Printing ribbon driving device

A driving device and a technology for printing ribbons, which are applied to inking devices, printing, etc., can solve the problems of entanglement of printing ribbons, poor processing performance, and high production costs, so as to reduce production costs, eliminate ribbon waste, and eliminate waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

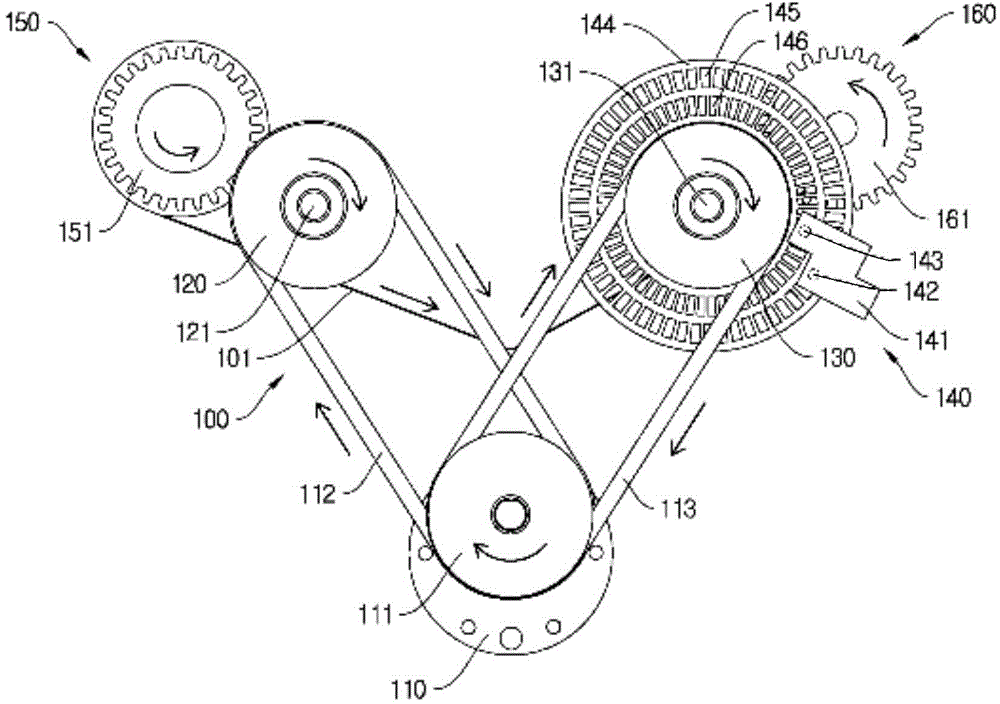

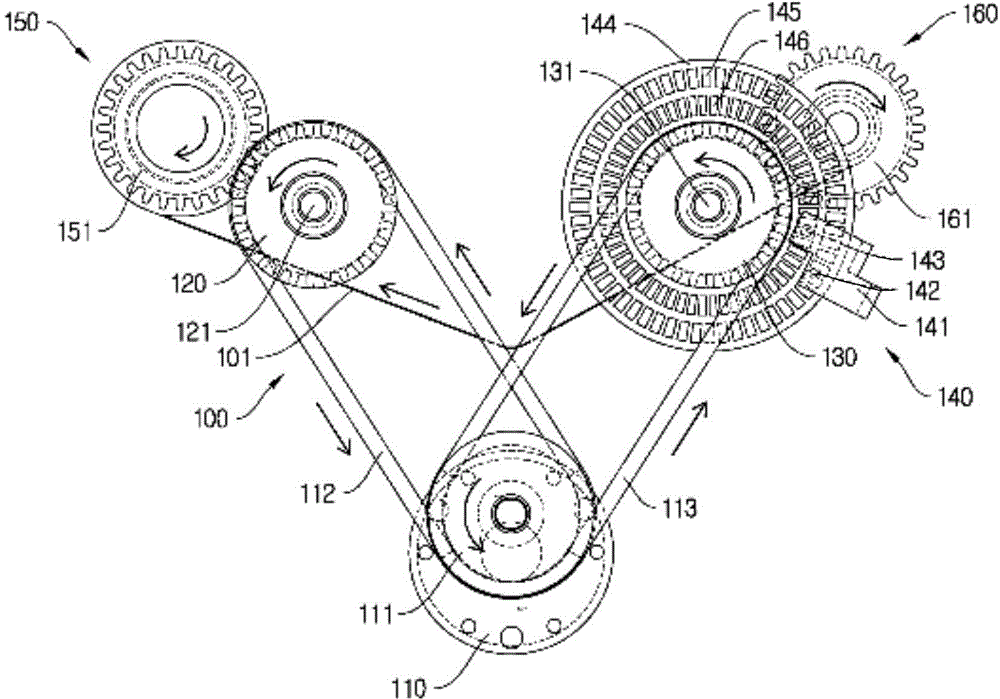

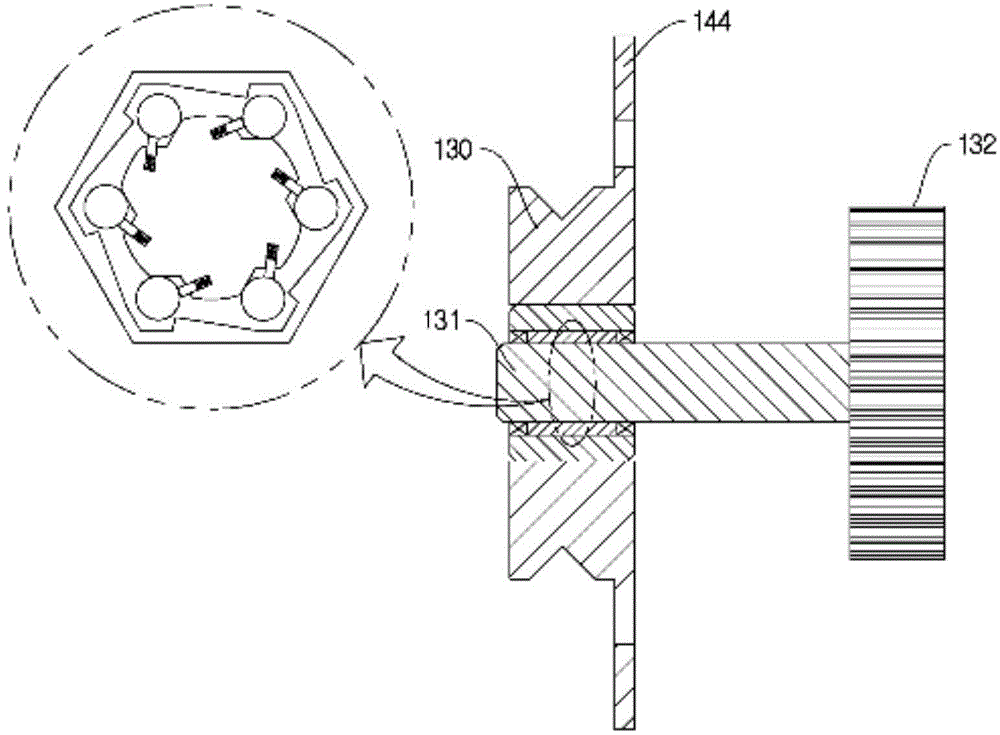

[0046] This embodiment provides a printing ribbon driving device, such as figure 1 , Figure 4 , Figure 5 As shown, the apparatus includes a ribbon supply shaft 150 , a ribbon take-up shaft 160 , a ribbon 101 and a drive 110 . The driver 110 is fixedly installed in the casing of the printer, and the output shaft of the driver 110 is fixedly installed with double driving pulleys 111 . Both the ribbon supply shaft 150 and the ribbon winding shaft 160 are rotatably installed in the housing of the printer through bearings, the ribbon supply shaft 150 and the ribbon winding shaft 160 are parallel to each other, and the ribbon 101 is wound around the ribbon supply shaft 150 and the ribbon winding shaft 160. The tape is wound on the shaft 160.

[0047] One end of the ribbon supply shaft 150 is fixedly mounted with a first driven gear 151, the first driven gear 151 is coaxially arranged with the ribbon supply shaft 150, the first driven gear 151 meshes with the first driving gear ...

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 is that the output shaft of the driver (two-way motor) is fixedly equipped with double drive pulleys, the ribbon supply shaft is equipped with the first pulley through the first one-way bearing, and the ribbon winding