Automatic production line for wooden door veneering

An automatic production line and veneer technology, which is applied to wood processing equipment, the joining of wooden veneers, and other plywood/plywood appliances, etc. It can solve the problems of low efficiency, poor precision, and the inability of the centering mechanism to grasp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

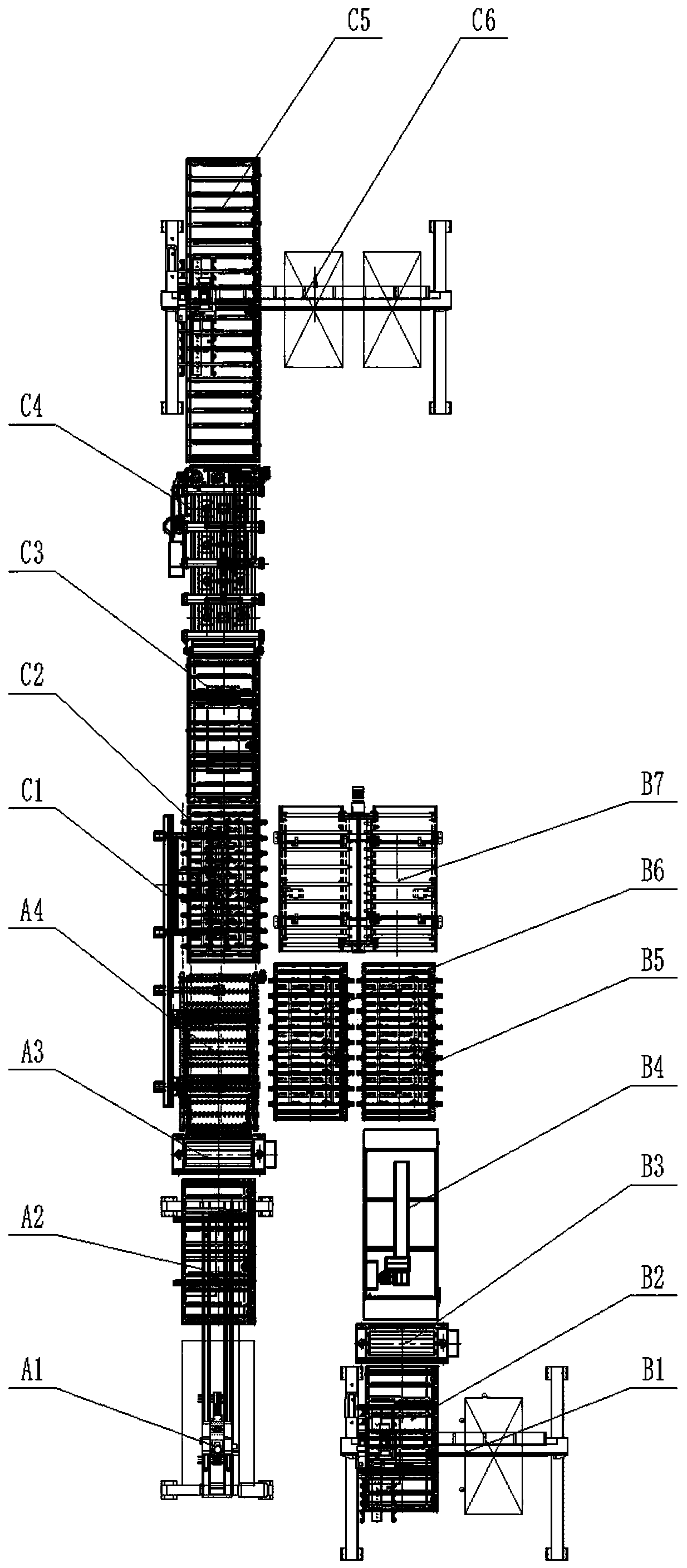

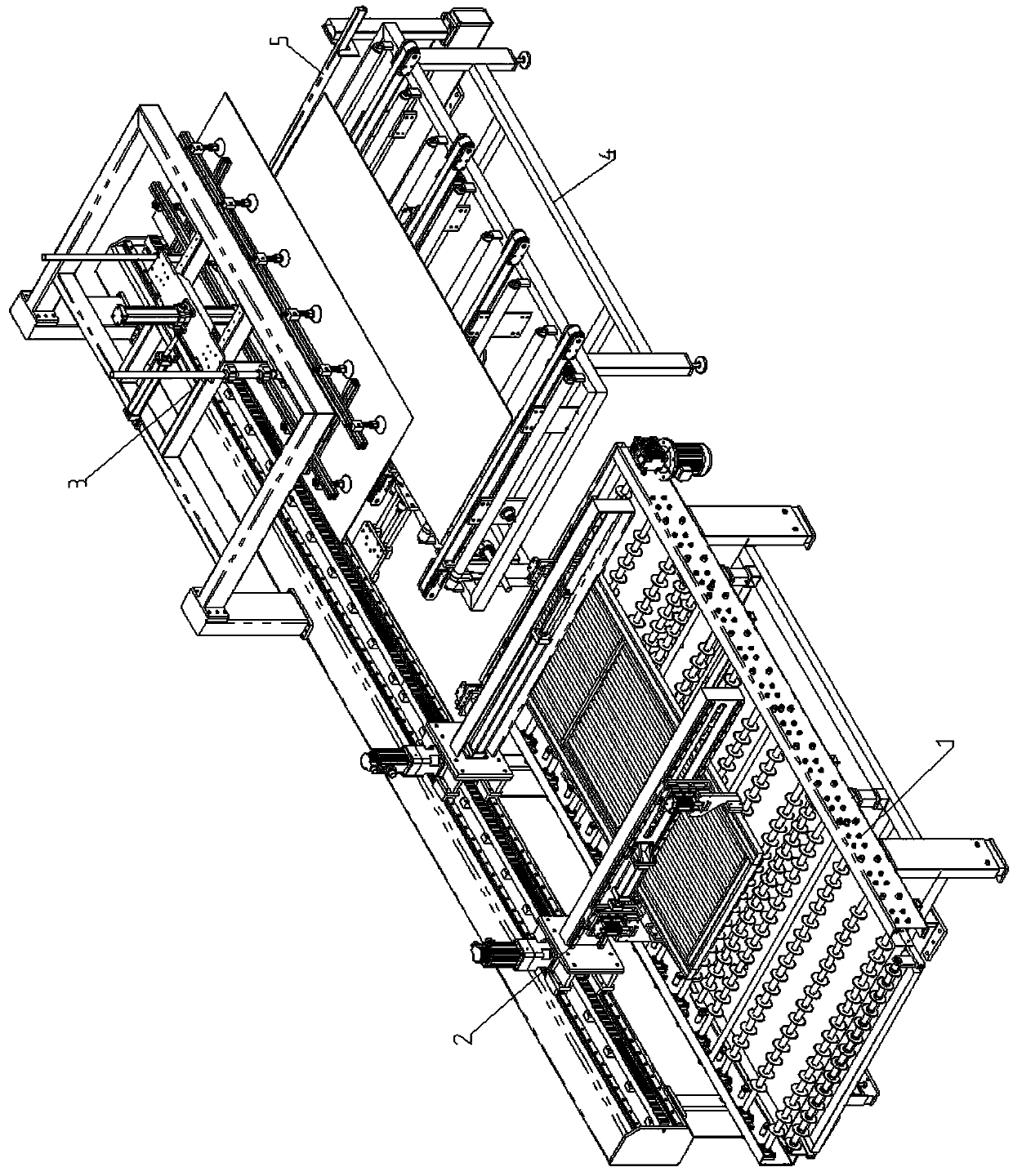

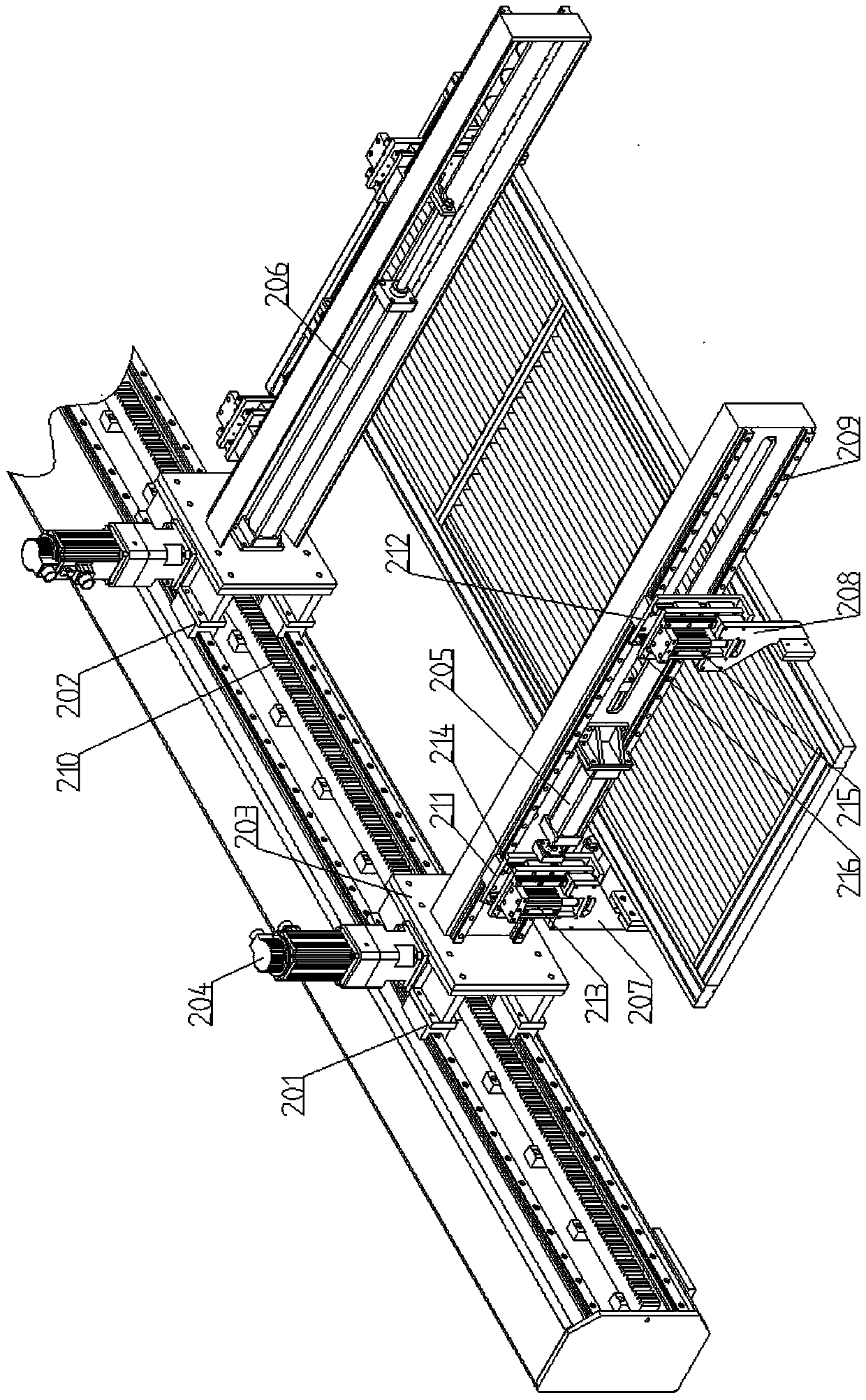

[0033] Such as figure 1 As shown, an automatic production line for veneering of wooden doors includes a core board gluing line A, a panel and bottom board gluing line B, and a plywood line C, wherein the core board gluing line A and the plywood line C are arranged in sequence according to the feeding direction, and the panel It is arranged in parallel with the base plate gluing line B and the above two. The core board gluing line A includes sequentially setting the core board feeding gantry machine A1, the first roller conveyor A2, the double-sided glue coating machine A3, and the disc conveyor A4. Panel and bottom panel gluing line B includes sequentially arranged panel and bottom panel feeding gantry machine B1, third roller conveyor B2, single-sided gluing machine B3, dryer B4, second diverting conveyor B5, cross panel turning machine B7, The second turning conveyor B5 and the third turning conveyor B6 are arranged in order perpendicular to the feeding direction, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com