Amorphous soft magnetic alloy magnetic core winding machine

A technology of winding machine and magnetic ring, which is applied in the manufacture of magnetic core/yoke, transformer/inductor core, inductor/transformer/magnet, etc. It can solve the problems of high tape brittleness, poor coating thickness control, and coating speed. Low-level problems, to achieve the effect of neat and uniform winding quality, good coating dielectric strength, and fast coating and winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

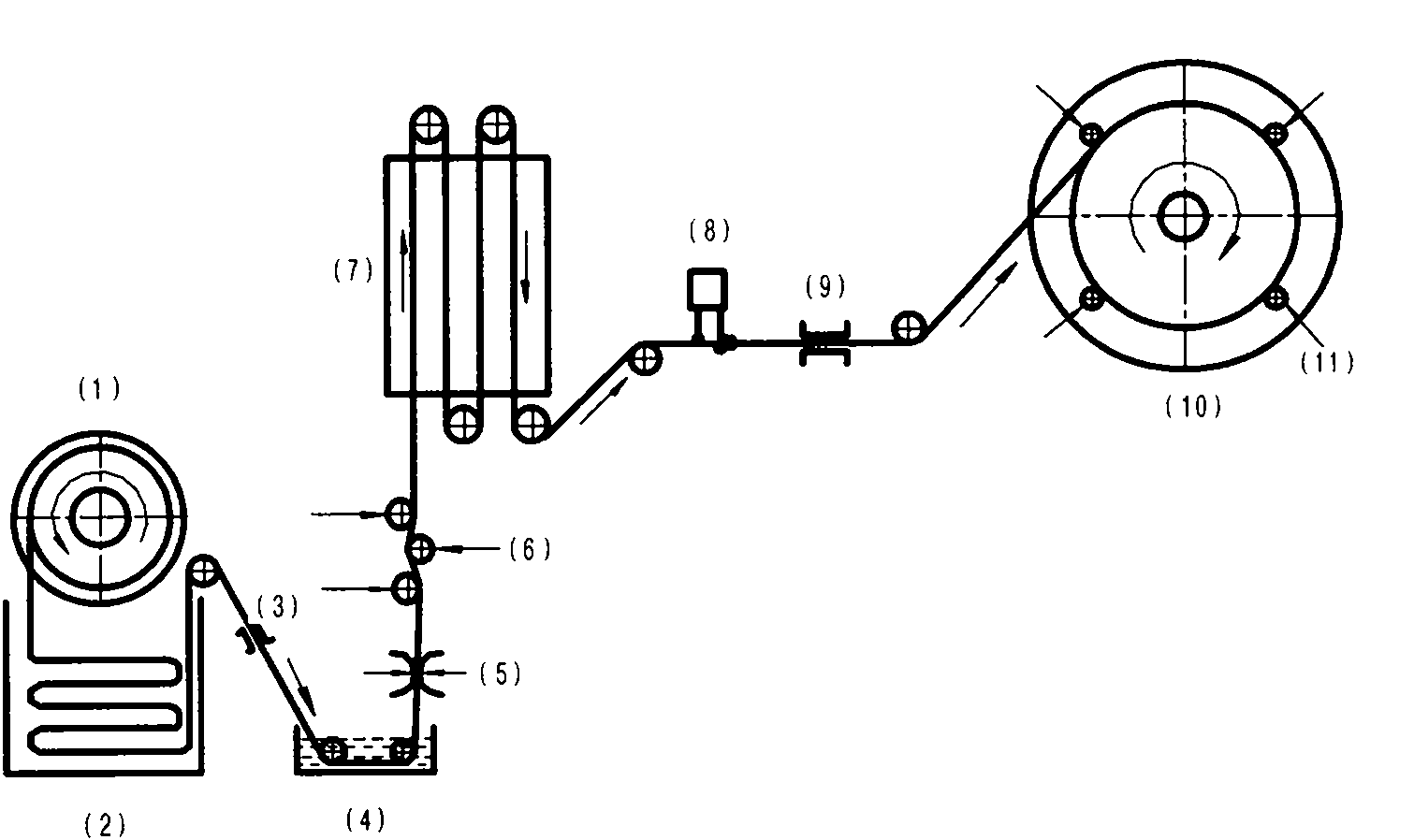

