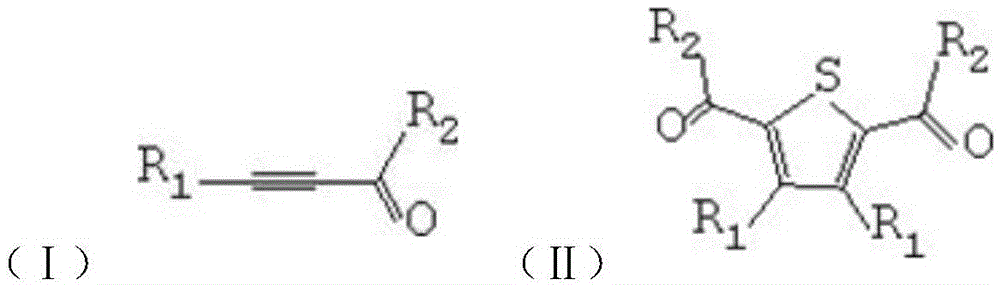

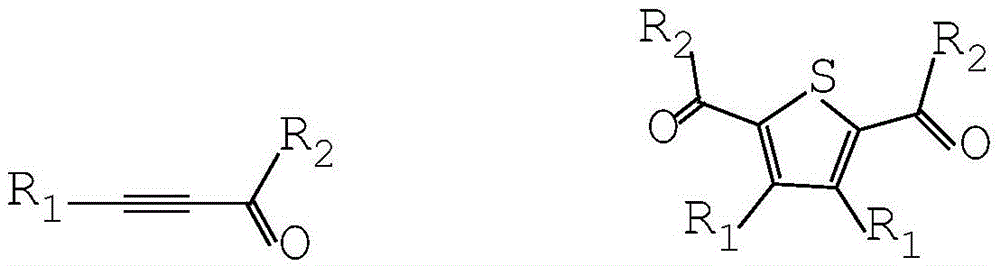

A kind of preparation method of fully substituted thiophene

A fully substituted and thiophene technology, applied in organic chemistry and other directions, can solve the problems of complex reaction steps, many by-products, harsh reaction conditions, etc., and achieve the effect of simple and easy separation of reaction products, few reaction by-products, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 fully substituted thiophene compound 2a

[0028] Reaction conditions: Elemental sulfur (3.0 mmol), acetylenic compound 1a (2.0 mmol), KOH (0.2 mmol) and toluene (2.0 mL) were sequentially added to the reactor, and stirred at 100° C. for 3 hours. The obtained mixture was separated by thin layer chromatography (eluent: V petroleum ether: V ethyl acetate = 20:1), the structure of the product was confirmed by NMR and IR to be fully substituted thiophene 2a, and the yield was 84%.

[0029]

Embodiment 2

[0030] The preparation of embodiment 2 fully substituted thiophene compound 2b

[0031] The fully substituted thiophene compound 2b was prepared from the acetylenic compound 1b, and the reaction conditions were as in Example 1. The structure of the product was confirmed to be fully substituted thiophene 2b by NMR and IR, and the yield was 88%.

[0032]

Embodiment 3

[0033] The preparation of embodiment 3 fully substituted thiophene compound 2c

[0034] Thiophene compound 2c was fully substituted by acetylenic compound 1c, and the reaction conditions were as in Example 1. The structure of the product was confirmed to be fully substituted thiophene 2c by NMR and IR, and the yield was 85%.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com