Glass gluing device

A glass coating and glass technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of low coating efficiency, many adsorption actions, high manufacturing cost and high consumption, and improve the utilization rate of plant space , The effect of reducing the walking distance and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0037] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself.

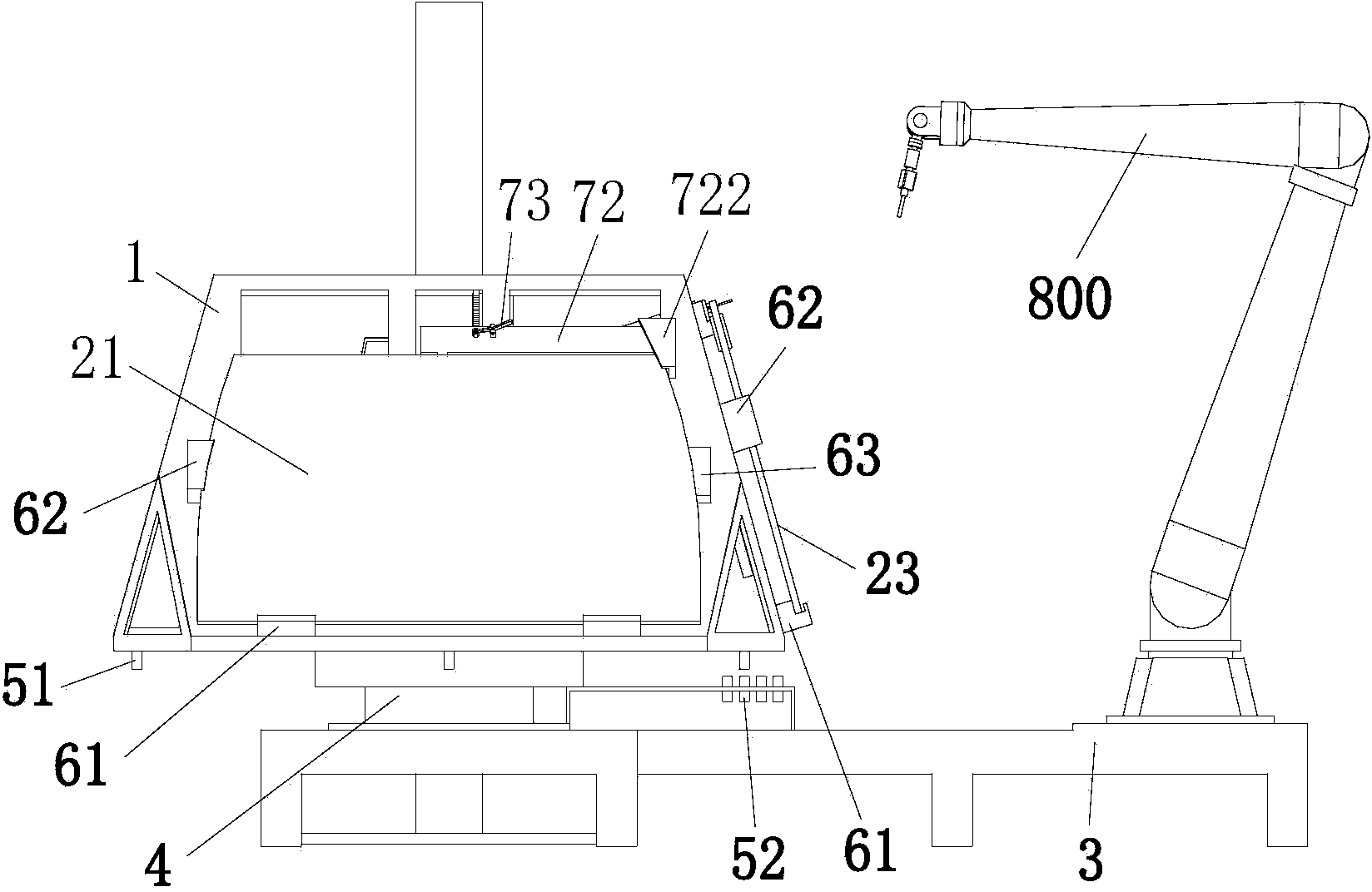

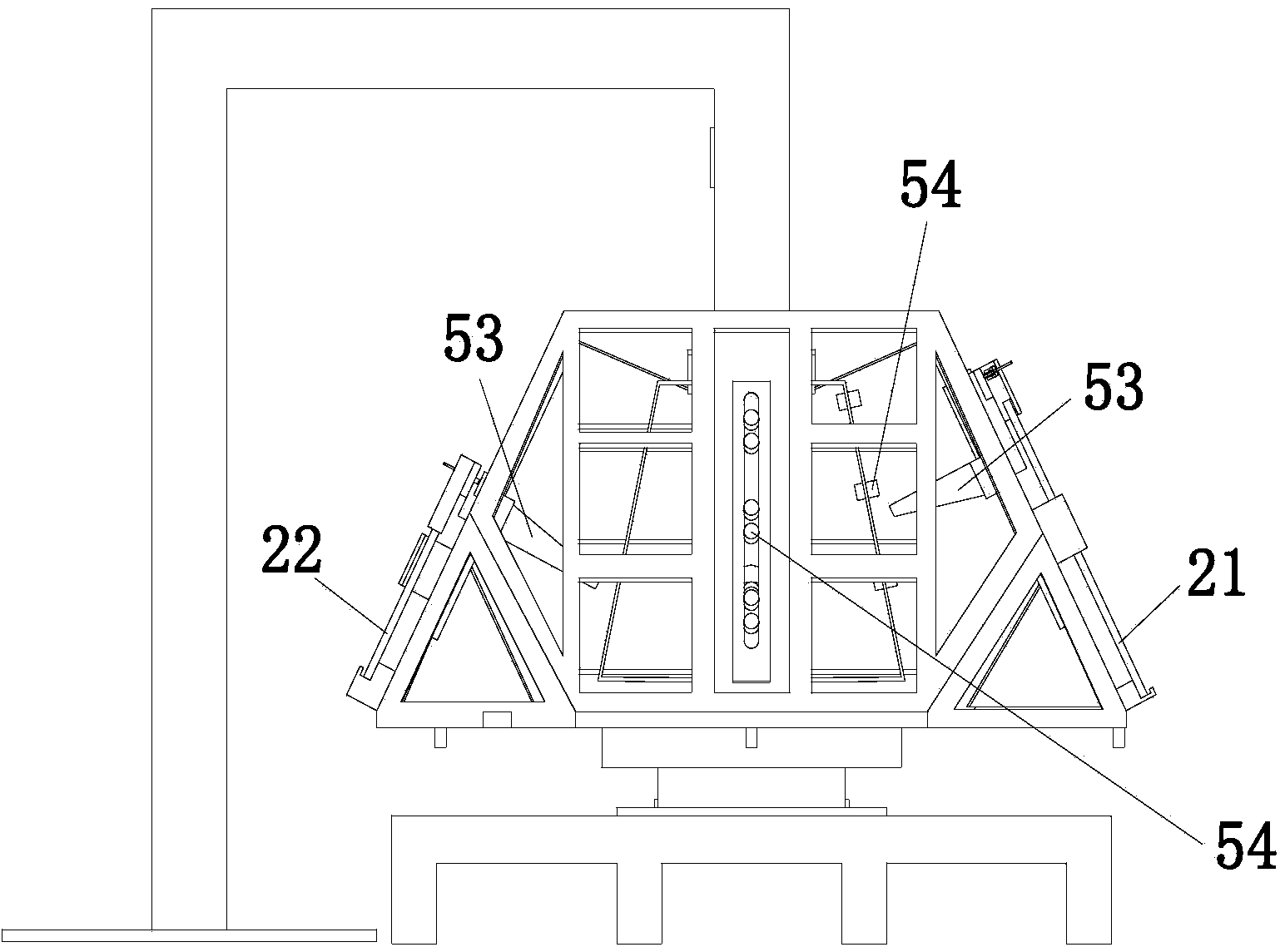

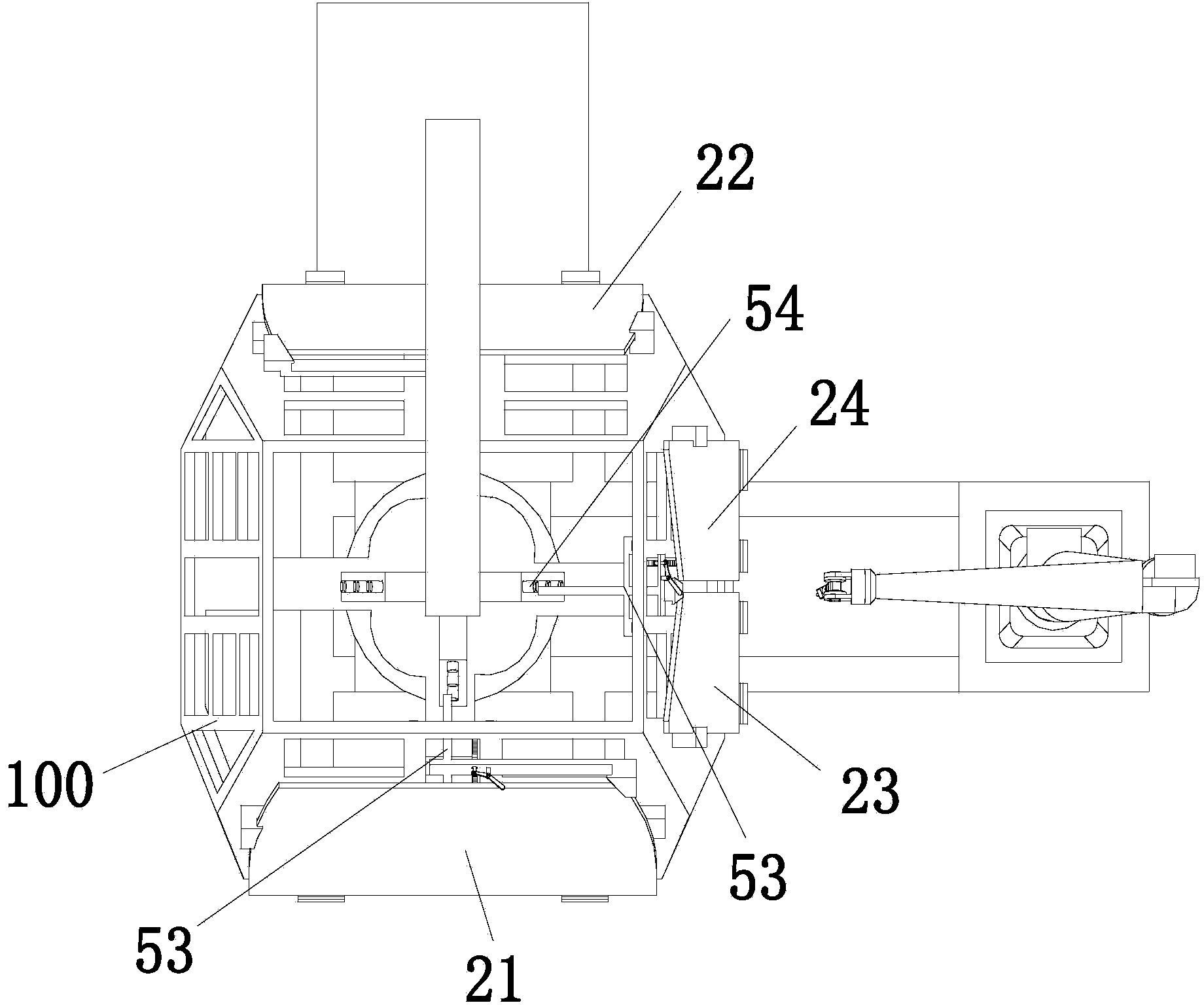

[0038] refer to Figure 1 to Figure 3 , The invention provides a glass gluing device. The glass gluing device includes a polyhedron turntable 1 and a base 3 for supporting the polyhedron turntable 1 . According to an embodiment of the present invention, the polyhedral turntable 1 is a structure similar to a pyramid shape capable of rotating around a longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com