Thin film packaging method

A technology of thin film packaging and packaging film, which is applied in the fields of electrical components, electrical solid devices, semiconductor/solid device manufacturing, etc., and can solve the problem of not being able to bind the driver chip to the flexible circuit board point screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

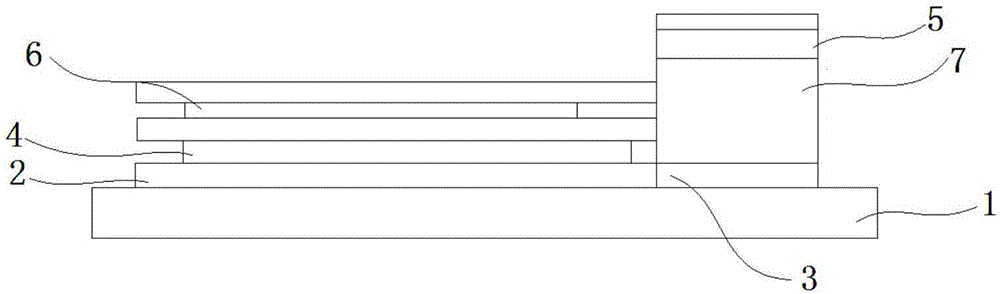

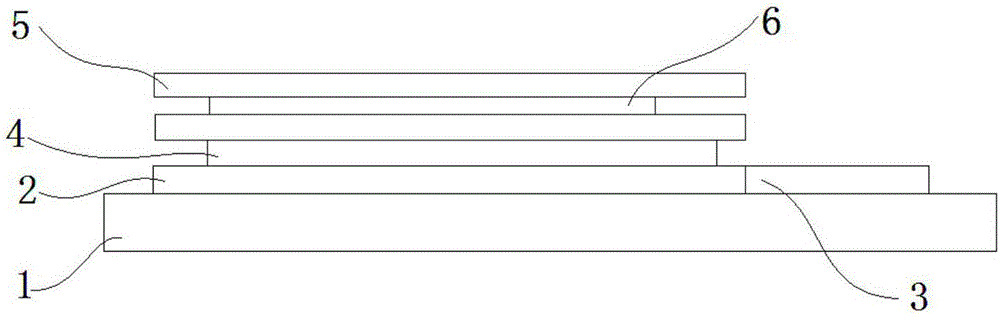

[0028] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. "Front", "rear", "left", "right", "upper" and "lower" in the text all refer to the placed state of the device in the drawings.

[0029] Existing thin-film packaging is basically an inorganic-organic composite structure, and it is the inorganic layer that plays the role of water-oxygen barrier. Therefore, improving the water-oxygen barrier effect of the inorganic layer is crucial to the packaging effect of thin-film packaging. The inorganic layer of the existing thin-film packaging mainly adopts the CVD / ALD film-forming method, but most of the films formed by the above-mentioned film-forming methods are film-formed on the entire surface. Perform operations such as binding driver chips / flexible circuit boards (IC / FPC) and dot screens on the film.

[0030] In order to solve the above technical problems, the application provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com