Patents

Literature

74results about How to "Rigid structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

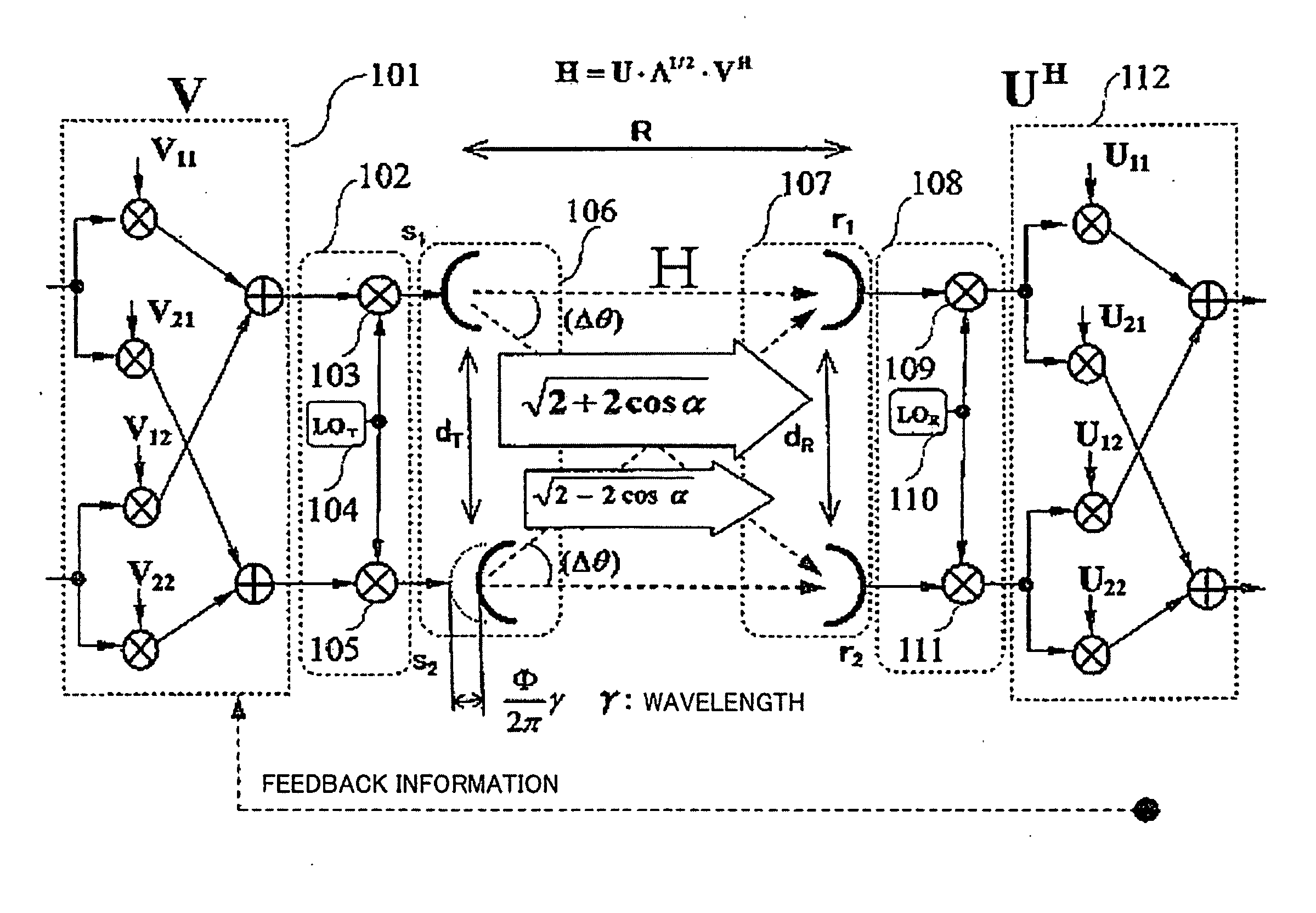

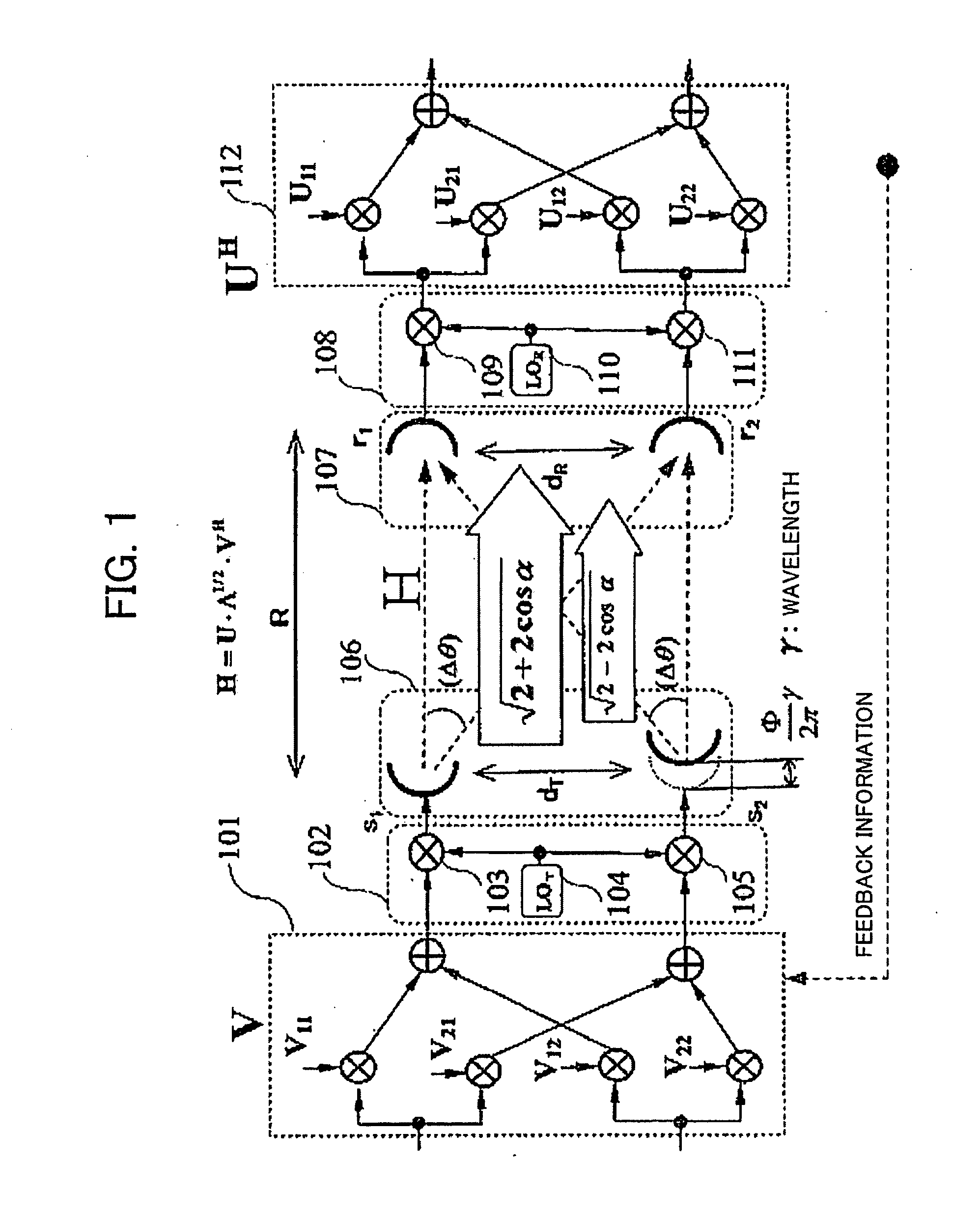

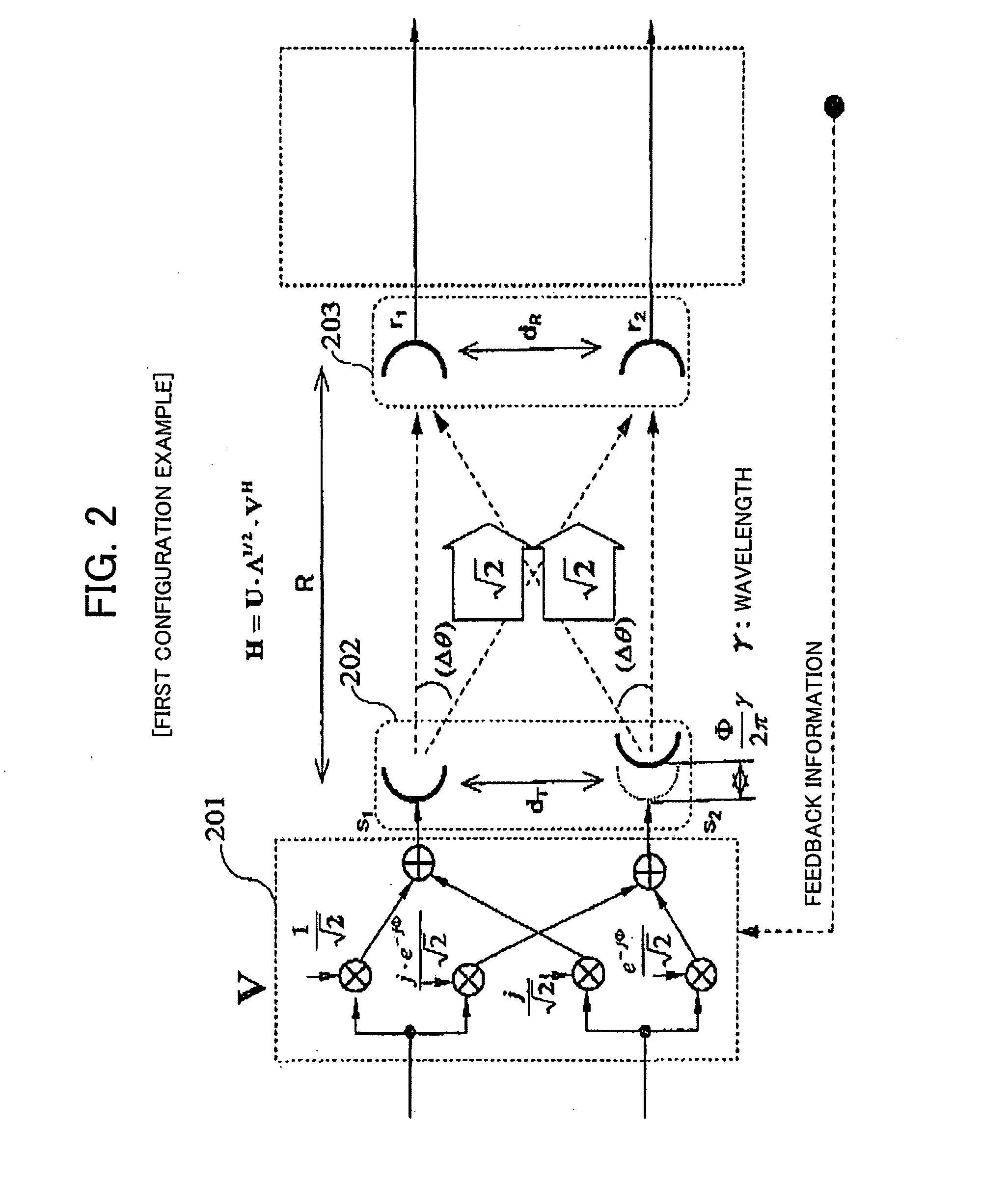

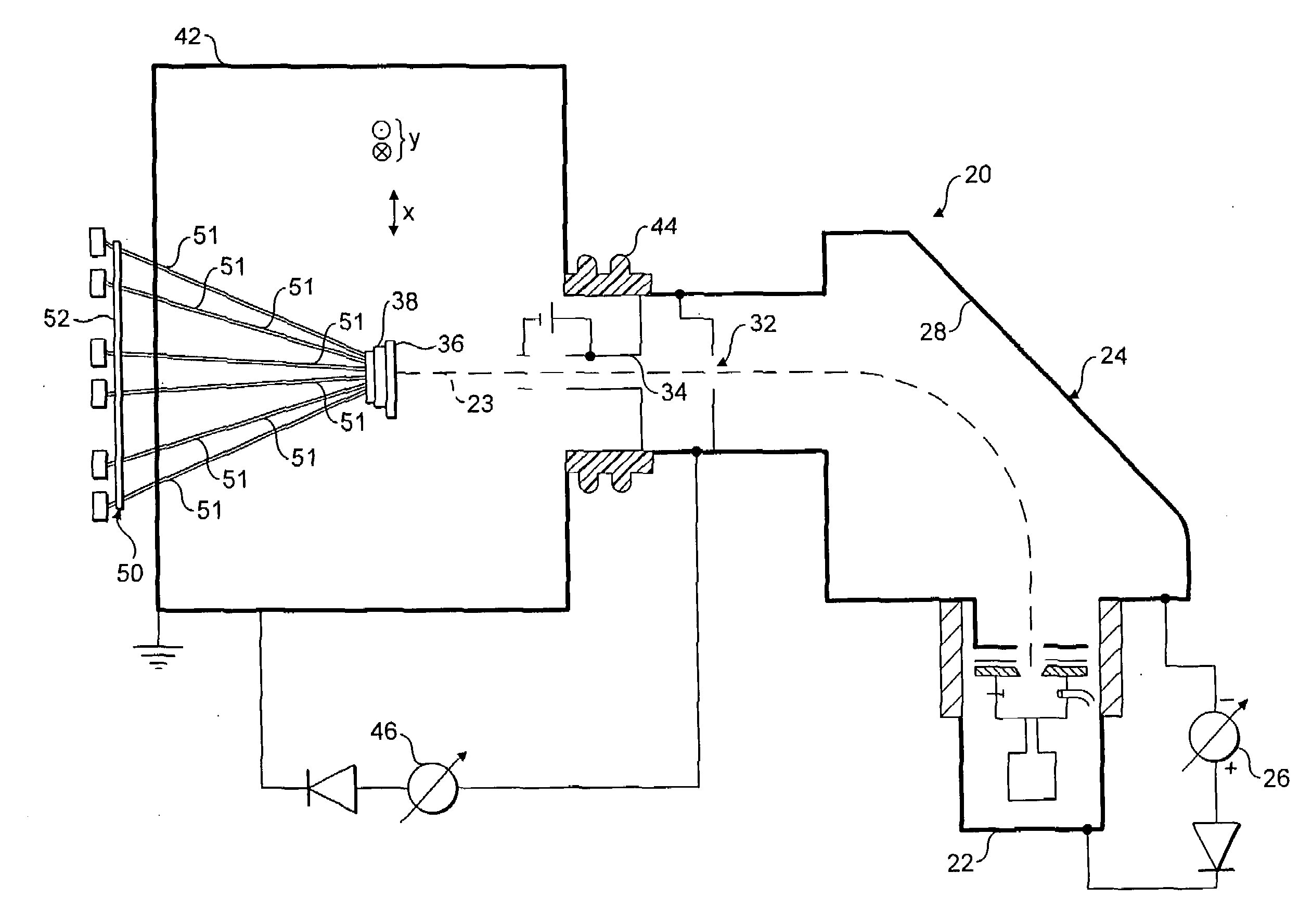

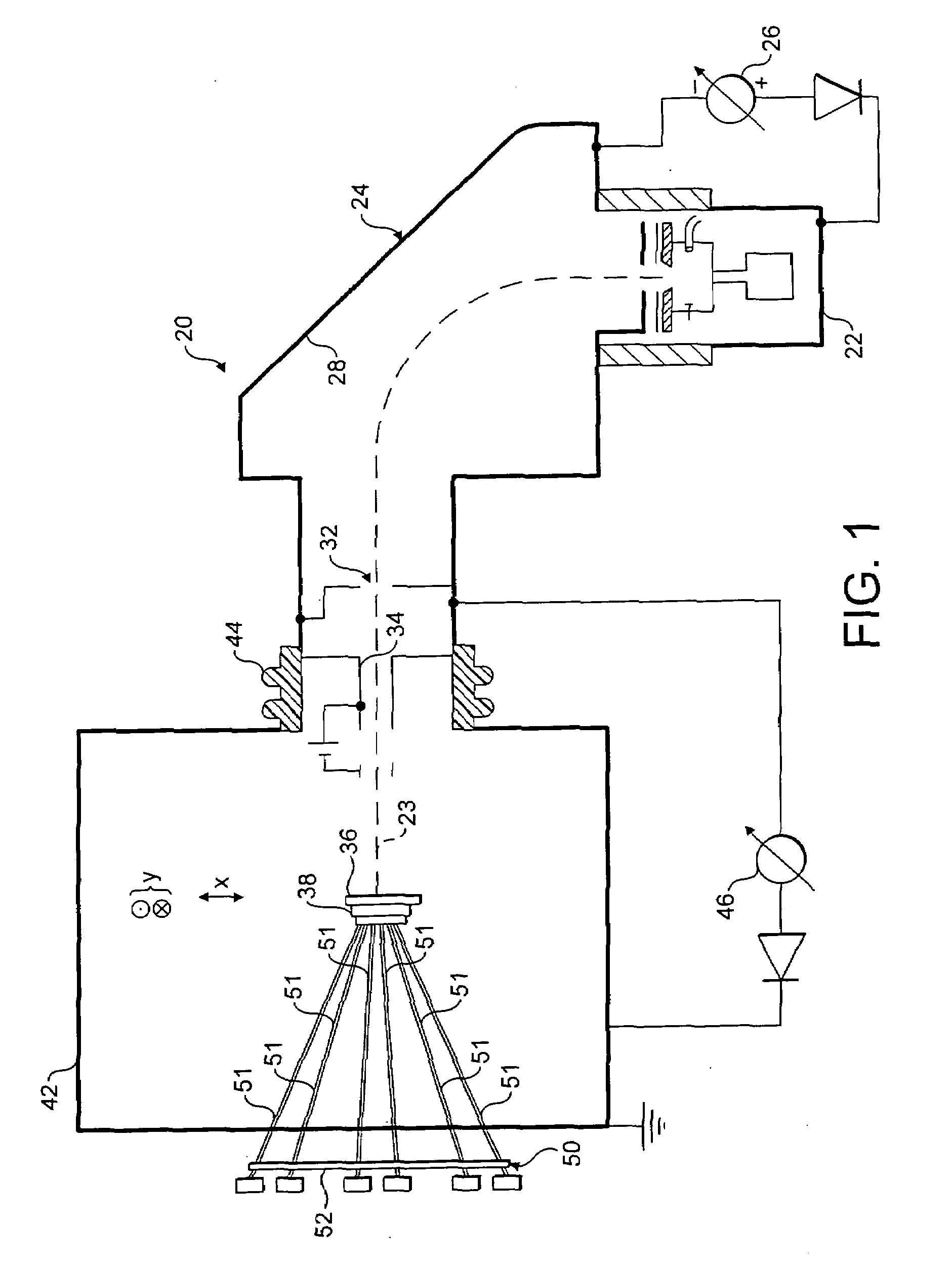

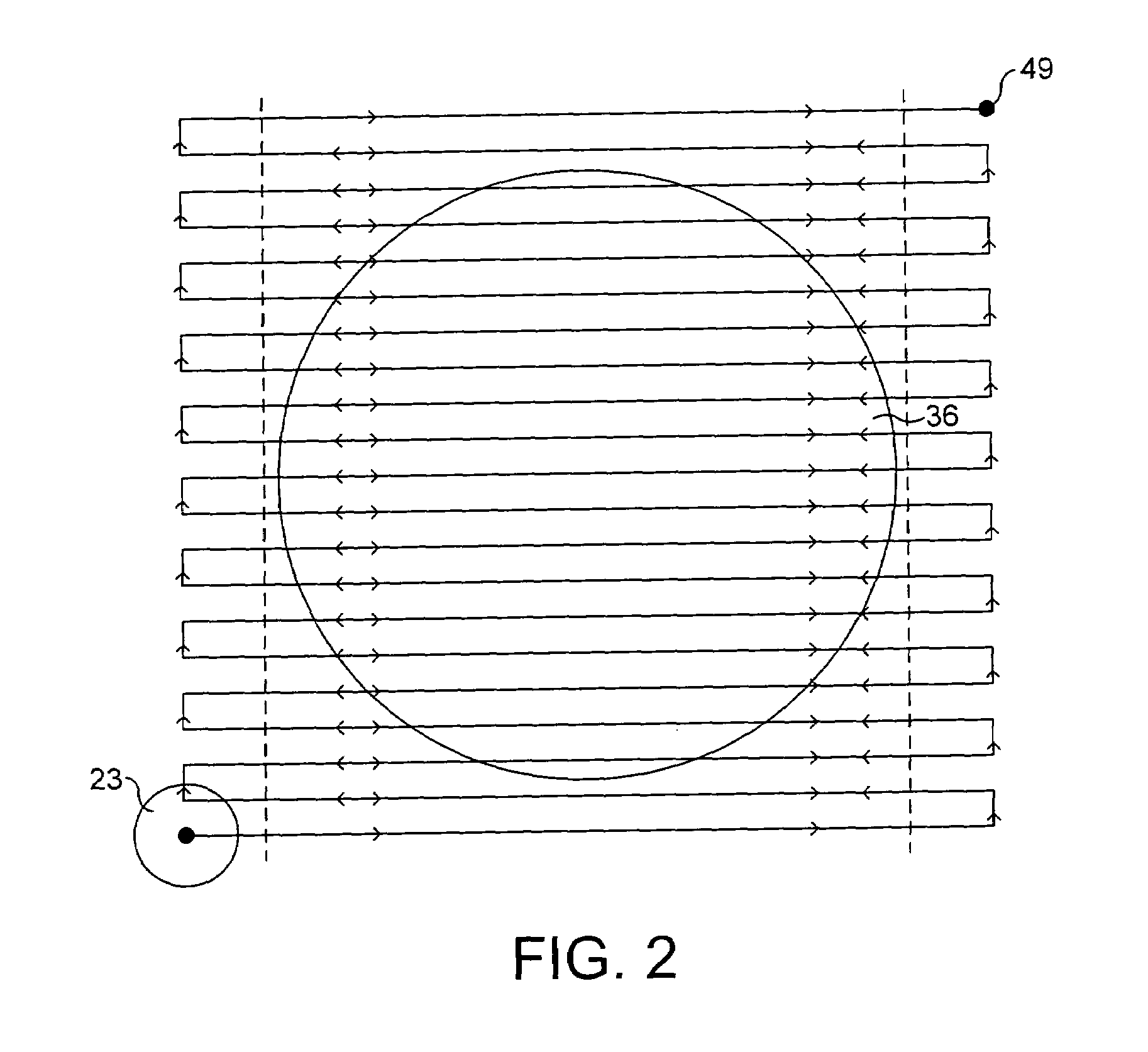

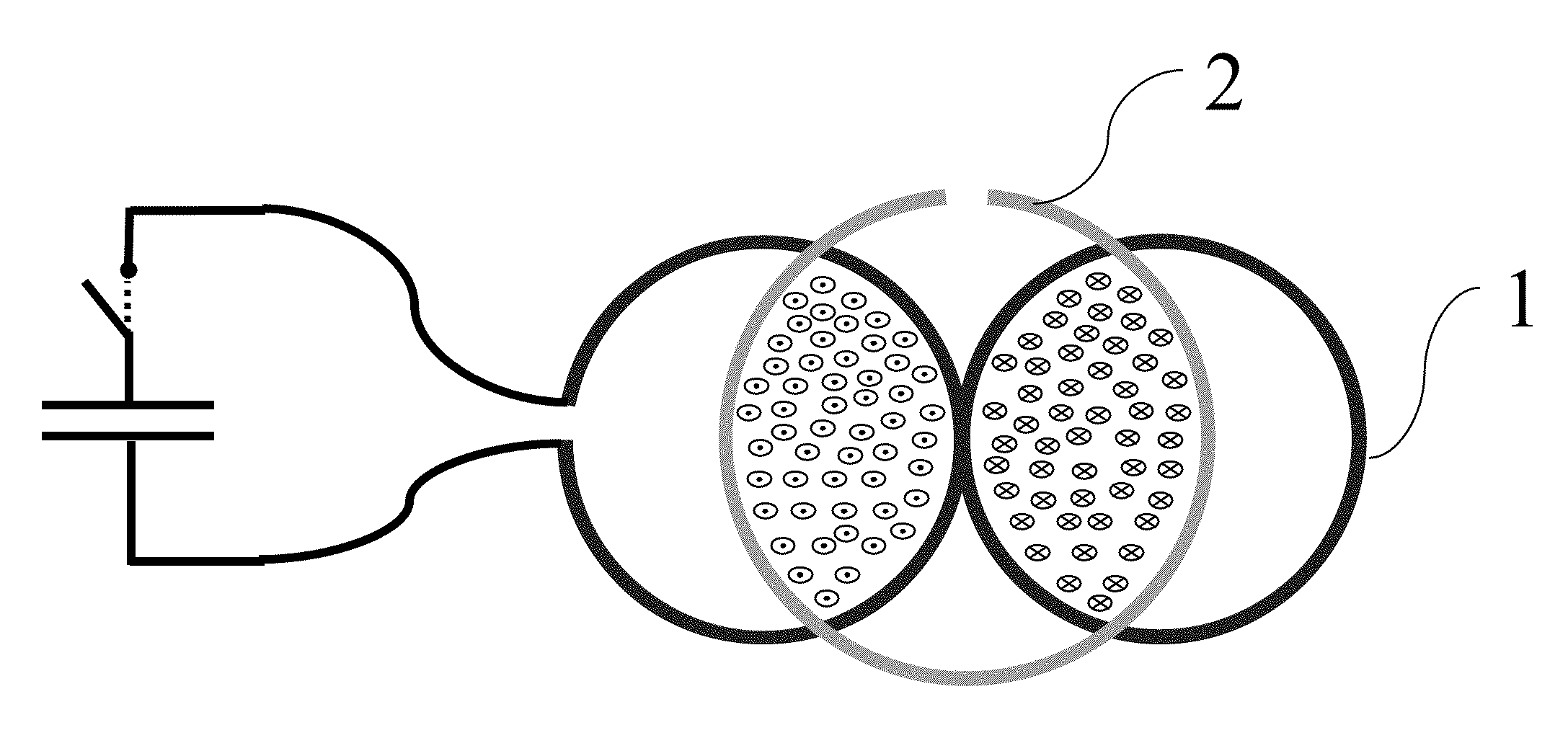

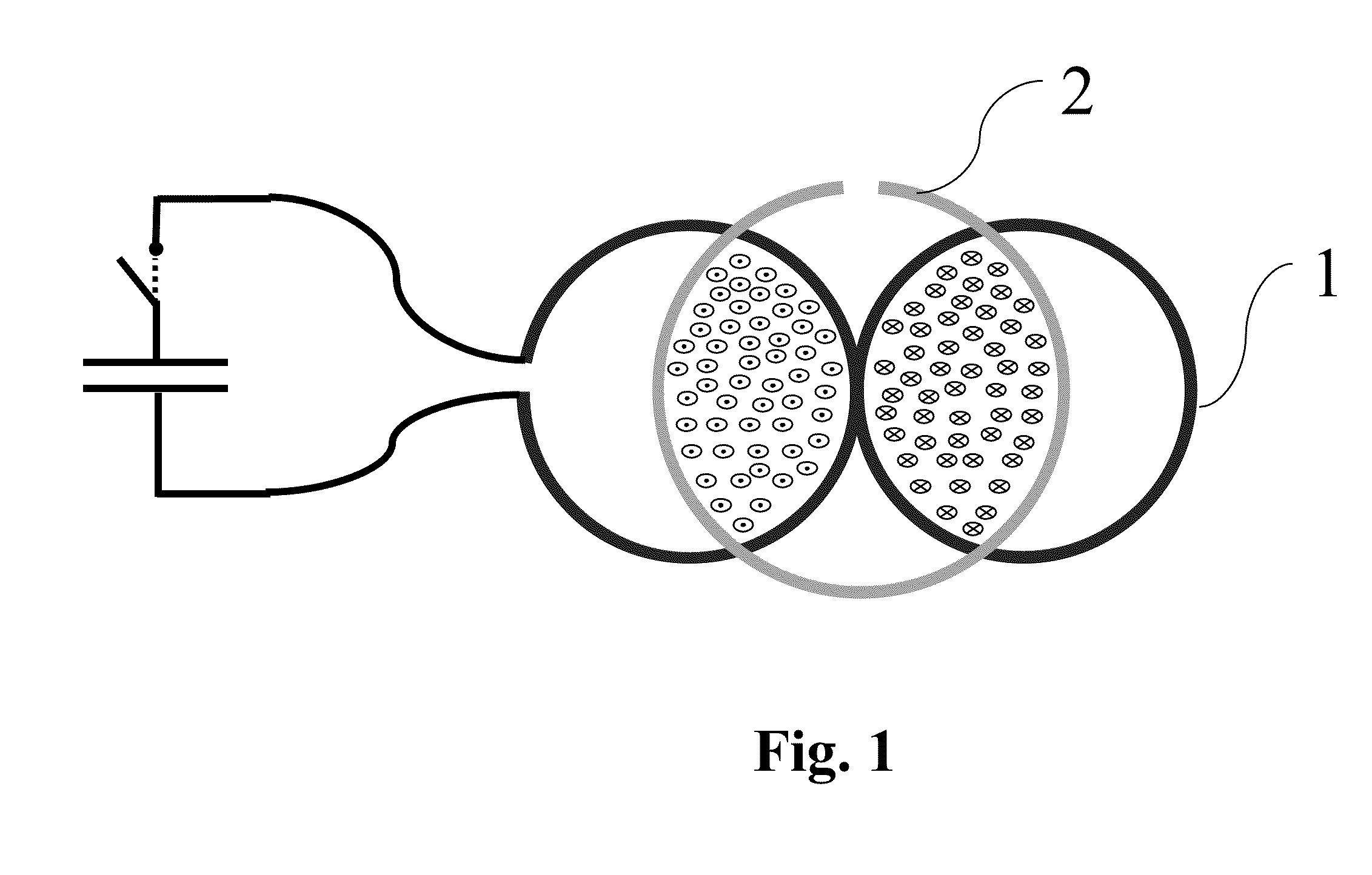

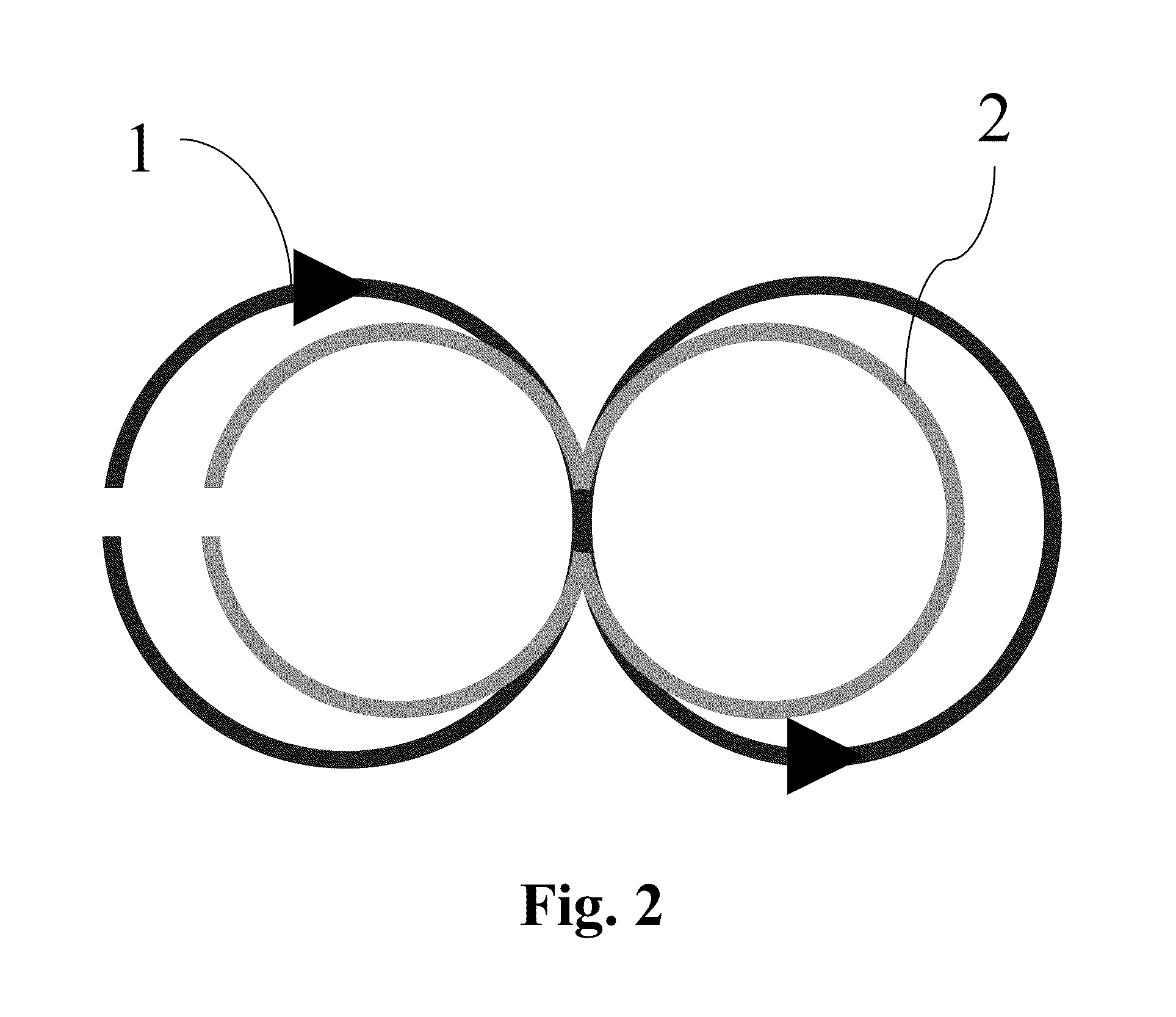

MIMO communication system having deterministic channels and method

InactiveUS20090296846A1Large communication capacityNone is problem freeMultiplex communicationDiversity/multi-antenna systemsFormation matrixChannel capacity

A MIMO communication system having deterministic channels wherein MIMO is applied to line-of-sight channels having a fixed geometrical positional relationship so as to increase the channel capacity. A line-of-sight MIMO communication system having a plurality of channels includes a channel matrix calculation processing section on a transmission or reception side or both of the transmission and reception sides. The channel matrix calculation processing section updates an orthogonal channel formation matrix in accordance with a fluctuation of a transmission antenna position or reception antenna position or a fluctuation of the channels.

