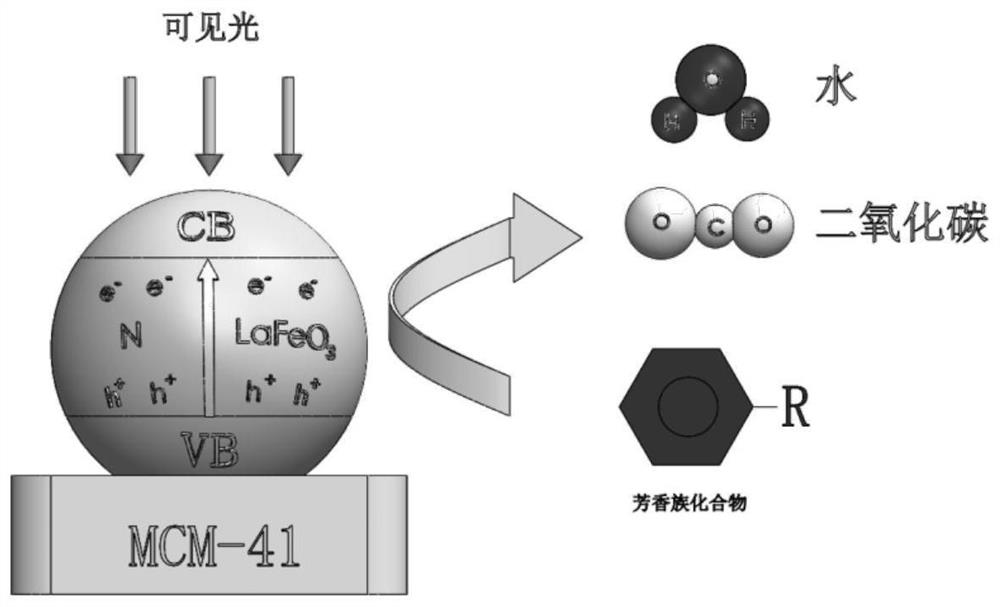

A kind of photocatalyst of nitrogen-modified perovskite composite molecular sieve and its preparation method and application method

A technology of composite molecular sieve and photocatalyst, applied in the field of photocatalyst and its preparation, can solve the problems of insufficient use of visible light, high electron-hole recombination rate, high energy consumption, etc., to promote rapid catalytic degradation and improve the absorption area. , the effect of improving the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 2.1646g of lanthanum nitrate, 2.02g of ferric nitrate, 0.3g of urea and 0.9012g of MCM-41 in a three-necked flask according to the molar ratio of 1:1:1:3, add 50mL of distilled water to dissolve, stir well to form A liquid; according to tartaric acid: The molar ratio of lanthanum nitrate is 1:1, add 0.7505g of tartaric acid, add 15mL of distilled water, dissolve and stir evenly to form B liquid. Slowly add liquid B to liquid A under stirring, react and polymerize into a sol in a water bath at 80°C, dry overnight to obtain a xerogel, and calcinate at 700°C for 4 hours at a rate of 2°C / min to obtain the catalyst N-LaFeO 3 @MCM-41-1.

[0027] Incorporation of N-LaFeO in the photocatalytic reactor 3 @MCM-41-1 catalyst, methanol and bisphenol A wastewater for photocatalytic reaction, the volume ratio of methanol and bisphenol A wastewater is 1:8, the dosage of photocatalyst in the mixture of methanol and bisphenol A wastewater per liter 0.20g; first carry out 30min d...

Embodiment 2

[0029] Weigh 2.1646g of lanthanum nitrate, 2.02g of ferric nitrate, 0.9g of urea and 2.1028g of MCM-41 in a three-necked flask according to the molar ratio of 1:1:3:7, add 50mL of distilled water to dissolve, and stir to form A liquid; : The molar ratio of lanthanum nitrate is 2:1, add 1.3409g malic acid, add 30mL distilled water, dissolve and stir to form B liquid evenly. Slowly add liquid B to liquid A under stirring, react and polymerize in a water bath at 80°C to form a sol, dry overnight to obtain a xerogel, and calcinate at 700°C for 4 hours at a rate of 2°C / min to obtain the catalyst N-LaFeO 3 @MCM-41-2.

[0030] Incorporation of N-LaFeO in the photocatalytic reactor 3 @MCM-41-2 catalyst, methanol and benzonitrile wastewater for photocatalytic reaction, the volume ratio of methanol and benzonitrile wastewater is 1:16, and the dosage of photocatalyst in the mixture of methanol and benzonitrile wastewater is 0.60g per liter ;First carry out 30min dark adsorption reactio...

Embodiment 3

[0032] Weigh 2.1646g of lanthanum nitrate, 2.02g of ferric nitrate, 0.6g of urea and 1.502g of MCM-41 in a three-necked flask according to the molar ratio of 1:1:2:5, add 50mL of distilled water to dissolve and stir evenly to form A liquid; The molar ratio of lanthanum is 3:1, add 1.3512g lactic acid as a complexing agent, add 45mL distilled water, dissolve and stir evenly to form B liquid. Slowly add liquid B to liquid A under stirring, react and polymerize into a sol in a water bath at 80°C, dry overnight to obtain a xerogel, and calcinate at 700°C for 4 hours at a rate of 2°C / min to obtain the catalyst N-LaFeO 3 @MCM-41-3.

[0033] Incorporation of N-LaFeO in the photocatalytic reactor 3 @MCM-41-3 catalyst, methanol and p-methoxybenzonitrile wastewater for photocatalytic reaction, the volume ratio of methanol and p-methoxybenzonitrile wastewater is 1:12, per liter of methanol and p-methoxybenzonitrile wastewater The dosage of the photocatalyst in the mixture is 0.40g; fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com