Wire coil with automatic wire winding function for electrical test

An electrical test and automatic technology, which is applied in the field of wire reels with automatic take-up function for electrical tests, can solve the problems of increased energy consumption, unusable use, large floor space, etc., and achieves the effect of saving energy and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

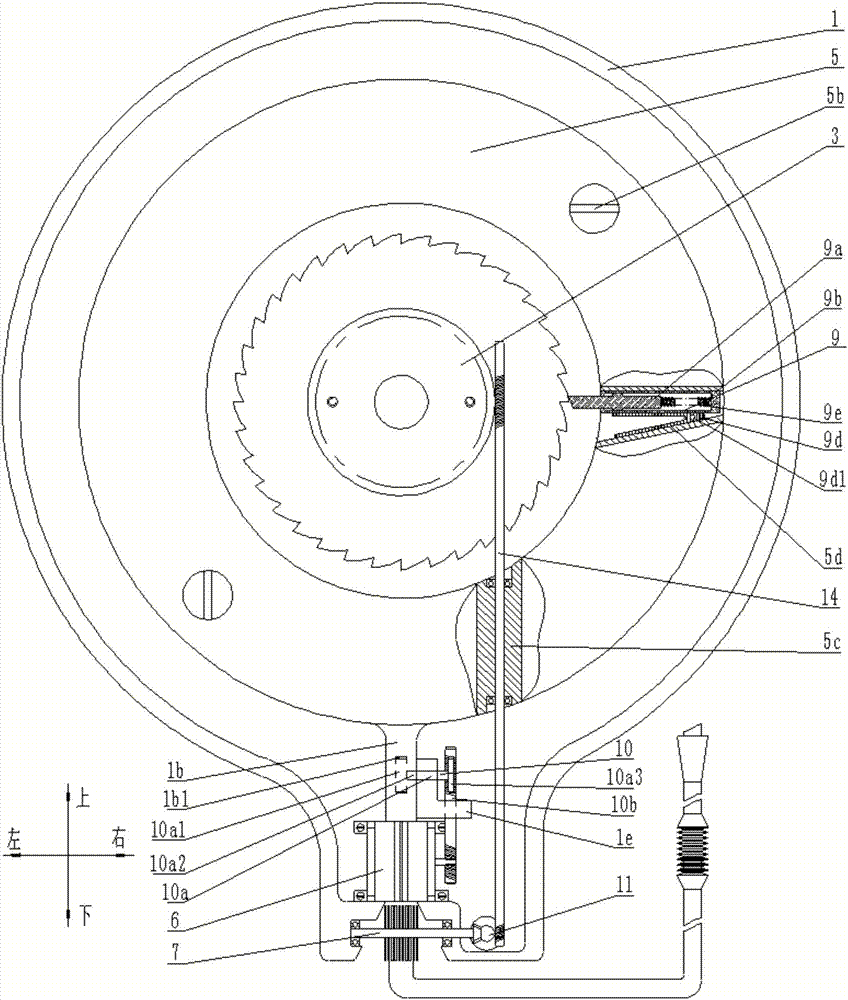

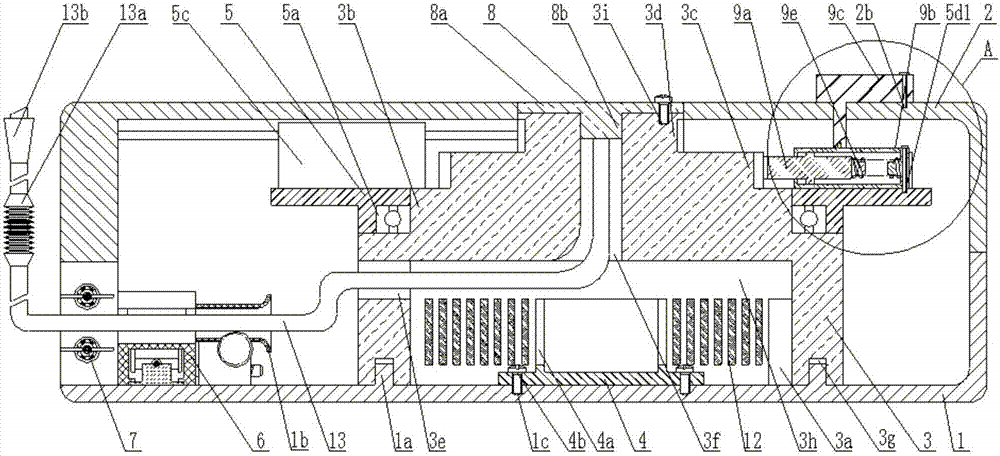

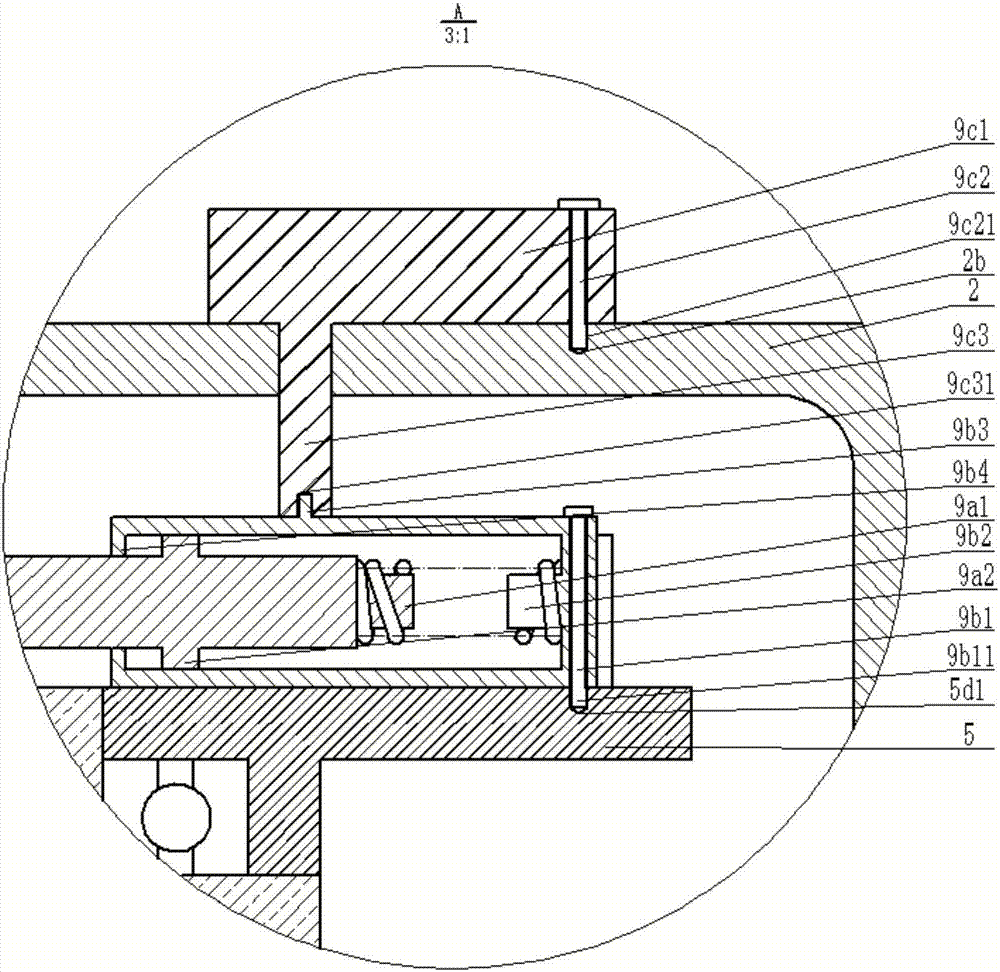

[0048] The accompanying drawing is the best embodiment of the wire reel with automatic wire take-up function for electrical testing, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0049] A wire reel with automatic wire take-up function for electrical testing, comprising a lower end cover 1, an upper end cover 2, and a coil spring 12 screwed together. The lower end cover 1 is provided with a circular guide rail 1a, and four threaded holes I1c are symmetrically arranged on the upper side of the lower end cover 1 near the center of the guide rail 1a, and the upper end of the lower end cover 1 is located at the center of the guide rail 1a. A coil spring winding device 4 is provided at the center, and a "one"-shaped slot 4a is provided on the coil spring winding device 4, and a screw I4b is provided on the lower plane of the coil spring winding device 4. The screw I4b is screwed into the threaded hole I1c, and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com