Owner:NEC CORP

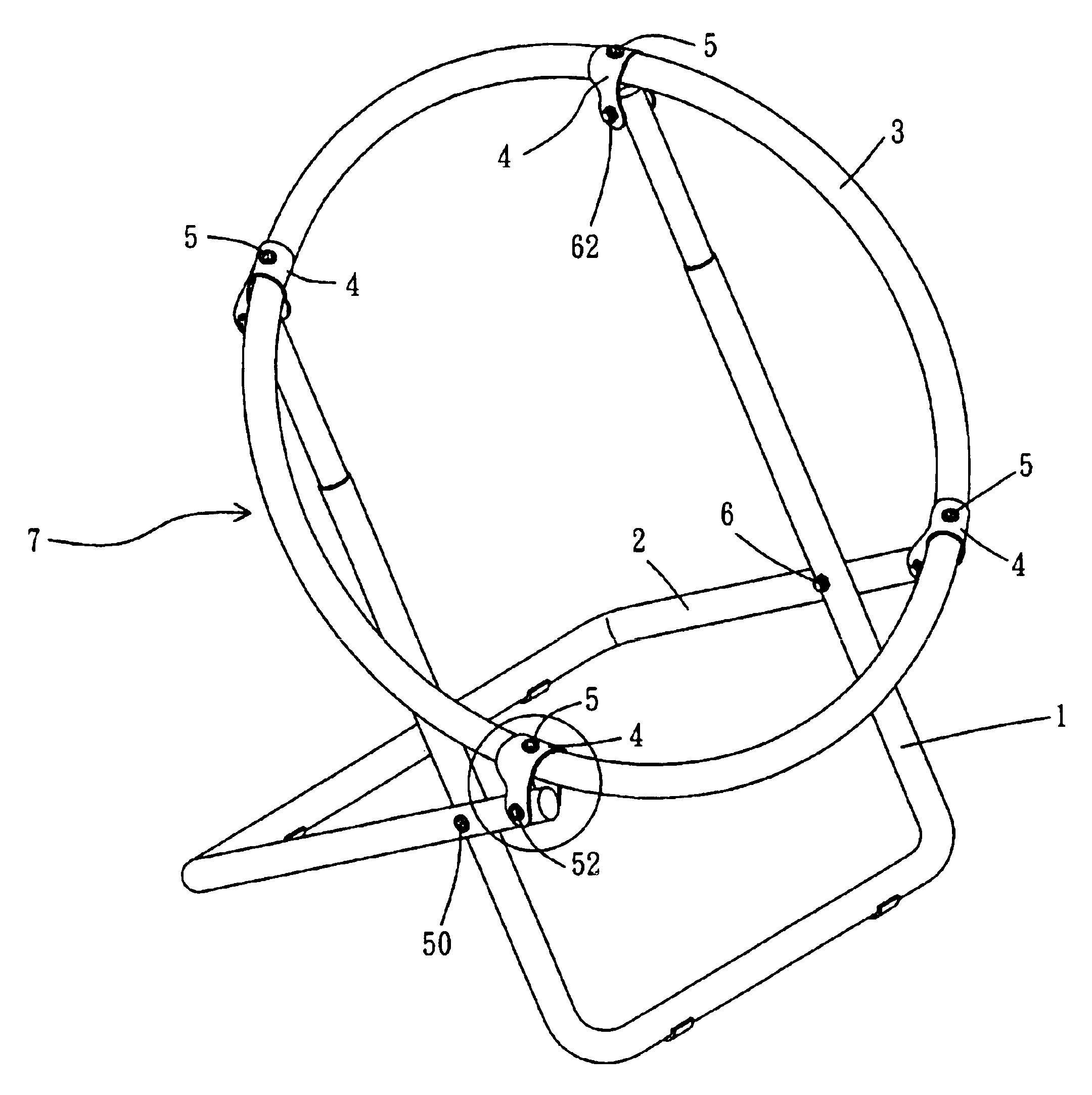

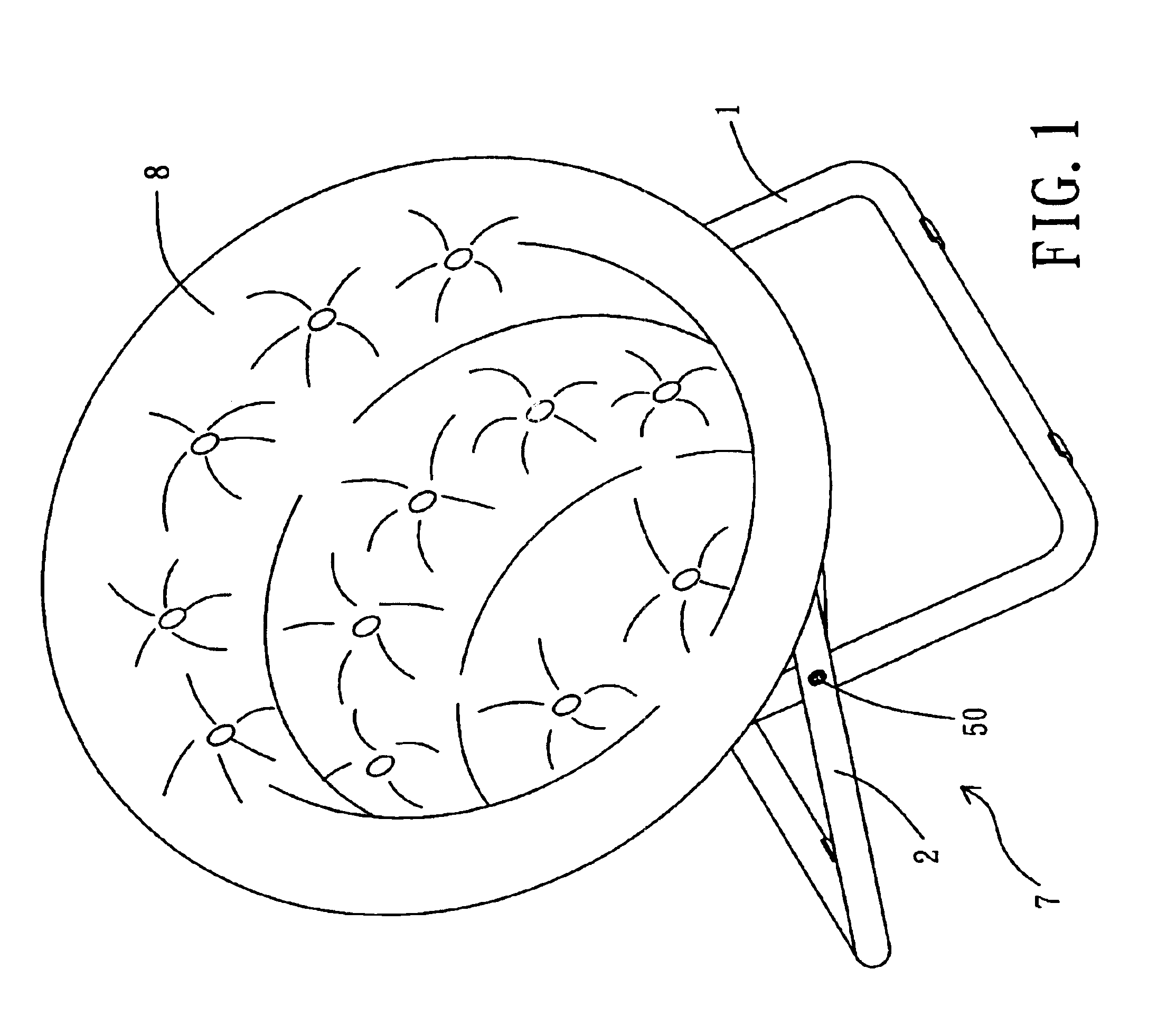

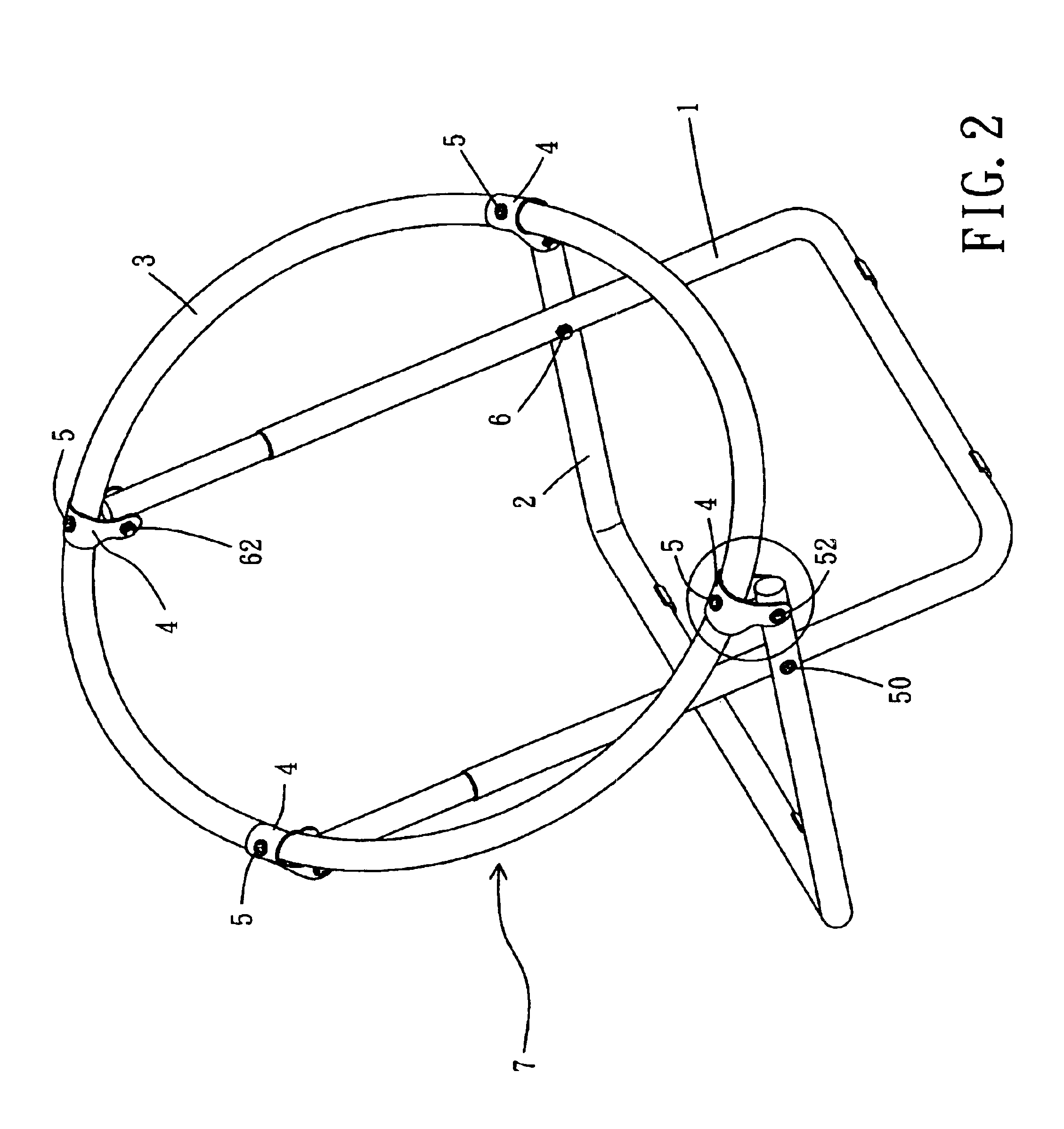

Chair having rigid structure

InactiveUS6840573B1Rigid structureEasy to disassembleFoldable chairDismountable chairsEngineeringMechanical engineering

Owner:YAO KING YURN

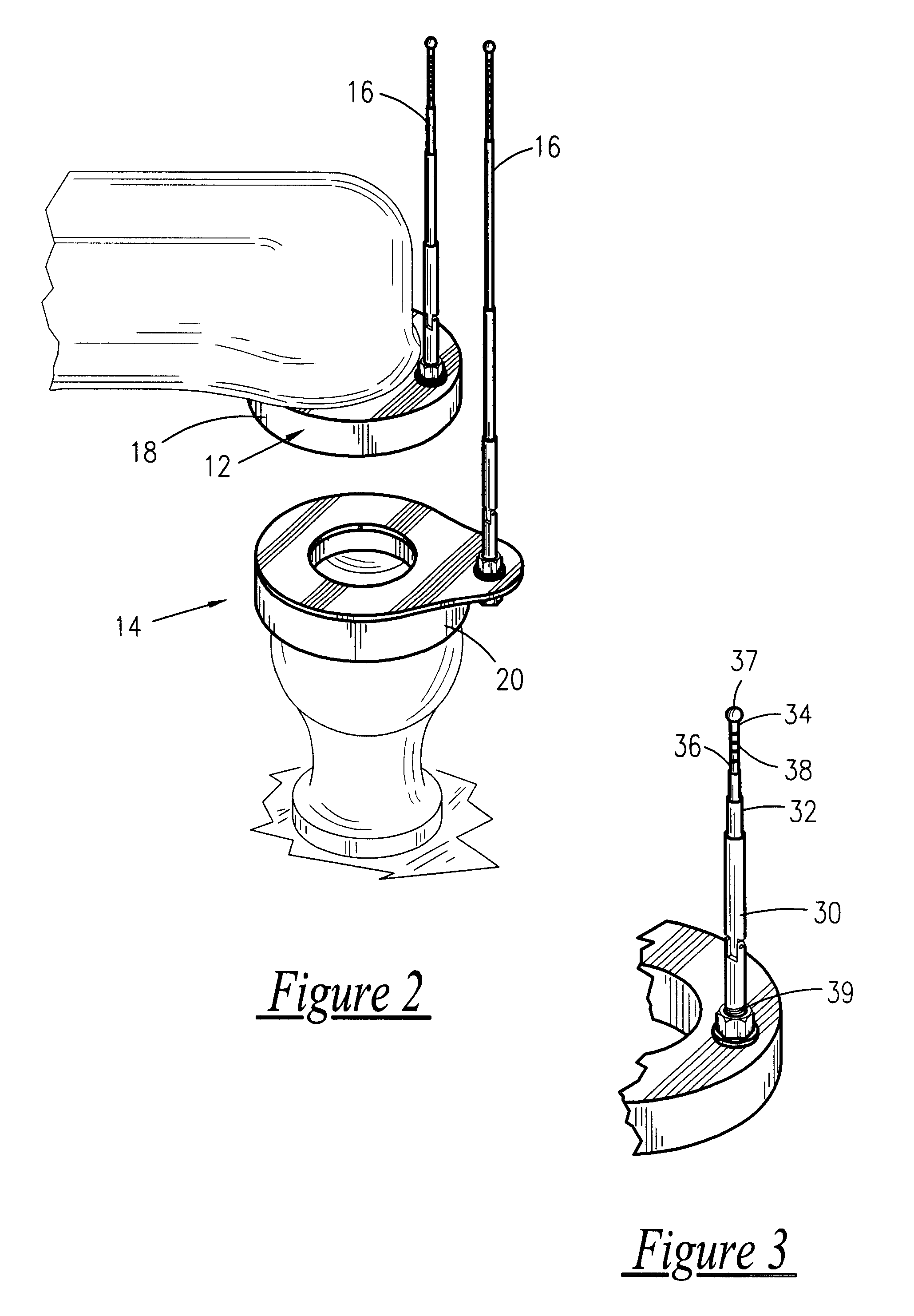

Magnetic, telescoping trailer hitch alignment device

InactiveUS6712378B1Easily dismountableRigid structureTowing devicesMechanical engineeringEngineering

