Full-automatic double-hollow glass gluing machine

A double-hollow, fully automatic technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of reduced efficiency, low efficiency, unfavorable continuous production, etc., and achieves high gluing efficiency, high degree of automation, Good quality glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

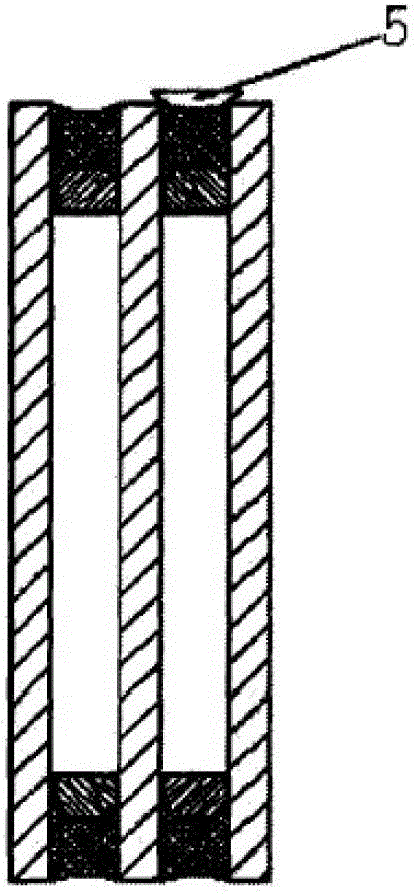

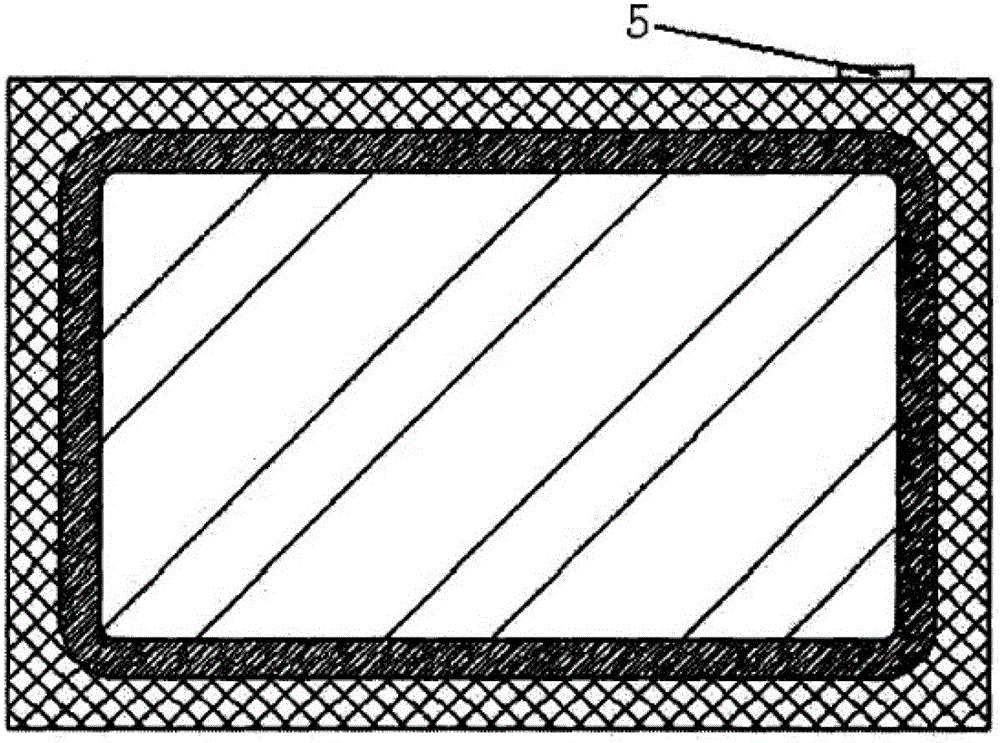

[0036] like Figure 3a , Figure 3b As shown, one glue nozzle has two glue outlets, and one glue application can complete two sealing coatings. The structure is described in detail below:

[0037] 1. Double measuring mechanism:

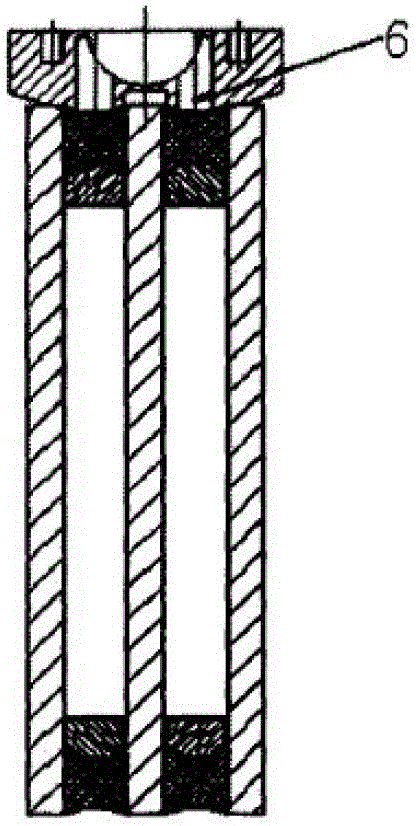

[0038] like Figure 4a , Figure 4b As shown, the dual measuring mechanism measures the cross-sectional depth of the two seals through two independent "depth measuring devices". . The height difference between the edge of the glass and the edge of the spacer is the glue depth per unit cross-sectional area. The greater the height difference, the greater the swing angle of the depth gauge.

[0039] The swing angle of the first depth measuring device is directly and equally transmitted to the first depth measuring shaft, which is connected with the rotary encoder, and converts the mechanical movement into an electrical signal, thereby calculating the gluing depth per unit cross-sectional area of the first seal.

[0040] Through the parallelogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com