Preparation methods of sulbenicillin sodium and injection thereof

A technology of sulfobenicillin sodium and solution is applied in the field of preparation of sulfobenicillin sodium and its injection, and can solve the problems of many by-products, complicated reactions, waste of raw materials, etc., and achieve simple steps, high product purity, and few reaction impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

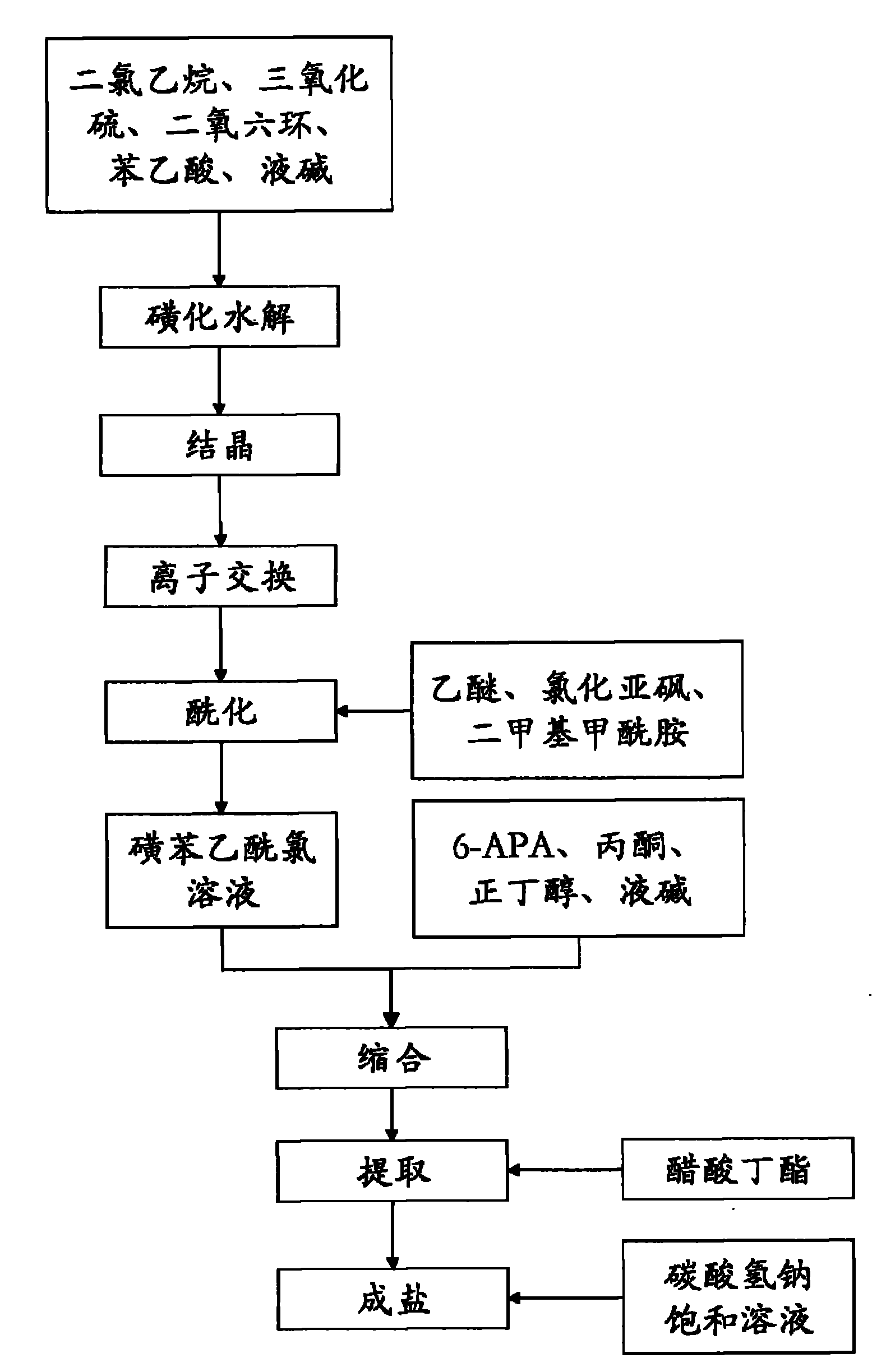

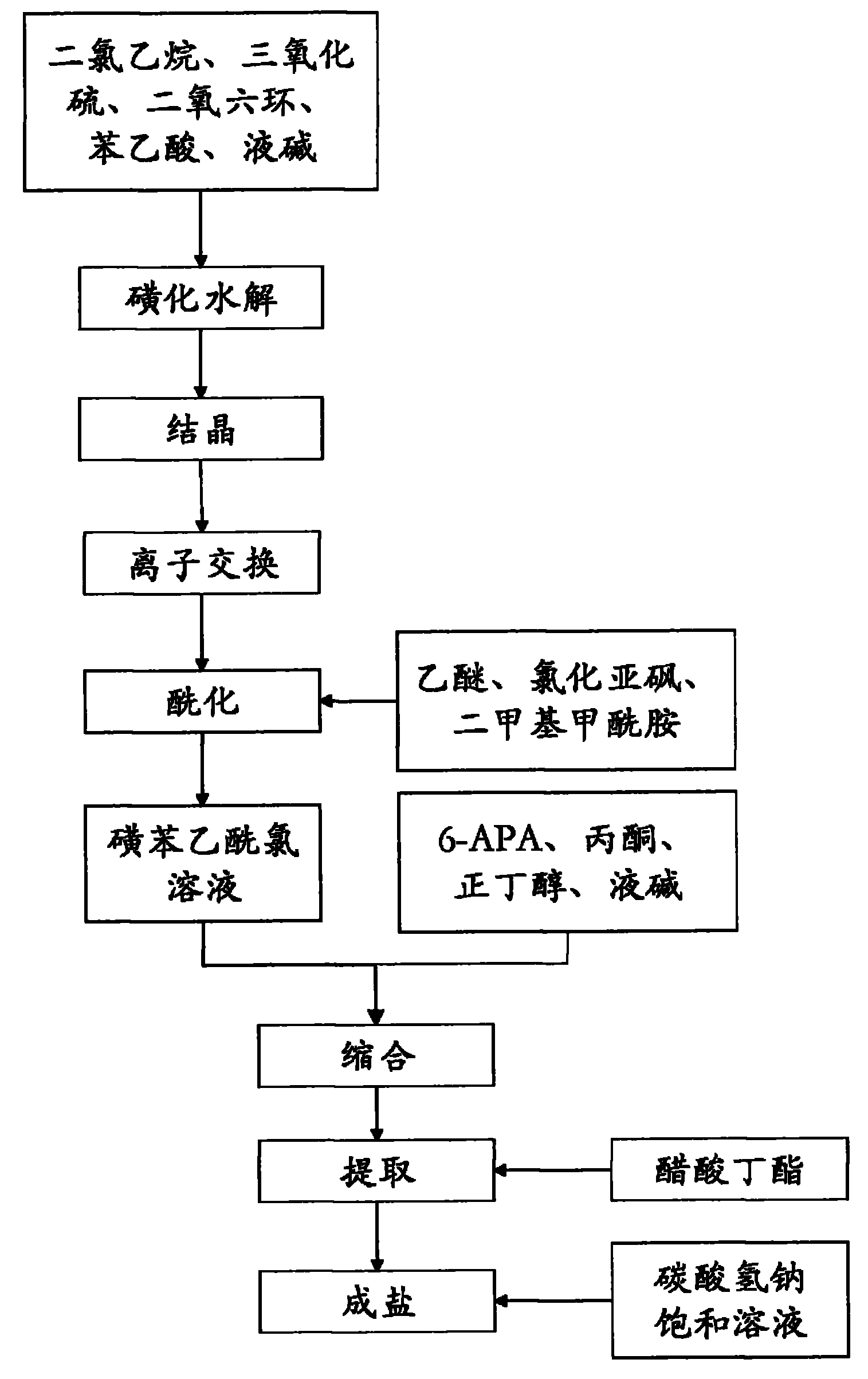

[0024] combine figure 1 , in a typical implementation of the preparation method of Sulbenicillin Sodium of the present invention, comprise the steps:

[0025] Sulfonation: Mix and stir dichloroethane and dioxane, lower the temperature to 0-5°C, add sulfur trioxide, then add phenylacetic acid, heat up to 30-45°C and stir to react to obtain solution A.

[0026] Dioxane will form a complex with sulfur trioxide. Therefore, delaying the addition of sulfur trioxide will reduce the consumption of dioxane and sulfur trioxide; Save raw materials.

[0027] The reaction equation that above-mentioned dioxane reacts with sulfur trioxide to generate dioxane sulfonate is as follows:

[0028]

[0029] Hydrolysis: Pour the above solution A into an appropriate amount of purified water at a temperature of 18-22°C, cool down to below 10°C, stir and stand to separate into the upper aqueous layer and the lower organic layer, take the upper aqueous solution, add sodium hydroxide or hydrogen Po...

Embodiment

[0088] In the preparation process of sulbenicillin sodium, all raw material consumptions are as shown in table 1.

[0089] Raw materials and consumption used in the preparation process of table 1 sulbenicillin sodium.

[0090] Excipient name

Dosage

Excipient name

Dosage

Industrial Grade Phenylacetic Acid

20kg

Industrial grade 6-APA

31.8Kg

Industrial grade dichloroethane

42kg

Industrial grade n-butanol

636L

Industrial grade dioxane

20kg

Pharmaceutical Grade Activated Carbon

2.5kg

Industrial Grade Sodium Bicarbonate

25kg

Industrial grade acetone

63.6L

Industrial Grade Sulfur Trioxide

115kg

Industrial Grade Ether

42kg

100kg

Pharmaceutical Grade Isopropyl Alcohol

352L

Industrial grade thionyl chloride

180kg

Pharmaceutical grade absolute ethanol

704L

Industrial grade dimethylformamide

1.8kg

Technical gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com