Screw adhesive supplier

A technology of gluing machine and screw, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve the problems of increasing workload and not being able to guarantee durability, and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

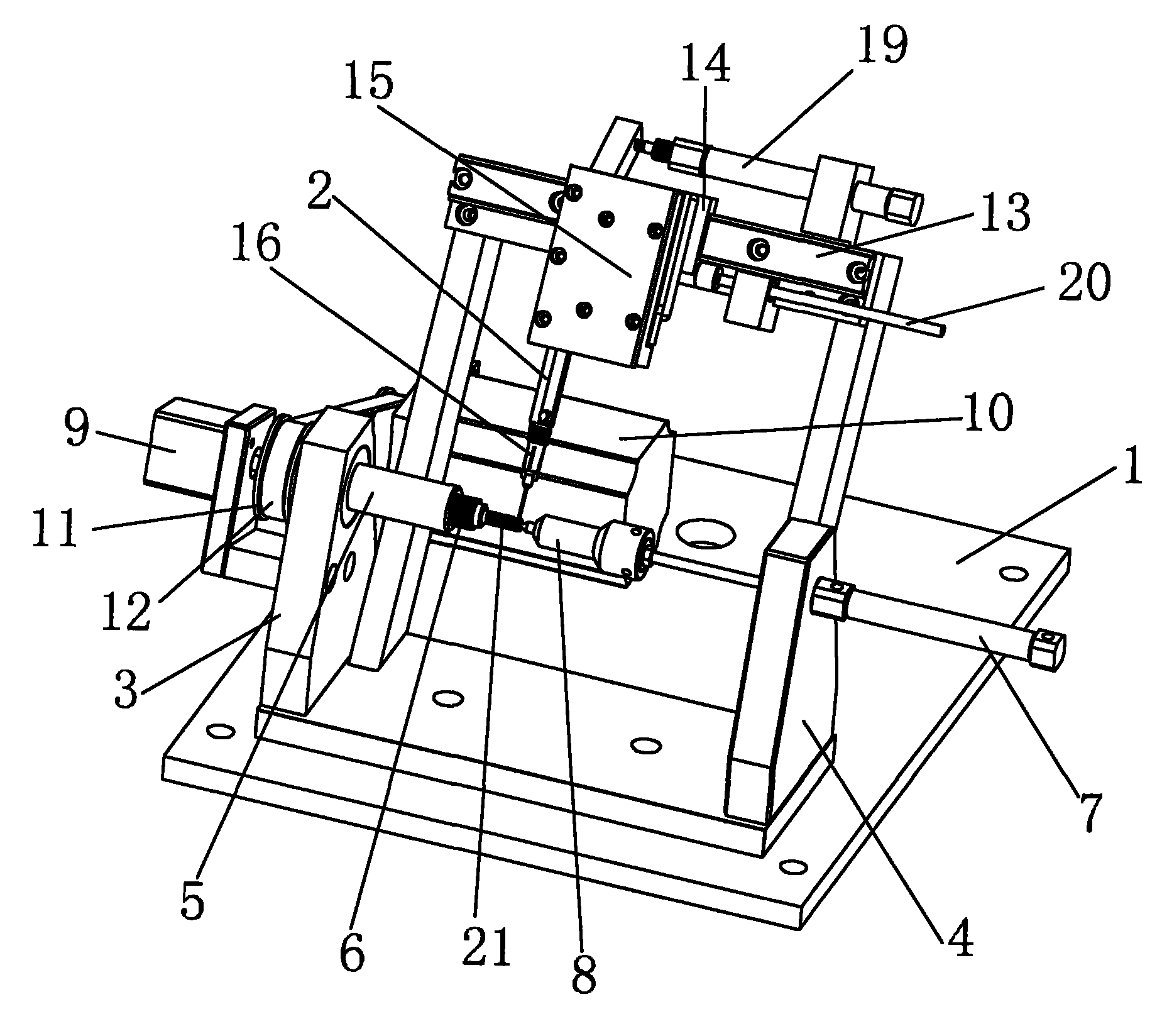

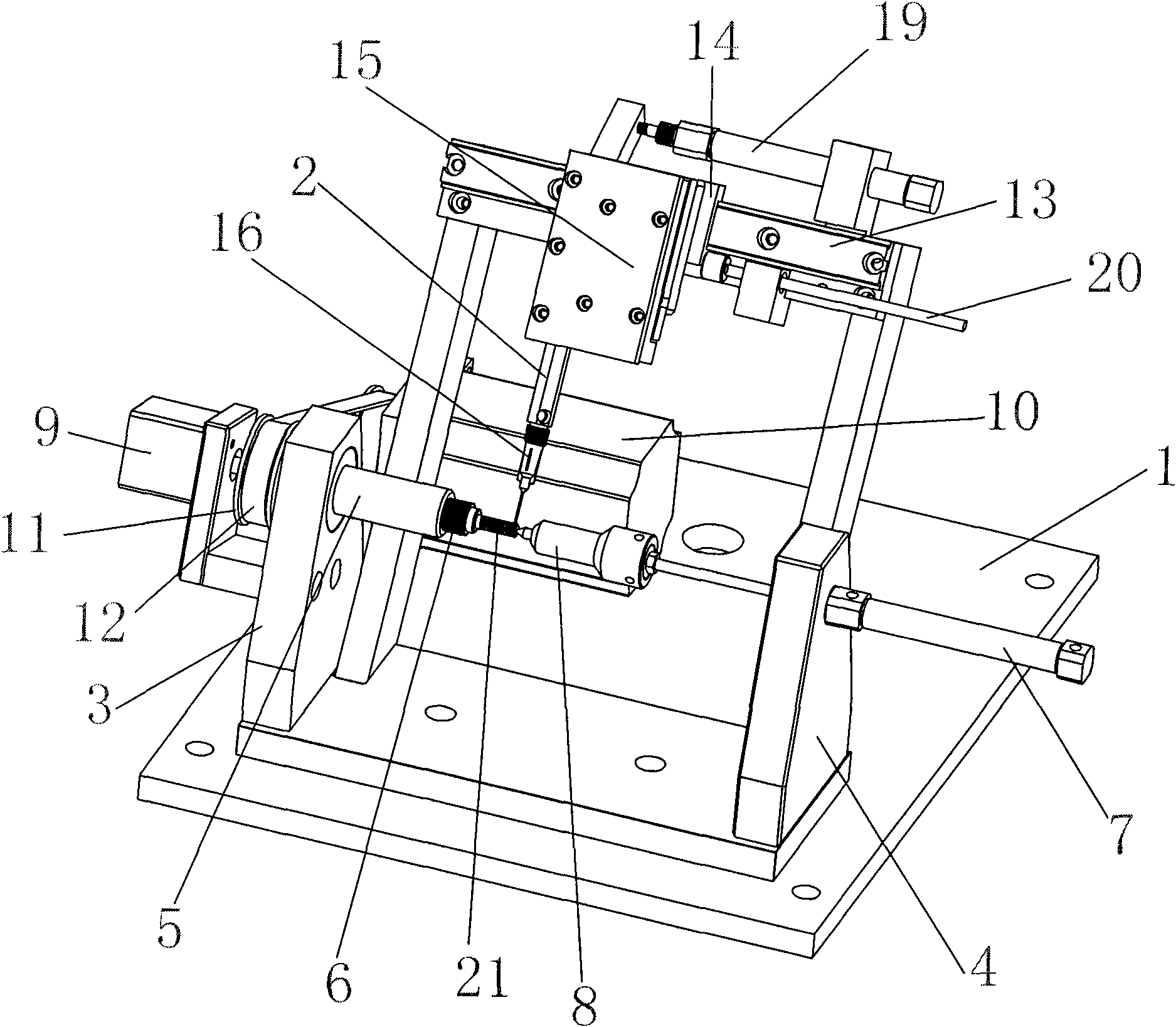

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

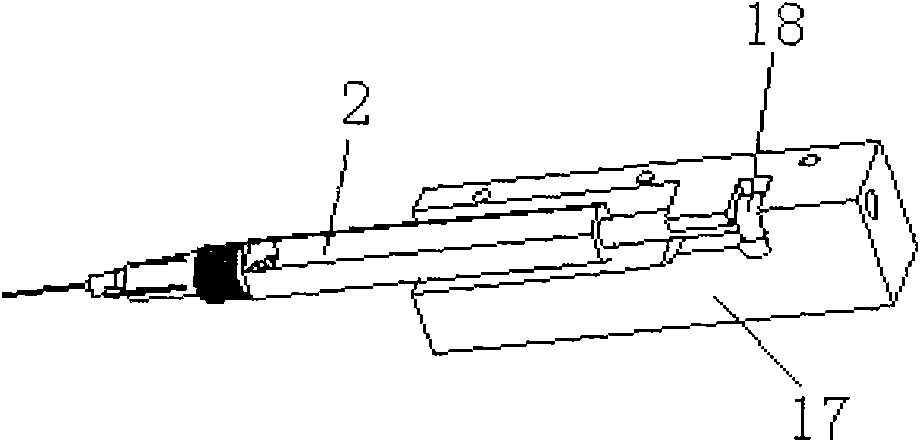

[0017] Referring to Fig. 1, a screw glue machine includes a machine platform 1 and a glue gun 2, and the machine platform 1 is provided with a first fixed seat 3 and a second fixed seat opposite to the first fixed seat 3 4. The first fixed base 3 is uploaded with a rotatable rotating shaft 5, the end of the rotating shaft 5 faces the second fixing base 4, and the end of the rotating shaft 5 is provided with a fixture 6; The second fixed seat 4 is provided with a clamping cylinder 7, the end of the piston rod of the clamping cylinder 7 faces the first fixed seat 3, and the end of the piston rod of the clamping cylinder 7 is connected with The tightening head 8, the said tightening head 8 is facing the said jig 6.

[0018] In this embodiment, the rotating shaft 5 is screwed to the fixture 6, and the end of the tightening head 8 is tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com