Ultrasonic scanning probe

An ultrasonic scanning and shell technology, applied in the field of medical ultrasound, can solve the problems that the transducer cannot achieve effective scanning and imaging is not omnidirectional, the transducer is unable to swing, and the scanning process is uneven, etc., and achieves large torque and swing speed. High, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

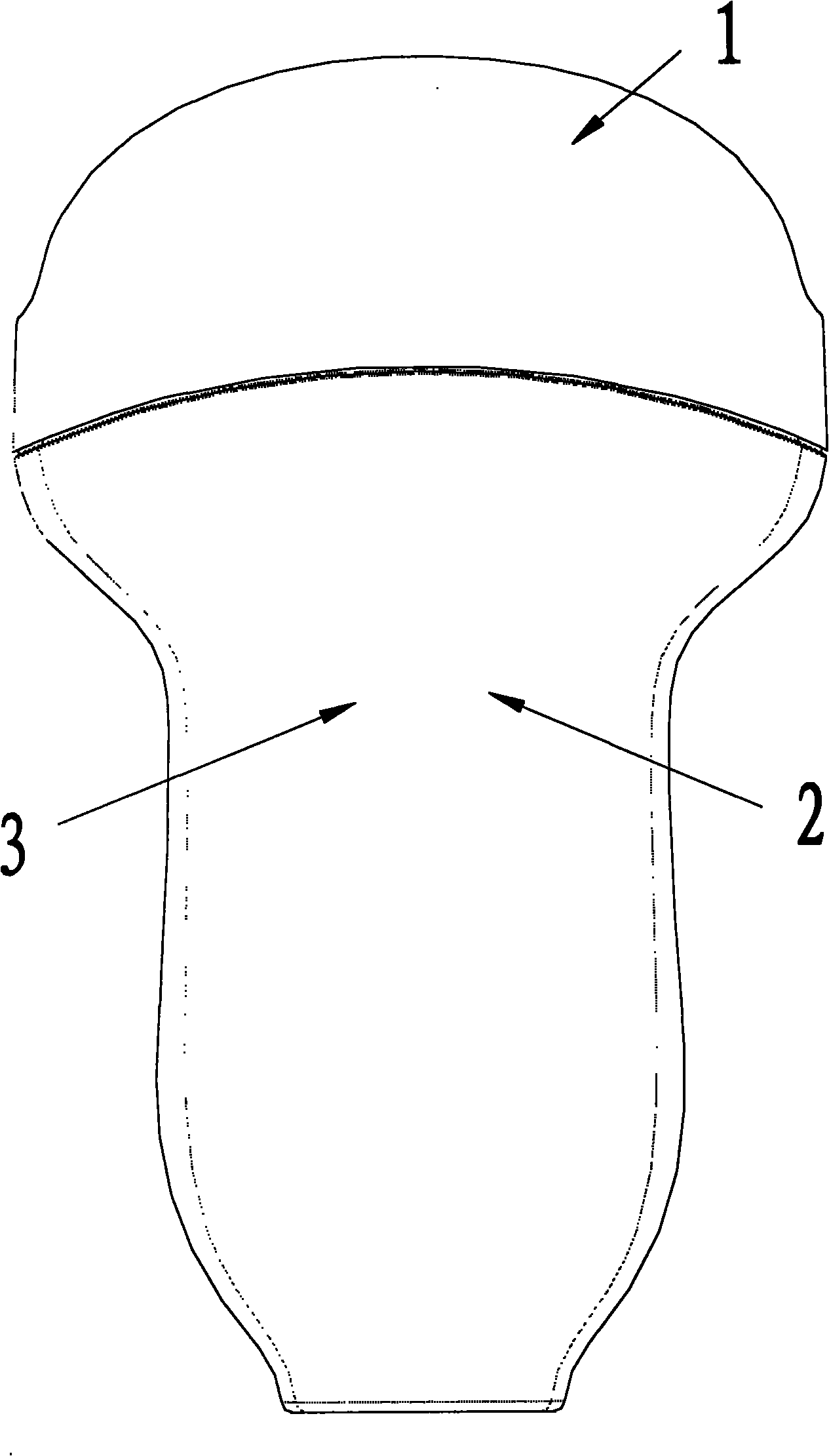

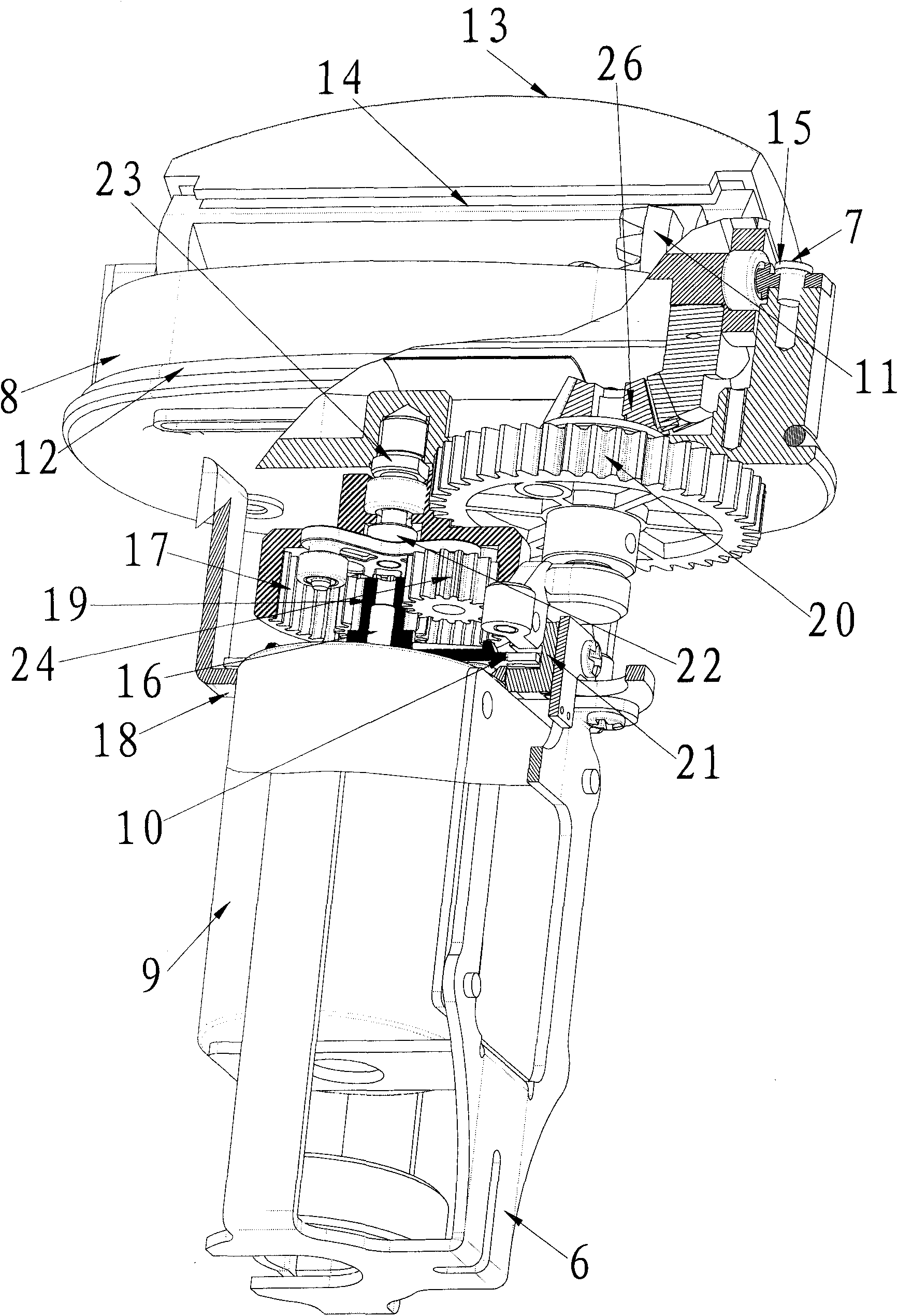

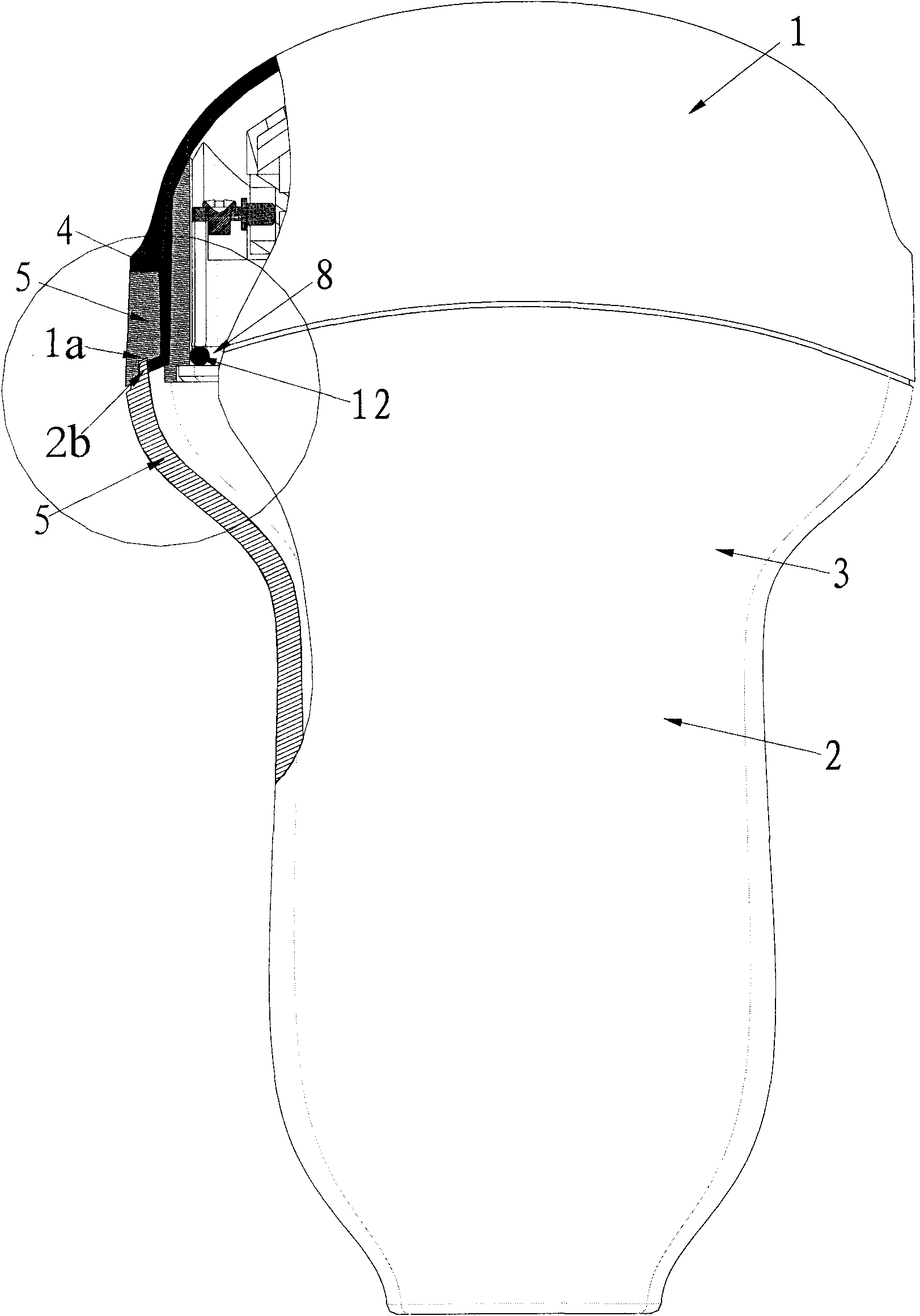

[0016] Preferred embodiments of the present invention are described in detail below, and its embodiment is shown in accompanying drawing, will represent identical or similar parts with identical reference numeral as far as possible in all accompanying drawings, and reference numeral is respectively: glue groove 1a , Glue line 2b, upper case 1, lower case 2, case 3, soft colloid 4, hard colloid 5, main control circuit board fixing frame 6, probe main body 8, drive motor 9, encoder detection wheel 10, half Bevel gear 11, sealing ring 12, transducer 13, transducer frame 14, transducer shaft 15, motor rotating shaft 16, double internal gear 17, motor fixing frame 18, motor gear 19, spur gear 20, coding Device 21, planetary carrier 22, planetary carrier shaft 23, planetary carrier 22, planetary gear 24, shaft bevel gear 26.

[0017] The ultrasonic scanning probe involved in the present invention adopts a planetary gear system in the power transmission of the motor in terms of body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com