eva automatic roll change bonding device

An automatic and bonding technology, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of restricting the production capacity of solar cell module production lines, affecting the process beat of the production line, and limiting balanced production, etc., to improve online production The effect of straight-through rate, improvement of labor productivity, and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

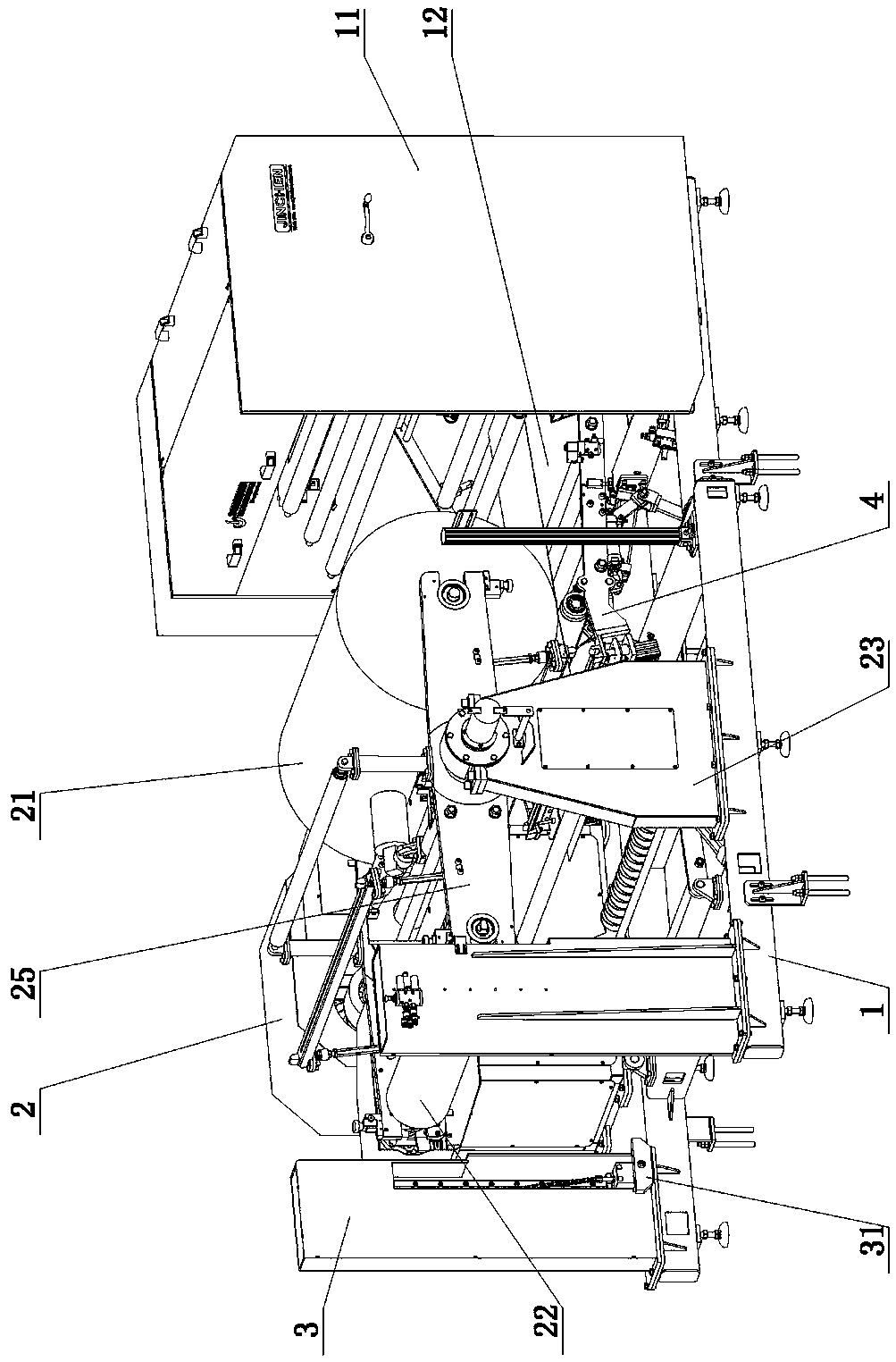

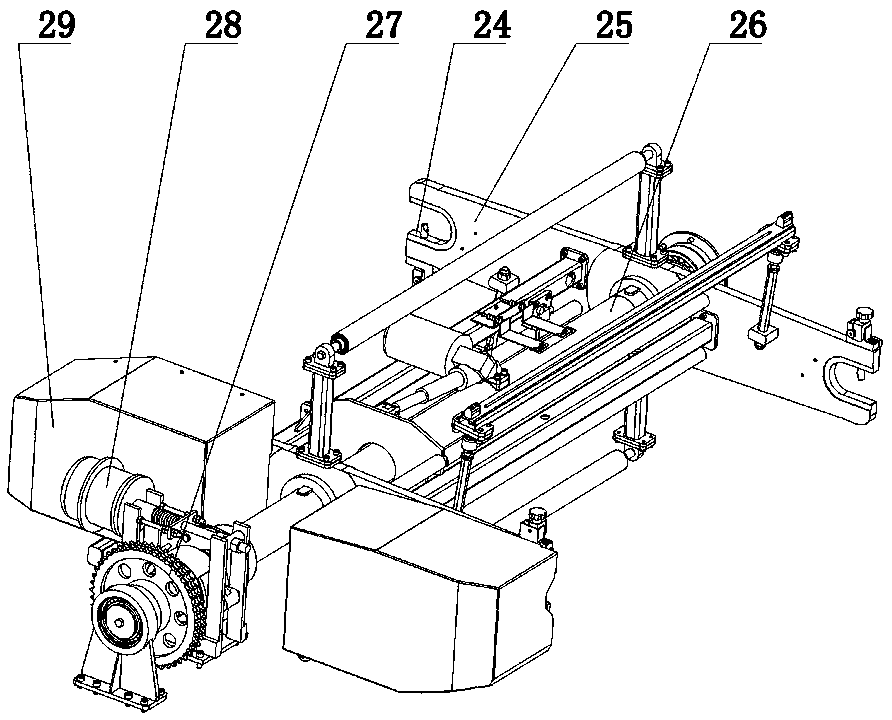

[0021] The present invention includes a frame 1, and an automatic roll changing device 2 is arranged on the frame 1. It is characterized in that: the automatic roll changing device 2 includes supporting seats 23 arranged on both sides of the Both ends of the arm 25 and