Owner:AUSTIN RONALD J

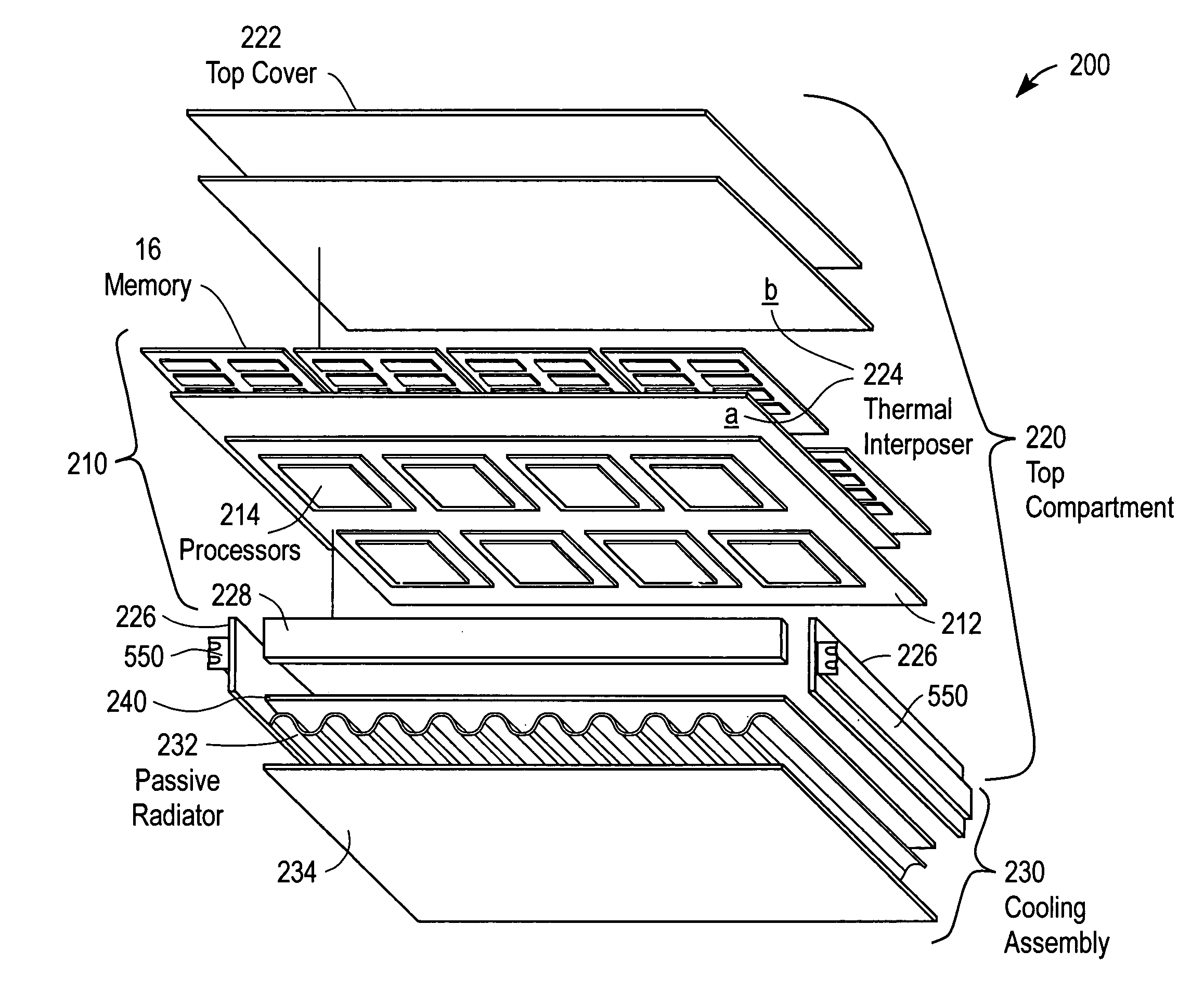

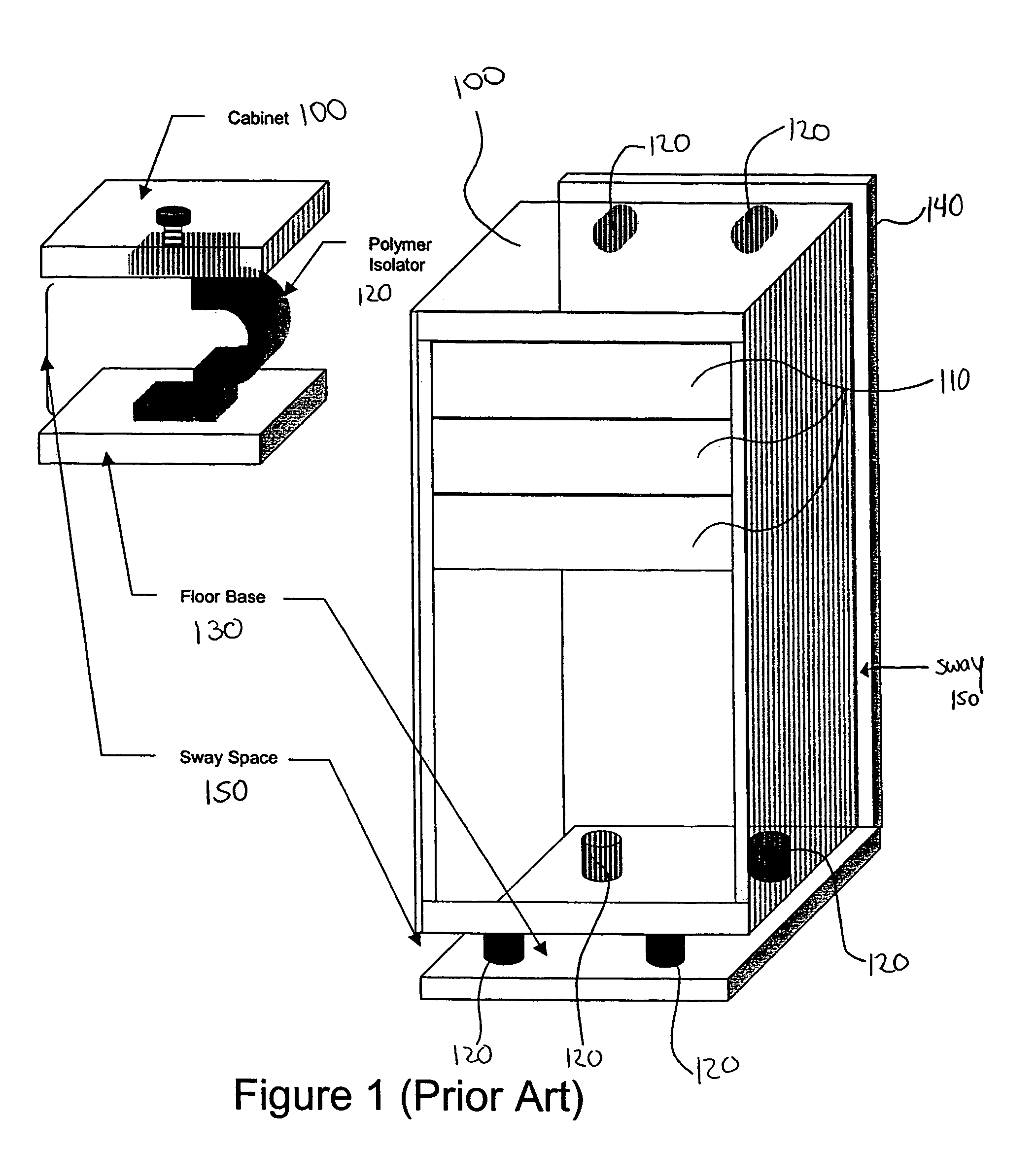

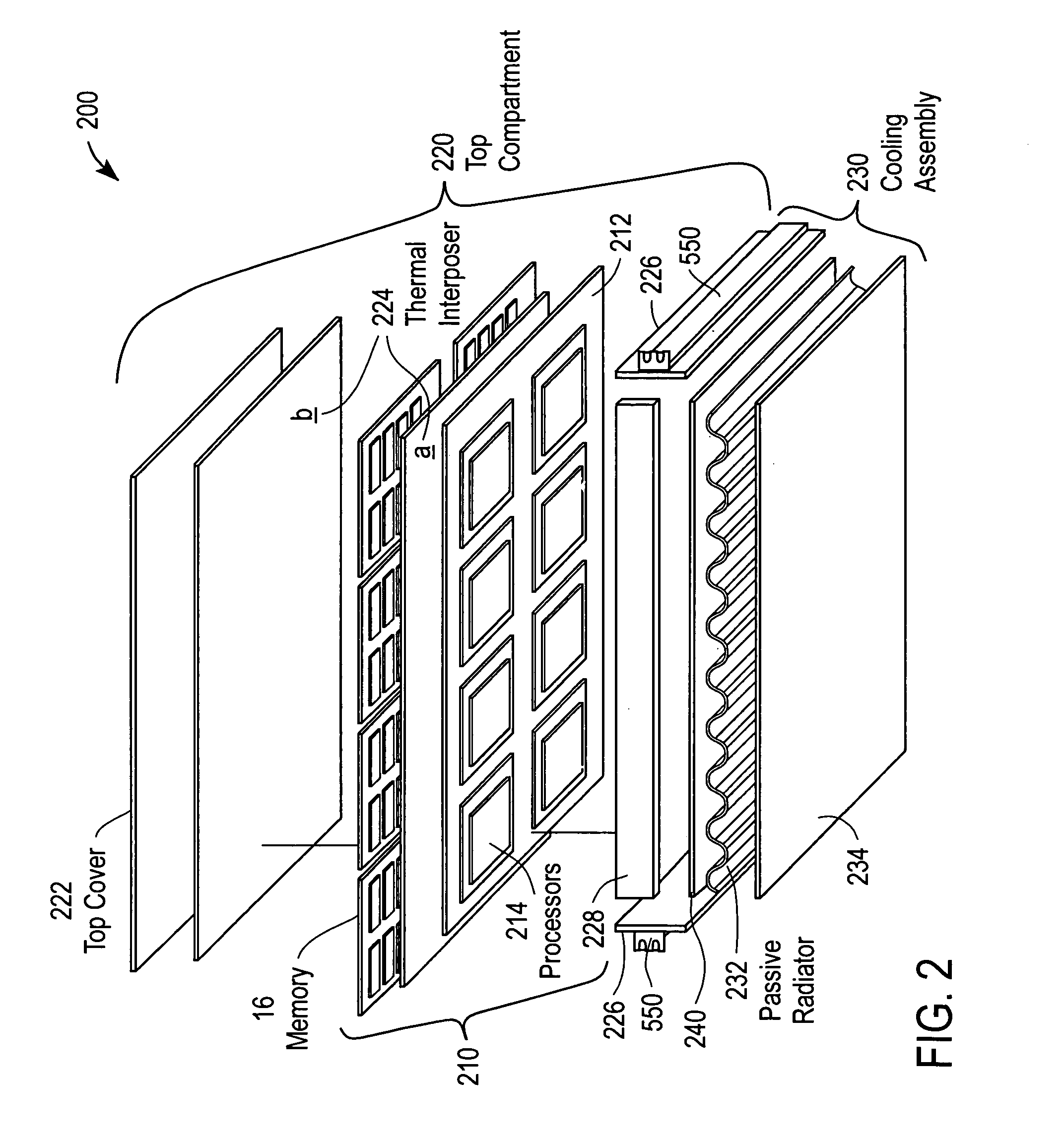

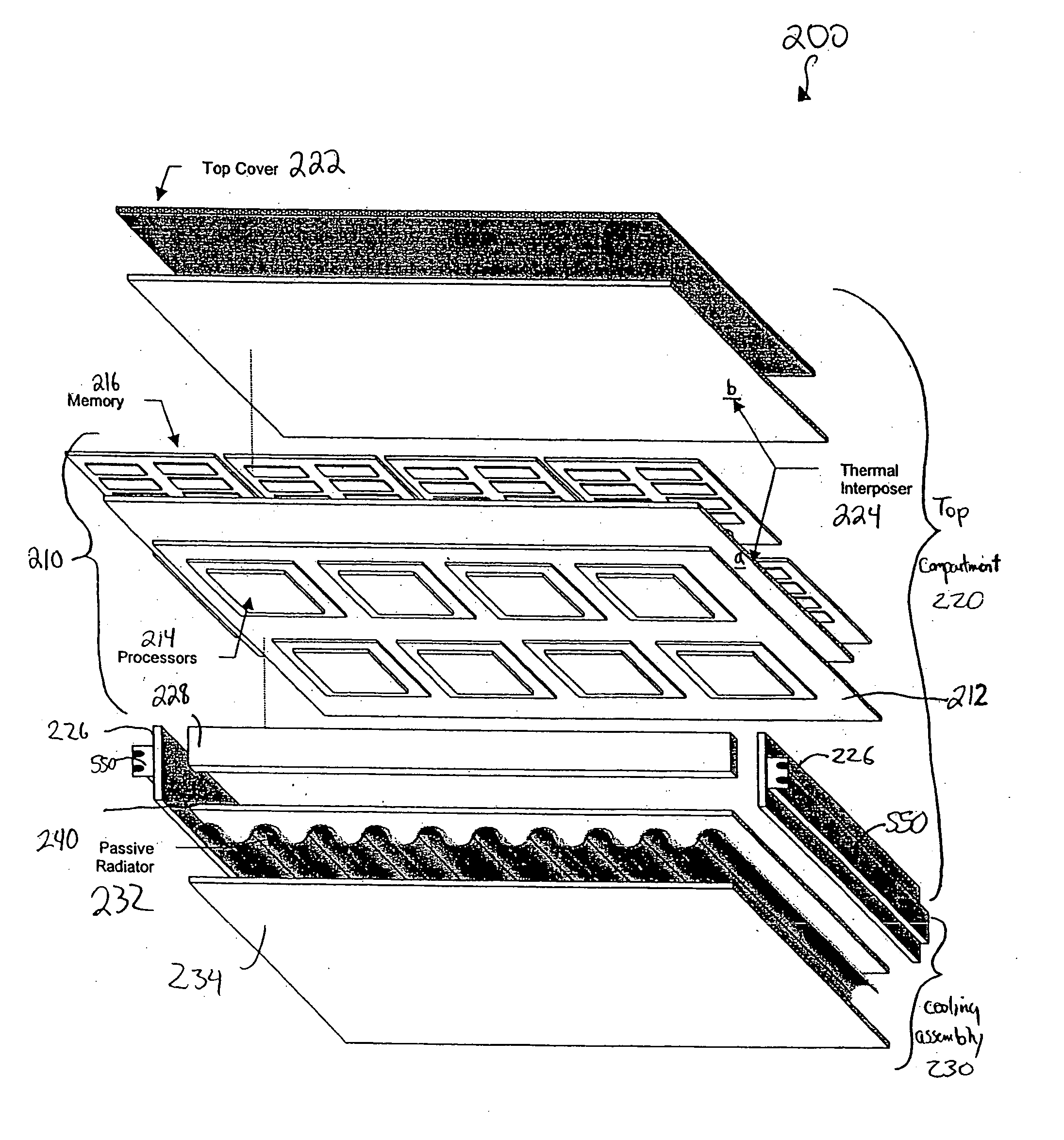

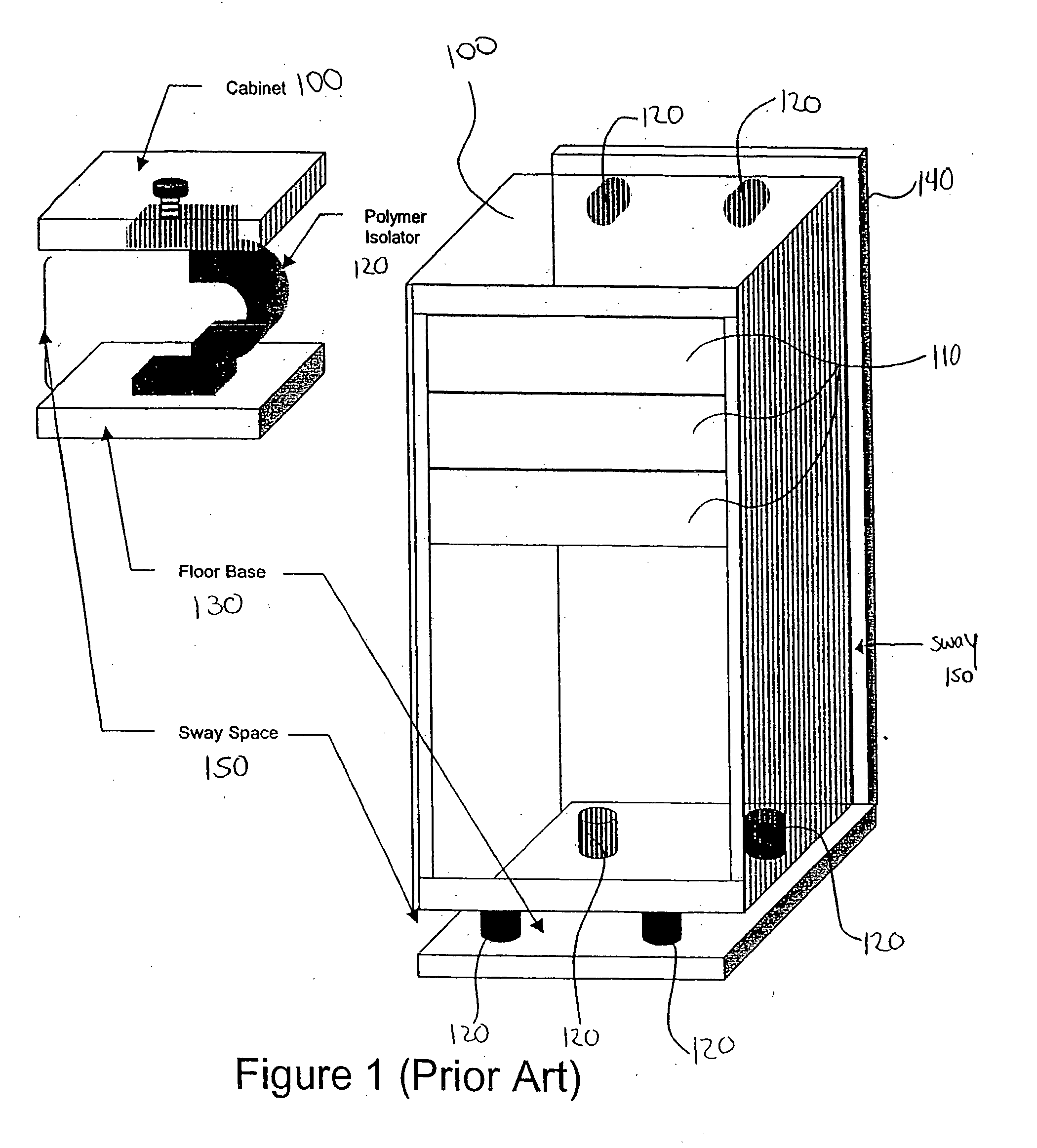

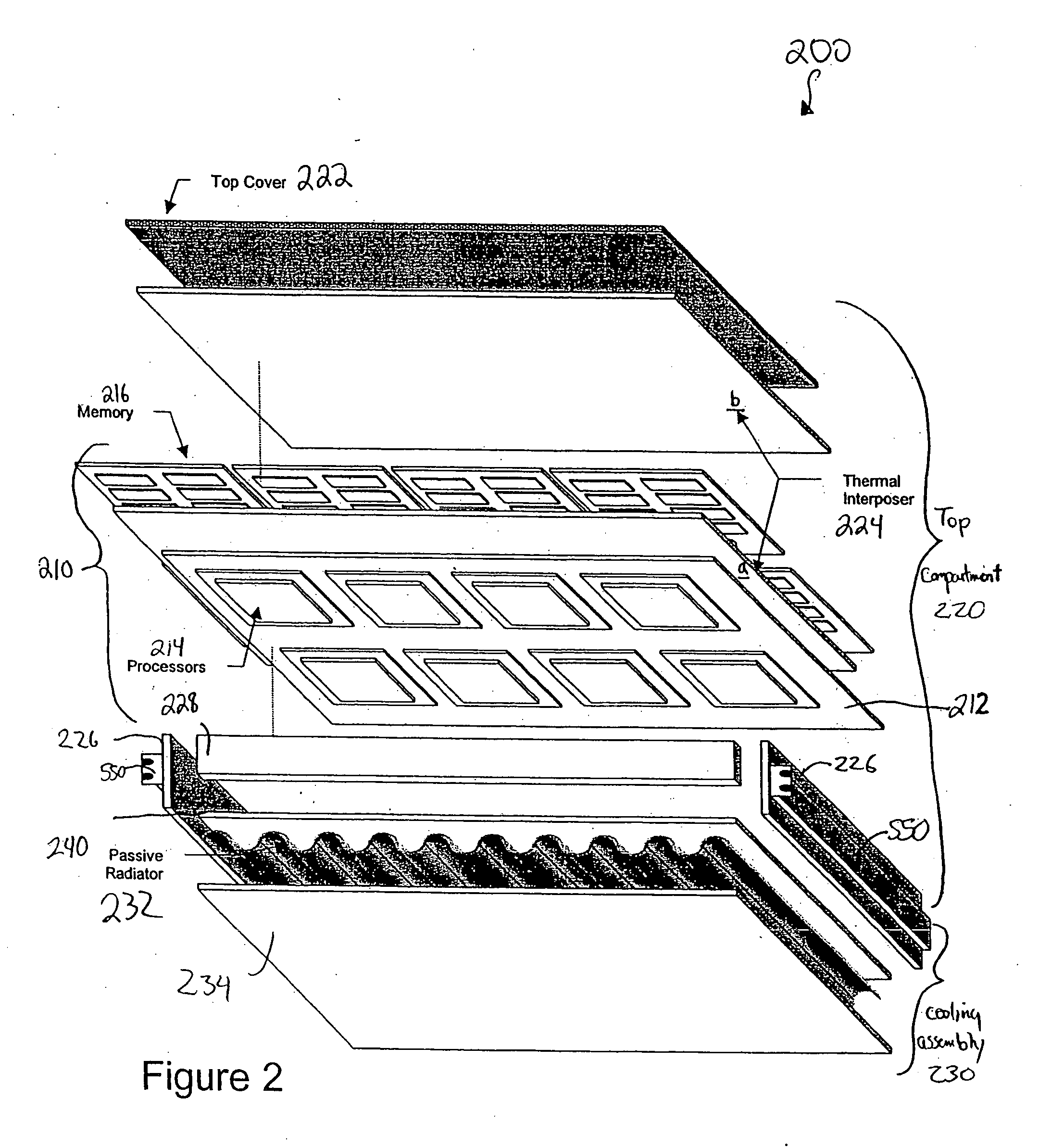

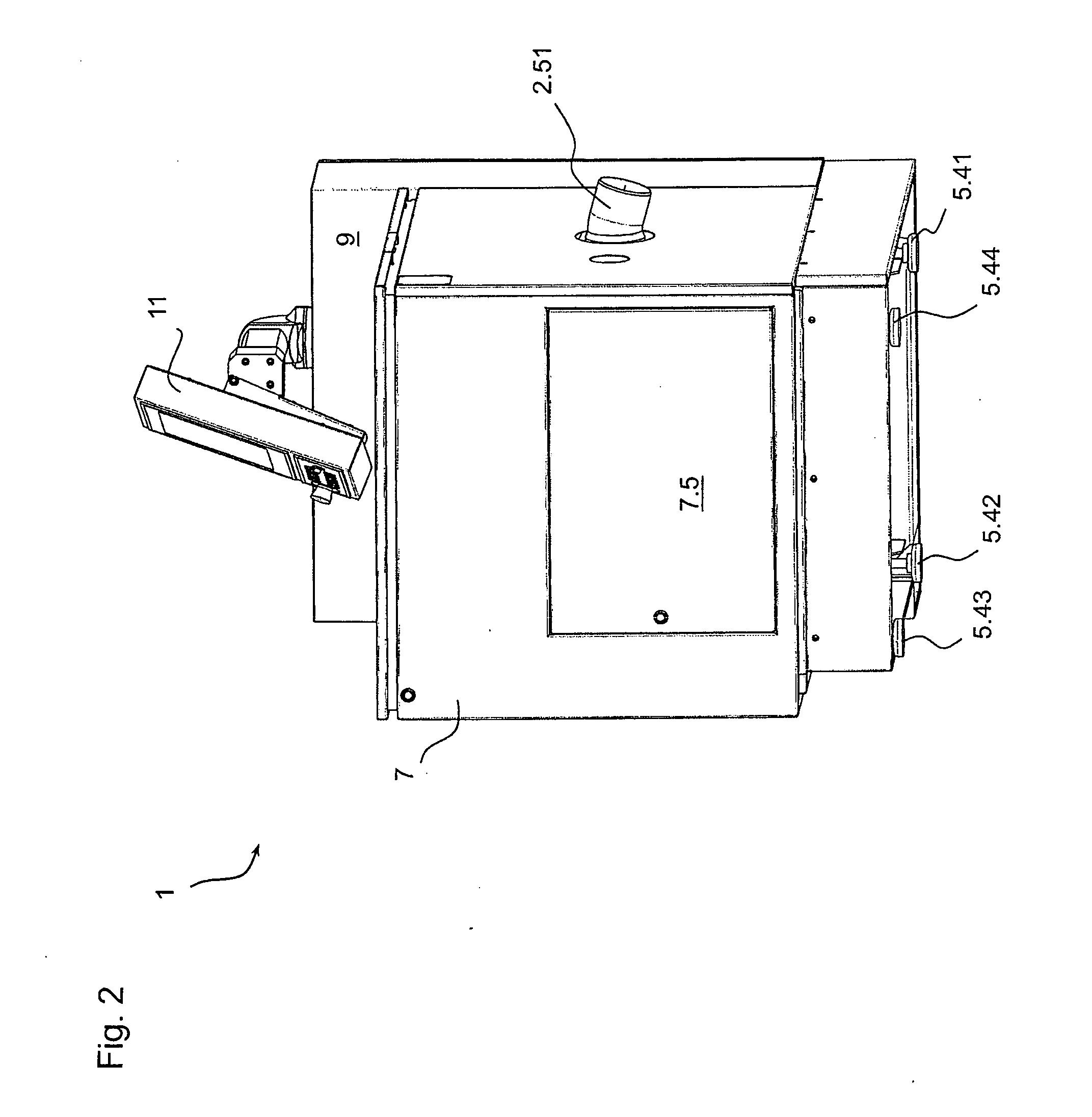

Ruggedized electronics enclosure

InactiveUS6944022B1Overcomes limitation and disadvantageHigh strength to weight ratioPrinted circuit board receptaclesModifications by conduction heat transferPassive radiatorEngineering

The present invention relates to a ruggedized enclosure for housing and protecting electronic circuits. The enclosure utilizes a top compartment for housing the circuit and a cooling assembly rigidly coupled to the top compartment. The cooling assembly utilizes a passive radiator to for a rigid truss plate structure. The truss plate structure rigidifies the enclosure helping to protect the enclosure and circuit from destructive shock events and destructive vibration events. The cooling assembly further provides an efficient heat exchange for removing heat from the electronic circuit. A method for protecting an electronic circuit utilizing a rigid truss plate structure is also provided.

