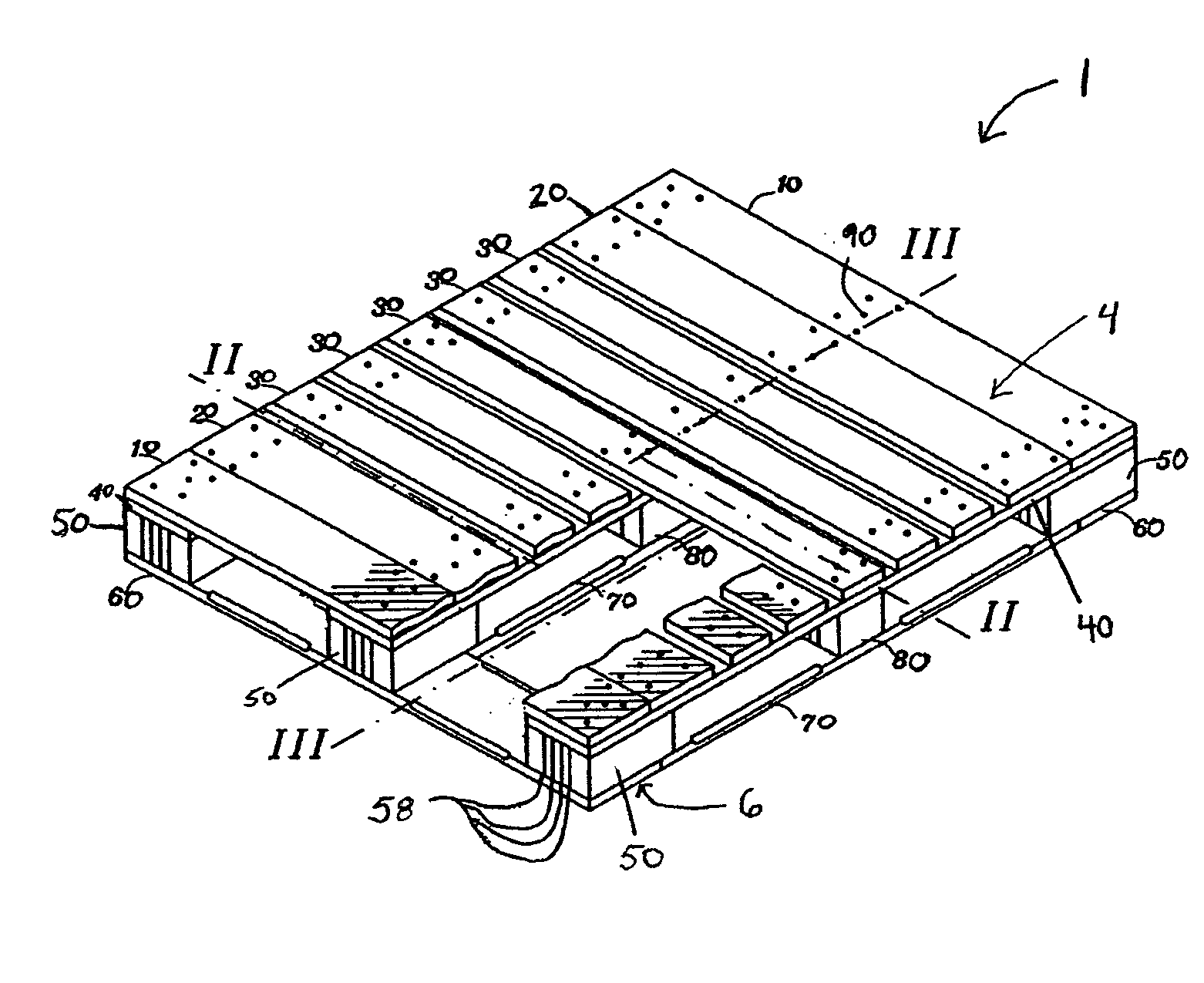

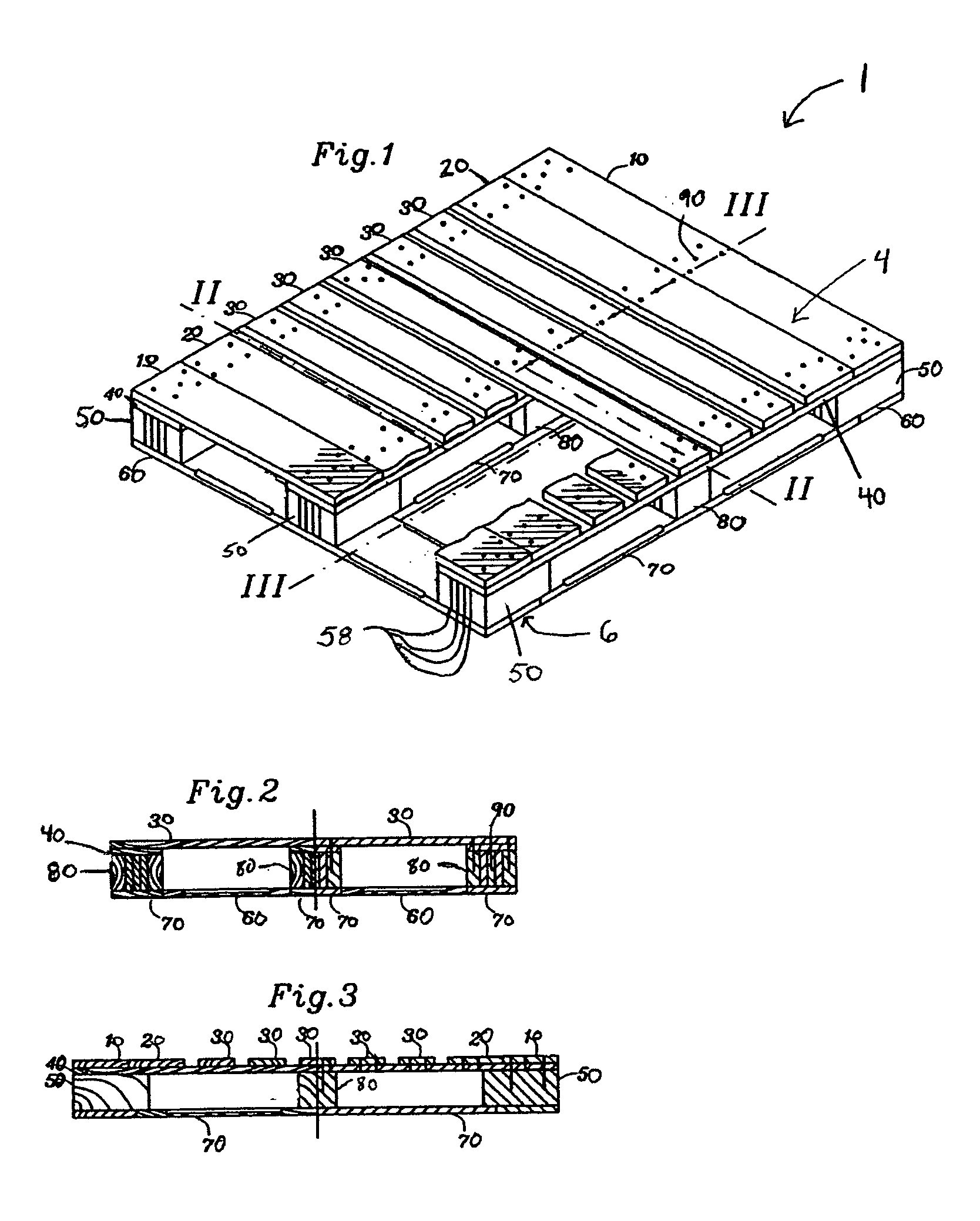

Pallet with laminate blocks

a technology of laminate blocks and pallets, applied in the field of pallets with laminate blocks, can solve the problems of limited life, difficult to thoroughly dry solid wood, and difficult to meet the needs of solid wood, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

