Wooden laminated floor product to improve strength, water protection and fatigue resistance

a laminated floor and wood technology, applied in the field of laminated products, can solve the problems of reducing the ability of the floor to react properly, affecting the strength and durability of the floor, and affecting the performance of the floor, so as to improve the strength, reduce the cost, and improve the effect of fatigue resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

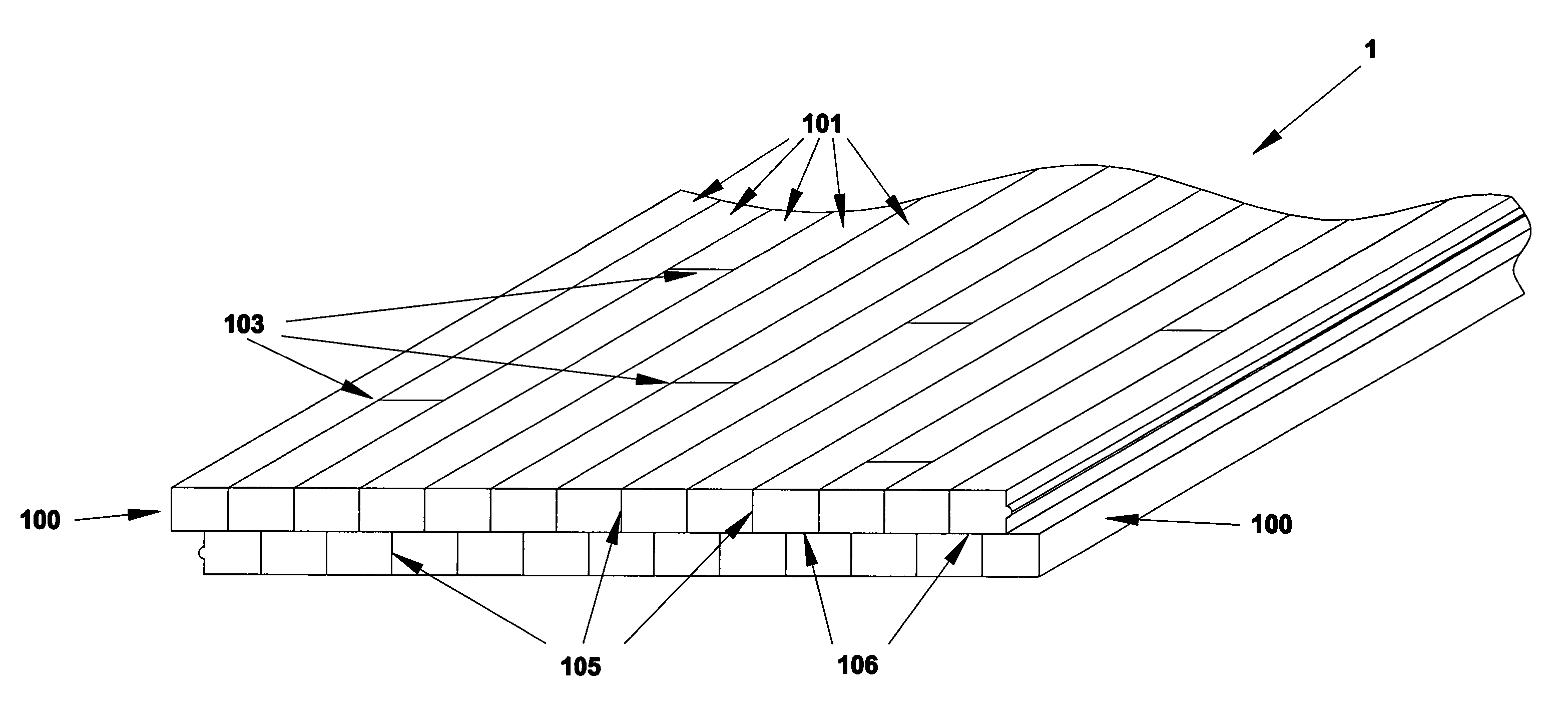

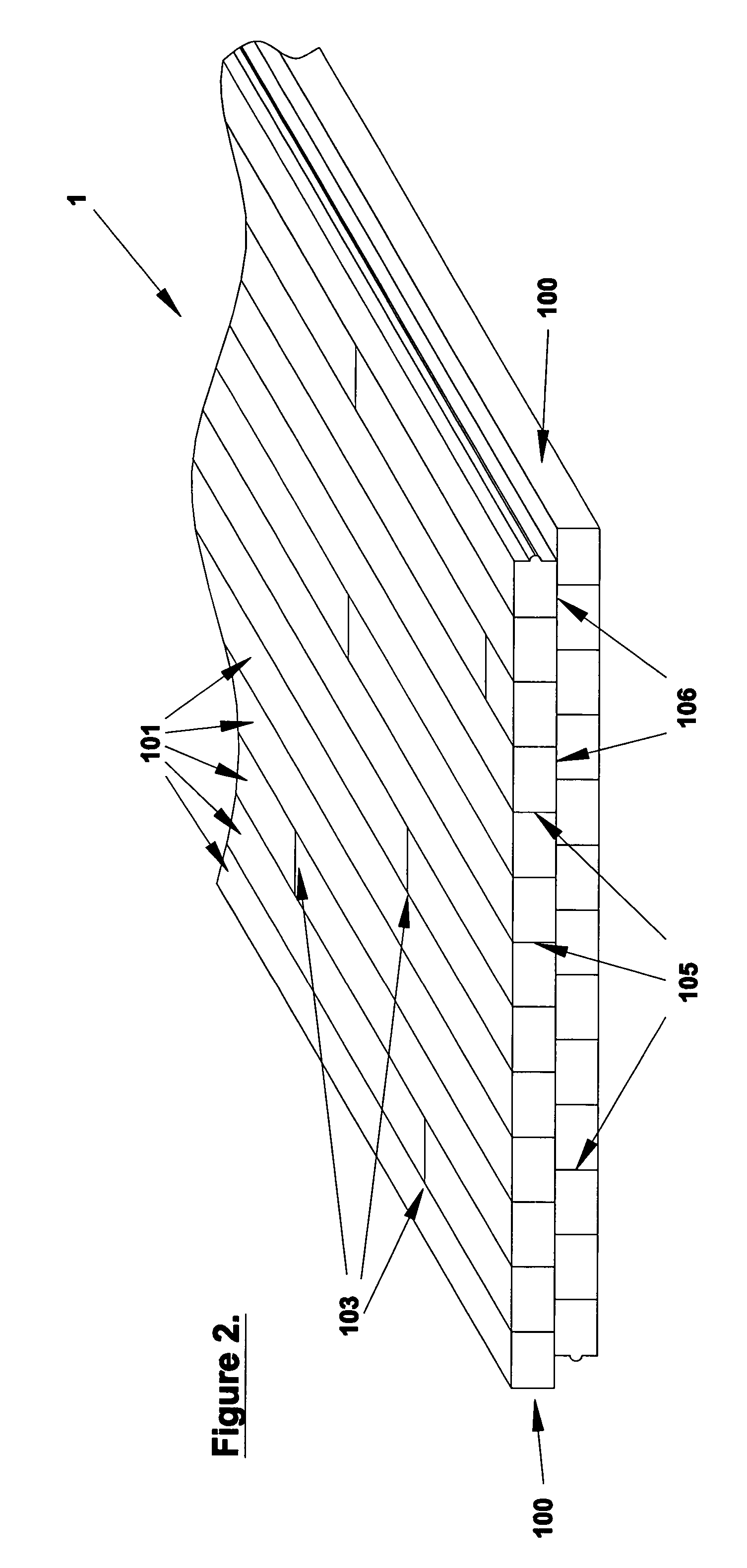

[0034] Referring now to FIG. 2, there is shown a perspective cross-section of a wood plank 1. A plurality of such wood planks 1 are arranged side by side to form a floor 10.

[0035] Each wood plank 1 is made of at least two layers of boards 100. Each board is made of a plurality of strips 101, each strip being joined end-to-end at a joint region 103, and each set of strips being joined side by side along a glue line 105.

[0036] In a preferred embodiment of the invention, the strips are hardwood boards, and the hardwood is further preferably selected from the group consisting of oak, maple, birch, beach, and larch.

[0037] In accordance with a preferred embodiment of the invention, one layer 100 is longitudinally offset from another layer 100, such that the glue lines of one board are offset from the glue lines of another board, as shown in FIG. 2. Although only two layers are shown in FIG. 2, it will be understood that more layers can be used depending on the thickness of the strips, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com