Complete gluing apparatus and gluing technology of new energy automobile assembled battery

A technology for new energy vehicles and battery assembly, which is applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc. The effect of labor intensity, improving labor safety and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a basis for limiting the present invention.

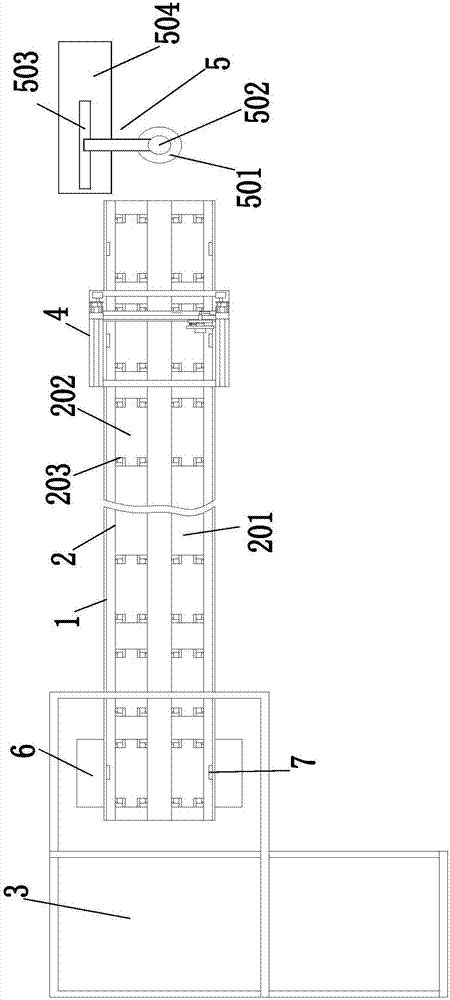

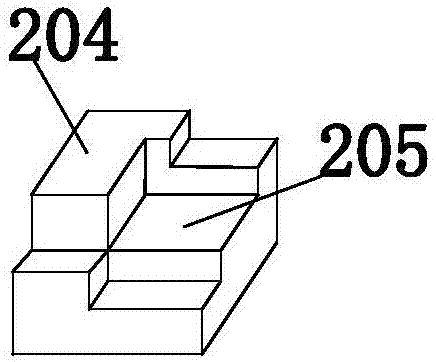

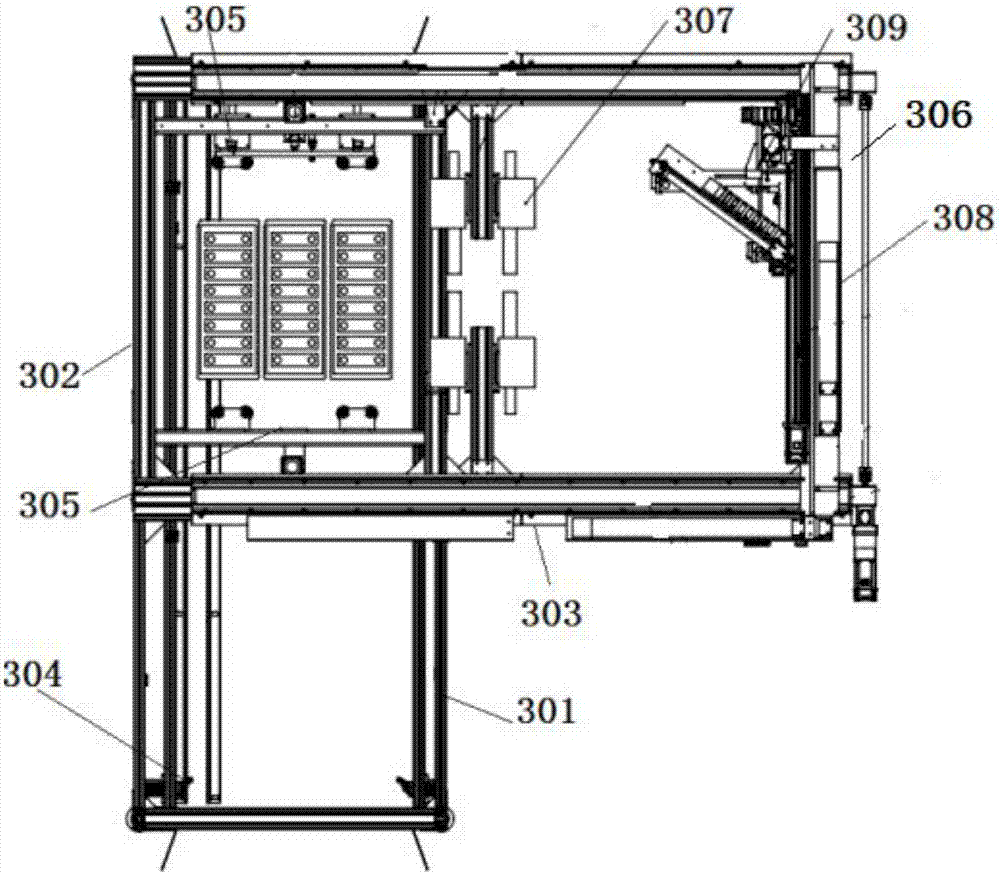

[0032] Example. A complete set of gluing equipment for battery assembly of new energy vehicles, the composition of which is as follows: Figure 1 to Figure 15 As shown, it includes the main frame 1, the main frame 1 is provided with a conveying device 2, and the upper part of the conveying device 2 is sequentially provided with a feeding device 3, a gluing device 4 and a cell grabbing and stacking device 5, and the two feeding ends of the main frame 1 A battery turning device 6 is provided on each side; a group of positioning sensors 7 are arranged on both sides of the conveying device 2, and the positioning sensor 7 is connected with a controller 8, and the controller 8 is connected with the battery turning device 6, the conveying device 2, and the feeding device. 3. The gluing device 4 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com