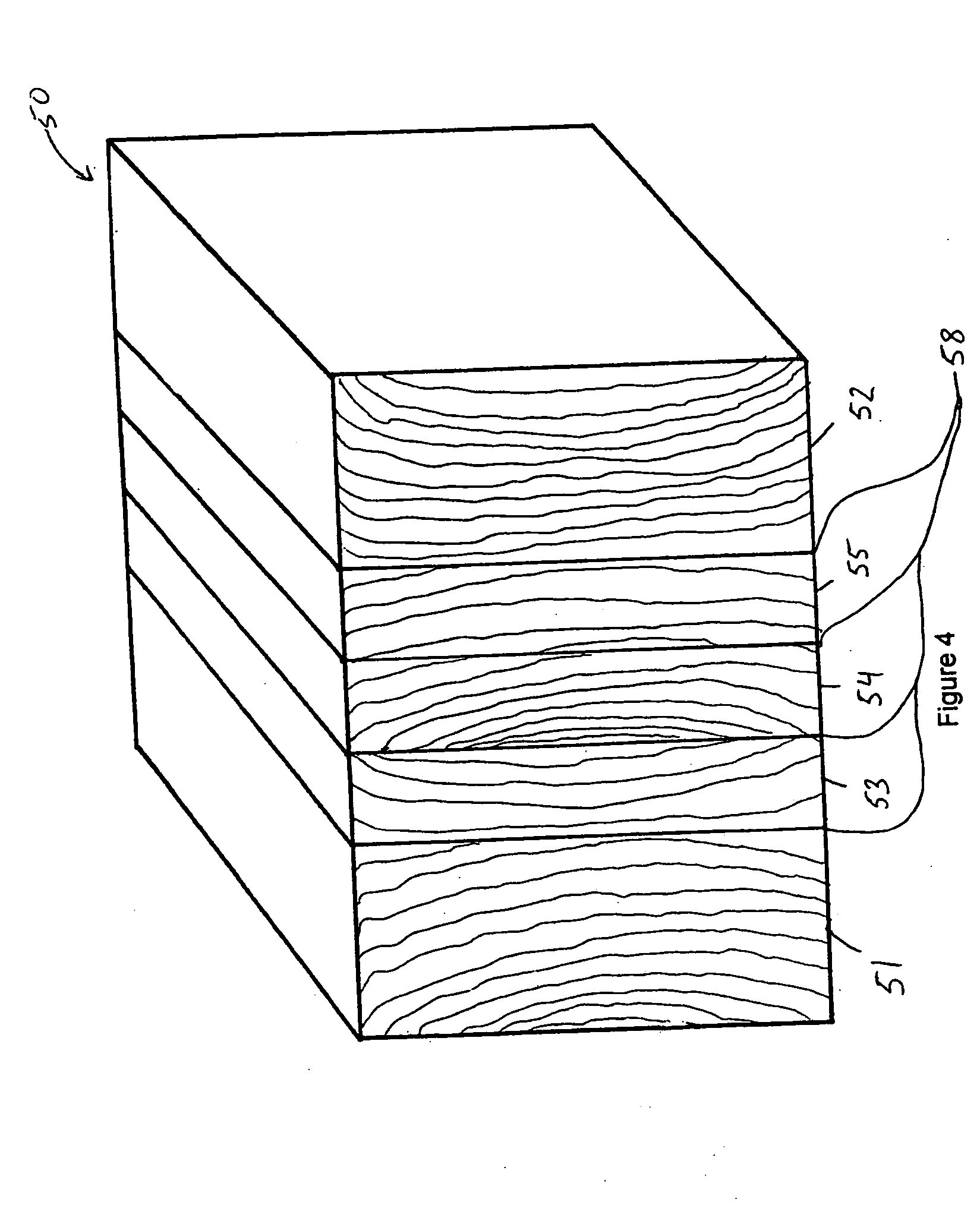

[0045] Various spacer block samples were constructed and tested according to ASTM D-1185 Fork Tine Test Methods for Pallets and Block Compression Test Methods for Pallets.

[0046] Example 1 is a laminate spacer block created from a series of 2×4 s and 1×4 s arranged in bookend fashion as shown in FIG. 4.

[0047] Example 2 is a laminate spacer block created from a series of 1×4 s arranged as shown in FIG. 5.

[0048] Example 3 is a laminate spacer block created from a series of 1×4 s and 2×4 s arranged in alternating fashion as shown in FIG. 6.

[0049] Comparative Example 1 is a solid timber block.

[0050] Comparative Example 2 is a laminated spacer block created from 7 1×1 s sandwiched between two 2×6 s, such that the glue lines and the grain orientation of the 2×6 s were parallel with the pallet deck.

[0051] Comparative Example 3 is a laminated spacer block created from a single 1×5 sandwiched between two 2×5 s, arranged such that the glue lines of the laminate and the grain orientation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com