Owner:MERCURY SYST TRUSTED MISSION SOLUTIONS INC

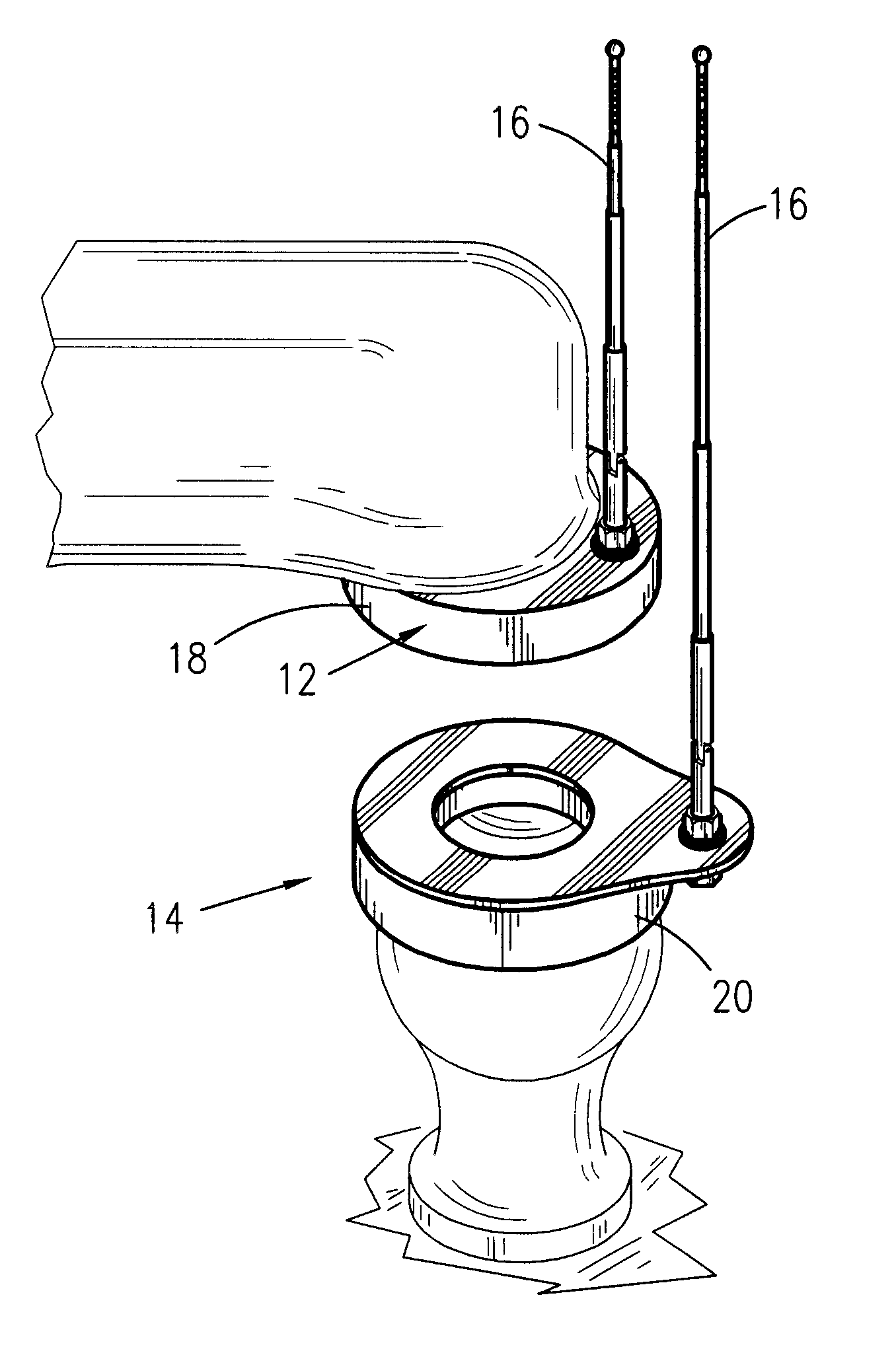

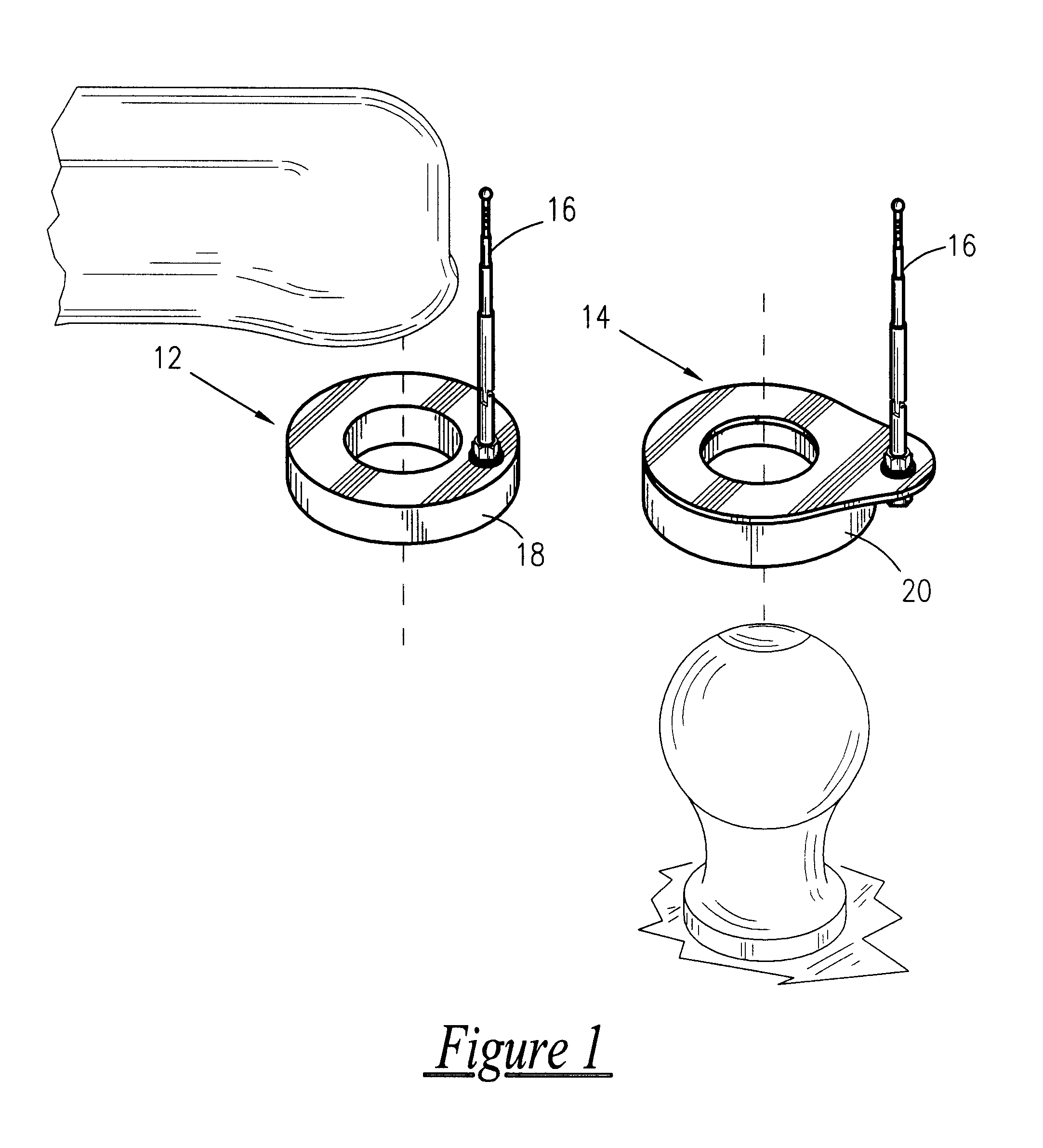

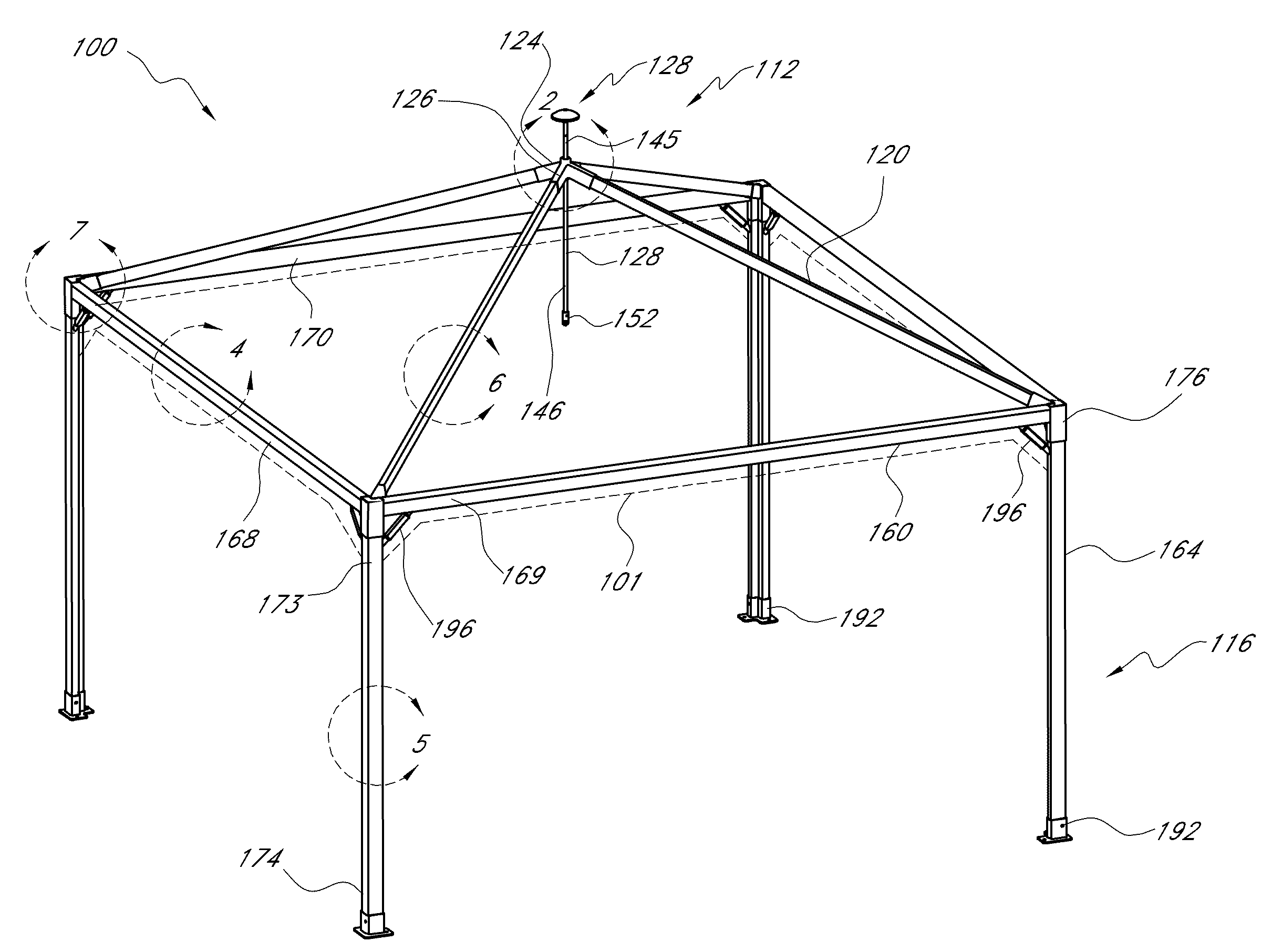

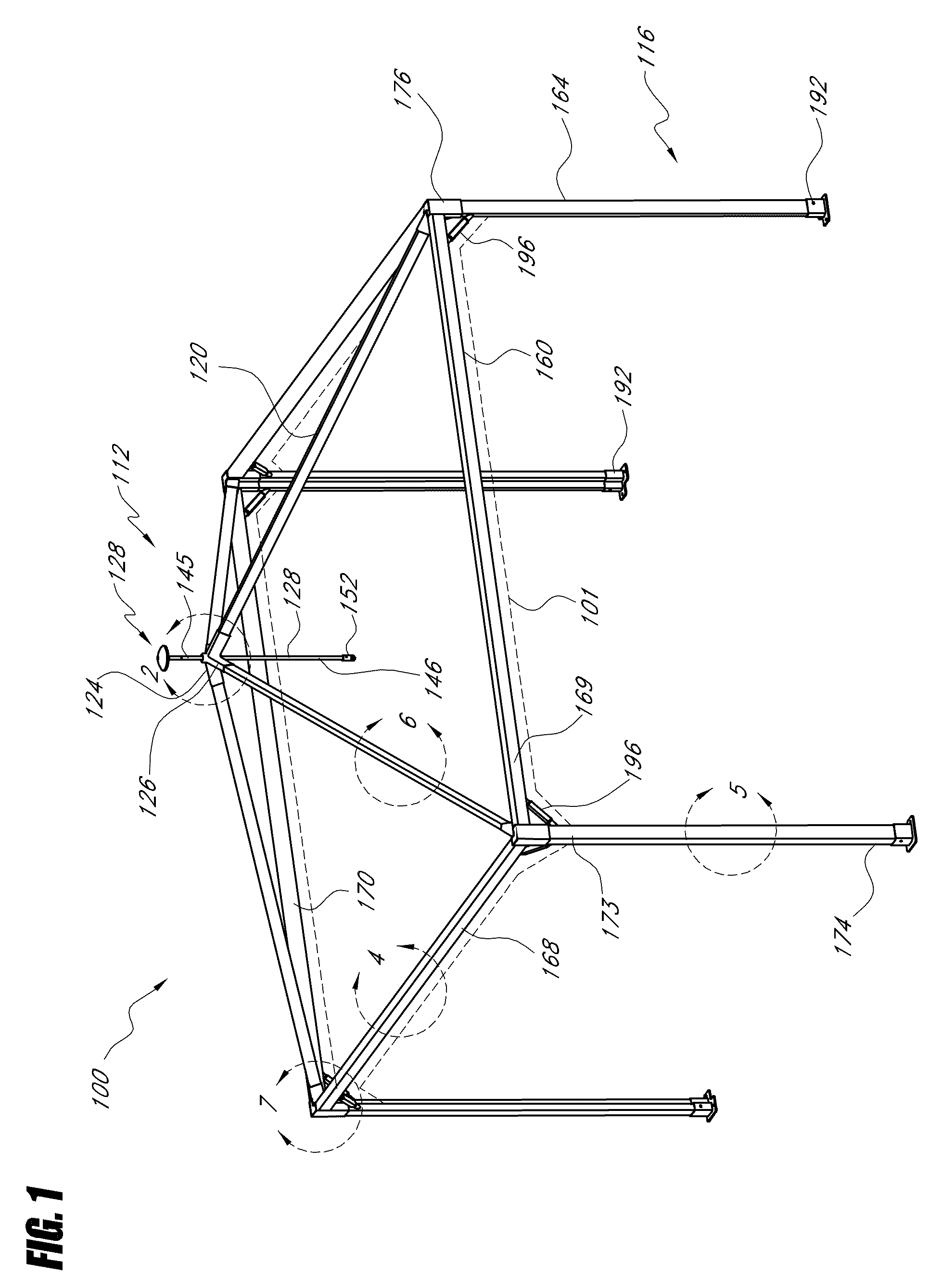

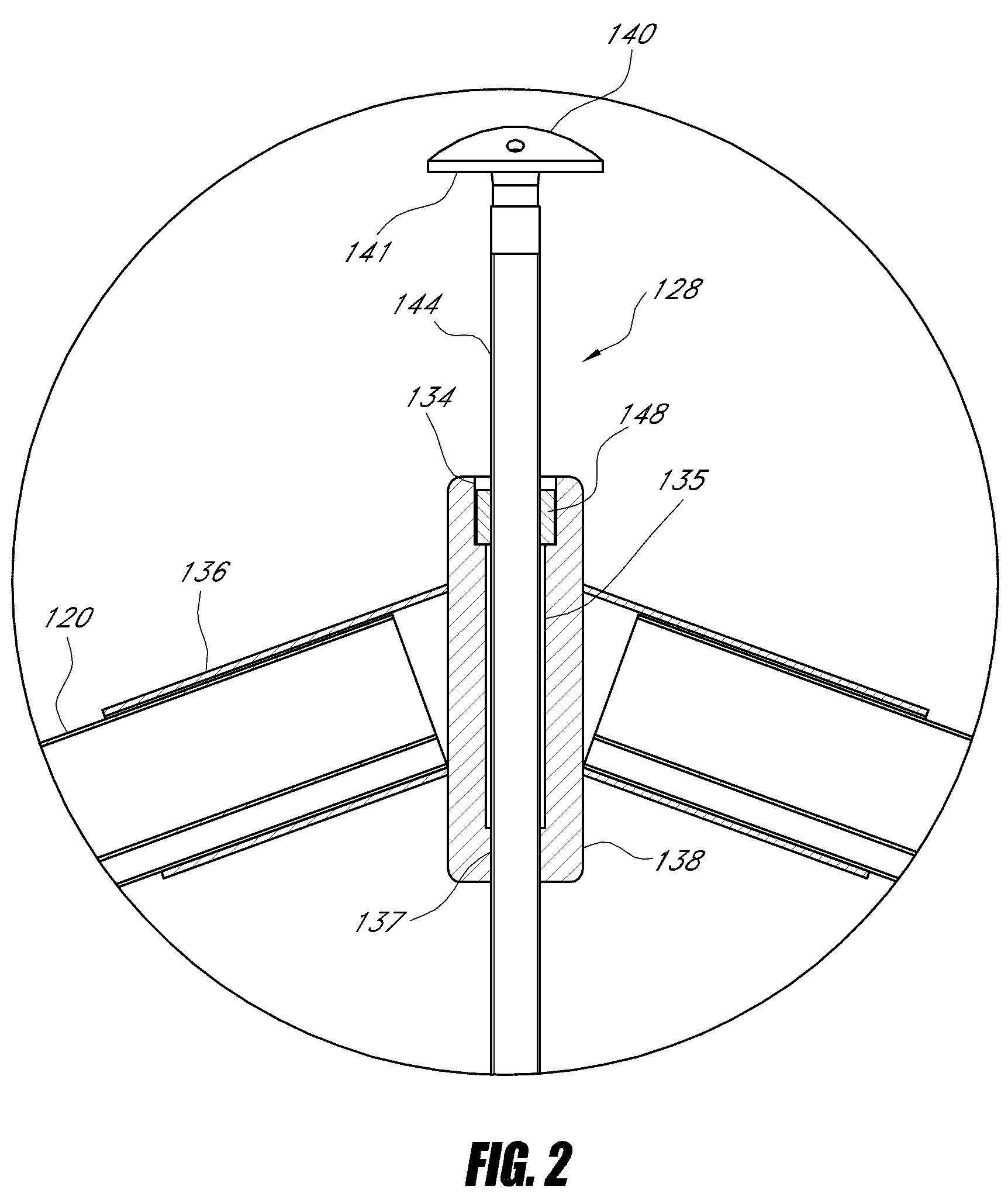

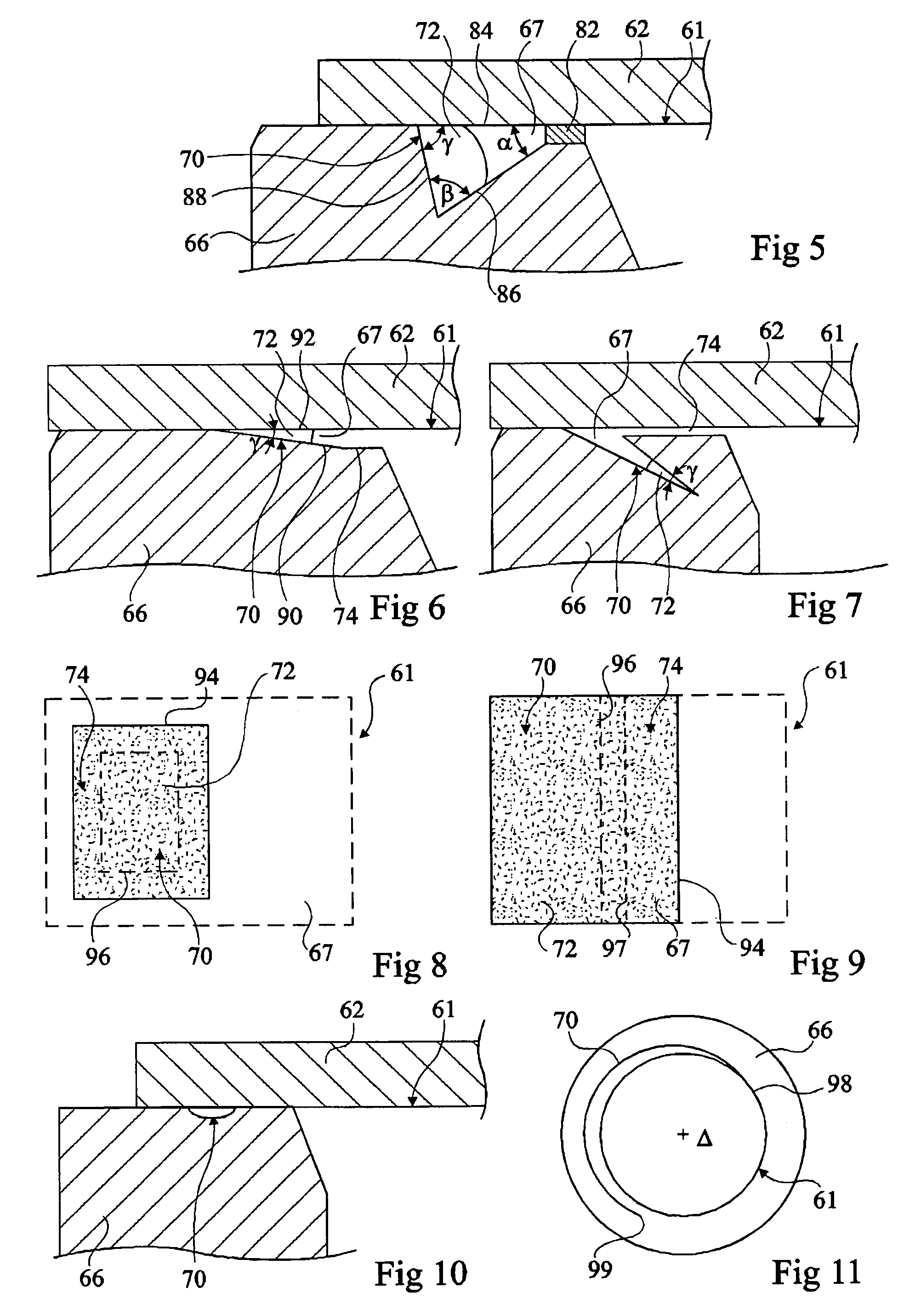

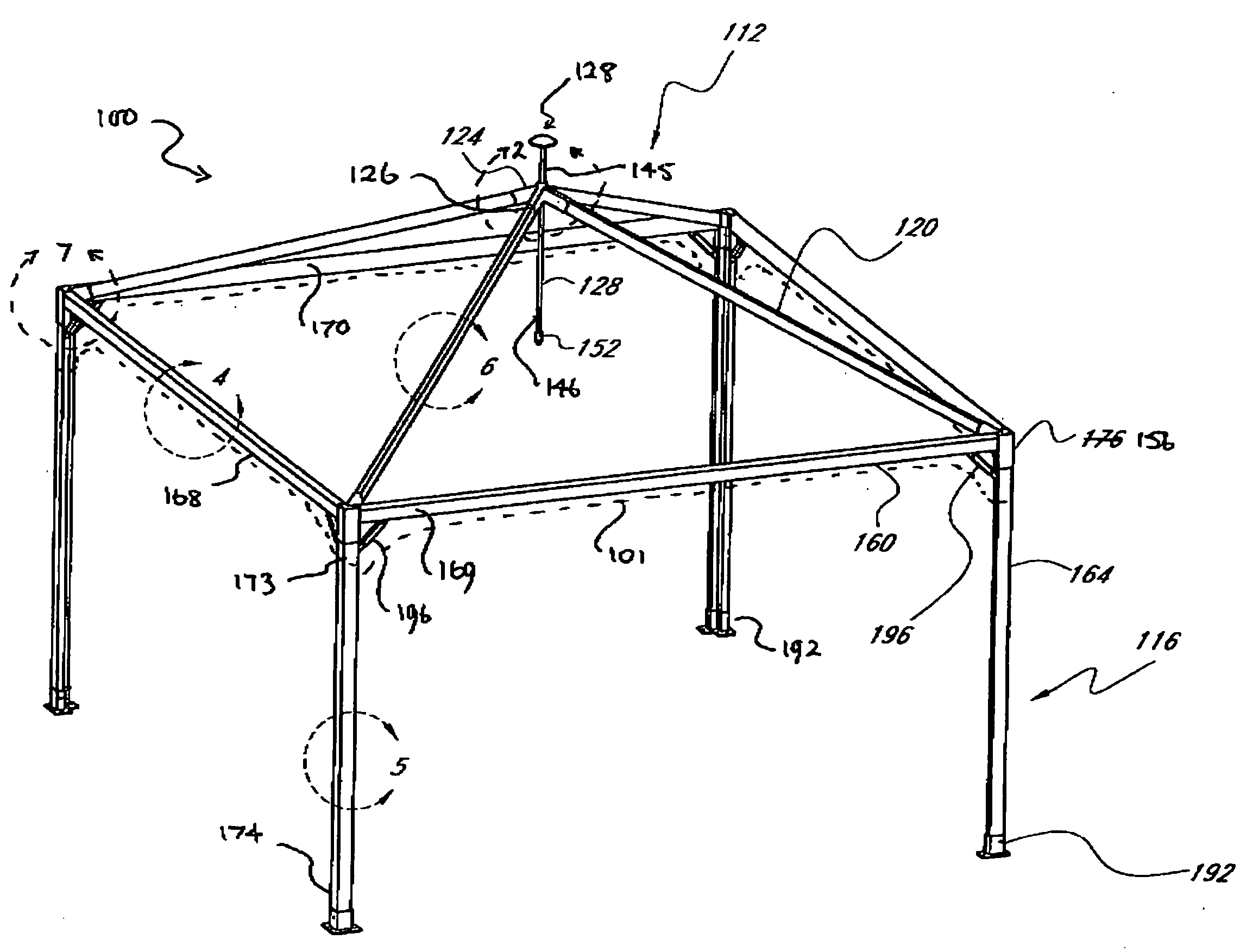

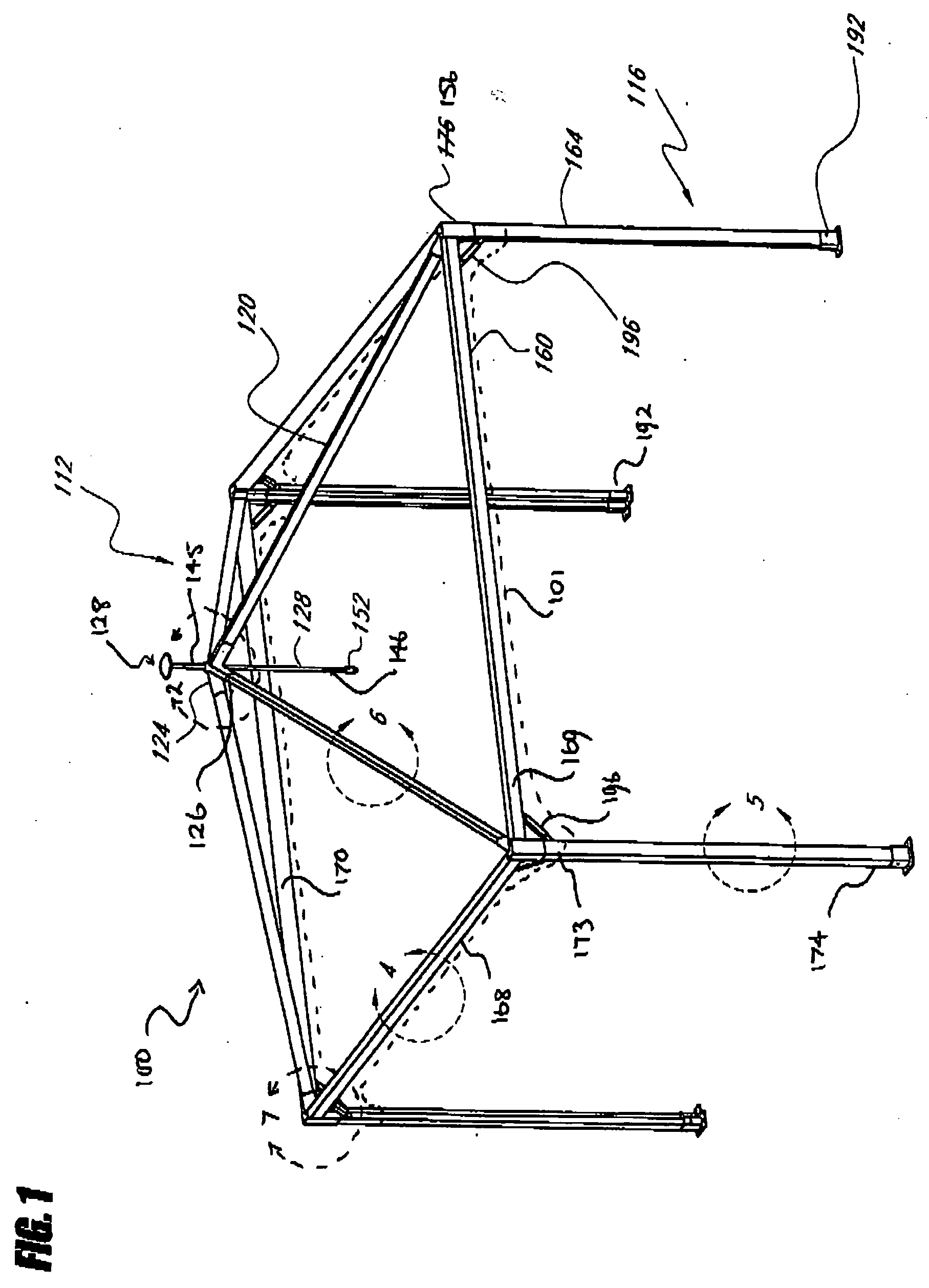

Bases and braces for support poles, such as poles for pavilions and umbrellas

ActiveUS7628164B2Increase the effective sectionStable structureTents/canopiesStands/trestlesEngineeringSupport surface

Bases are disclosed that comprise a projecting portion designed to receive over it the hollow end of a pole or other elongate member, which may form part of a structure such as a pavilion or umbrella. The projecting portion of the base comprises wedges that move in response to the end of the pole moving over the projecting portion and in so moving, the wedges increase the effective cross section of the projecting portion to engage the inner surface of the end of the pole and to thereby stabilize the structure on a support surface, such as the ground. Braces are also disclosed that pull together adjacent poles of a pavilion to make the structure more rigid.

