Coiling production device of glass fiber cloth

A production device and glass fiber technology, which are applied in the field of glass fiber cloth roll production devices, can solve the problems that the efficiency of the production process needs to be improved, the influence of the next process, etc., and achieve the effects of reasonable structure design, improved efficiency, and favorable drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

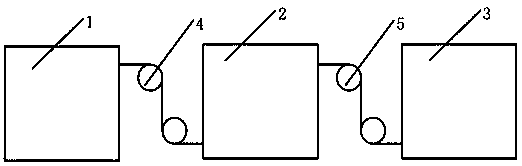

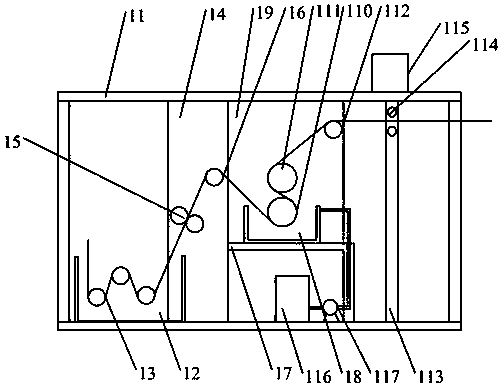

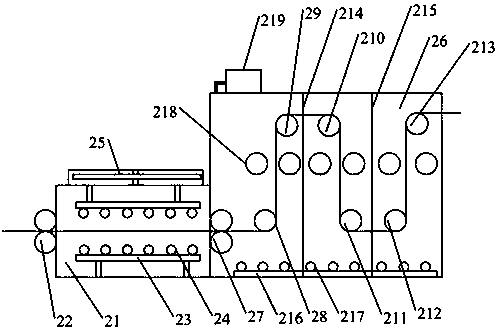

[0029]Comprising a gluing device 1, the gluing device 1 includes a gluing frame body 11, and a gluing tank 12 and a gluing tank 18 are respectively installed on the gluing frame body 11; a immersion roller 13 is installed in the immersion tank 12, and The upper end of the glue tank 18 is equipped with a rubber roller 110 and a rubber roller 111; the outlet end of the glue device 1 is connected to the drying device 2 through the first device connecting roller 4; the drying device 2 includes a preheating drying box 21 and multi-stage drying box 26; the top and bottom of the preheating drying box 21 are respectively fixed with preheating plates 23, and several preheating pipes 24 are fixed on the preheating plate 23, and the preheating pipes 24 are evenly A heating hole is provided; a drying plate 216 is provided at the bottom of the multi-stage drying box 26, a drying pipe 217 is provided on the drying plate 216, and a heating hole is provided on the drying pipe; the outlet end o...

Embodiment 2

[0031] The gluing device comprises a gluing frame body 11, the bottom end of the gluing frame body 11 is equipped with a soaking tank 12, and a soaking roller 13 is installed in the soaking tank 12; The first column 14 is arranged on the side, and a group of squeeze rollers 15 is installed in the middle of the first column 14; the first glue turning roller 16 is installed obliquely above the squeeze roller 15; the rear end of the first column 14 is welded There is a supporting platform 17; the upper end of the supporting platform 17 is provided with a glue coating groove 18, and the two sides of the supporting platform 17 are provided with a second column 19; 110, the upper end of the upper end of the rubber roller 110 is provided with an even rubber roller 111 in the vertical direction; the second rubber upper turn roller 112 which is rotatably connected to the second column 19 is arranged above the said uniform rubber roller 111; There is a third column 113; the upper end of...

Embodiment 3

[0038] The drying device includes a preheating drying box 21, the front end of the preheating drying box 21 is provided with a first conveying roller 22, and the top and bottom of the preheating drying box 21 are respectively fixed with a preheating plate 23. Some preheating pipes 24 are fixed on the hot plate 23, and heating holes are evenly arranged on the preheating pipes 24; the top of the preheating box is provided with an exhaust hole, and an exhaust fan 25 is installed on the exhaust hole; The rear end of the drying box 21 is connected with a multi-stage drying box 26; the inner front end of the multi-stage drying box 26 is provided with a second transfer roller 27; the rear end of the second transfer roller 27 is provided with a first drying turning roller 28. The upper end of the first drying turning roller 28 is provided with a second drying turning roller 29; the rear end of the second drying turning roller 29 is provided with a third drying turning roller 210, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com