Swing-arm-type automatic winding and centering device

A technology of centering device and swing arm type, applied in the field of swing arm type automatic winding centering device, can solve the problems of deviation between input value and actual value, sensor easily damaged, low centering accuracy, etc. High performance, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

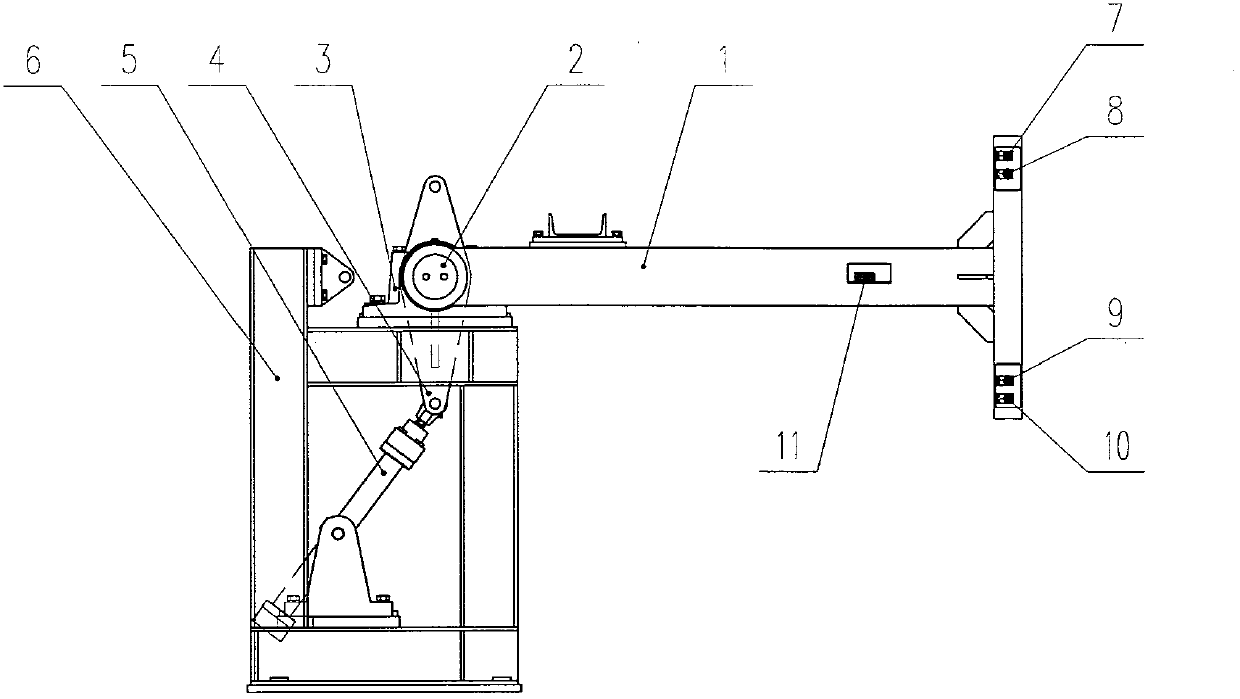

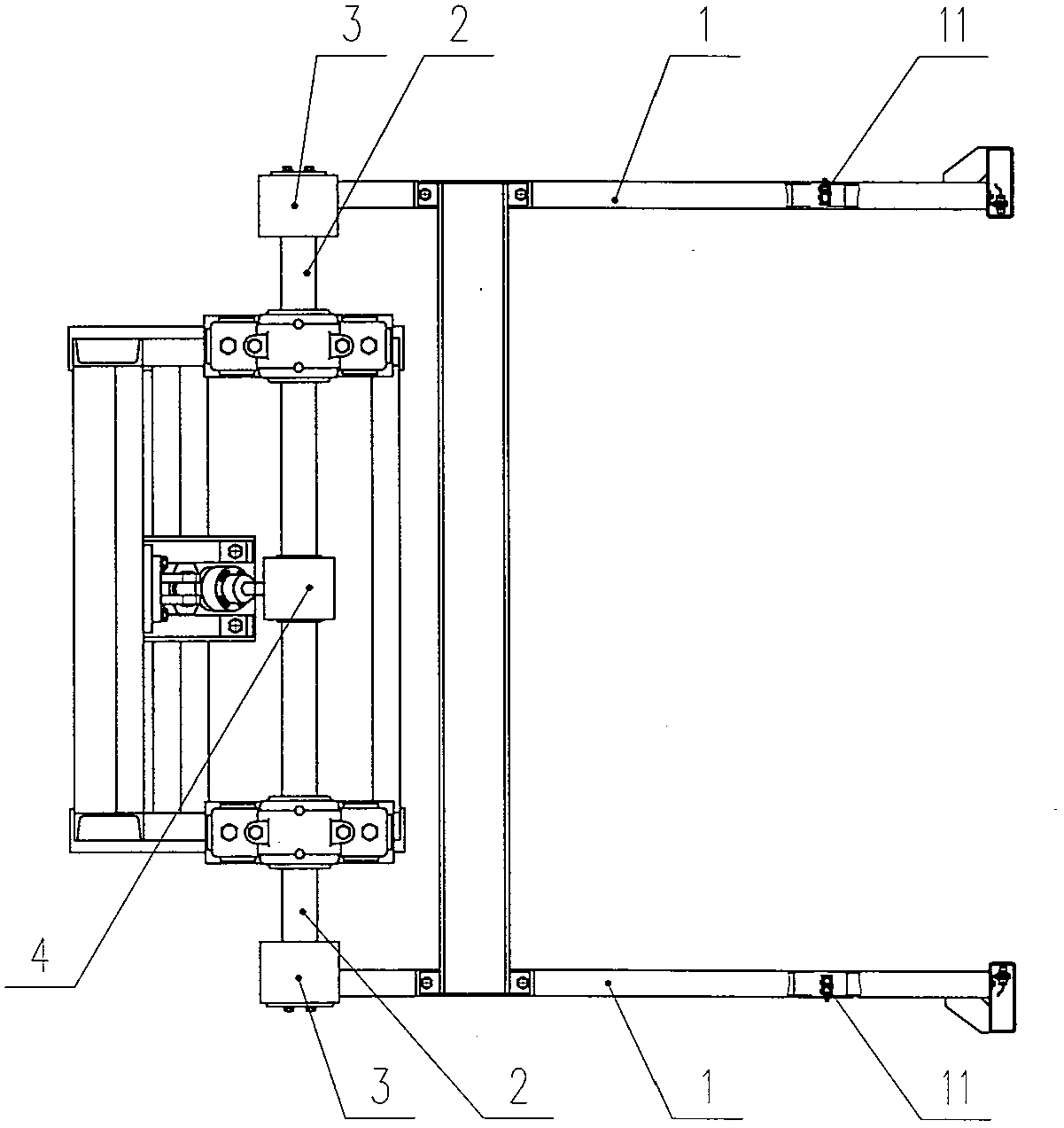

[0016] refer to figure 1 with figure 2 , a swing arm type automatic winding centering device, including a pair of swing arms 1, the swing arms 1 are connected together through the shaft 2, the bearing seats 3 supporting the shaft 2 are fixed on the