PMI (polymethacrylimide) foam sandwich aircraft radar cover and manufacturing method thereof

A radome and foam technology, which is applied to other home appliances, frameless domes, home appliances, etc., can solve the problems of difficult foam interlayer molding, poor wave transmission performance, and high defective rate, so as to eliminate The foam density and thickness change is large, the foam thickness change is small, and the rigidity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

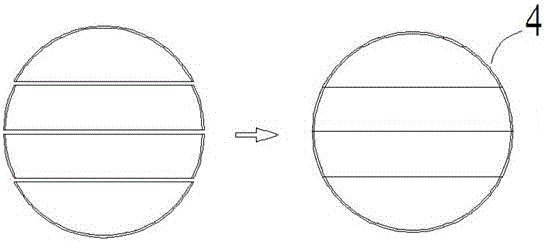

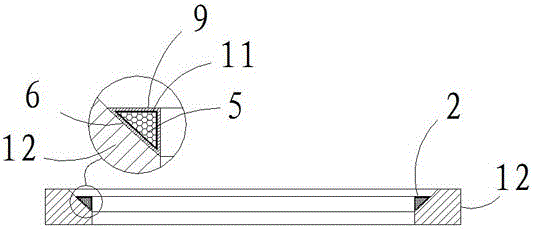

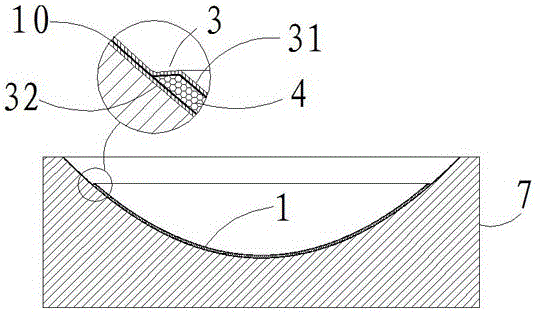

[0023] like Figure 1 to Figure 4 As shown, an embodiment of the present invention includes: a concave cover body 1 and a flange ring 2, the concave surface cover body 1 is composed of a skin layer 3, a cover body adhesive layer 10 and a first sandwich layer 4, and the skin layer 3 includes The upper skin 31 and the lower skin 32, the skin layer 3 adopts glass fiber prepreg, and the first sandwich layer 4 adopts PMI foam; the flange ring 2 is bonded by the flange skin 9 and the flange layer 11 and the second sandwich layer 5, the flange skin layer 9 is made of glass fiber prepreg, the flange adhesive layer 11 is made of epoxy film, and the second sandwich layer 5 is made of PMI foam, so The flange ring 2 is an annular body with a triangular radial section, and the flange ring 2 is provided with an adhesive surface 6 that matches the upper edge of the concave cover body 1; the bonding of the flange ring 2 The surface 6 is bonded to the upper edge of the concave cover body 1 . ...

Embodiment 2

[0032] like Figure 1 to Figure 4 Shown, the product of the second embodiment of the present invention is the same as embodiment 1. Considering the connection between the product and the aircraft fuselage, the product of this embodiment adds a pre-embedded metal connector. After the overall processing of the product is completed, the metal connector can be drilled and tapped.

[0033] A kind of manufacture method of PMI foam interlayer aircraft radome, comprises the steps:

[0034] Step 1. Preparation of materials and molds: Prepare glass fiber prepreg, PMI foam, epoxy film, cover body molding mold 7, flange ring molding mold 12, foam cutting mold, and choose ZG35 material for the mold material;

[0035] Step 2. Processing of the flange ring: conventional milling and processing into flange foam blanks. Considering the connection between this product and the aircraft fuselage, metal connectors need to be pre-embedded. In this embodiment, the following steps are added: in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com