Automatic alignment laminating machine of double-station CCD

A technology of automatic alignment and laminating machine, applied in the direction of lamination device, control lamination, lamination, etc., can solve the problems of poor alignment accuracy, many positioning parts of laminating machine, complicated installation, etc., to achieve alignment accuracy High, avoid glue overflow and bubble production, high glue coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

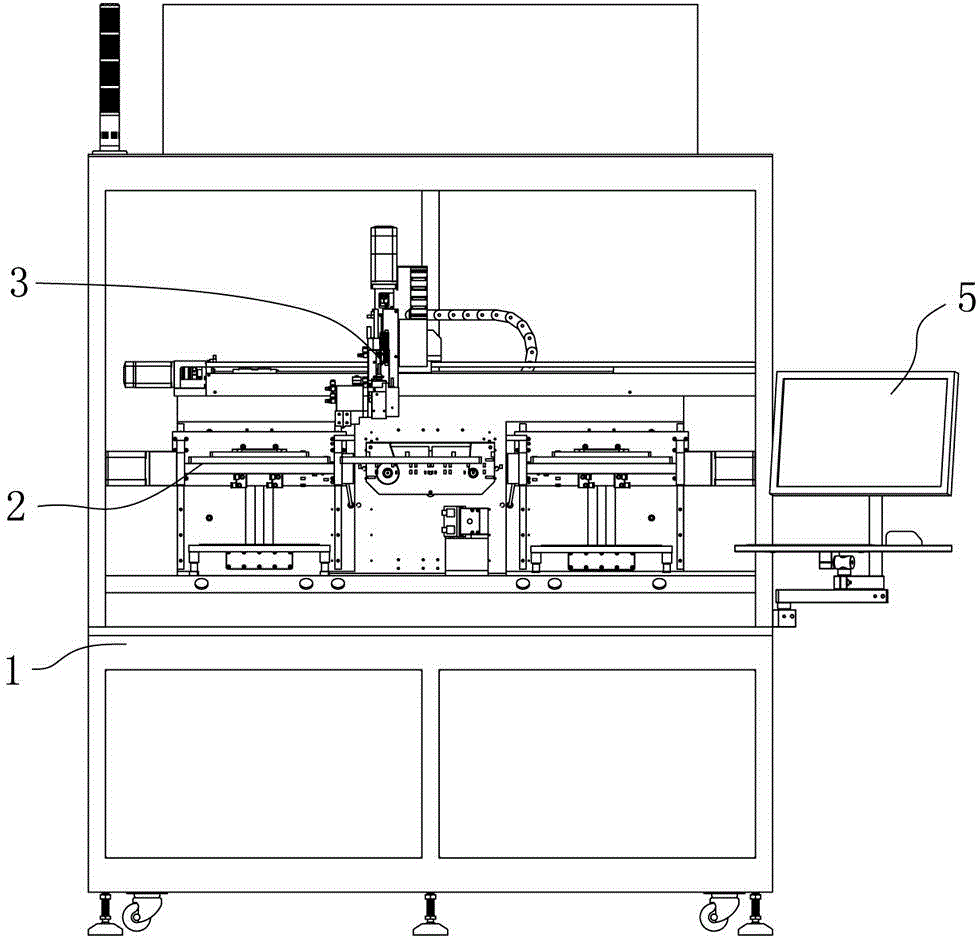

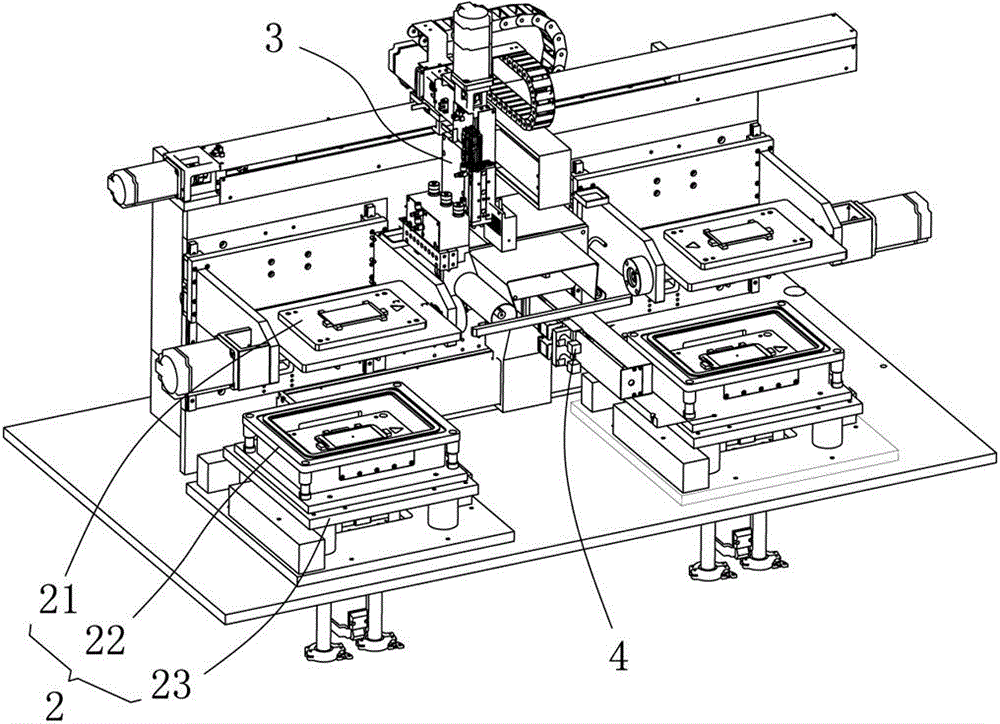

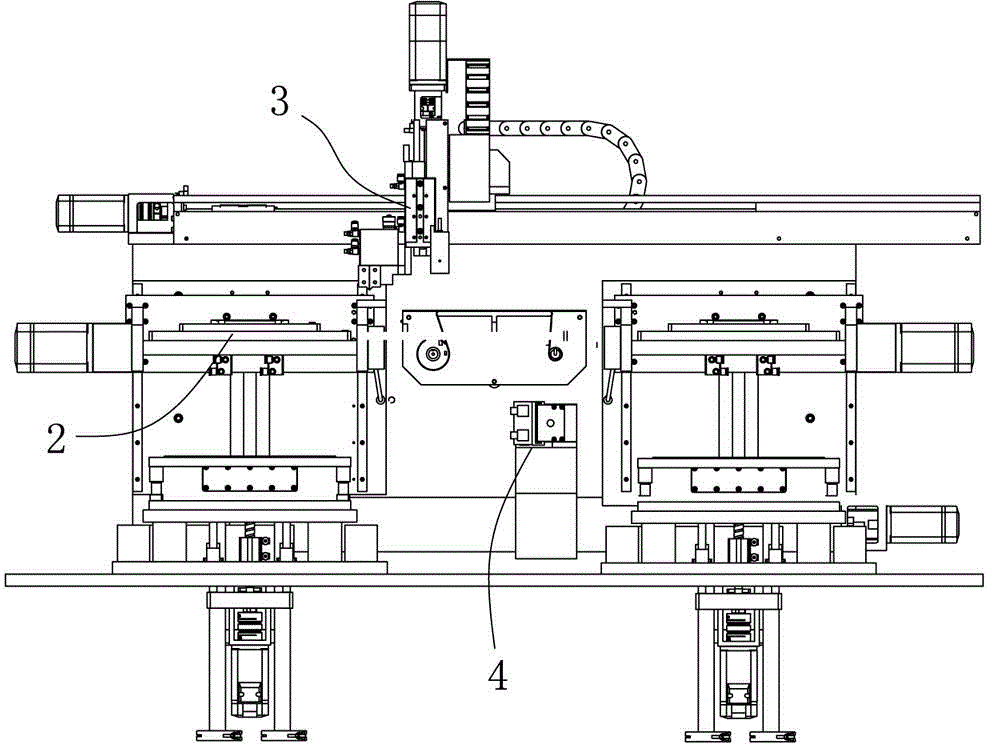

[0025] Example: see Figure 1 to Figure 10 , a dual-station CCD automatic alignment bonding machine, including a machine 1 and a flipping and vacuum bonding system 2 installed thereon, a UV glue slit coating system 3 and a CCD automatic alignment system 4, wherein:

[0026] Turning and vacuum bonding system 2, which includes the turning table 21 of the left and right stations and the corresponding vacuum bonding fixture 22 below, and the bonding fixture is placed on the XXY automatic calibration table 23;

[0027] UV glue slit coating system 3, which is arranged above the flipping and vacuum laminating system for coating at two laminating stations. The coating system includes a glue-coating three-axis manipulator 31 and a connected slit coating head 32. The slit coating head 32 can uniformly apply glue on the glass of the touch screen at one time, and the slit coating head gluing method is linear gluing;

[0028] The CCD automatic alignment system 4 includes a CCD camera and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com