Owner:JOEN AN MA OLIVER

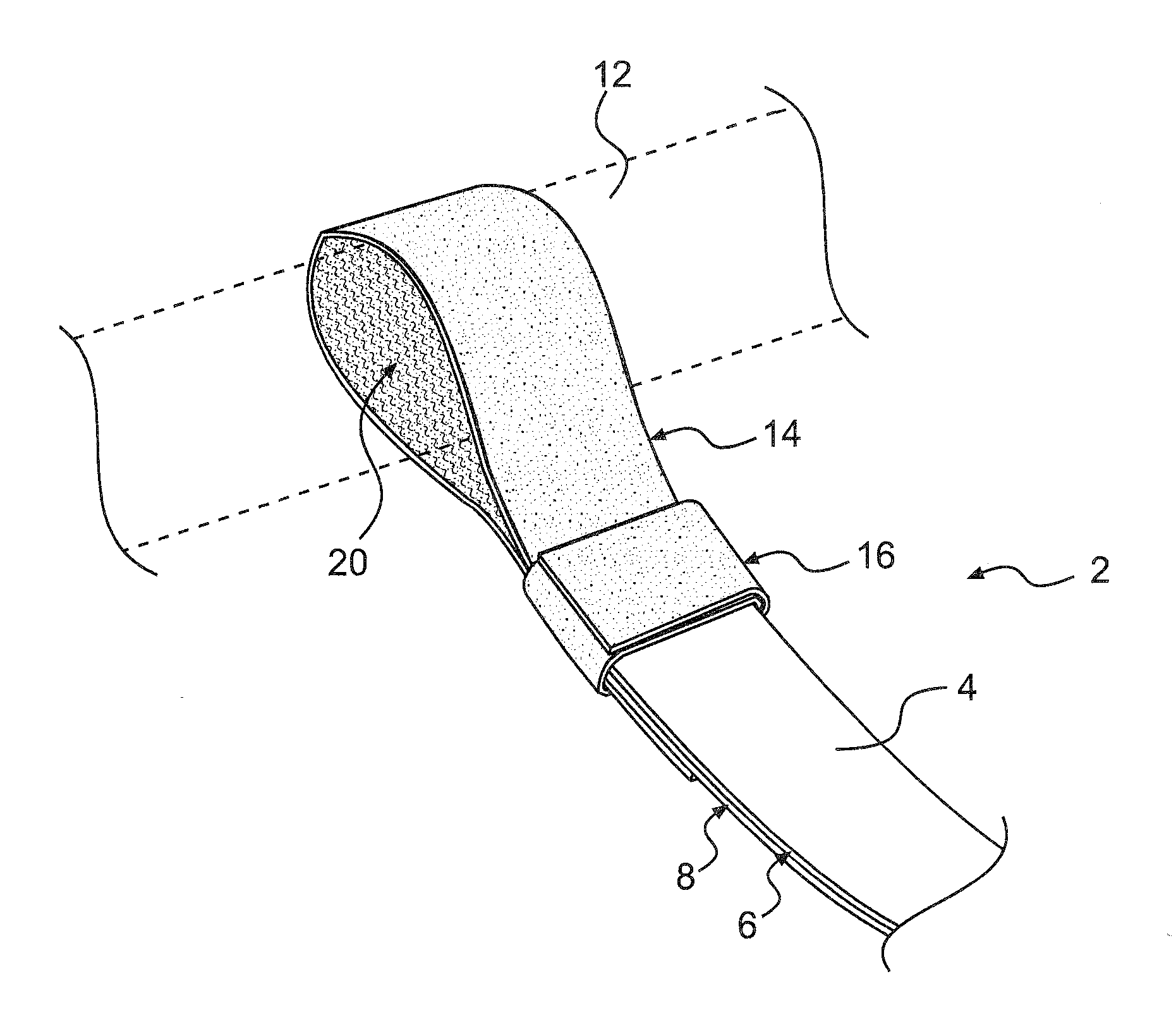

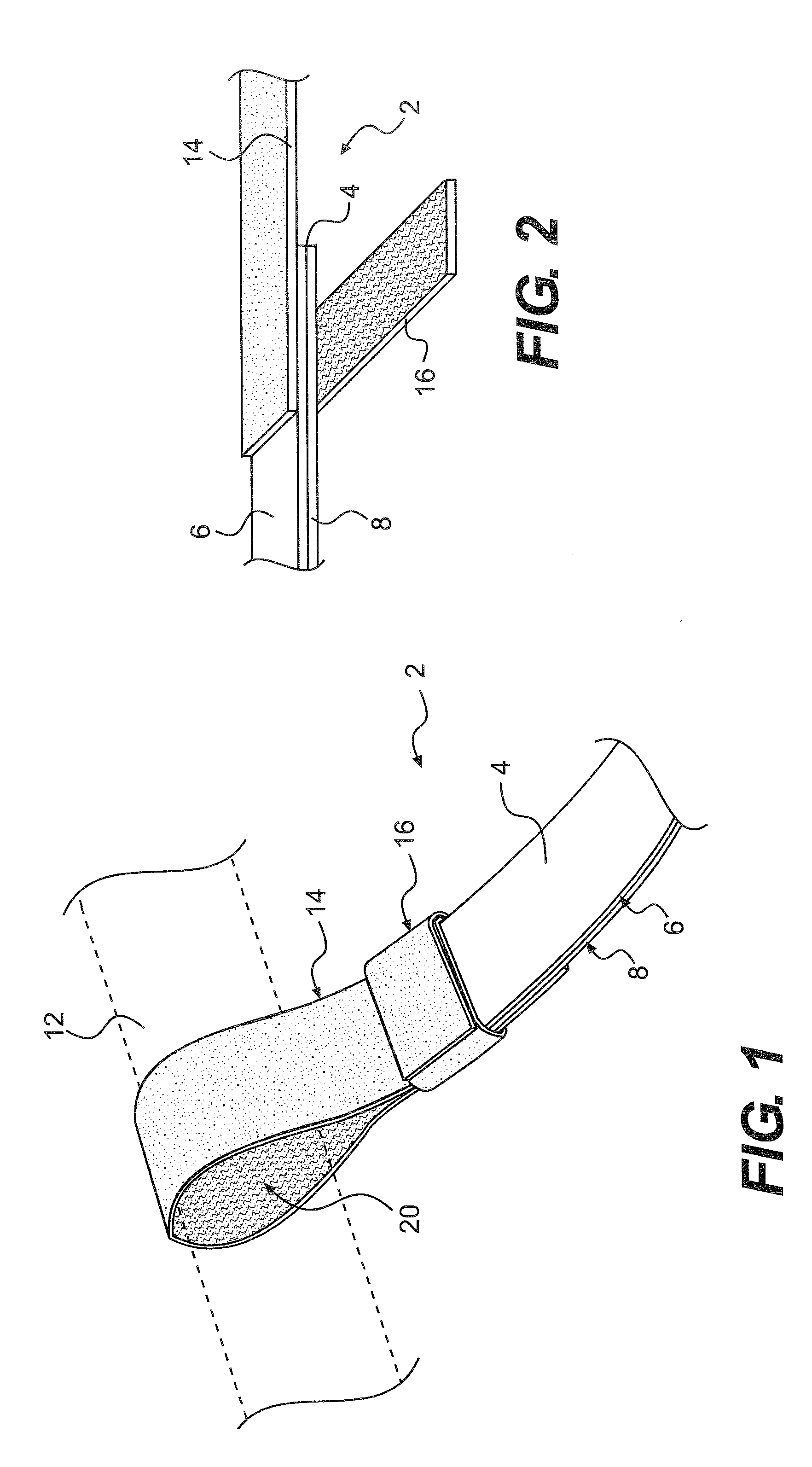

Stretchable, elastic tie-down device with fabric fastening means

InactiveUS20100257703A1Rigid structureHigh strengthSnap fastenersClothes buttonsAnchor pointRigid structure

The invention relates to an elastic tie down device with flexible, fabric hook and loop fastener panels that reduce or eliminate the safety and other risks associated with tie down devices that include rigid structural elements such as hooks, locks, clamps, and the like. Such a device would prevent damage or marring of the surface to which the tie-down device is being secured. The tie-down device would be suitable with a wide range of connection points so as to be operable with larger anchor points or oddly shaped anchor points that are not operable with traditional tie down hooks. The improved device might also allow for the selective attachment of a traditional, rigid hook.

