Special stove for liquid fuel

A liquid fuel and stove technology, applied in the field of stove manufacturing, can solve problems such as difficulty in normal use, and achieve the effects of quick cleaning, low combustion cost, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

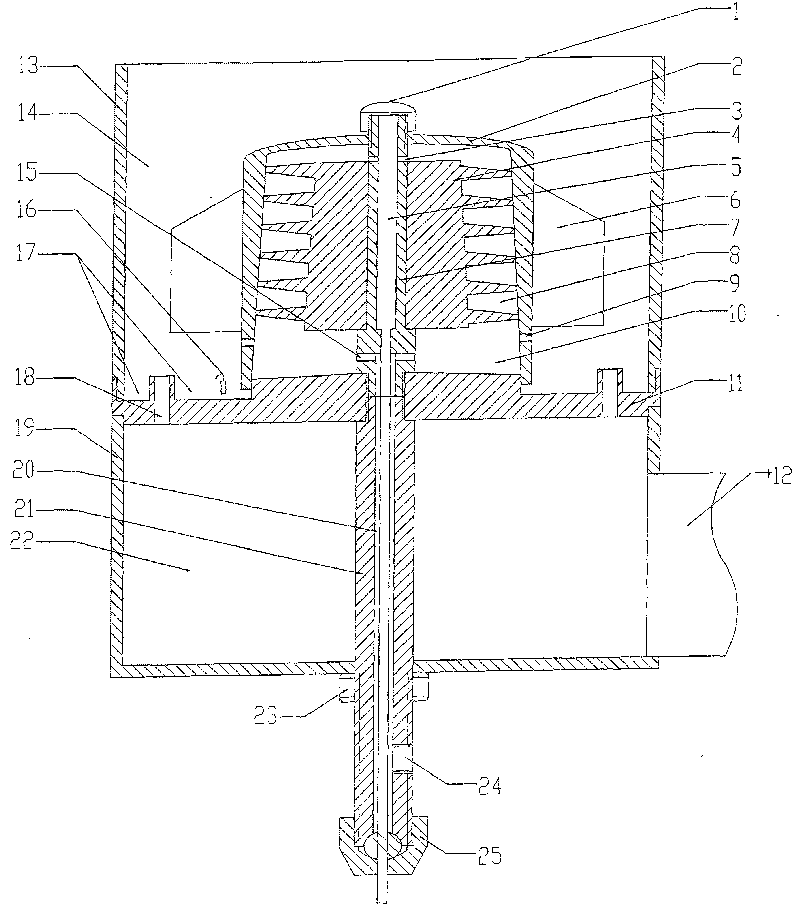

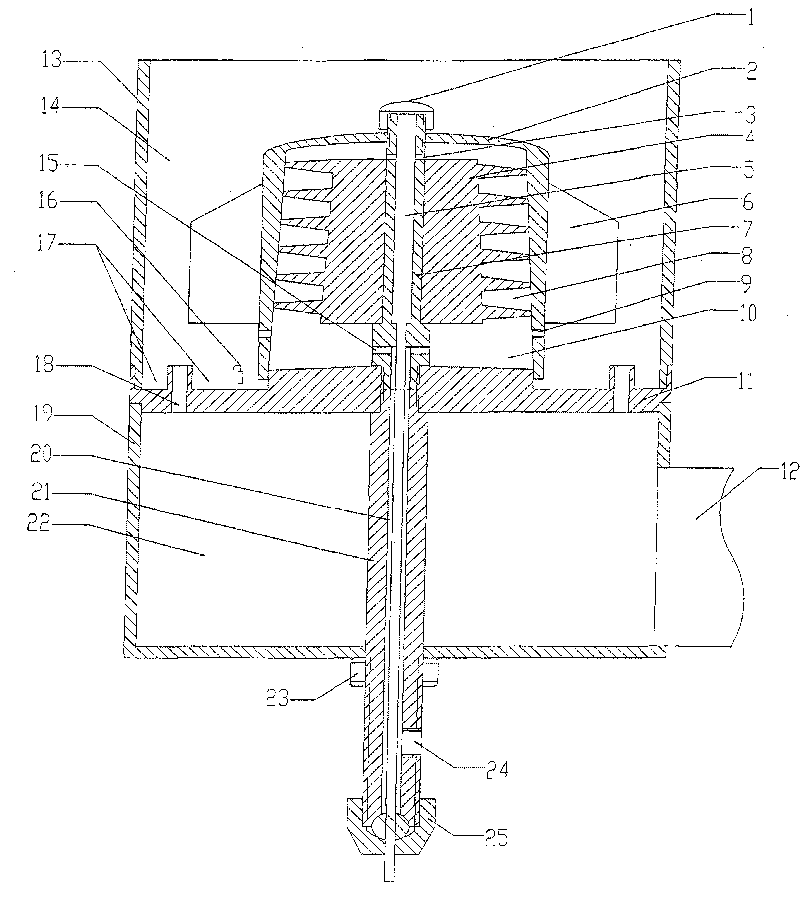

[0016] The present invention mainly consists of a combustion chamber cover 13 with a combustion chamber base 11 inside, an air buffer outer cover 19 with an air inlet pipe 12 placed at the bottom of the combustion chamber base 11, and a preheated fuel diversion groove placed on the combustion chamber base 11. The air nozzle 18 of 17, the igniter 16, the fire-distributing carburetor jacket 2 with the fuel steam nozzle 9, the lower screw 21 with the liquid fuel pipe 5 and the preheating fuel pipe 20 inside, are placed in the fire-distributing carburetor jacket 2 and surround The fire-distributing carburetor 4 of the liquid fuel pipe 5, the liquid fuel liquid outlet hole 3 provided on the liquid fuel pipe 5 on the fire-distributing carburetor 4 top, the preheating fuel outlet hole 3 provided on the preheating fuel pipe 20 at the bottom of the fire-distributing carburetor 4 The liquid hole 15 is placed on the fire-distributing wing 6 on the periphery of the fire-distributing carbur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com