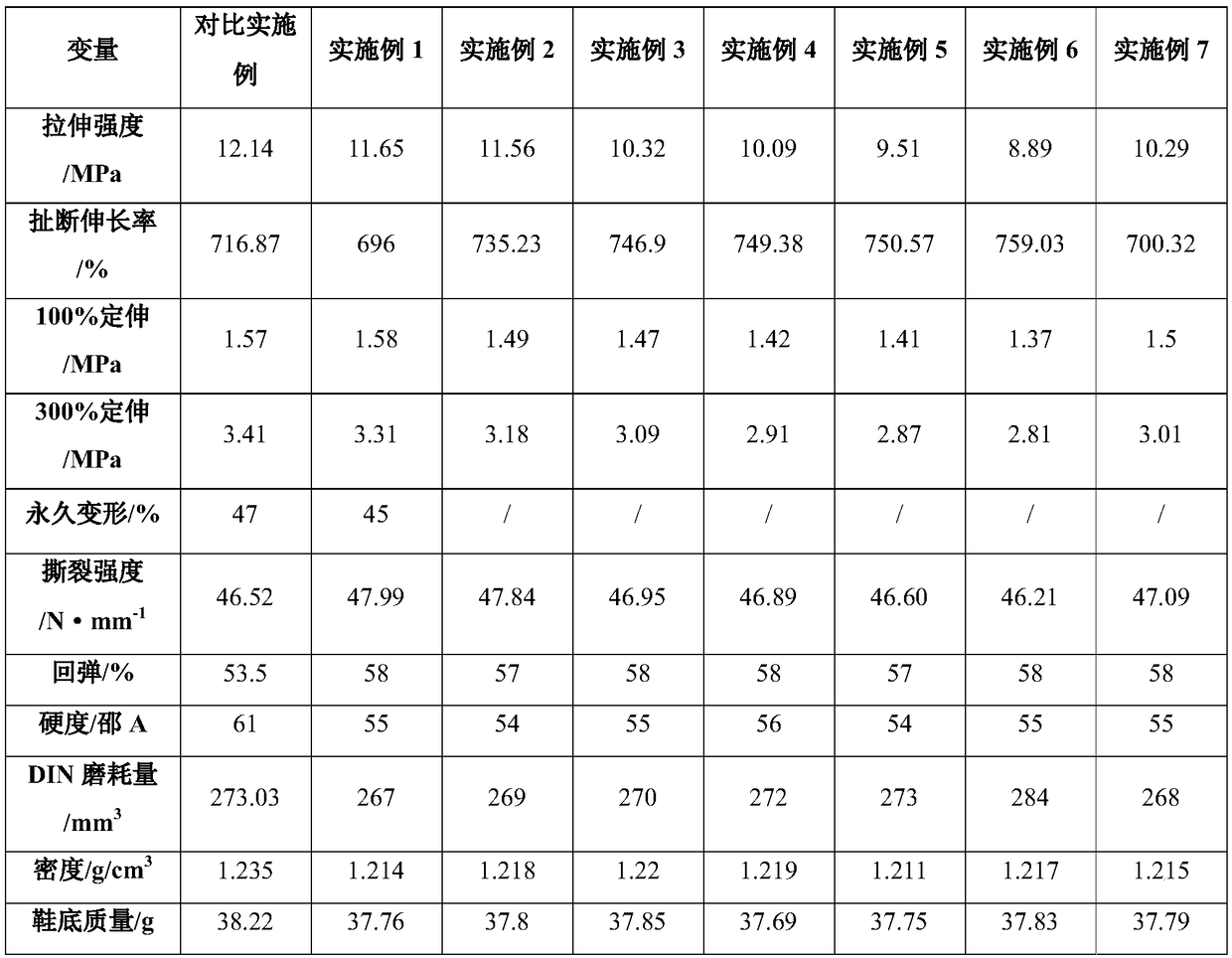

Examples

Embodiment 1

[0084] The foam sole material of the present embodiment comprises the following components by weight:

[0085] 50 parts of natural rubber, 20 parts of styrene-butadiene rubber, 30 parts of butadiene rubber, 25 parts of white carbon black, 25 parts of modified superfine kaolin, 1.5 parts of 4,4-oxobisbenzenesulfonyl hydrazide, 3 parts of silane coupling agent, 2 parts of inorganic nano whiskers, 40 parts of light calcium carbonate, 0.8 parts of stearic acid, 0.5 parts of paraffin, 5 parts of zinc oxide, 6 parts of PEG-4000, 30 parts of epoxy oil, 2 parts of styrenated phenol, 2 parts of phenolic resin, 2.6 parts of sulfur, 0.4 parts of diphenylguanidine, 0.6 parts of 2-mercaptobenzothiazole, 1.2 parts of 2,2'-dithiodibenzothiazole.

[0086] It is prepared by the following method:

[0087] 1) Internal mixer mixing: The initial temperature of the internal mixer mixing process is 90°C, and the rotor speed is 77r / min. Put the natural rubber into the open mill for masticating 5 ti...

Embodiment 2

[0092] The foam sole material of the present embodiment comprises the following components by weight:

[0093] 50 parts of natural rubber, 20 parts of styrene-butadiene rubber, 30 parts of butadiene rubber, 40 parts of white carbon black, 10 parts of modified ultrafine kaolin, 1.5 parts of 4,4-oxobisbenzenesulfonyl hydrazide, 3 parts of silane coupling agent, 40 parts of light calcium carbonate, 0.8 parts of stearic acid, 0.5 parts of paraffin, 5 parts of zinc oxide, 6 parts of PEG-4000, 30 parts of epoxy oil, 2 parts of styrenated phenol, 2 parts of phenolic resin, 2.6 parts Sulfur, 0.4 parts of diphenylguanidine, 0.6 parts of 2-mercaptobenzothiazole, 1.2 parts of 2,2'-dithiodibenzothiazole.

[0094] It is prepared by the following method:

[0095] 1) Internal mixer mixing: The initial temperature of the internal mixer mixing process is 90°C, and the rotor speed is 77r / min. Put the natural rubber into the open mill for masticating 5 times to make masticated natural rubber. ...

Embodiment 3

[0100] The foam sole material of the present embodiment comprises the following components by weight:

[0101] 50 parts of natural rubber, 20 parts of styrene-butadiene rubber, 30 parts of butadiene rubber, 30 parts of white carbon black, 20 parts of modified superfine kaolin, 1.5 parts of 4,4-oxobisbenzenesulfonyl hydrazide, 3 parts of silane coupling Agent, 40 parts of light calcium carbonate, 0.8 parts of stearic acid, 0.5 parts of paraffin, 5 parts of zinc oxide, 6 parts of PEG-4000, 30 parts of epoxy oil, 2 parts of styrenated phenol, 2 parts of phenolic resin, 2.6 parts Sulfur, 0.4 parts of diphenylguanidine, 0.6 parts of 2-mercaptobenzothiazole, 1.2 parts of 2,2'-dithiodibenzothiazole.

[0102] It is prepared by the following method:

[0103]1) Internal mixer mixing: The initial temperature of the internal mixer mixing process is 90°C, and the rotor speed is 77r / min. Put the natural rubber into the open mill for masticating 5 times to make masticated natural rubber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com