Polyurethane composite rubber roll and manufacture method thereof

A manufacturing method and technology of polyurethane rubber, applied in chemical instruments and methods, rubber layered products, layered products, etc., can solve the problems of unusable rubber rollers, few repairs of roller cores, low heat transfer coefficient, etc., and achieve good Use effect, eliminate the overall separation, the effect of high conduction uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

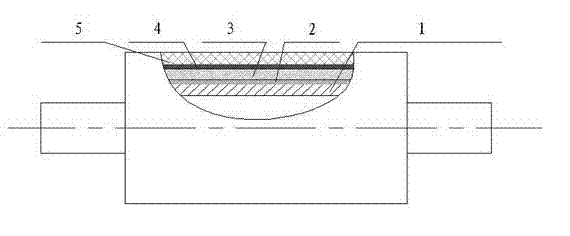

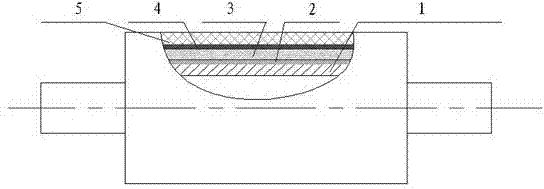

[0040] Coating a Φ550×2950mm paper press roll with a core diameter of 526mm, the specific process is as follows:

[0041] (1) Coating of the interface bonding layer 1: First, the roller core is sprayed with iron sand, then cleaned and dried with gasoline, and then coated with adhesive: epoxy resin D.E.R.330 (Dow Company) / curing agent DEH29 (Dow Company ), brush twice, the thickness is 0.06mm, and then enter the oven at 90°C for 1.5h,

[0042] (2) Coating of FRP layer: Bisphenol F-type epoxy resin YDF-170 (Dongdu Chemical Company), alicyclic amine curing agent DCH-99 (DuPont Company) system and 1500tex untwisted glass fiber SE1200 (Owens Corning Company), wrapped by a wet winding process, winding once, and the winding thickness is 5mm. After the epoxy resin gels, enter the oven for post-treatment at a temperature of 100°C±5°C for 3 hours. Carry out turning and grinding processing at last, trim roundness, guarantee the thickness of FRP layer to be 3mm.

[0043] (3) Coating ...

Embodiment 2

[0047] Cover a Φ650×3150mm papermaking press roll with a core diameter of 600mm. The basic steps are the same as in Example 1. During the FRP coating process, layered winding is performed 3 times, and the interval between layered windings. Treatment conditions: temperature is 55±5°C, time For 1.5 hours, the cumulative thickness of winding is 15mm, and the thickness of 12mm is maintained after turning and grinding. Adhesive CH219 (Shanghai Lord Chemical Co., Ltd.) is used for the second interface adhesive layer, and the thickness of the polyurethane rubber layer is kept at 13mm.

Embodiment 3

[0049] Cover a Φ550×2950mm papermaking press roll with a core diameter of 526mm. The basic steps are the same as in Example 1. During the FRP coating process, a glass fiber braid with a width of 80mm is used for wet winding process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com