Automatic winding machine

A technology of automatic winding machine and winding mechanism, which is applied in the direction of coil manufacturing, conveying filamentous materials, thin material processing, etc., can solve the problems of increased machine maintenance cost, equipment failure, high labor cost, etc., to reduce maintenance cost and The effects of labor input, improved yield rate, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

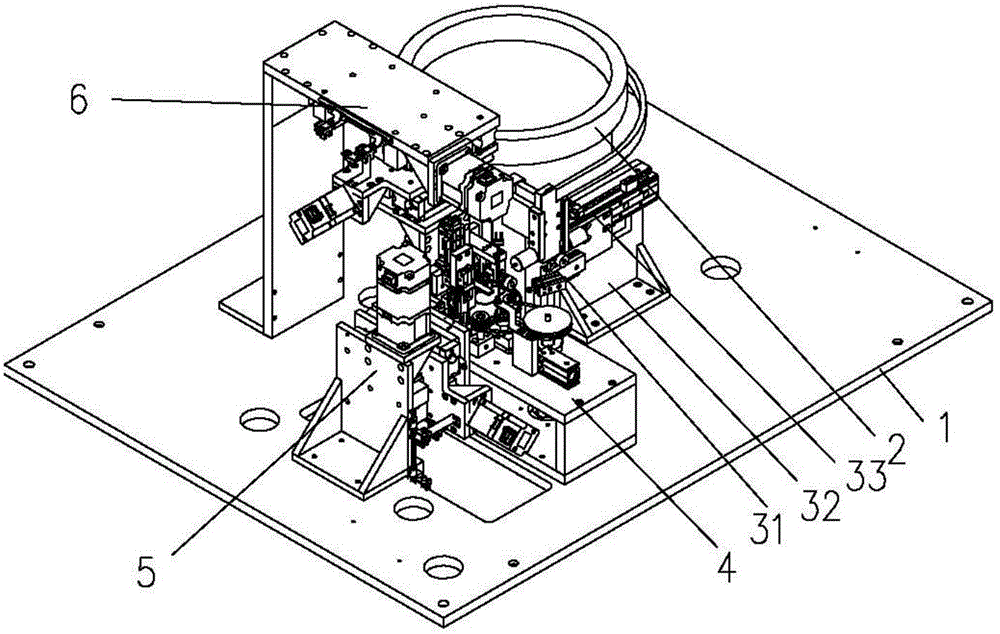

[0020] Such as picture 1, the automatic winding machine disclosed by the present invention includes a substrate 1, a winding mechanism 4, a wire feeding mechanism 5, a traction mechanism 6, a vibrating plate 2, a feeding mechanism 3 and a PLC controller ( picture not shown in); the vibrating plate 2 and all mechanisms are installed on the base plate 1, and the vibrating plate 2 and each mechanism are respectively connected with the PLC controller; the wire storage ring 43 of the present embodiment is a Zhentaicheng wire storage ring.

[0021] The winding mechanism 4 includes an introduction base 41 and a driving wheel 42 installed on the introduction base, a wire storage ring 43, a wire storage ring transmission mechanism 44, a clamping mechanism 45, a wire pressing mechanism 46, a clamping wheel mechanism 47 and a side The slider 48; the guide base 41 is fixed on the base plate 1, and the guide base 41 is provided with a driving wheel 42, a wire storage ring transmission mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com