Three-dimensional microstructure electroforming method and apparatus

A microstructure and electroforming technology, applied in the direction of electrophoresis electroforming, etc., can solve the problems of difficult glue removal, long processing cycle, rough surface, etc., and achieve easy automation and mass production, high copying accuracy and repeatability, and rough surface small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

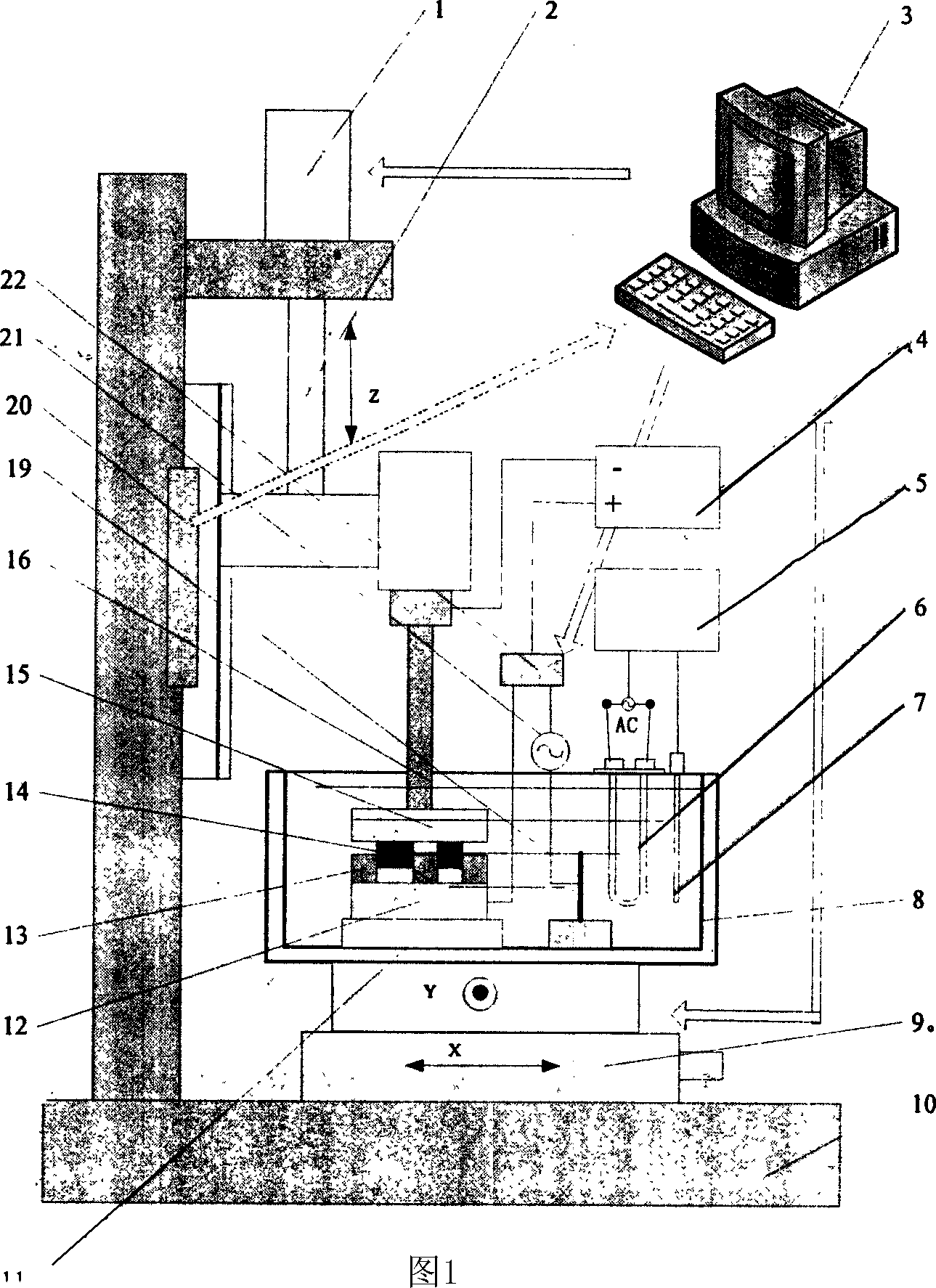

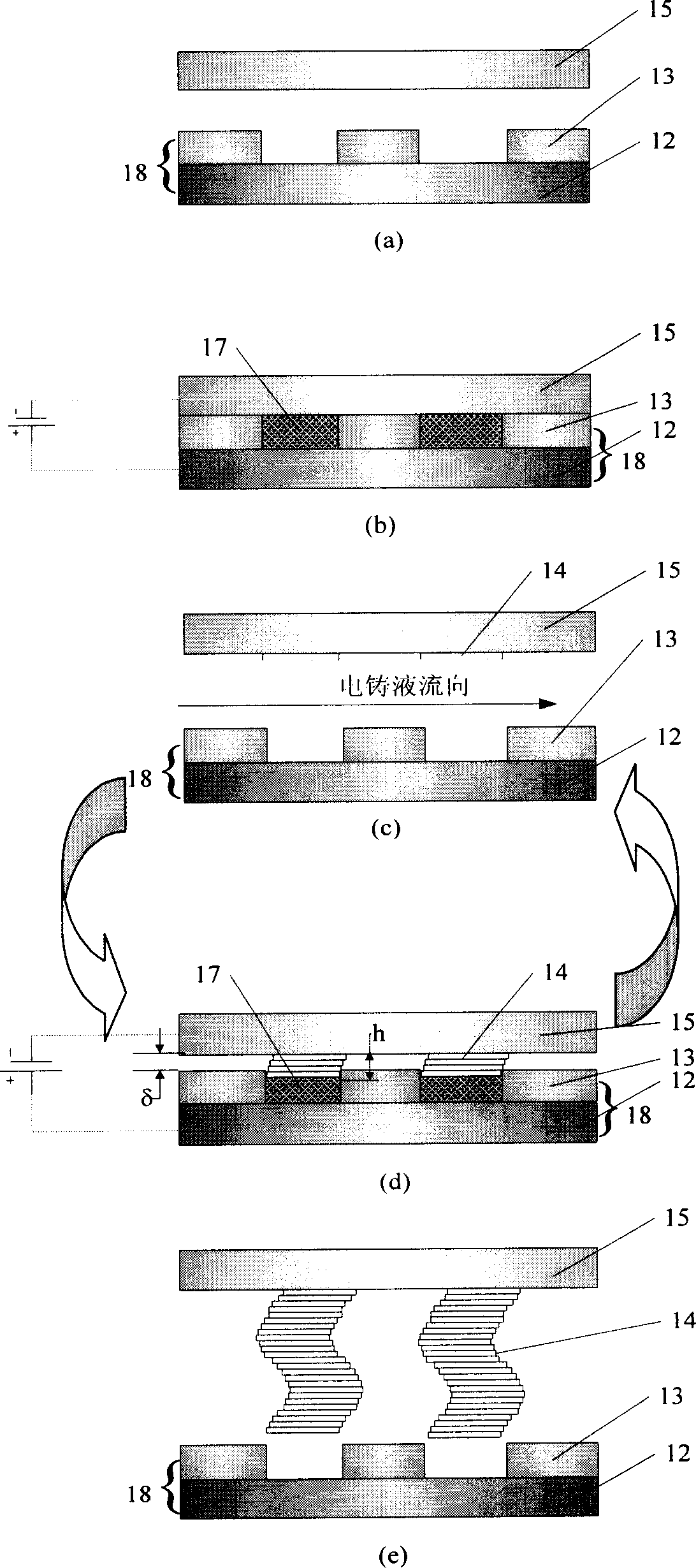

[0029] As shown in FIG. 1 , the “three-dimensional microstructure electroforming device” of the present invention includes a motor 1 , a power supply 4 , a temperature controller 5 , a heater 6 , a temperature sensor 7 , an electroforming tank 9 , and a machine tool body 10 . Its characteristics are: the computer 3 controls the on-off of the electronic switch 22 to realize the power supply 4 for the electroforming branch and the online measurement branch respectively; the shielding anode film plate 18 is composed of the anode substrate 12 and the shielding film 13, and passes through the anode The installation fixture 11 is installed on the CNC workbench 9, and the cathode 15 is properly connected to the Z-axis 2; during electroforming, the computer 3 controls the Z-axis 2 and the CNC workbench 9 to move accordingly, so as to drive the shielding anode film plate 18 Make relative movement with the cathode 15; during online measurement, the computer 3 controls the Z-axis 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com