the rotating arm 25 are provided with roll mounting grooves 24 , and both ends of a rotating arm 25 are respectively provided with an unwinding mechanism 29 corresponding to the material roll mounting grooves 24 .

[0022] As a preferred solution of the present invention, a bonding device 4 is provided on the side of the discharge end of the frame 1 corresponding to the bottom of the rotary arm 25 .

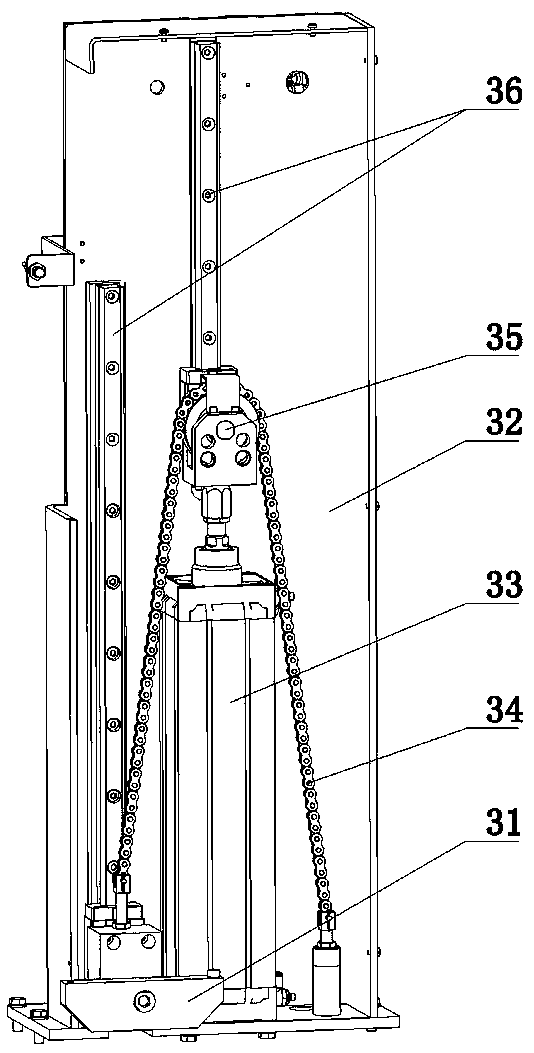

[0023] Described bonding device 4 comprises the thrust cylinder 45 that is arranged on the frame 1, and thrust cylinder 45 links to each other with a compression arm 41 by link mechanism 48, and one end of compression arm 41 is hingedly arranged on the frame 1, and the compression arm 41 A pressure roller 46 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com