Automatic gluing and board pasting device for melamine impregnated paper composite board

A technology of melamine and impregnated paper, which is applied in the direction of adhesive application device, wooden veneer joint, wood processing equipment, etc. It can solve the problems of easy generation of air bubbles when pasting impregnated paper, layered bulging of composite boards, and high maintenance cost, and achieves Avoid bulging and layering, reduce production costs, and reduce manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

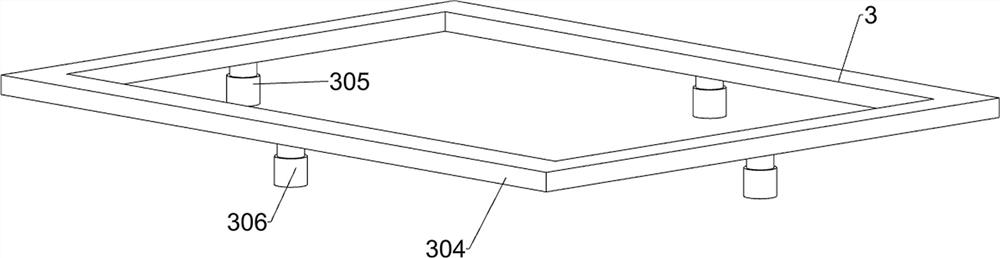

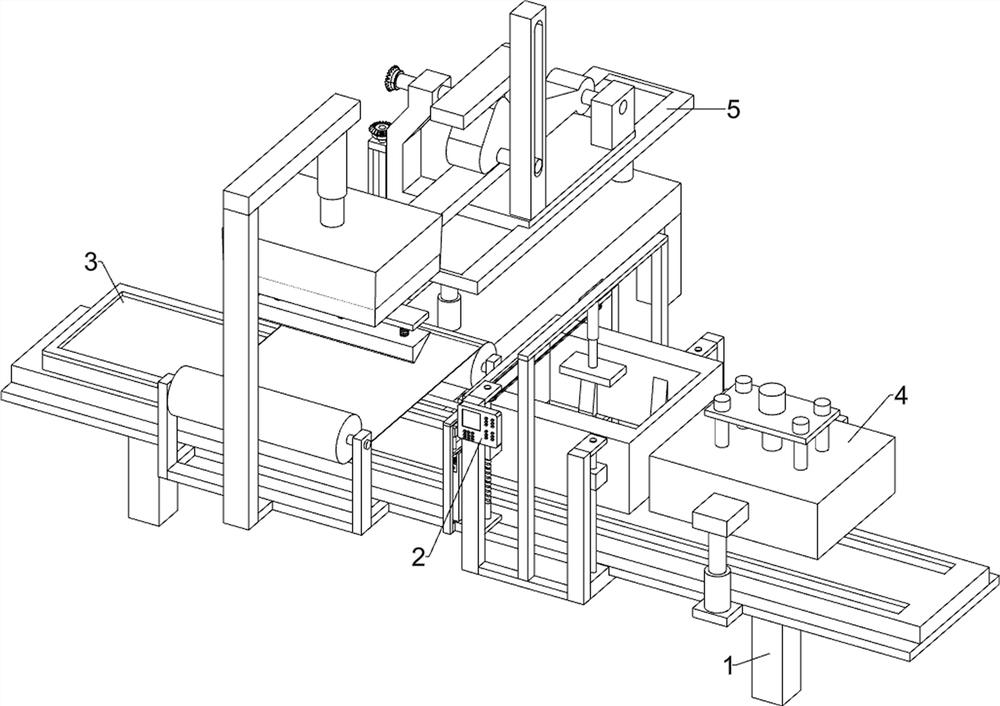

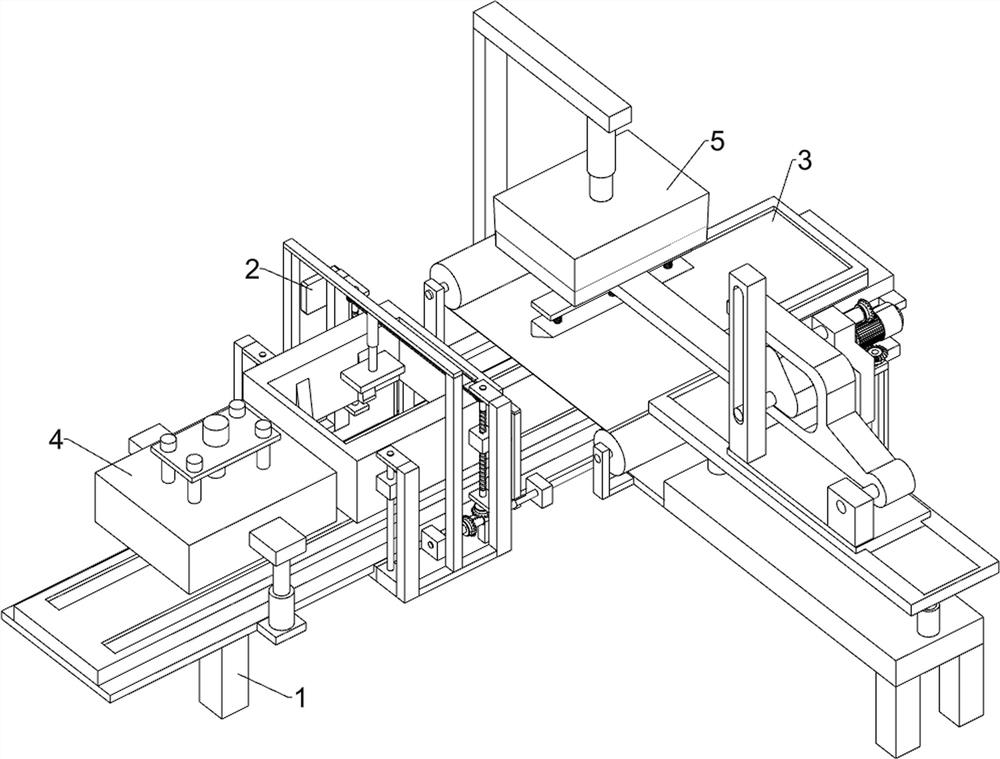

[0033] A kind of melamine-impregnated paper composite board automatic glue coating device, such as Figure 1-13 As shown, it includes chassis 1, controller 2, conveying and gluing assembly 3, panel pressing assembly 4 and sticker smoothing assembly 5; chassis 1 is connected to controller 2; chassis 1 is connected to conveying and coating assembly 3 are connected; the bottom frame 1 is connected with the plate pressing assembly 4; the bottom frame 1 is connected with the sticker smoothing assembly 5; the plate pressing assembly 4 is connected with the sticker smoothing assembly 5.

[0034] Working principle: When preparing for work, place the device on a horizontal surface, turn on the power, put the processed substrate into the conveying glue assembly 3 on the chassis 1, and control the conveying glue assembly 3 to the substrate through the controller 2 Carry out gluing treatment, and then transport the substrate to the laminating and pressing assembly 4 for fiberboard laminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com