Thermoplastic polymer film composite linerless aluminum foil tape

A thermoplastic polymer and aluminum foil tape technology, applied in the direction of film/sheet adhesives, adhesives, layered products, etc., can solve the problems of high production cost, waste of resources, waste, etc., and achieve simple manufacturing process and manual operation Convenience and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

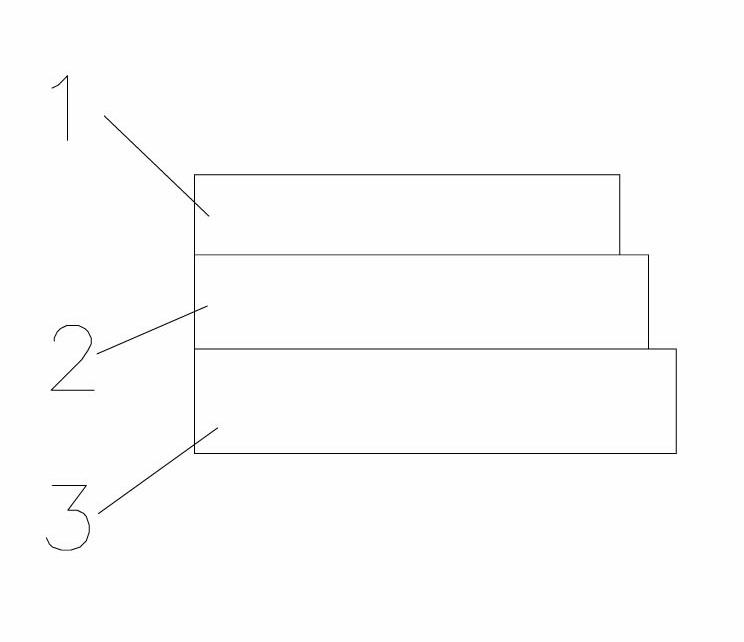

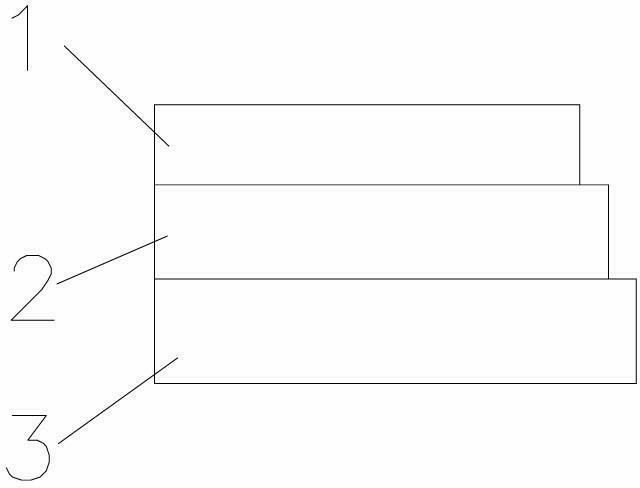

[0023] refer to figure 1 , a thermoplastic polymer film composite aluminum foil tape without liner, which is composed of a thermoplastic polymer film 1, an aluminum foil layer 2 and an adhesive layer 3, wherein the aluminum foil layer 2 is located in the middle layer, and the thermoplastic polymer film 1 is heated with the The aluminum foil layer 2 is bonded together, which reduces the use of backing paper. Because the weight of backing paper generally requires more than 80g / cm2, under the same circumstances, the weight of the backing paper aluminum foil tape is heavier than the aluminum foil tape of the present invention. Transportation is inconvenient. The volume of the aluminum foil tape with backing paper is 6 to 12 times that of the present invention, so it occupies a large area for stacking and is difficult to recycle. Compared with the present invention, it saves resources and reduces production costs.

[0024] The thermoplastic polymer film 1 has self-adhesiveness in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com