Owner:VASS RICHARD G

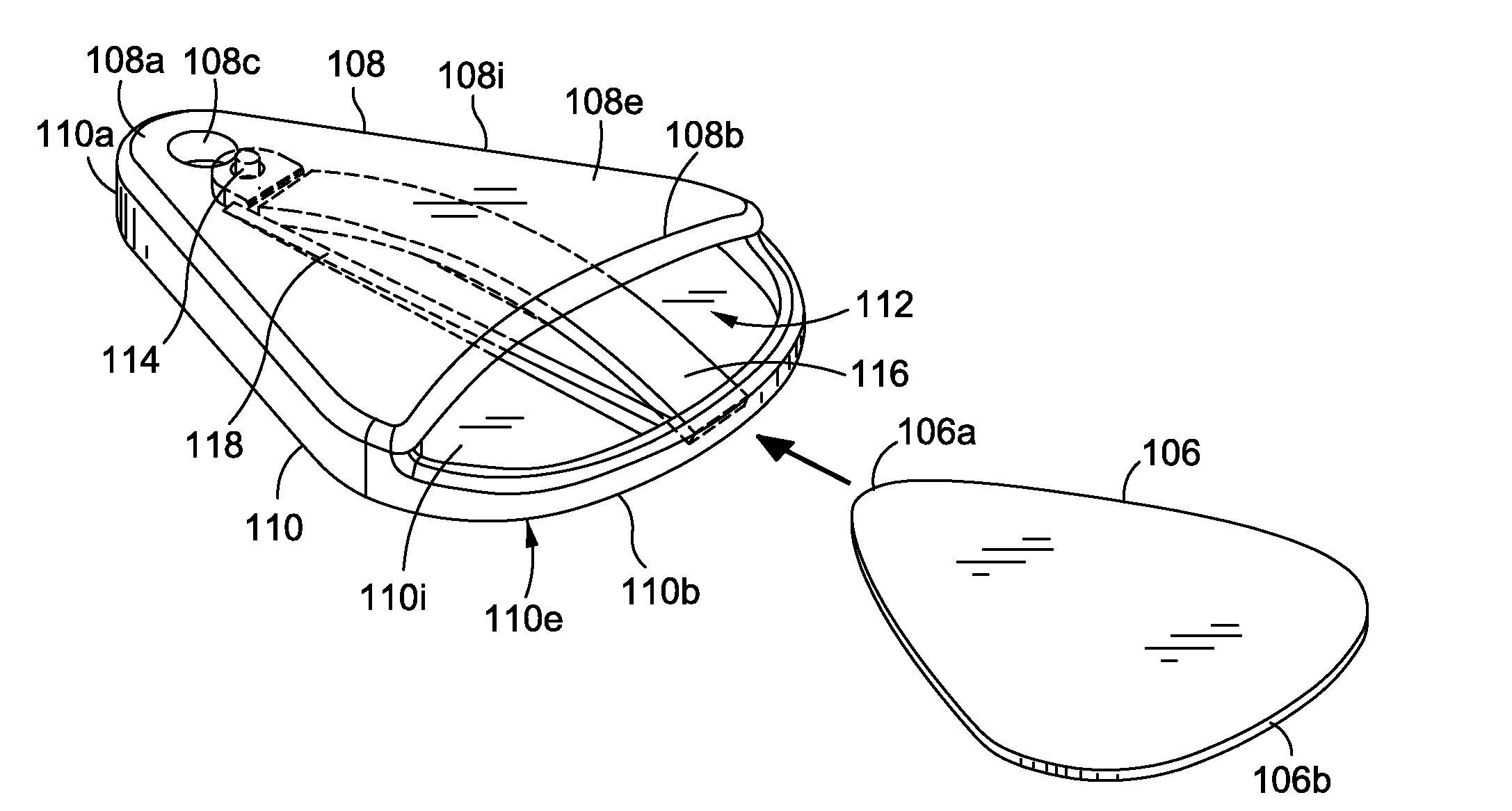

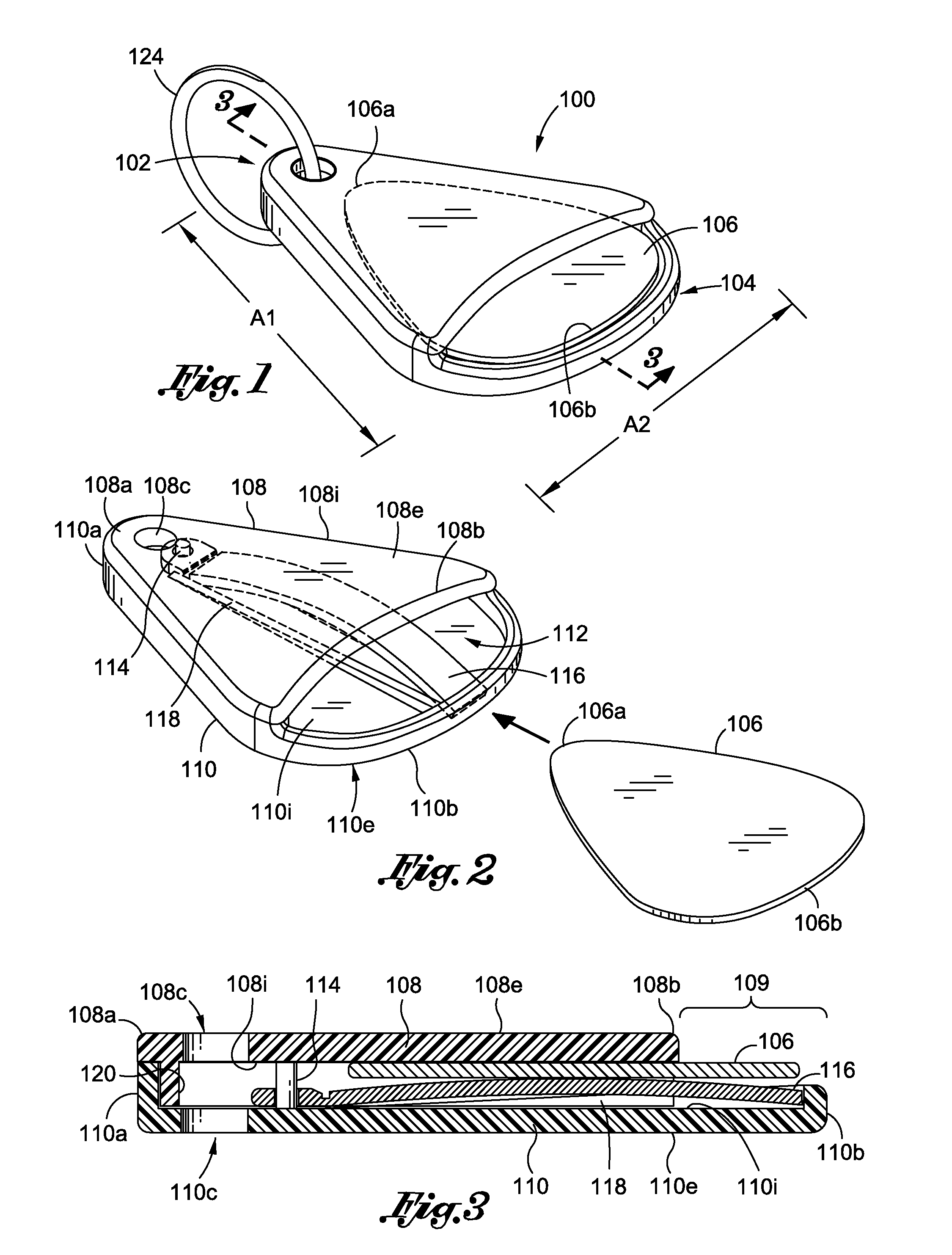

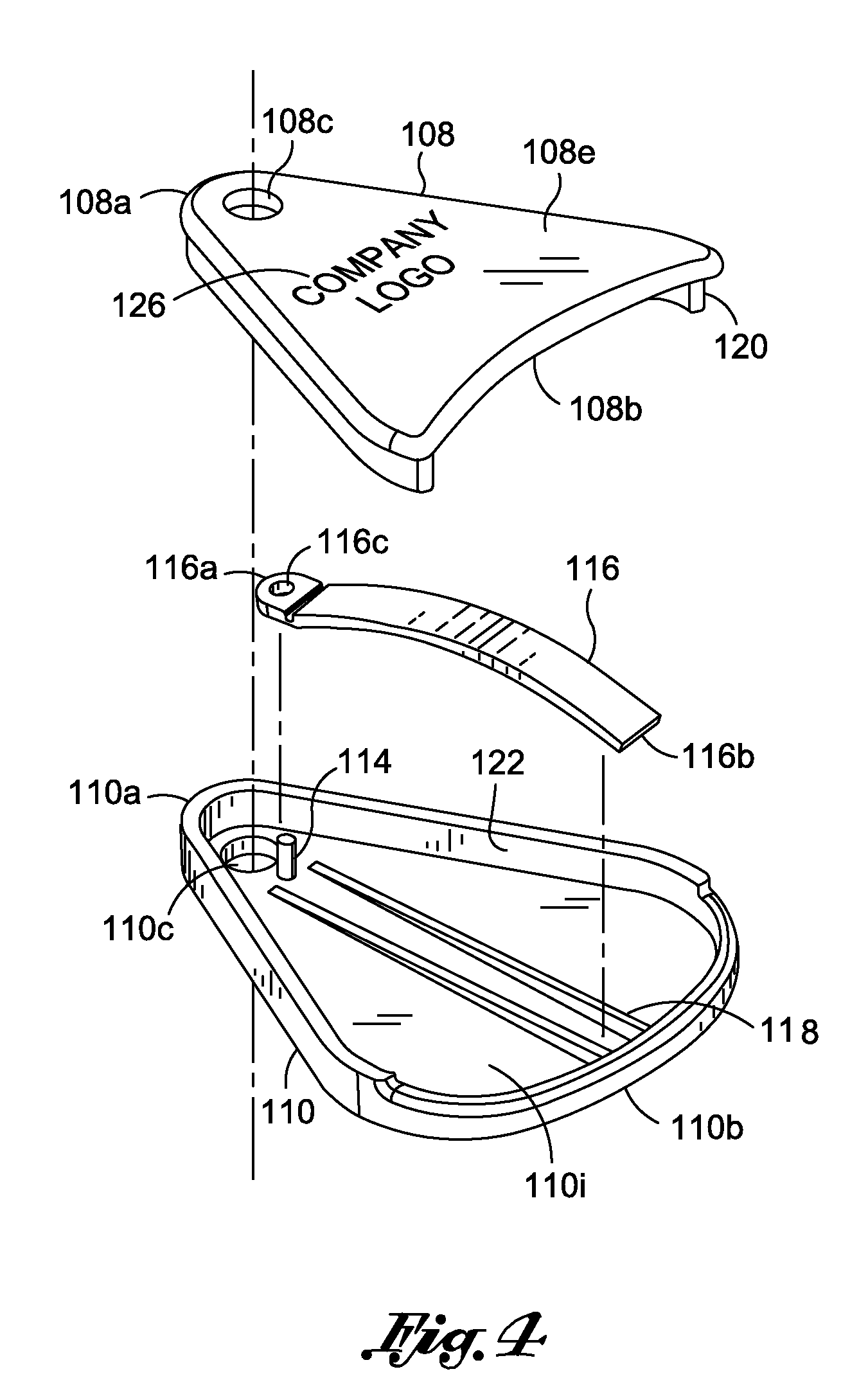

Musical instrument pick holder

InactiveUS7626103B1Easy accessRigid structureStringed musical instrumentsEngineeringTemporary storage

A musical instrument pick holder that provides convenient temporary storage of one or more picks. The pick holder provides a housing that is the same or substantially the same shape as the pick. The pick holder stores one or more picks therein and provides for quick and easy access to the picks. The pick holder has an internal biasing member that releasably retains the picks therein. The pick holder further provides one or more exterior surfaces that are suitable for placement of advertising or marketing indicia or graphical elements. The pick holder further comprises a key ring or other clasping element for releasable coupling with another items such as the garment of a musician.

Owner:PHILLIPS WILLIAM A

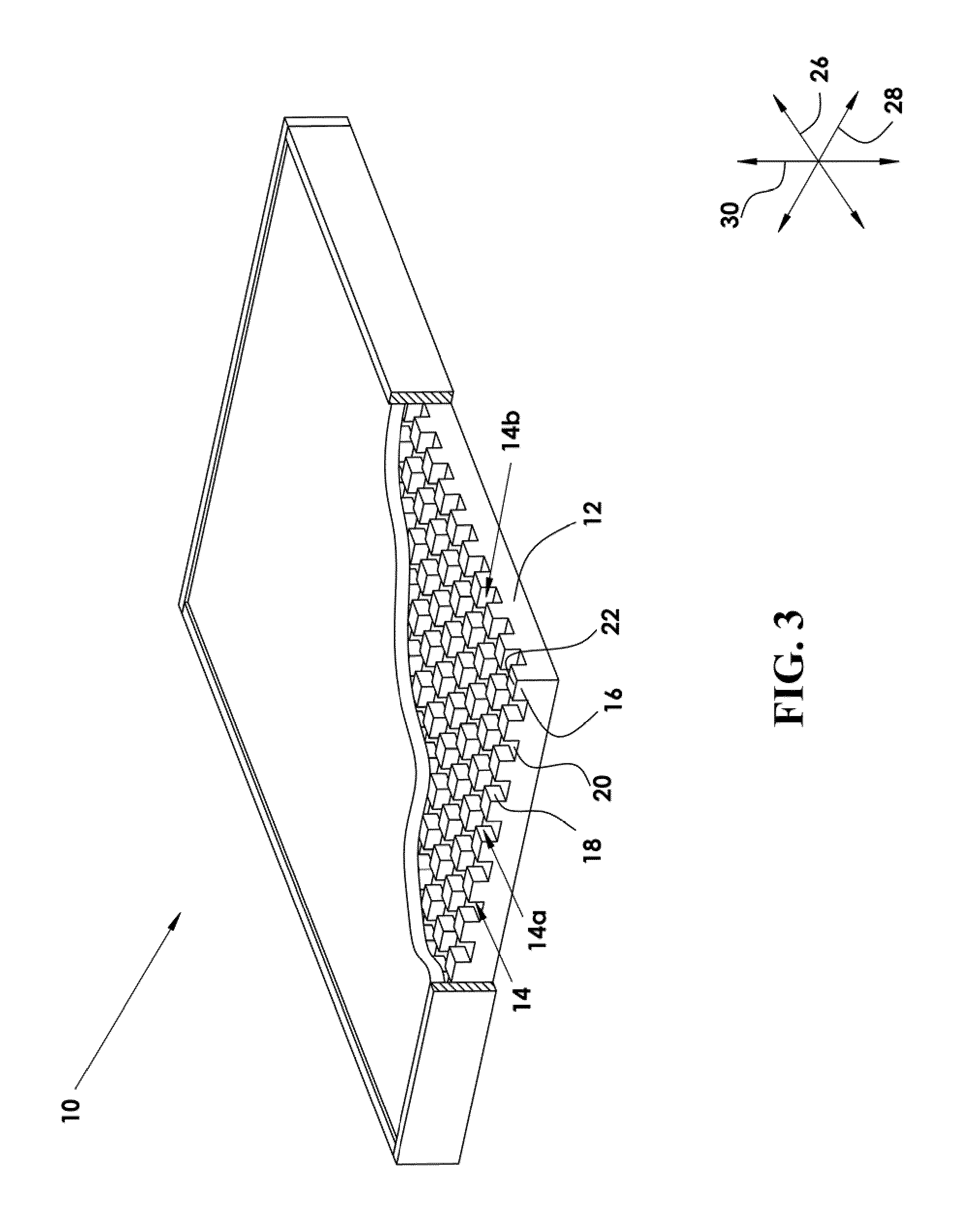

Collapsible wing and unmanned aircraft system including collapsible wing

ActiveUS9010693B1Rigid structureEasily transportAircraft stabilisationRemote controlled aircraftAirplaneJet aeroplane

A collapsible wing, methods of producing the collapsible wing, and an unmanned aircraft system that includes the collapsible wing are provided.

Owner:CAWTU

Mechanical scanner

InactiveUS20080142728A1Quick scanReduce vibrationThermometer detailsBeam/ray focussing/reflecting arrangementsIon beamEngineering

A mechanical scanner for ion implantation of a substrate, the mechanical scanner comprising a hexapod with a movable platform for holding the substrate, wherein the hexapod is arranged to have six degrees of freedom to allow the movable platform to be traversed relative to an ion beam along a predetermined path.

