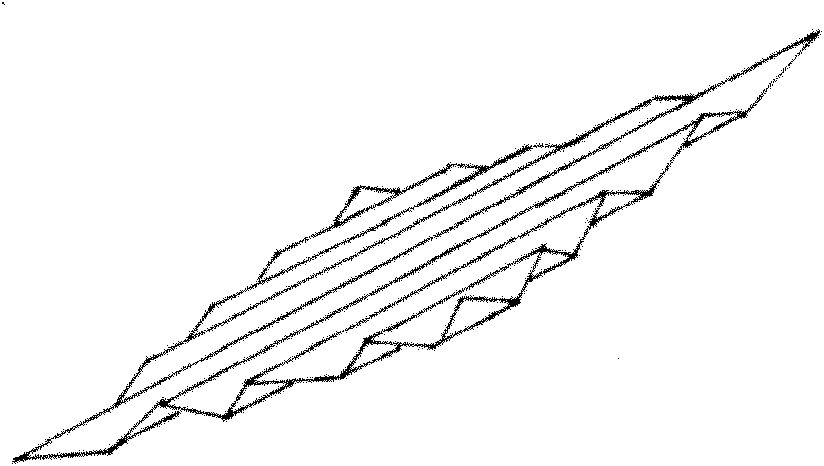

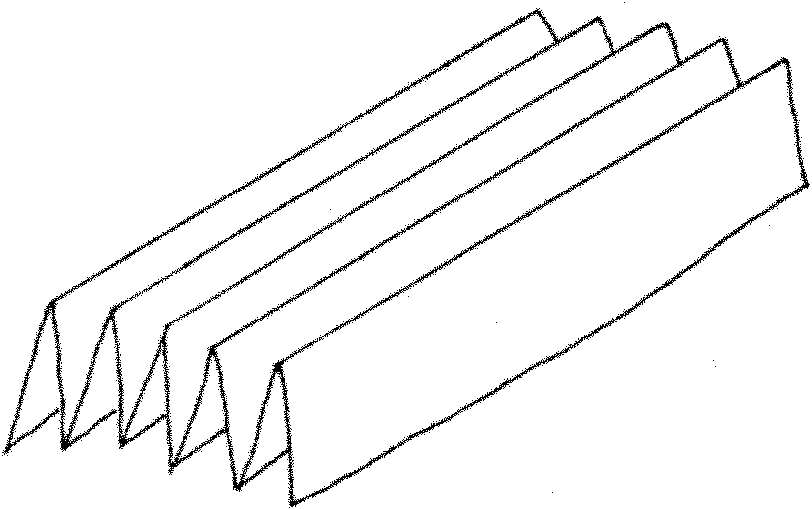

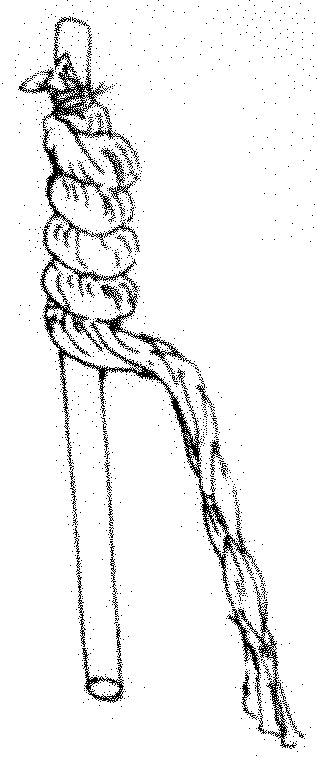

Method for roll-press dyeing through twisting

A roll press-dyeing and twist-dyeing technology, applied in the field of roll press-dyeing, can solve the problems of limited expressive techniques and styles, few crafts and patterns, etc., and achieve the effect of reducing production process and material costs, enriching expression forms, and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Prepare the fabric

[0035] The present invention is suitable for natural fabrics such as cotton, hemp, silk, wool, etc., and can also use viscose fiber and a small amount of chemically synthesized fabrics. Take the commonly used cotton and silk as examples here. Cotton fabric has good hygroscopicity and air permeability, complete varieties and specifications, low price, and simple dyeing process. Twisted twist roll press dyeing process can prepare fine cotton gauze mosquito net cloth or pure cotton knitted cloth.

[0036] Silk fabrics are shiny, have a unique "siming" sound, feel smooth, elegant, gorgeous, with a wide variety, moisture absorption, heat resistance, light resistance, water resistance, and alkali resistance. Such as electric spinning, double wrinkle, plain wrinkle satin, georgette, silk knitted fabric, etc. Silk fabrics can be well designed by using different hand-dyeing methods according to different situations, and the effects are also different. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com