Glue-pouring integrated machine and coating method thereof

An all-in-one machine and gluing machine technology, applied in the field of gluing machines, can solve problems such as large amount of programming, low processing efficiency, and error-prone, and achieve high-precision processing, improve gluing efficiency, and work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

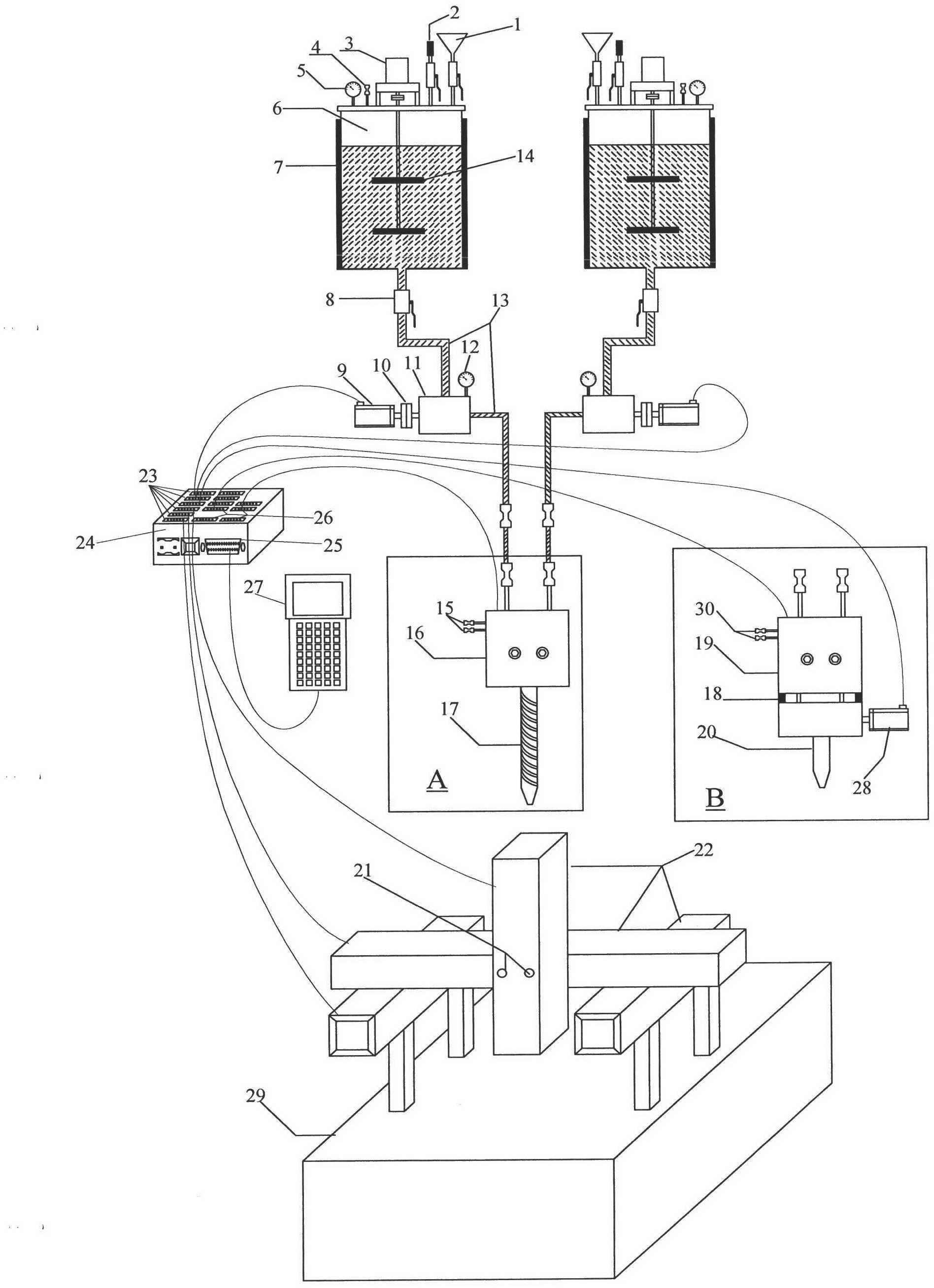

[0030] Open the pressure relief valve 2 to release the pressure in the glue container. Refer to the pressure gauge 5 to control the pressure in the glue container. After the pressure is unloaded, open the feed valve 1 to feed A glue and B glue into two glue containers 6 respectively, and then Close feed valve 1 and pressure relief valve 2. According to the viscosity of the glue and whether there are additives, connect the air pressure inlet 4, turn on the stirring motor 3, and drive the stirring blade 14 to stir the glue A and glue B respectively so that the components added in the glue are uniform, and heat and keep warm through the heating and heat preservation device 7 . The glue container 6 is connected with the glue conveying pump 11 through the conduit 13, and the conduit near the glue container 6 is provided with a glue outlet valve 8, and the glue conveying pump 11 is provided with an output glue pressure gauge 12, a glue conveying motor 9, and the glue conveying motor...