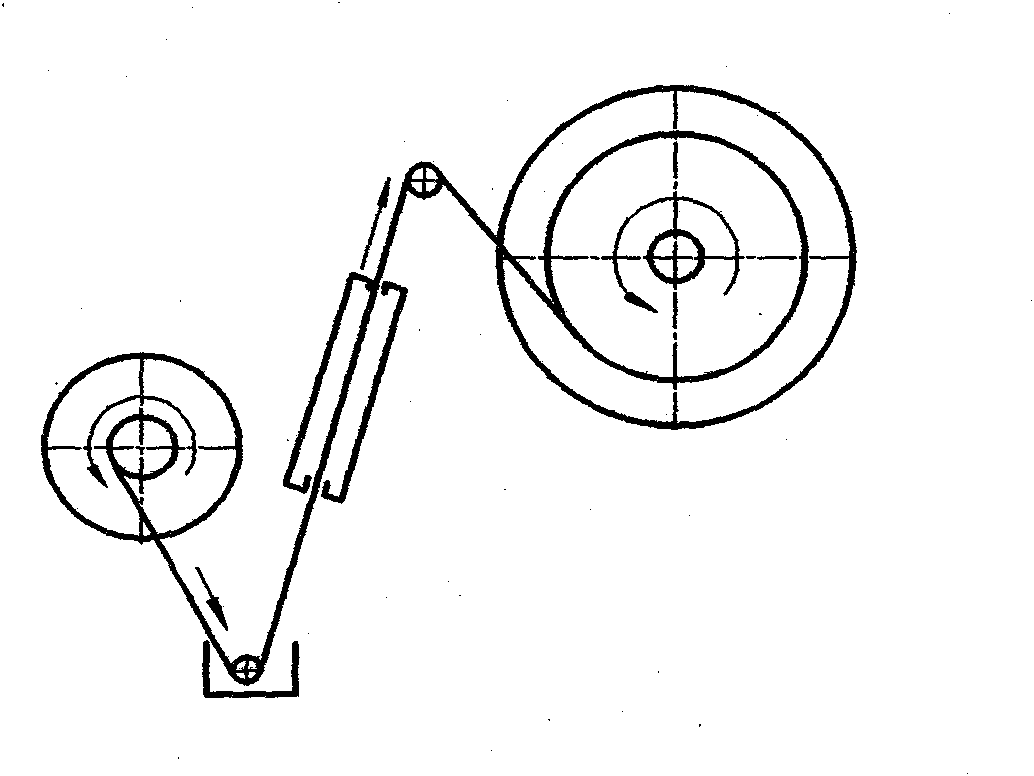

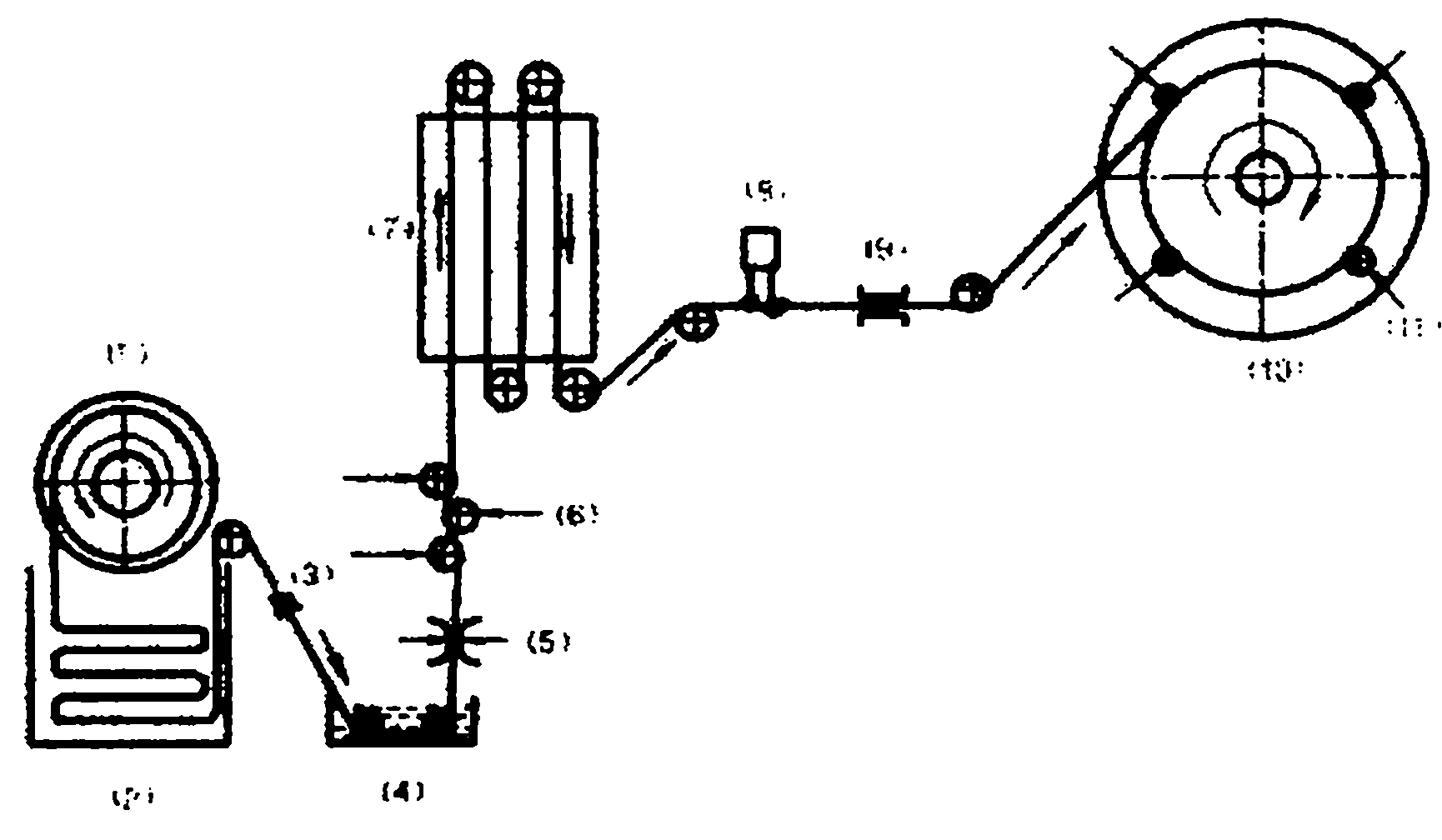

[0013] The discharge mechanism 1 has a shaft driven by an adjustable speed motor. There is a fixed baffle (disc) near the motor end of the shaft, and a detachable baffle at the other end. The state of the goods is rolled into a disc shape) After being placed on the discharge shaft, a baffle is installed to prevent the coil from loosening. The material storage box 2 is a box with an inner dimension of 400-600 mm in length, 10-50 mm in width, continuously adjustable, and 400-600 mm in height, with openings on both sides of the upper part; the front and back panels of the material storage box are smooth glass plates, and the box The inner width is adjusted to be 1-2mm larger than the width of the amorphous alloy strip to be wound, and the front glass plate has a loose leaf, which can be quickly opened to organize the strips in the box; the storage box is placed at the discharge position of the discharge mechanism Directly below, the strip exiting from the material tray automatica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com