Automatic gluing system and gluing method thereof

A glue application and automatic technology, applied in the field of glue application system, can solve the problems of product yield decline, alignment, and the impact of module imaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] According to the claims of the present invention and the content disclosed in the specification, the technical solution of the present invention is specifically described as follows.

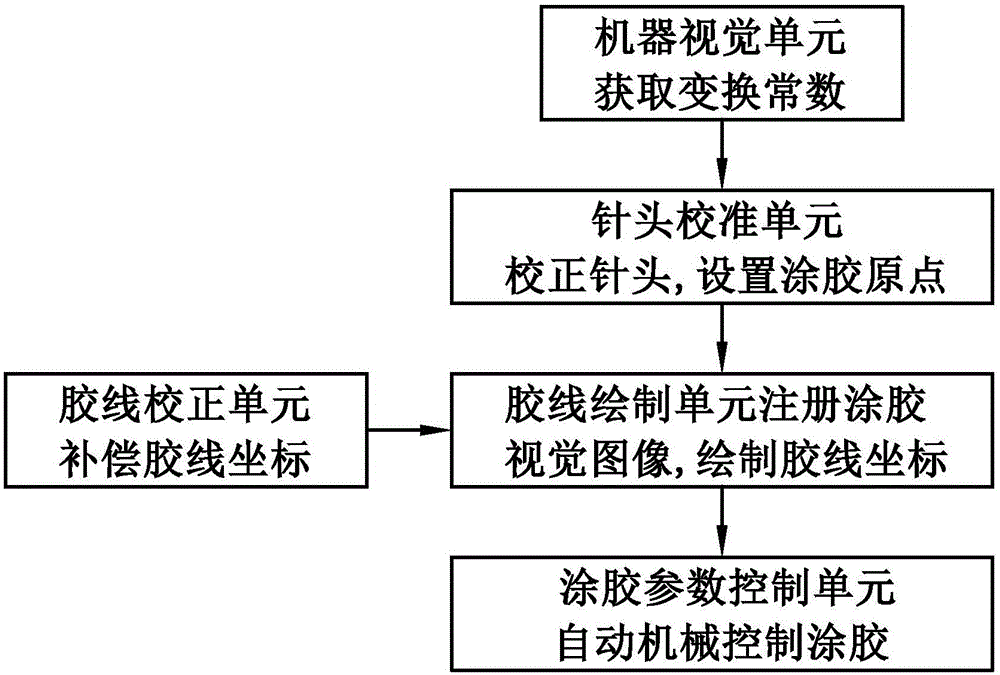

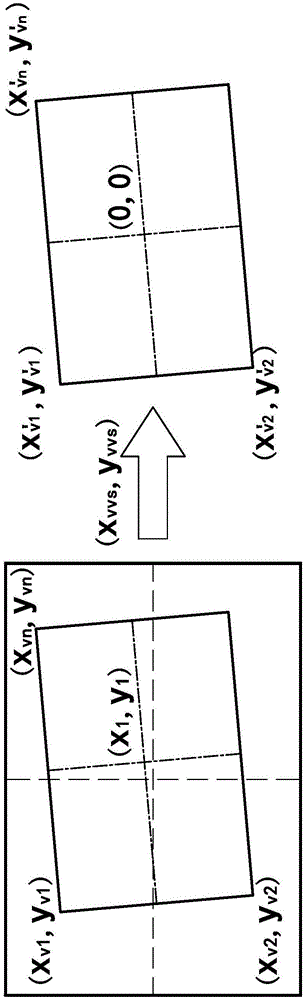

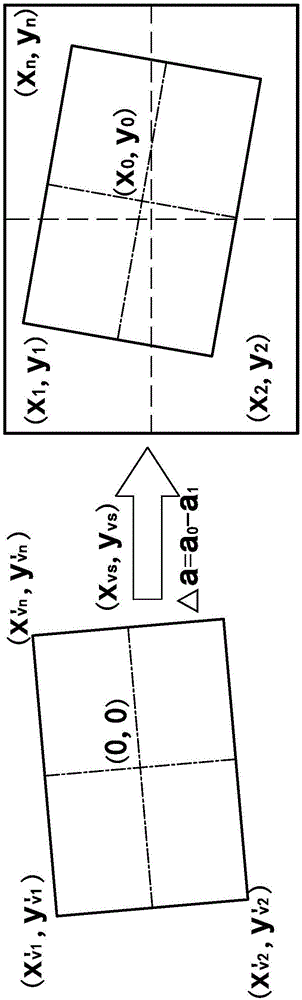

[0076] Such as figure 1 A kind of automatic gluing system shown comprises a machine vision unit, and described machine vision unit is used for obtaining conversion constant, obtains the positional relation of object pixel coordinate and machine coordinate; A needle head calibration unit, described needle head calibration unit is with For correcting the position of the needle head, the transformation constant obtained by the machine vision unit is used to set the collagen coating point of the needle head; and a glue line drawing unit, the glue line drawing unit is used to register the glue coating visual image to obtain the registration image, by The registered image draws glue line path coordinates. Therefore, the automatic gluing system adopts machine vision automatic gluing instead of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com