Automatic adhesion device for outer surface of bushing

A technology for outer surface and casing, which is applied in the field of automatic gluing device for outer surface of casing, which can solve problems such as poor effect and uneven glue application, and achieve the effect of simple structure, strong standardization and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

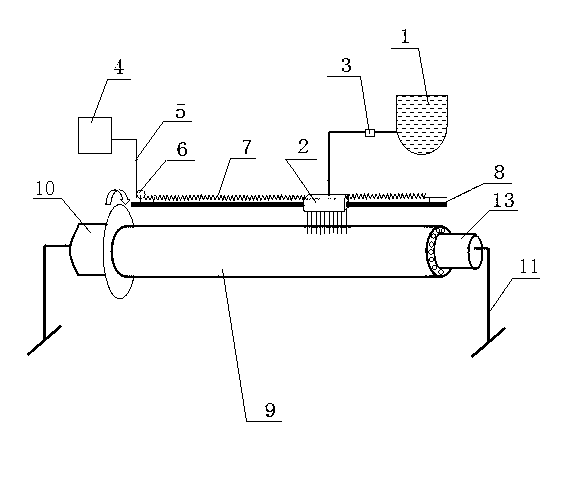

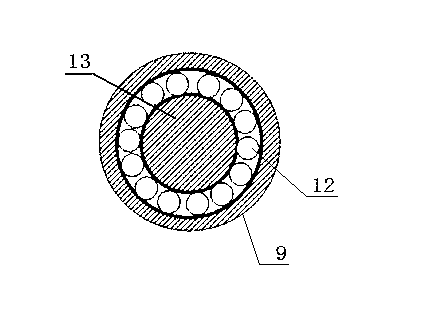

[0015] Such as figure 1 As shown, the automatic gluing device for the outer surface of the casing includes a glue box 1, a glue brush 2, a glue injection control device 3, a glue brush feeding mechanism, and a rotating bracket. The glue brush feeding mechanism is composed of a bidirectional motor 4 and a transmission shaft 5 , cardan shaft 6, and transmission screw 7 are connected sequentially. The rubber box 1 and the rubber brush 2 are connected through pipelines. The glue injection control device 3 is connected in series on the pipeline connecting the rubber box 1 and the rubber brush 2. The base of the rubber brush 2 Wear on the sliding polished rod 8, the transmission screw mandrel 7 of the rubber brush feeding mechanism is threadedly connected with the base of the rubber brush 2, and when the transmission screw mandrel 7 rotates, the rubber brush 2 moves in a straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com