Automatic double-station gluing machine

A glue applicator and double station technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problem of not being able to apply adhesive at the same time, and achieve high gluing efficiency and applicability, convenient operation and adjustment, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

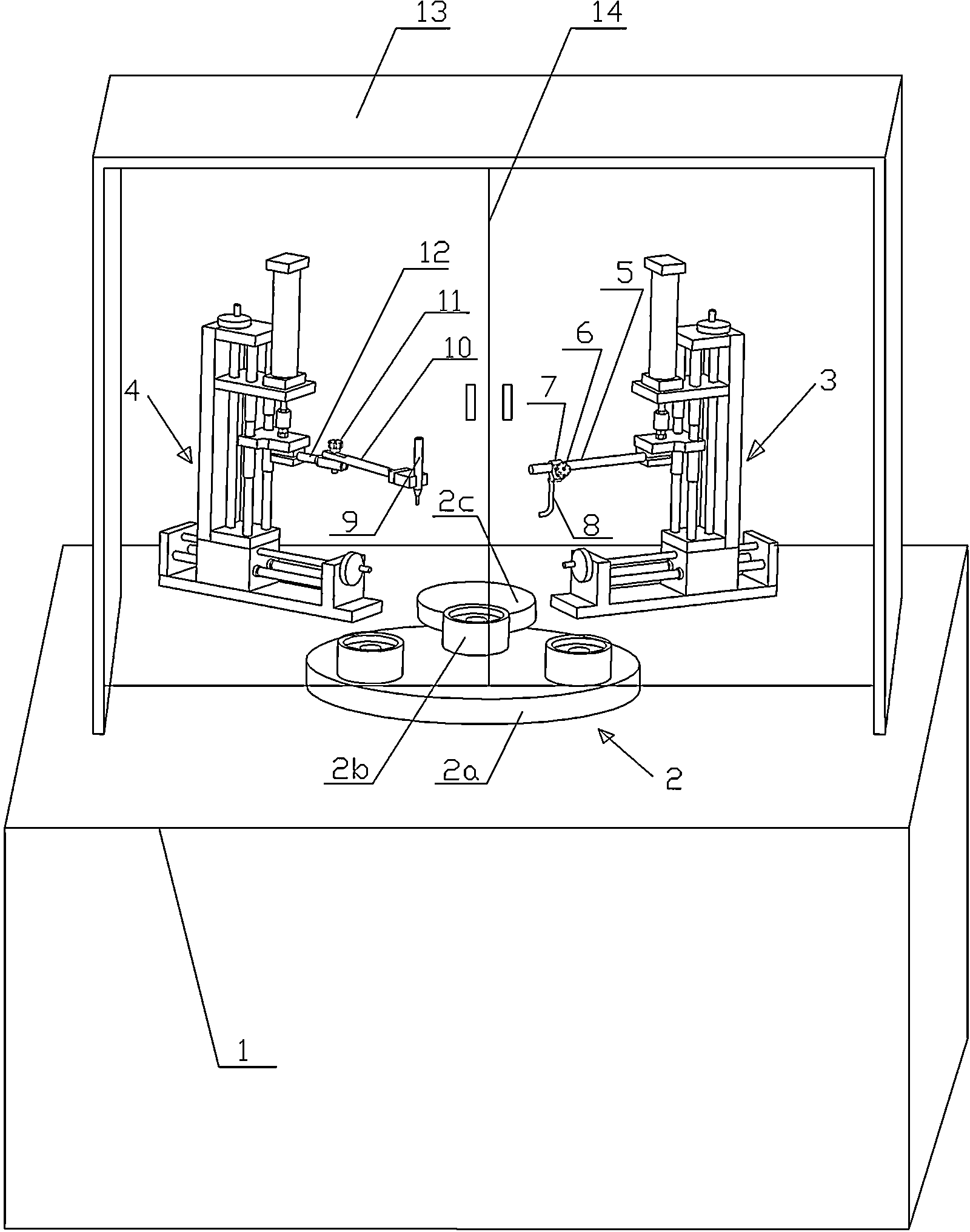

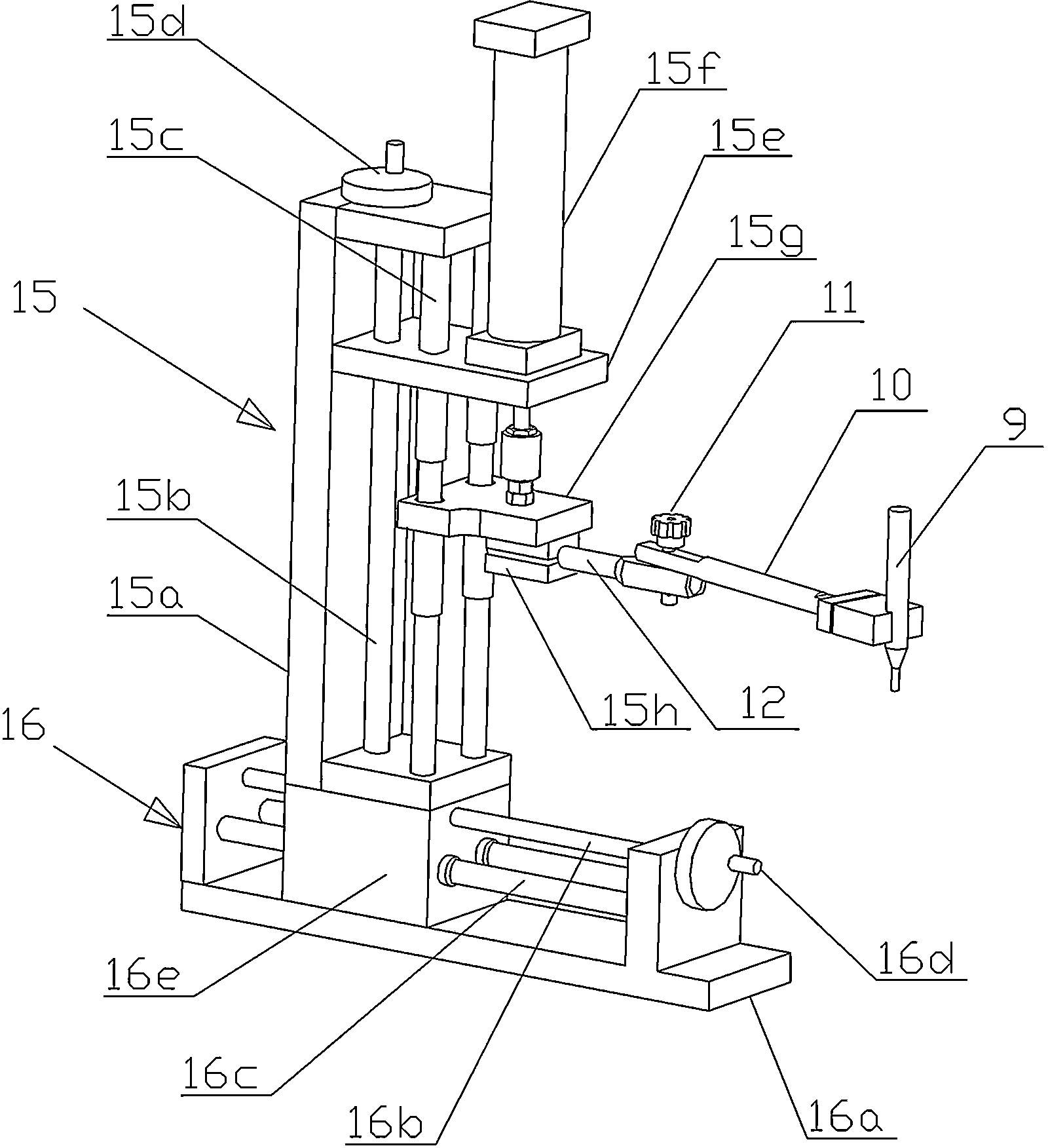

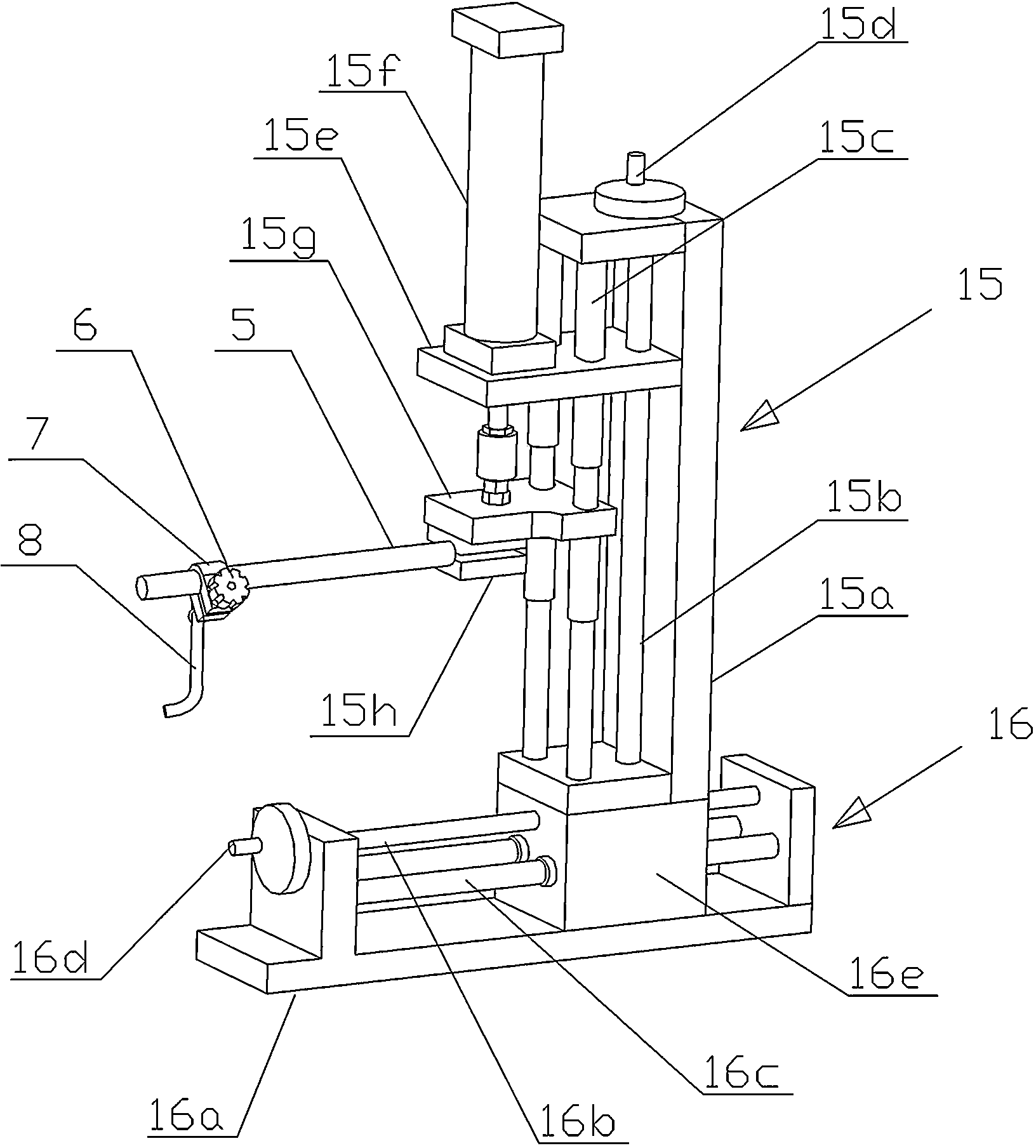

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a double-station automatic gluing machine provided by the present invention includes a workbench and a rotary device 2 on which workpieces are mounted. The rotary device includes a rotary disc 2a driven by a drive motor, and the rotary disc is evenly distributed. A group of workpiece clamping seats 2b distributed in a circular shape, the workpiece clamping seats 2b and the rotary table 2a are connected and matched through the bearing seat, and the workbench on the side of the rotary table is also provided with a friction wheel 2c, when the rotary table When the corresponding workpiece clamping seat 2b rotates to the side of the rubbing wheel 2c, the outer circle of the rubbing wheel and the corresponding workpiece clamping seat are fit together;

[0018] The workbench is provided with a first connecting rod 12 controlled by the first transmission mechanism 4 for lifting and translation. One end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com