Embodiment 2

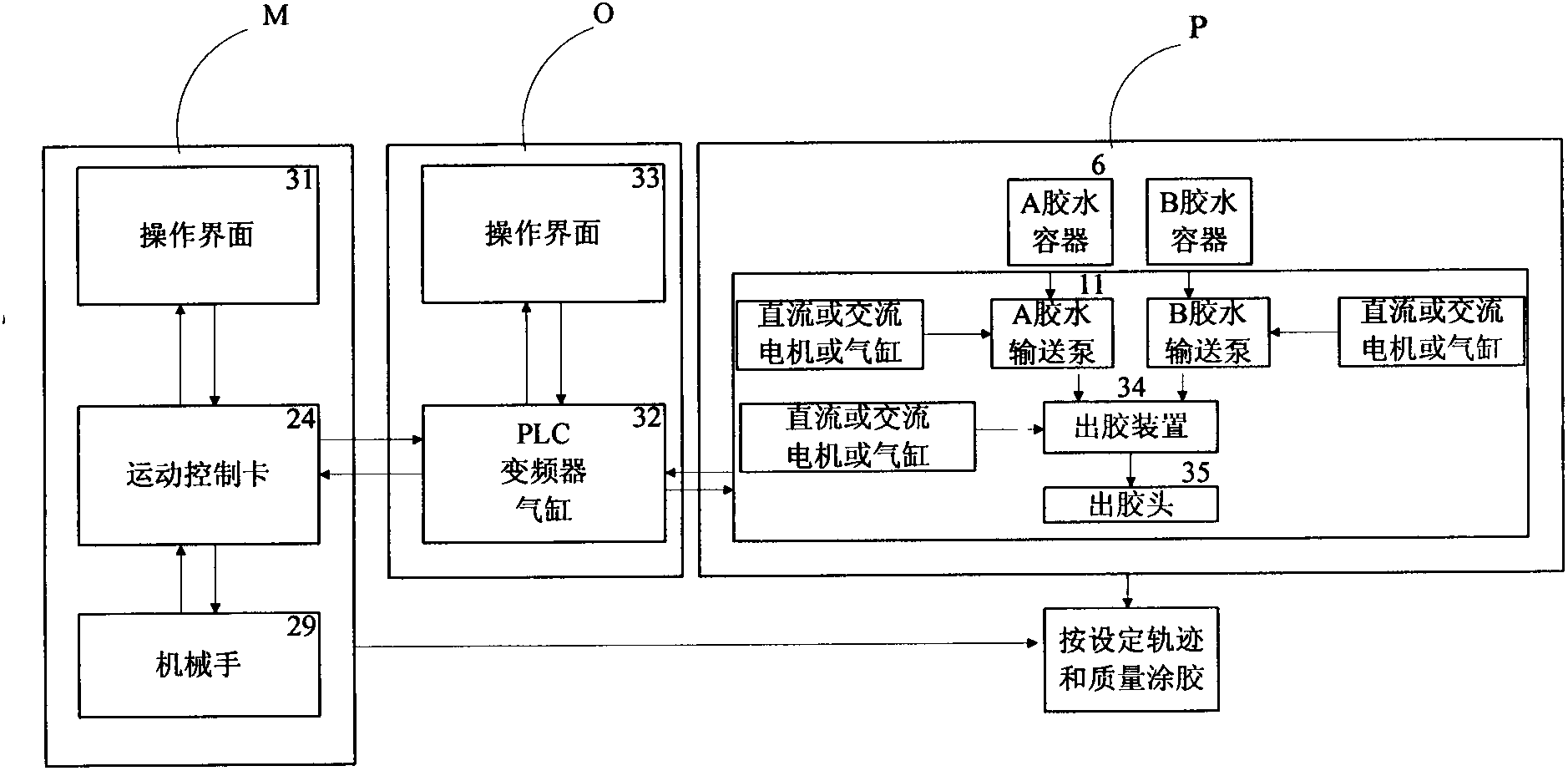

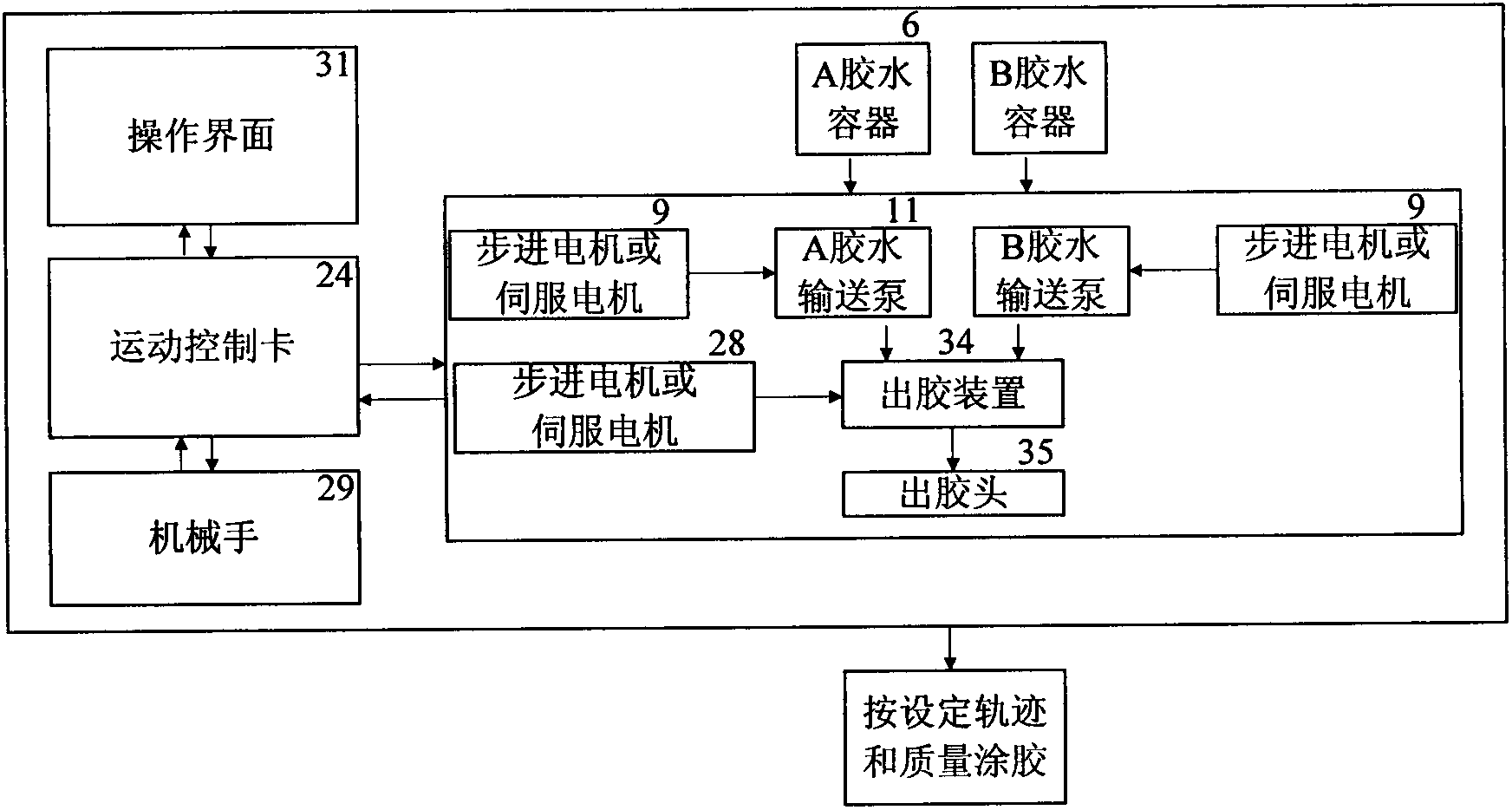

[0034] see figure 2 , image 3 and Figure 4 , the glue filling method of the all-in-one machine equipment is through the following steps

[0035] Achieved:

[0036] (1) the control parameter of motion control card 24 is set, the rotating speed of conveying motor 9, the rotating speed of the mixing motor 28 of glue discharge device B, the motion trajectory of the mechanical arm 22 of manipulator 29;

[0037] (2) Put the raw material in the raw material container 6, press the raw material into the conveying pump 11 by adjusting the air pressure in the container 6, control the conveying pump 11 through the motion control card 24 to transport the raw material to the mixing module of the glue filling machine, and drive it according to the conveying motor 9 The transfer pump 11 transfers the preset ratio A and B raw materials to the glue outlet 34 for mixing;

[0038] (3) Control the glue discharge device through the motion control card 24 until the stirring and mixing are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com