Gluing device for leather shoe manufacturing

A leather shoe and extrusion device technology, which is applied to footwear, application, and bonding shoe parts, etc., can solve problems such as damage to human skin, waste of glue water resources, and glue glue is easy to stick on people's hands, etc., so as to improve the efficiency of gluing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

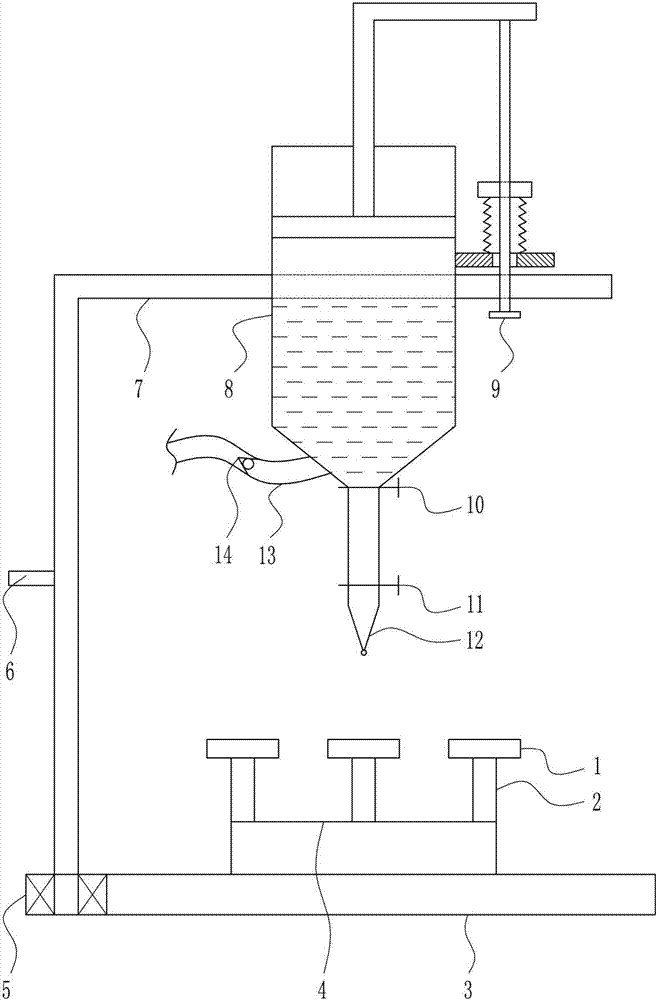

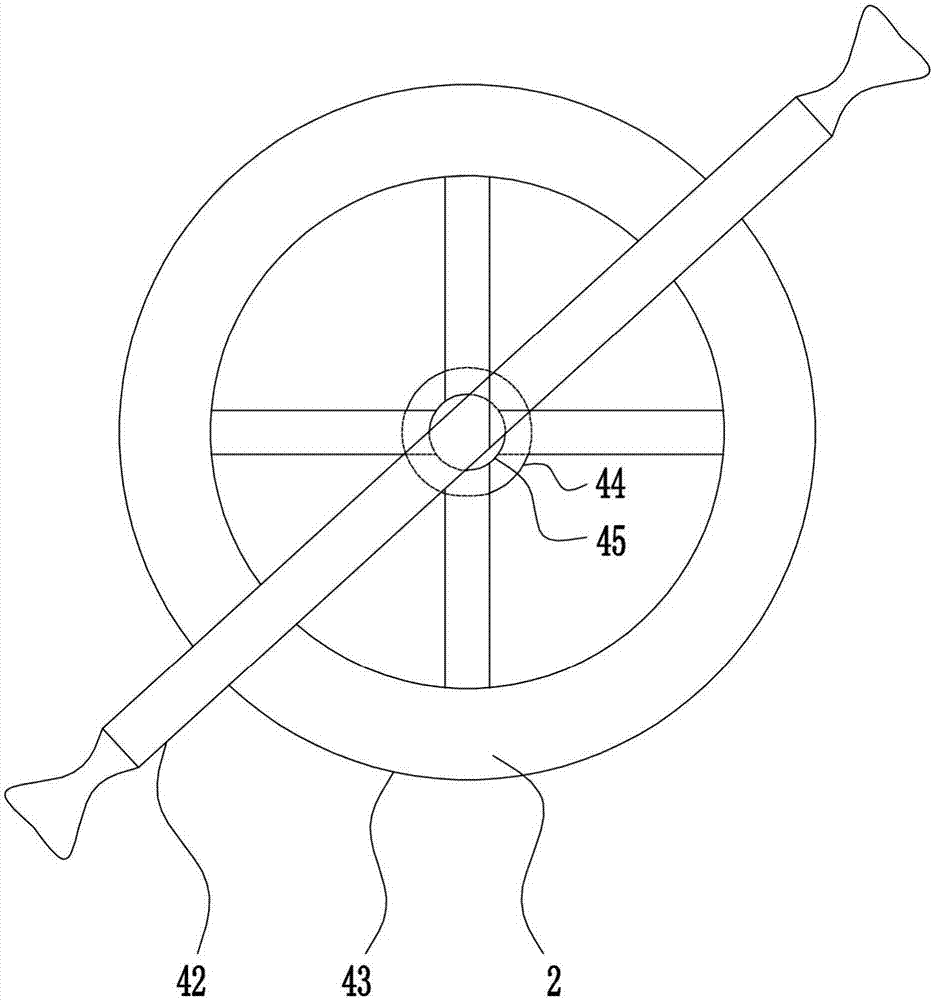

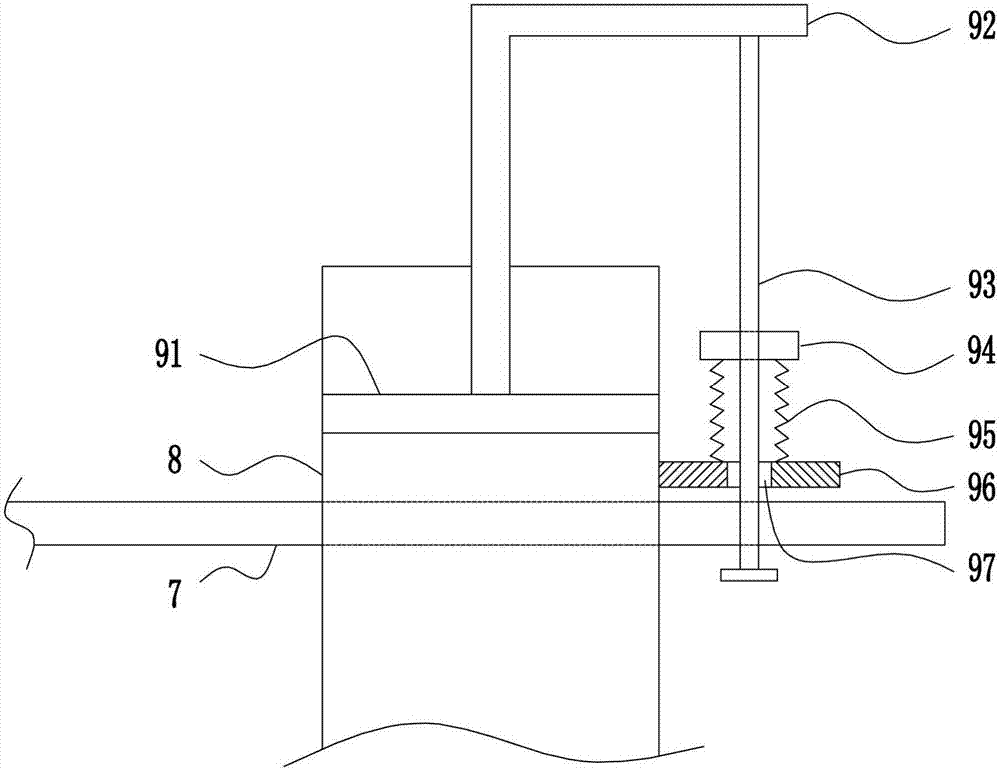

[0037] A kind of gluing device for manufacturing leather shoes, such as Figure 1-7As shown, it includes a shoe mold 1, a pole 2, a bottom plate 3, a rotating device 4, a second bearing seat 5, a handle 6, an L-shaped rotating rod 7, a plastic box 8, an extrusion device 9, a first valve 10, a second Two valves 11, nozzles 12, hoses 13 and one-way valve 14, the bottom plate 3 is provided with a rotating device 4, the rotating device 4 is uniformly connected with a pole 2, the upper end of the pole 2 is connected with a shoe mold 1, and the rotating device 4 The left side of the L-shaped rotating rod 7 is provided with a second bearing seat 5, the second bearing seat 5 is equipped with an L-shaped rotating rod 7, the left middle part of the L-shaped rotating rod 7 is connected with a handle 6, and the front side of the top of the L-shaped rotating rod 7 is provided with a glue Box 8, the lower part of the plastic box 8 is provided with a first valve 10 and a second valve 11, the...

Embodiment 2

