Liquid metal heat dissipation-based high-power LED (Light Emitting Diode) light source with threaded connection structure

A technology of LED light source and liquid metal, which is applied in the field of lighting source, can solve the problem of incomplete heat conduction of thermal interface, small thermal conductivity of silver glue, thermal damage of chip, etc., achieve good heat dissipation effect, reduce die-bonding process, increase The effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

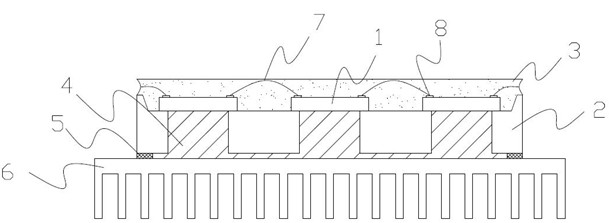

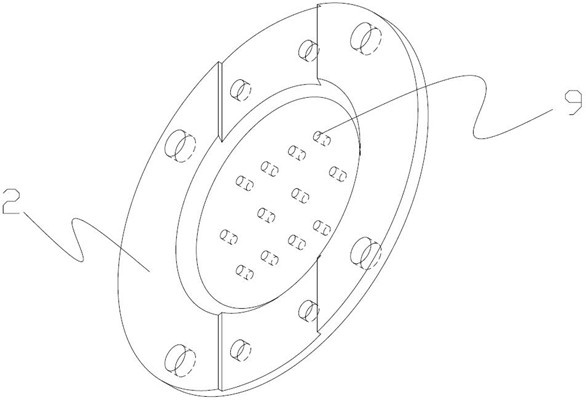

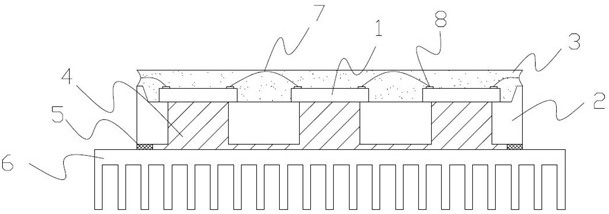

[0014] Such as figure 1 , 2 As shown, the high-power LED light source based on room temperature liquid metal micropore heat conduction includes LED chip 1, microporous packaging substrate 2, fluorescent adhesive layer 3, room temperature liquid metal 4, sealing layer 5, heat sink 6, gold wire 7, LED chip Electrode 8 and micropore 9; Radiator 6 is provided with sealing layer 5, microporous packaging substrate 2 in sequence, LED chip 1 is arranged on micropore 9 of microporous packaging substrate 2, micropore of microporous packaging substrate 2 9 is filled with liquid metal 4 at room temperature, LED chip 1 is provided with LED chip electrode 8, and gold wire 7 is connected to LED chip electrode 8, and fluorescent glue layer 3 is covered on LED chip 1.

[0015] There are multiple LED chips 1 , and the LED chip electrodes 8 on two adjacent LED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com