Powder spreading device and powder spreading method for selective laser melting (SLM) equipment

A laser selective melting and powder spreading device technology, which is applied in the field of additive manufacturing, can solve the problems of powder spreading influence, long consumption time, easy loss, etc., and achieve the effect of improving molding efficiency, reducing powder waste, and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

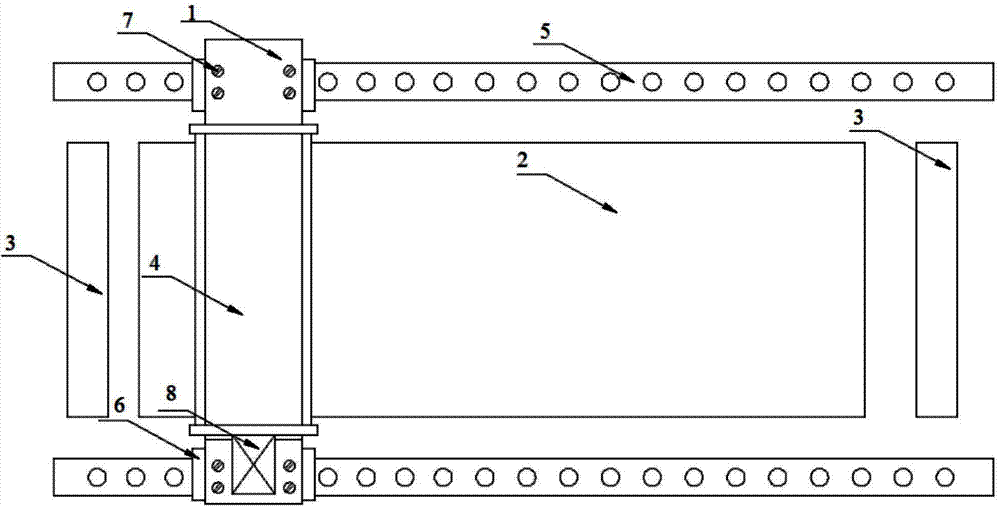

[0027] A laser selective melting SLM equipment powder spreading device is a device for laying a new layer of powder during the SLM forming process. The structure of this embodiment is as follows figure 1 and 2 As shown, it includes the powder spreading main body 1, the auxiliary guide rail linear motor 6, the auxiliary powder spreading guide rail 5 and the spilled powder recovery hanger box 3, and the auxiliary powder spreading guide rail 5 is arranged on both sides of the forming cylinder 2, and the forming cylinder 2 The two ends of the powder spreading device are respectively provided with overflow powder recovery hanging ear boxes 3 for recovering excess powder. The two ends of the powder-spreading main body 1 are fixed on the sliders on the auxiliary powder-spreading guide rail 5 by connecting screws 7 . The auxiliary guide rail linear motor 6 is used to drive the powder spreading main body 1 to slide on the auxiliary powder spreading guide rail 5 .

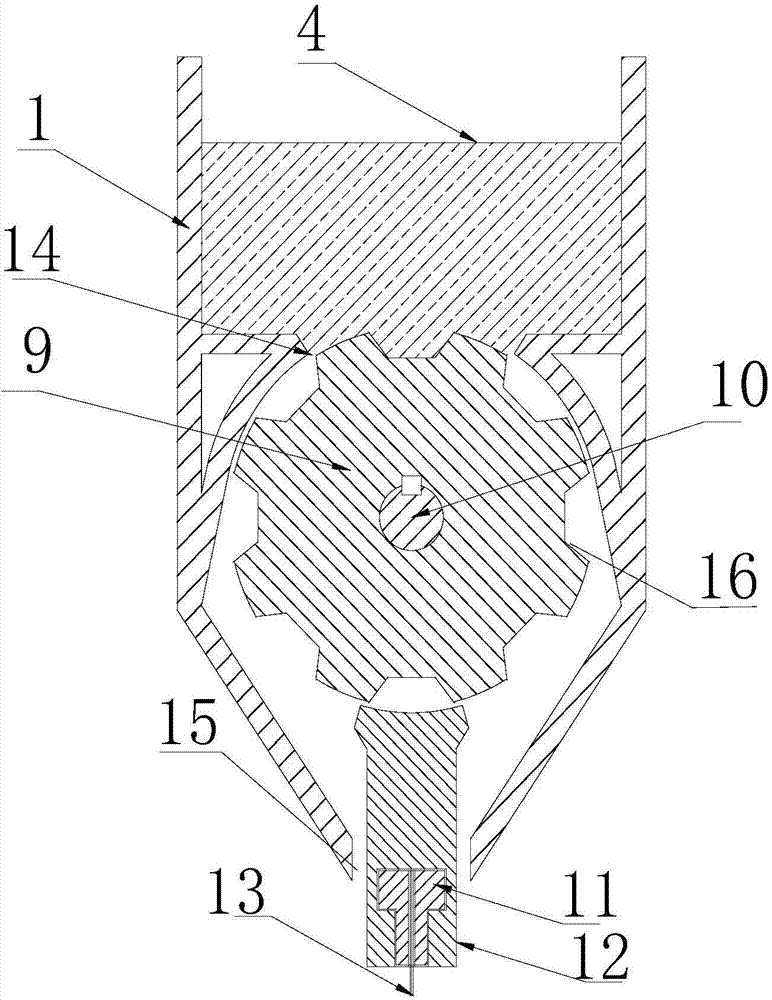

[0028] Such as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com