shaft The second pulley is installed through the second one-way bearing, the double drive pulley is connected with the first pulley through the first drive transmission belt, the double drive pulley is connected with the second pulley through the second drive transmission belt, and the outer ring of the first one-way bearing rotates clockwise , the inner ring can rotate freely, and it is locked when it rotates counterclockwise. When the outer ring of the second one-way bearing rotates counterclockwise, the inner ring can rotate freely, and it is locked when it rotates clockwise.

[0068] The ribbon sensor detection device is arranged at the first pulley, and the ribbon sensor detection device is used t...

Embodiment 3

[0070] The difference between this embodiment and Embodiment 1 is that the first gear is fixedly installed on the output shaft of the driver, the second gear is installed on the ribbon supply shaft through the first one-way bearing, and the ribbon winding shaft passes through the second one-way bearing. The third gear is installed on the bearing, and the second gear and the third gear are both meshed with the first gear. When the outer ring of the first one-way bearing rotates clockwise, the inner ring can rotate freely, and it is locked when it rotates counterclockwise. The second one-way bearing When the bearing outer ring is rotated counterclockwise, the inner ring can rotate freely, and when it is rotated clockwise, it is locked.

[0071] The ribbon sensor detection device is arranged at the third gear, and the ribbon sensor detection device is used to detect the rotation information of the third gear, and transmit the detected rotation information to the controller of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com