Extractant and its oil extraction desulfurization method, application of a kind of ionic liquid

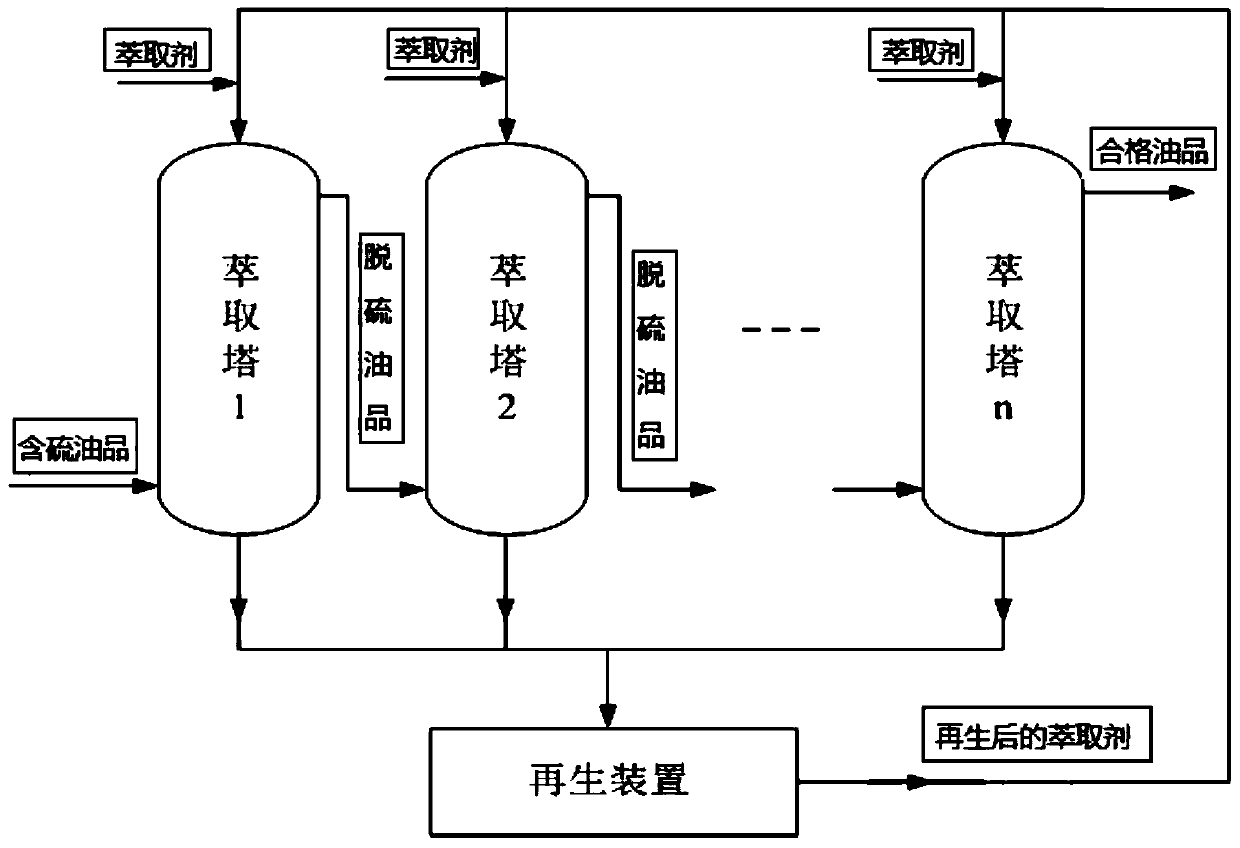

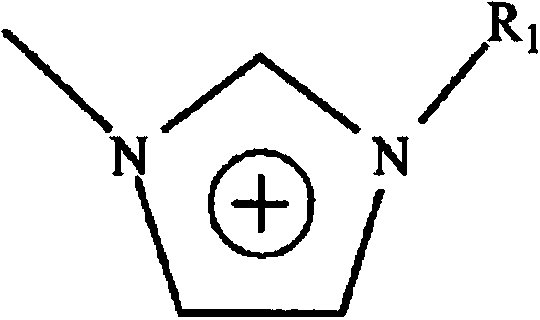

A technology of ionic liquid and extractant, which is applied in the application field of ionic liquid, can solve the problems of low desulfurization effect of extractant, high requirements for desulfurization process conditions, inconvenient separation, etc., and achieve good desulfurization ability, good reproducibility, and recycling convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 20g[Emim][H 2 PO 4] and 20g of simulated gasoline containing sulfur (thiophene) 500ppm were added to the flask, heated to 50°C under normal pressure stirring, magnetic stirring for 3hr, stirring speed at 500rpm, standing for 2hr, and layering. The sulfur content and nitrogen content of the upper oil phase are accurately detected with a sulfur and nitrogen analyzer. The sulfur content in the upper oil phase dropped to 327ppm, and the single-stage desulfurization rate was 34.6%. The nitrogen content of the upper oil phase is 1.36ppm (the initial nitrogen content of the model oil is 1.35ppm), indicating that the solubility of the ionic liquid in the oil phase is negligible. After use, the ionic liquid phase is recovered and reused through vacuum distillation.

Embodiment 2

[0040] 20g[Bmim][H 2 PO 4 ] and 20g of simulated gasoline containing sulfur (thiophene) 500ppm were added to the flask, heated to 50°C under normal pressure stirring, magnetic stirring for 3hr, stirring speed at 500rpm, standing for 2hr, and layering. The sulfur content and nitrogen content of the upper oil phase are accurately detected with a sulfur and nitrogen analyzer. The sulfur content of the upper oil phase is reduced to 320ppm, and the single-stage desulfurization rate is 36.0%. The nitrogen content of the upper oil phase is 1.38ppm (the initial nitrogen content of the model oil is 1.35ppm), indicating that the solubility of ionic liquids in the oil phase is negligible. After use, the ionic liquid phase is recovered and reused through vacuum distillation.

Embodiment 3

[0042] 20g[Bmim][H 2 PO 4 ] and 20g of simulated gasoline containing sulfur (benzothiophene) 500ppm were added into the flask, heated to 60°C under normal pressure stirring, magnetic stirring for 3hr, stirring speed at 500rpm, standing for 2hr, and layering. The sulfur content and nitrogen content of the upper oil phase are accurately detected with a sulfur and nitrogen analyzer. The sulfur content in the upper oil phase dropped to 326ppm, and the single-stage desulfurization rate was 34.8%. The nitrogen content of the upper oil phase is 1.39ppm (the initial nitrogen content of the model oil is 1.35ppm), indicating that the solubility of the ionic liquid in the oil phase is negligible. After use, the sulfide in the ionic liquid is eluted by chloroform, and the stripping agent in the ionic liquid phase is separated by vacuum distillation, and the ionic liquid and stripping can be reused.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com