Powder charging system and powder charging method for producing polyurethane sealant

A technology of polyurethane sealant and feeding system, which is applied to the powder feeding system and powder feeding field for the production of polyurethane sealant, which can solve the problems of many operators, large fluctuations in the amount of powder added, and high labor costs, and achieve improvement. The effect of high glue quality, high measurement accuracy and low cooling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

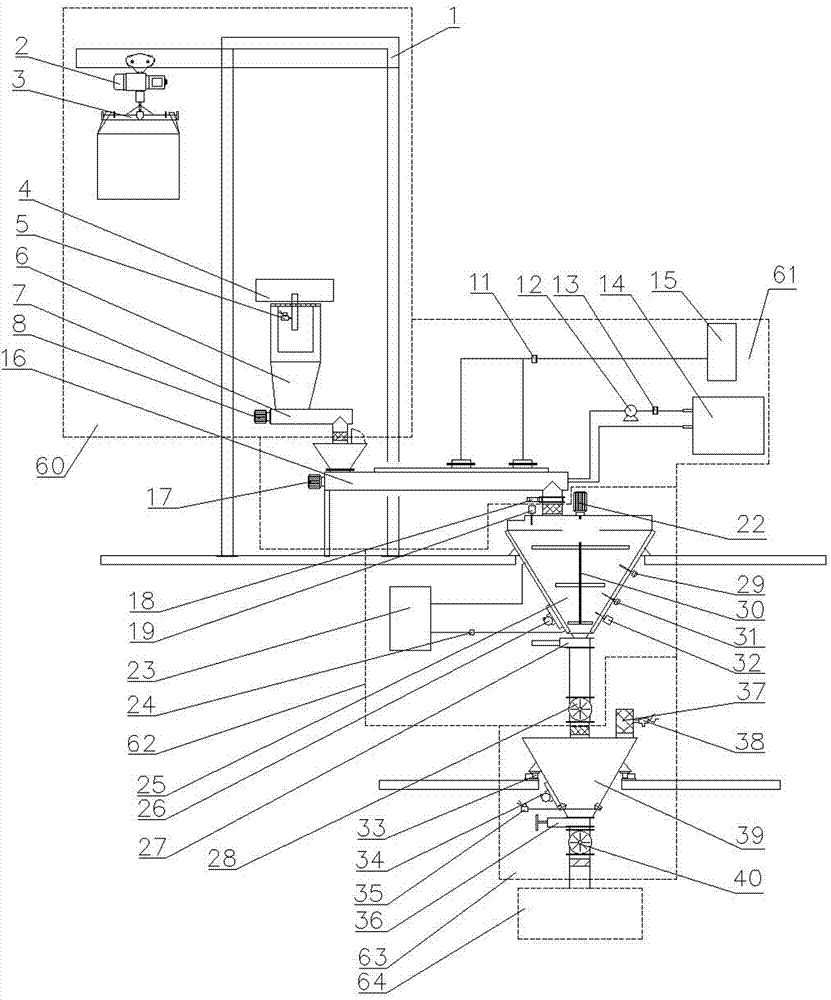

[0029] Such as figure 1 As shown, the present invention comprises charging system 60, drying system 61, cooling system 62 and weighing system 63, and charging system 60, drying system 61, cooling system 62 and weighing system 63 are connected successively to form the sealing of powder. Transmission channel.

[0030] The charging system 60 includes a hopper 6 and a lifting mechanism arranged on the top of the hopper 6. The lifting mechanism is an electric hoist 2 arranged on the top of the hopper 6. The electric hoist 2 is installed at a suitable height of the support 1. The electric hoist 2 A packaging bag clamp 3 is connected to clamp the powder packaging bag. The inlet of the feeding hopper 6 is provided with a pneumatic feeding massager 4 , and a control valve 5 is provided on the ventilation line of the feeding massager 4 . The action of the feeding massager 4 is controlled by the control valve 5 . The feeding massager 4 is set for the powder in the powder packaging bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com