bracket 6, and the middle of the shaft 2 is fixed The swing rod 4 which forms 90° with the swing arm 1 is connected with the swing cylinder 5, and the swing cylinder 5 pushes the swing rod 4 to rotate 90°, drives the shaft 2 to rotate, thereby drives the swing arm 1 to swing up and down.

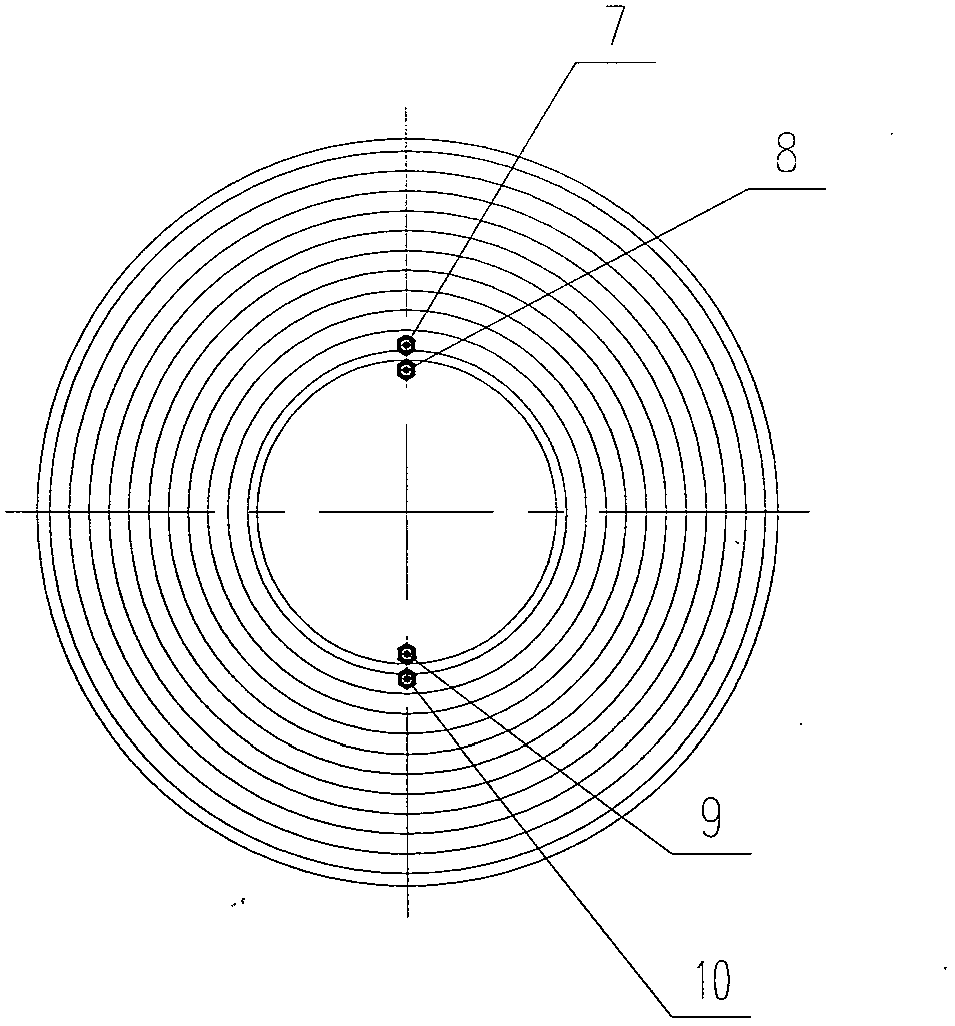

[0017] refer to figure 1 with image 3 , the front end of the swing arm 1 is a T-shaped structure, and four groups of opposite-beam photoelectric switches are symmetrically arranged in the vertical direction centered on the T-shaped center. The distance between the second group of photoelectric switches 8 and the third group of photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com