Full-automatic hot-pressing gluing equipment

A fully automatic and equipment-based technology, applied in plywood presses, veneer presses, wood processing appliances, etc., can solve problems such as potential safety hazards, cumbersome operation process, and extended processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

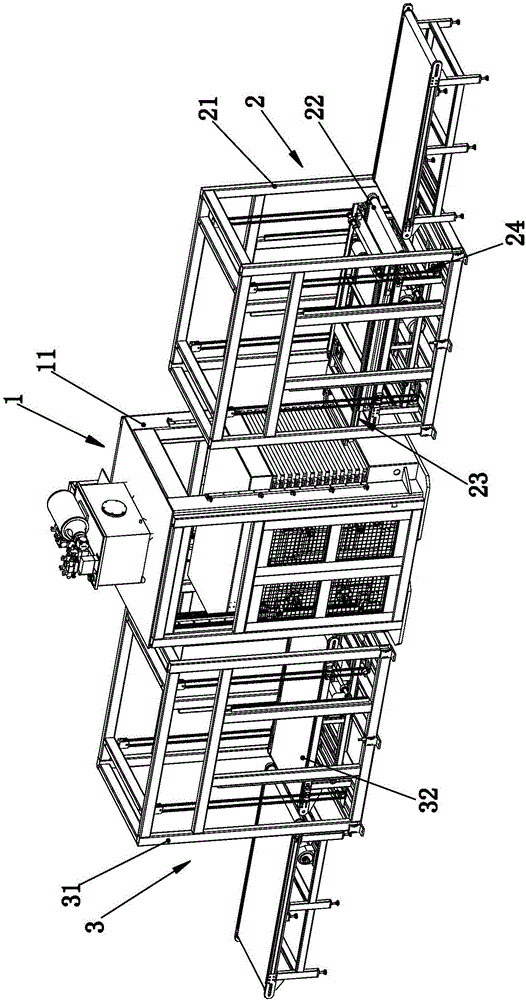

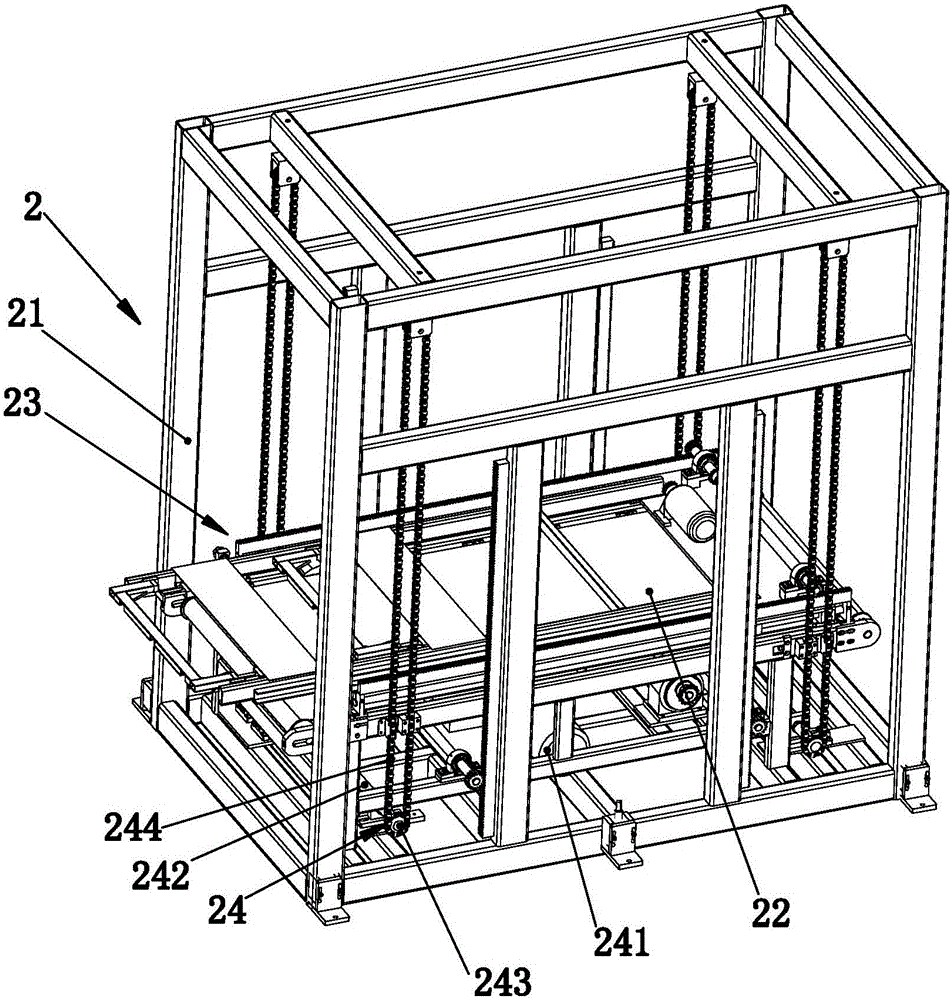

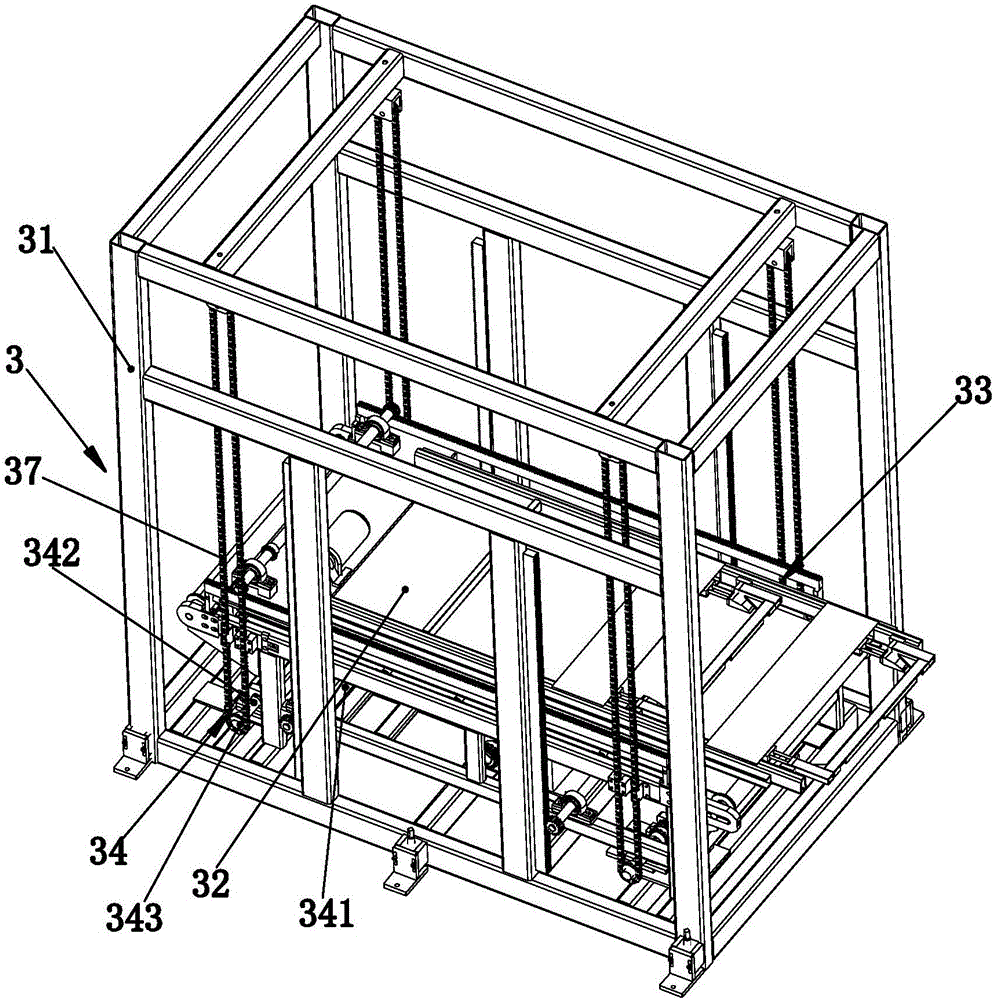

[0026] Such as figure 1 — Figure 8A fully automatic hot-pressing gluing equipment shown includes a gluing device 1, and the gluing device 1 includes a body 11, a plurality of pressing boards 12 erected on the body 11 and arranged in stacks, and driving the pressing boards 12 to compress or separate The driving mechanism 13 has a pressing space 121 between the pressing plates 12, and the body 11 is provided with a heat energy generator 14 that can add heat energy to the interior of the pressing plates 12, and the two sides of the body 11 are respectively symmetrically provided with an input device for the object to be glued. 2 and complete the glued object output device 3, the object to be glued input device 2 includes a frame 21, a conveying platform 22 erected on the frame 21, and a feeding mechanism 23 erected on the conveying platform 22 and capable of reciprocating movement along the conveying platform 22 And be located on the frame 21 and can implement lifting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com