[0039] A kind of gluing device for manufacturing leather shoes, such as Figure 1-7 As shown, it includes a shoe mold 1, a pole 2, a bottom plate 3, a rotating device 4, a second bearing seat 5, a handle 6, an L-shaped rotating rod 7, a plastic box 8, an extrusion device 9, a first valve 10, a second Two valves 11, nozzles 12, hoses 13 and one-way valve 14, the bottom plate 3 is provided with a rotating device 4, the rotating device 4 is uniformly connected with a pole 2, the upper end of the pole 2 is connected with a shoe mold 1, and the rotating device 4 The left side of the L-shaped rotating rod 7 is provided with a second bearing seat 5, the second bearing seat 5 is equipped with an L-shaped rotating rod 7, the left middle part of the L-shaped rotating rod 7 is connected with a handle 6, and the front side of the top of the L-shaped rotating rod 7 is provided with a glue Box 8, the lower part of the plastic box 8 is provided with a first valve 10 and a second valve 11, th...

Embodiment 3

[0042] A kind of gluing device for manufacturing leather shoes, such as Figure 1-7 As shown, it includes a shoe mold 1, a pole 2, a bottom plate 3, a rotating device 4, a second bearing seat 5, a handle 6, an L-shaped rotating rod 7, a plastic box 8, an extrusion device 9, a first valve 10, a second Two valves 11, nozzles 12, hoses 13 and one-way valve 14, the bottom plate 3 is provided with a rotating device 4, the rotating device 4 is uniformly connected with a pole 2, the upper end of the pole 2 is connected with a shoe mold 1, and the rotating device 4 The left side of the L-shaped rotating rod 7 is provided with a second bearing seat 5, the second bearing seat 5 is equipped with an L-shaped rotating rod 7, the left middle part of the L-shaped rotating rod 7 is connected with a handle 6, and the front side of the top of the L-shaped rotating rod 7 is provided with a glue Box 8, the lower part of the plastic box 8 is provided with a first valve 10 and a second valve 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com