Dust removal apparatus having automatic winding function

A dust removal device and functional technology, applied in the field of dust removal devices with automatic winding function, can solve the problems of processing troubles, separate functions, high production costs, etc., and achieve the effects of avoiding secondary pollution, improving dust removal efficiency, and saving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

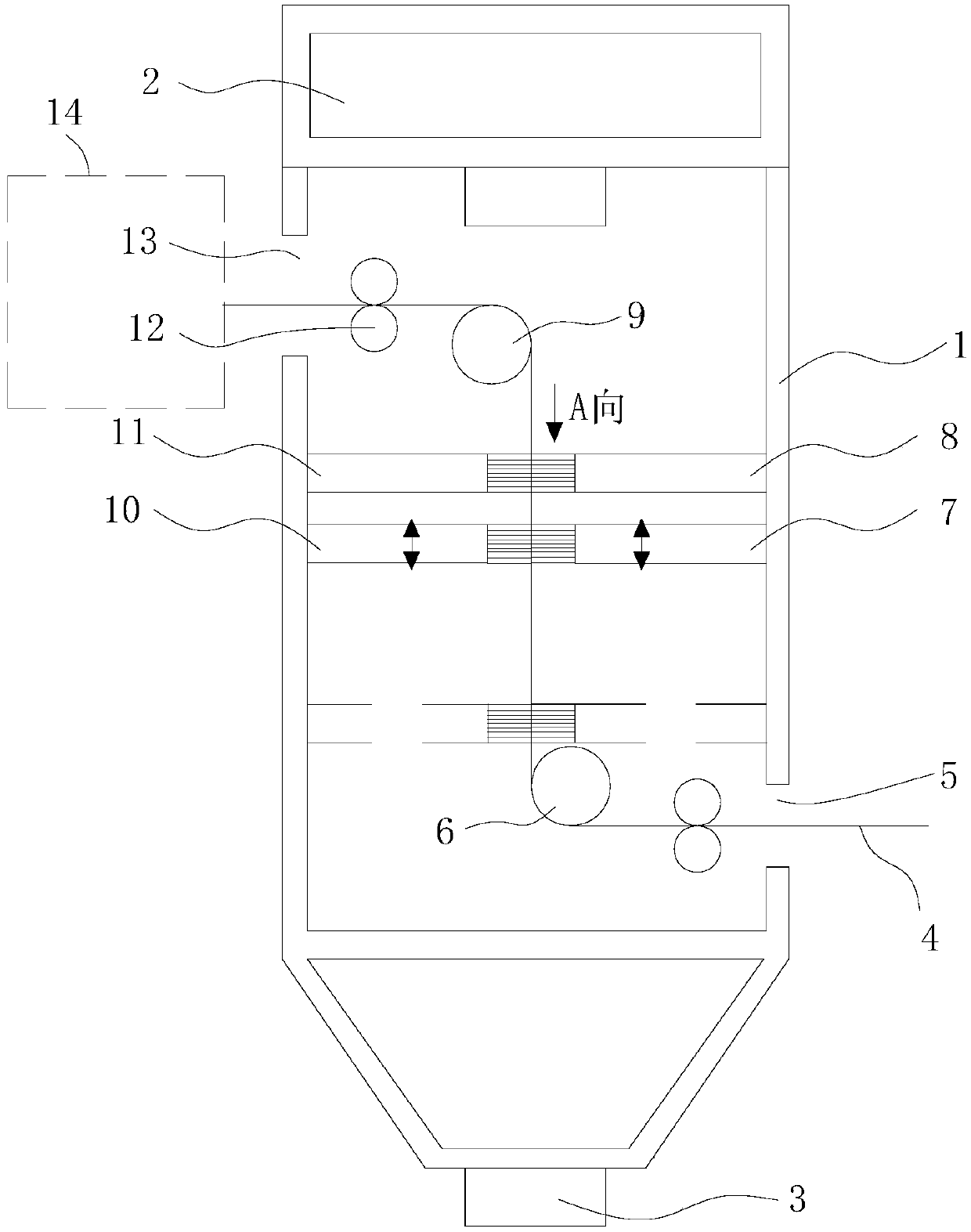

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

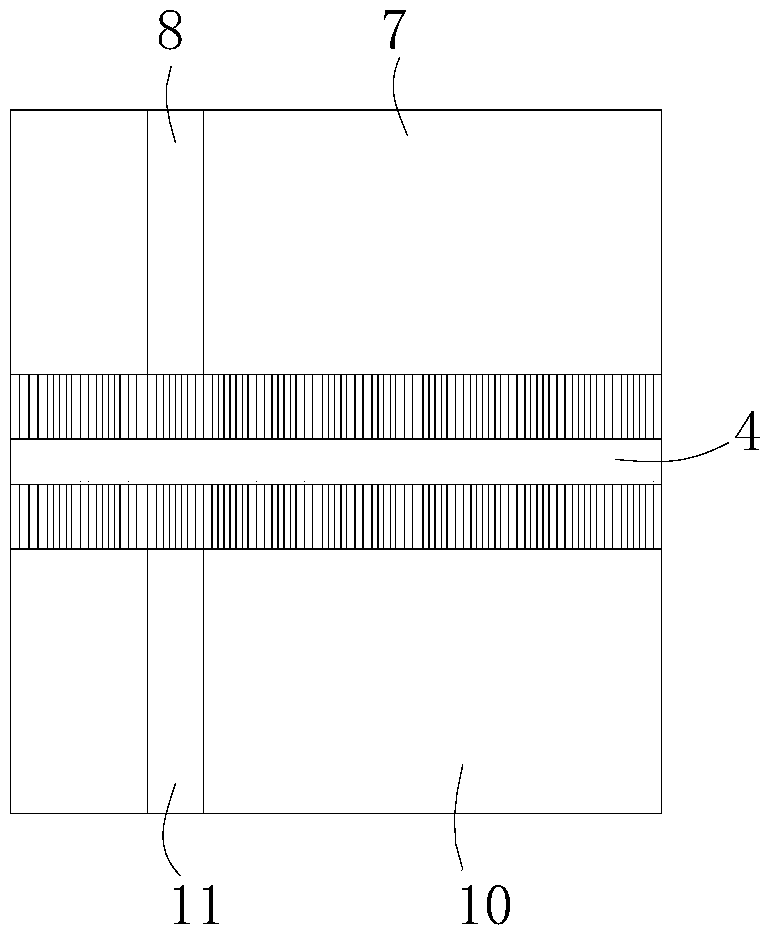

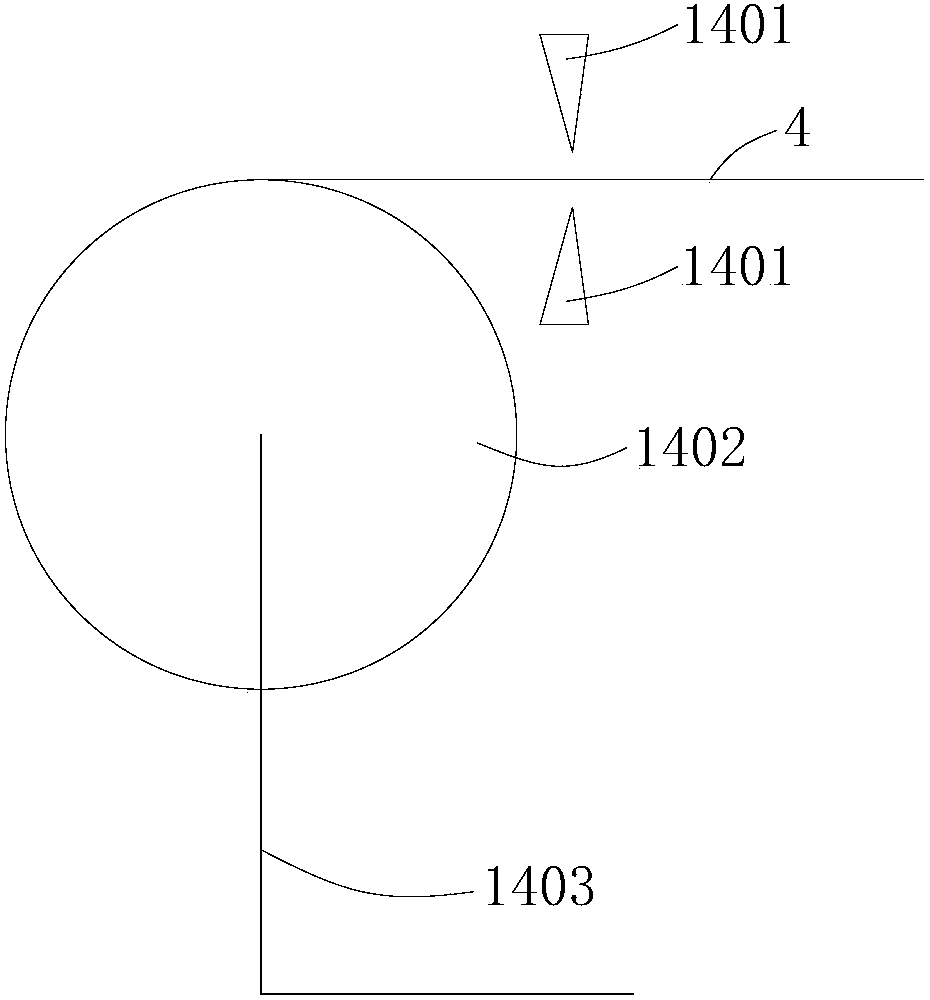

[0018] Such as Figure 1 to Figure 3 As shown, a dust removal device with automatic winding function includes a box body 1, a deionization fan 2 is arranged on the top of the box body 1, an exhaust fan 3 is arranged at the bottom of the box body 1, and a bottom of one side of the box body 1 is arranged There is a cloth inlet 5, and the top of the other side of the box is provided with a cloth outlet 13, and the outside of the cloth outlet 13 is provided with a cloth winding device 14, and the box 1 is provided with a vertically symmetrical shaper near the cloth outlet 13. Roller 12, the inside of the shaping roller 12 is provided with a steam generator, the surface of the shaping roller 12 is uniformly provided with steam distribution holes, and the inner middle position of the box body 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com