Method for preparing Nano granules of stannic oxide

A technology of nano-tin oxide and particles, applied in the field of nano-materials, can solve the problems of cumbersome, time-consuming, and long gelation time, and achieve the effects of improving efficiency, good gelation quality, and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

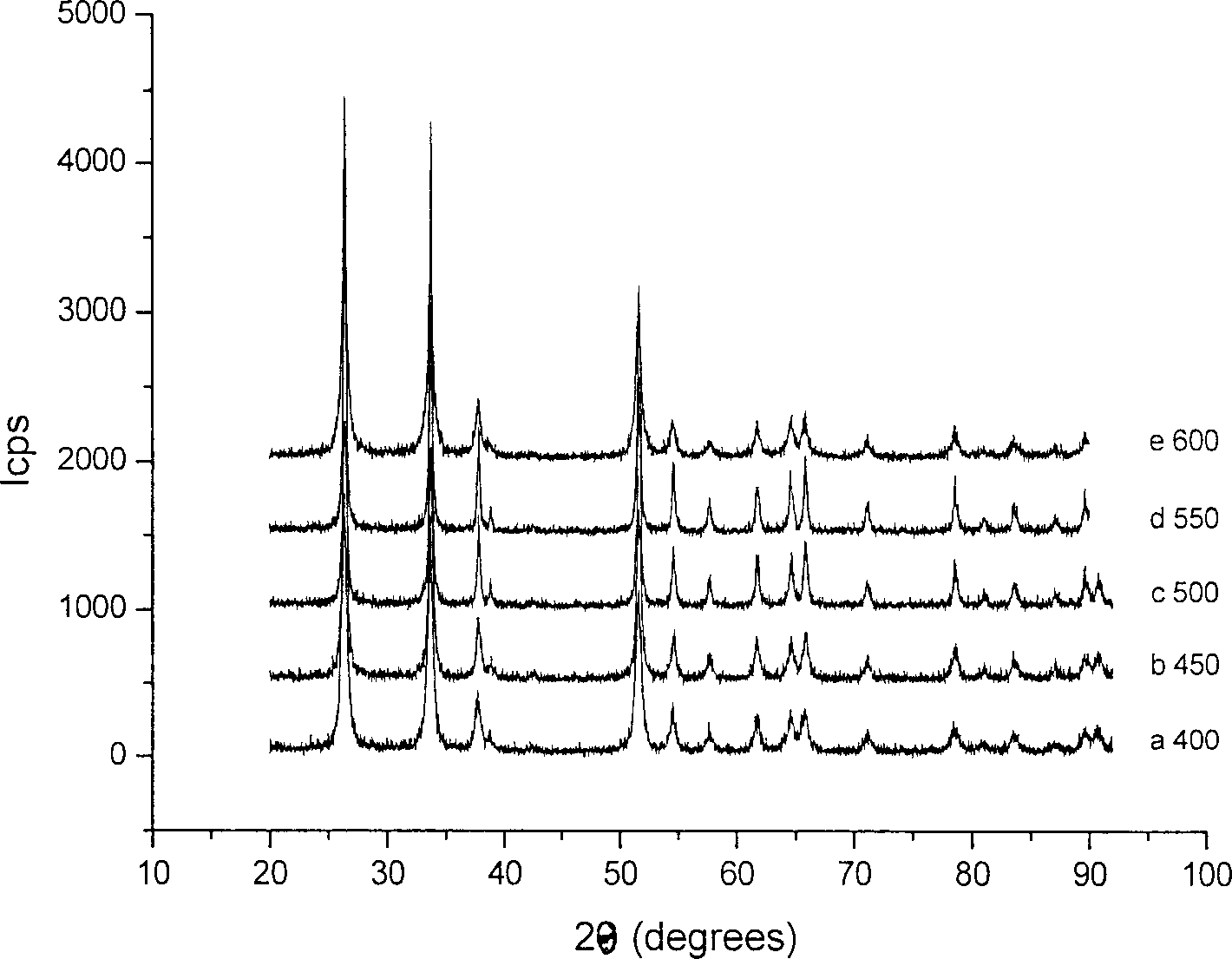

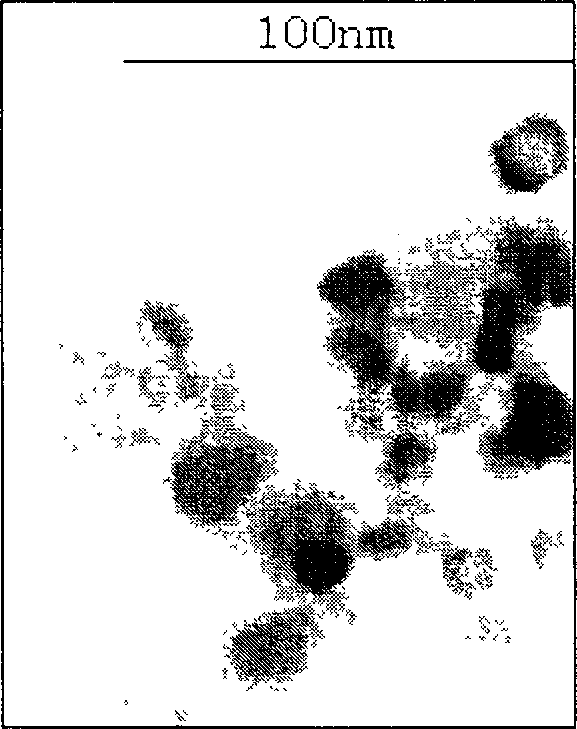

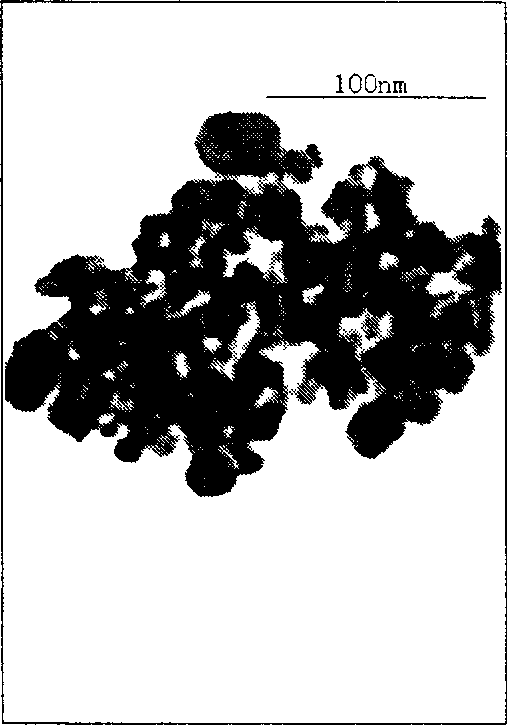

[0015] 1. Take SnCl 4 ·5H 2 About 7.0188g of O, 8.4065g of citric acid, and 0.3g of polyethylene glycol (400) were added to 10ml of deionized water and mixed, stirred evenly, then put into a microwave oven and heated for 9min with medium microwave power, and then roasted in a muffle furnace at 600°C for 3h . According to the results of XRD, the grain size of nanoparticles obtained by the Scherrer equation is 17.4nm.

[0016] 2. Take SnCl 4 ·5H 2 Add about 7.0188g of O, 8.4056g of citric acid, and 0.3g of polyethylene glycol (400) into 10ml of deionized water and mix, stir evenly, then put it in a microwave oven and heat it with medium microwave power for 13min, then bake it in a muffle furnace at 500°C for 4h . According to the results of XRD, the grain size of nanoparticles obtained by the Scherrer equation is 18.3nm

[0017] 3. Take SnCl 4 ·5H 2 About 7.0188g of O, 16.8112g of citric acid, and 0.3g of polyethylene glycol (600) were added to 15ml of deionized water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com