Automatic cutting and rubberizing machine

A gluing machine and cutting technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the large position error of the electrical connection area of the conductive copper plate, the increased production cost of the sheet adhesive film, and the location of the glue Problems such as deviations are prone to occur, and the effects of overcoming deviations, improving work efficiency, and increasing the speed of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

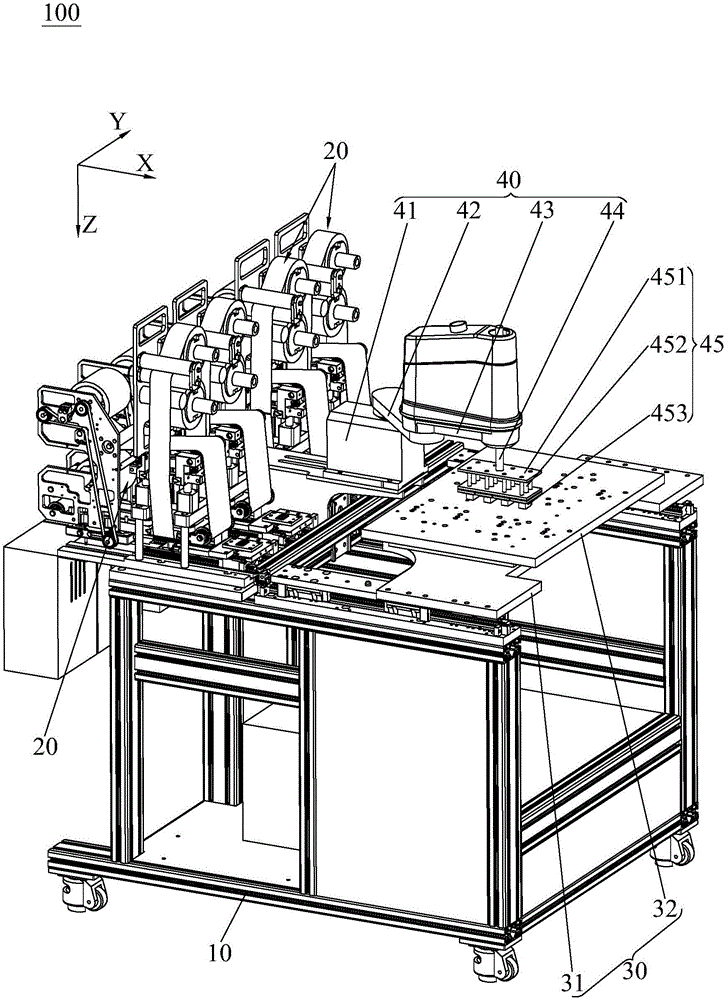

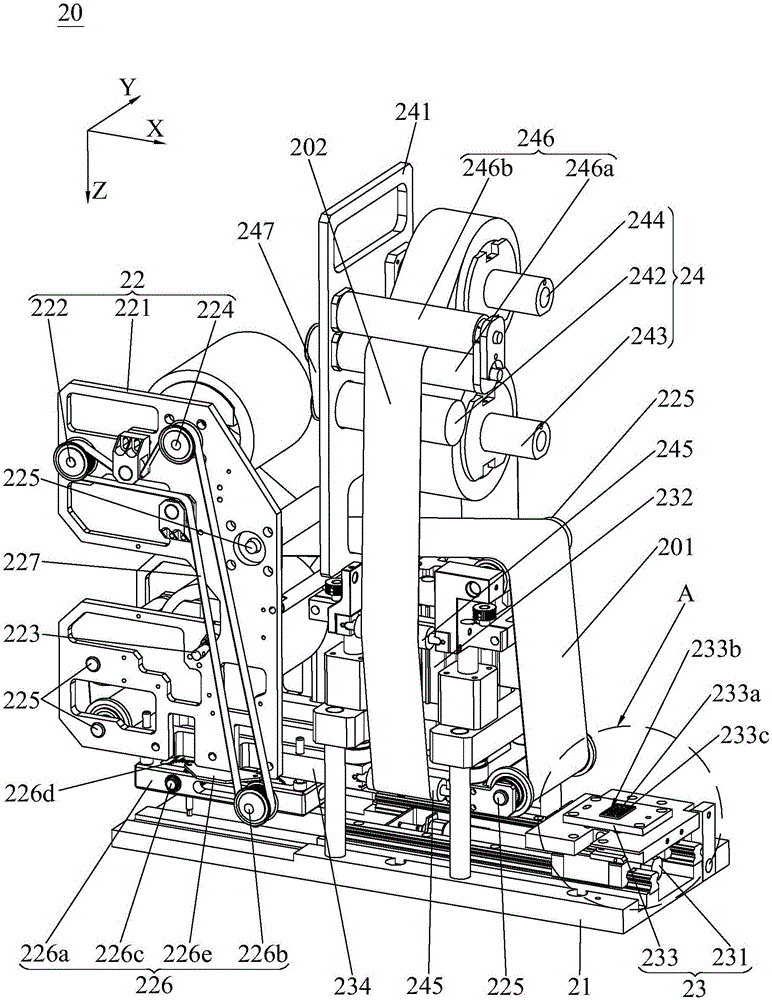

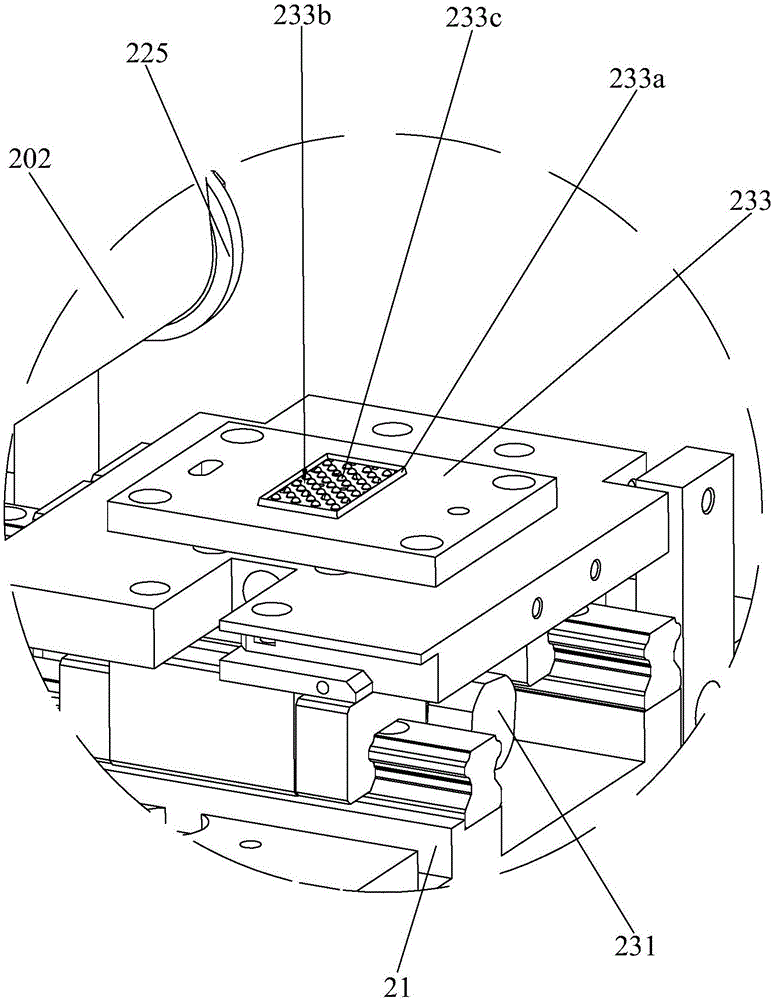

[0028] see figure 1 and figure 2 , the automatic cutting and gluing machine 100 of the present invention comprises a frame 10, a carrying platform 30, a gluing manipulator 40 and four slicing devices 20, and the slicing device 20 includes a fixed substrate 21, a film conveying mechanism 22 and a film slicing mechanism 23 , the fixed substrate 21 is arranged on the frame 10, the adhesive film conveying mechanism 22 and the adhesive film slicing mechanism 23 are all arranged on the fixed substrate 21, and the adhesive film conveying mechanism 22 sends the strip-shaped adhesive film 201 to be cut into the adhesive film slice Mechanism 23, the adhesive film slicing mechanism 23 cuts out the sheet adhesive film (not shown in the figure) from the strip adhesive film 201, and the adhesive film conveying mechanism 22 rolls up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com