Owner:APPLIED MATERIALS INC

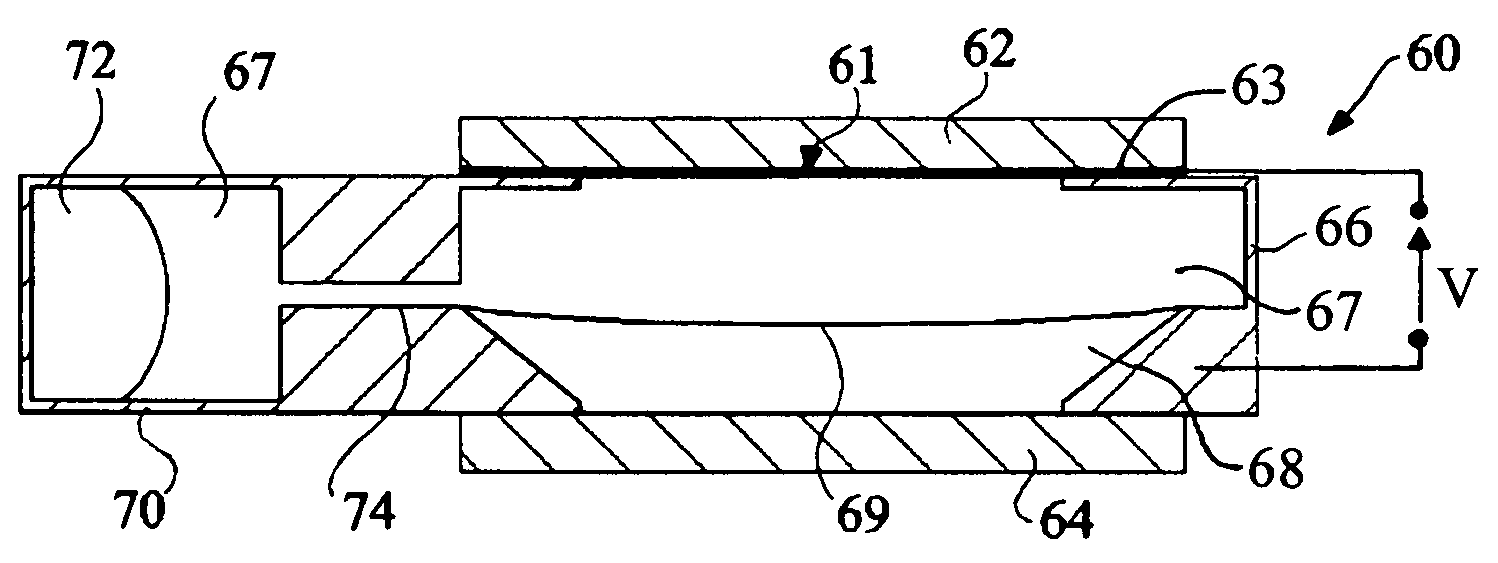

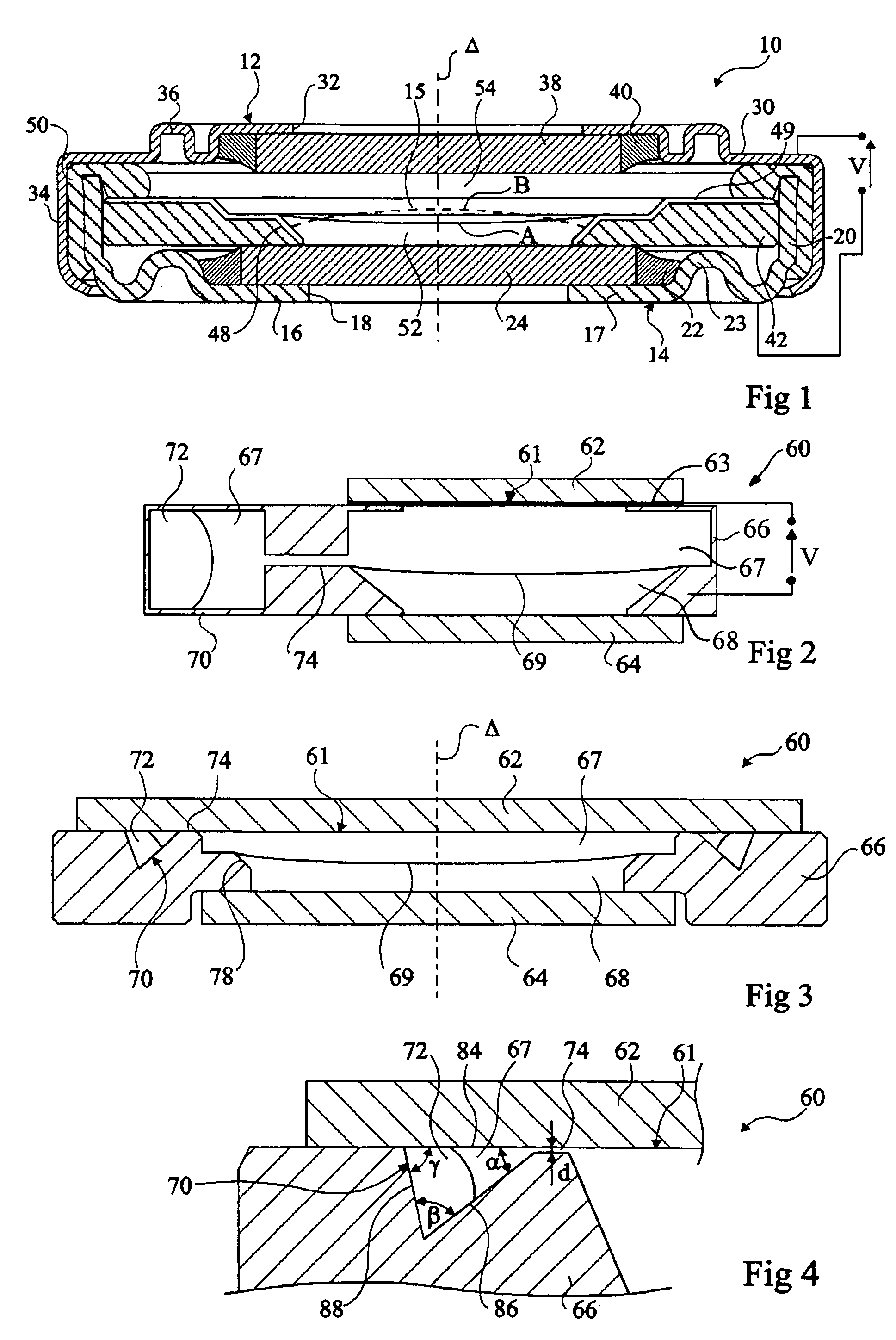

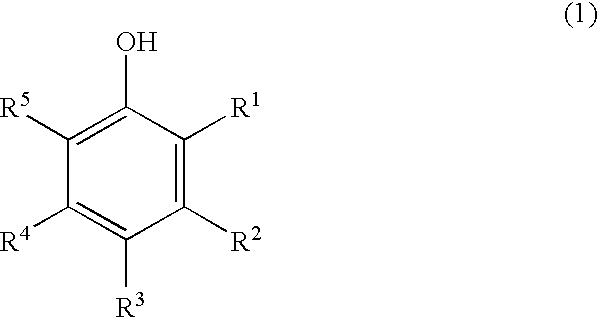

Variable-focus lens and method of manufacturing the same

Owner:INVENIOS FRANCE SAS

Optical disc and ultraviolet-curable composition for optical disc

InactiveUS20090207723A1Increased durabilityHigh fastnessMechanical record carriersRecord information storageEpoxyMeth-

An optical disc of the present invention includes at least a light reflection layer and a light transmission layer formed on a substrate, wherein recording and reading are performed by a laser beam through the light transmission layer, the light transmission layer is formed from a cured film of a ultraviolet-curable composition containing an epoxy acrylate resin obtained by reacting a half ester compound (A), which is obtained from a lactone-adduct of a hydroxyalkyl (meth)acrylate (a1) and a dibasic acid anhydride (a2), and an epoxy resin (B), and the film thickness of the light transmission layer is from 50 to 150 μm.

Owner:DAINIPPON INK & CHEM INC

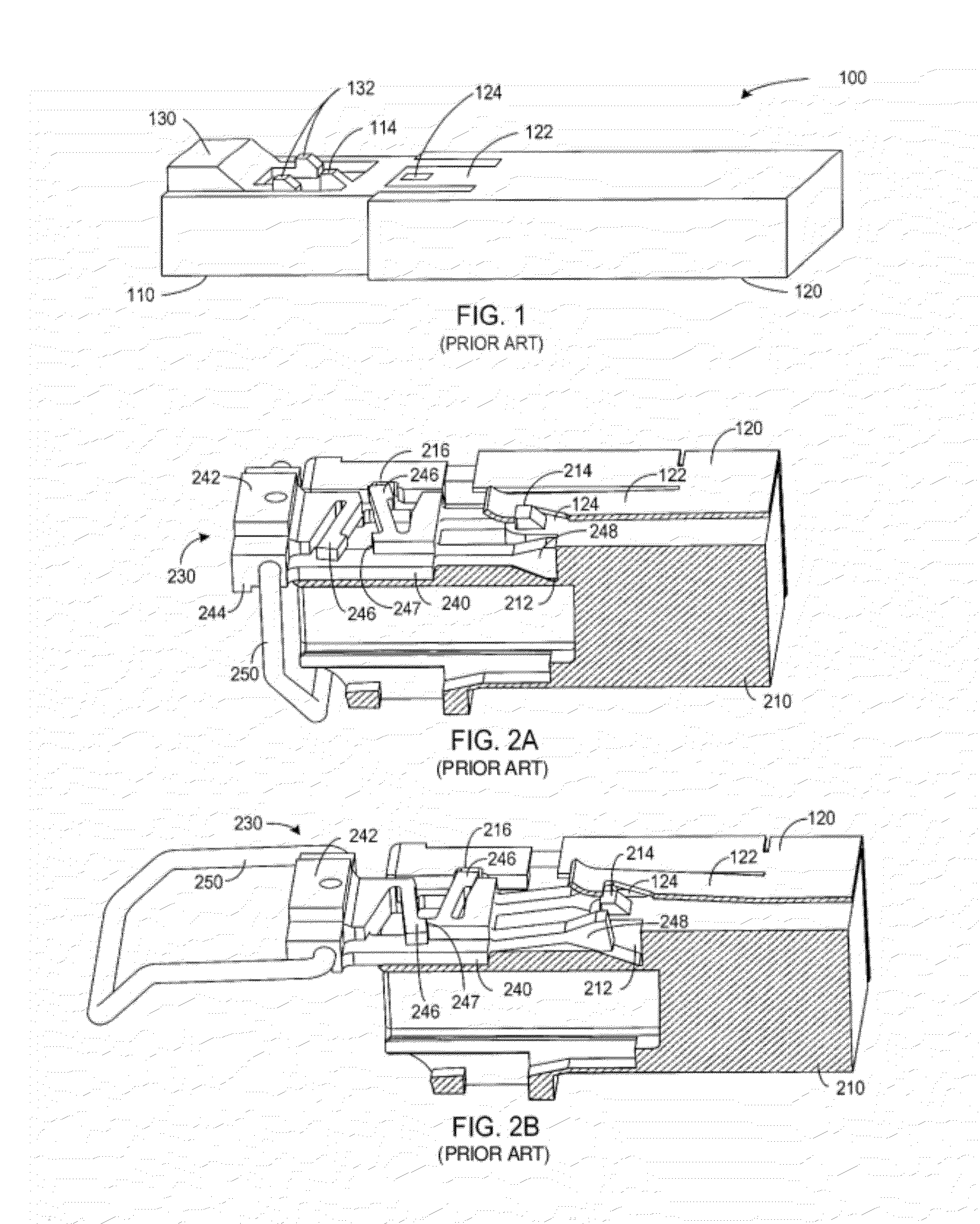

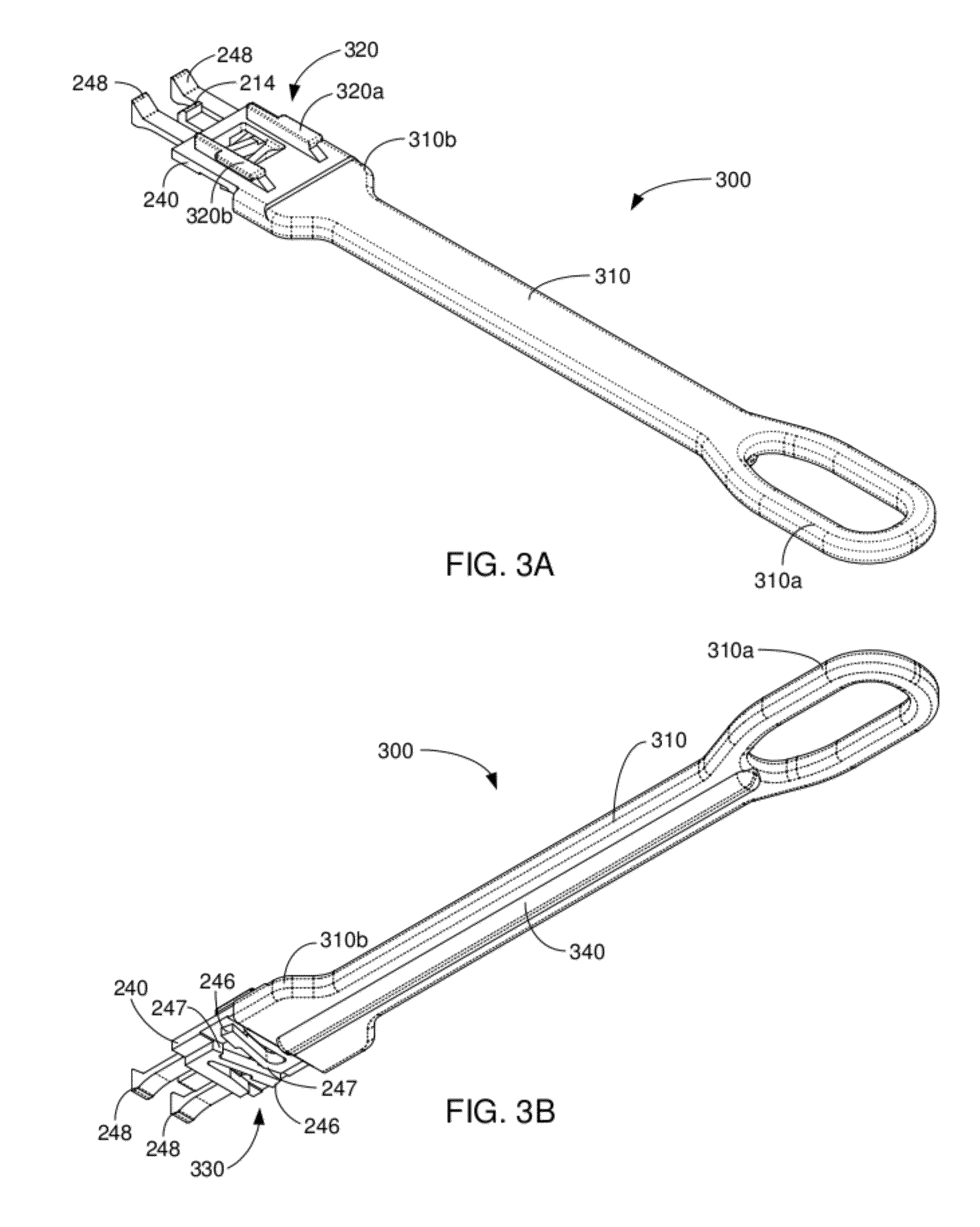

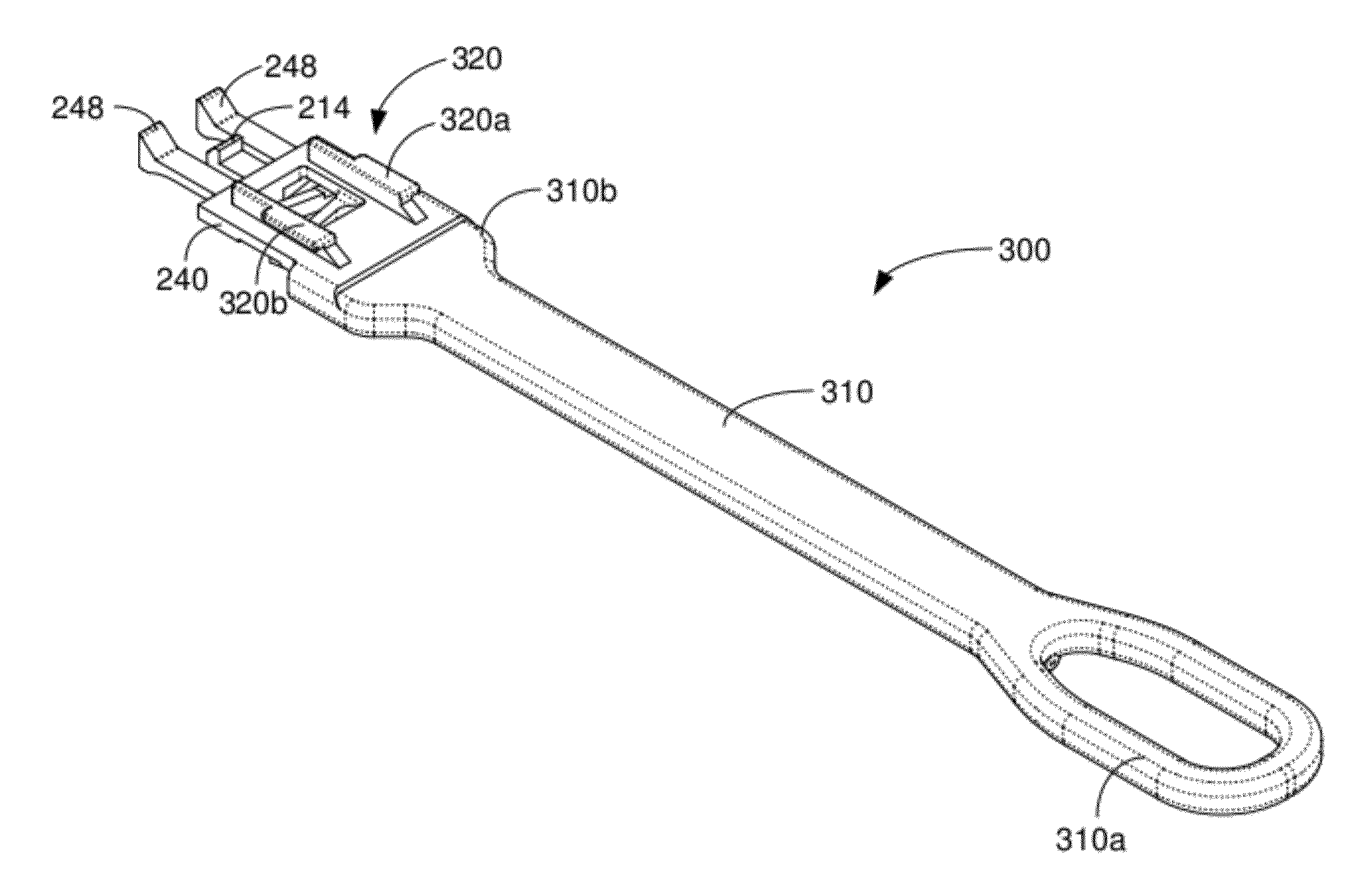

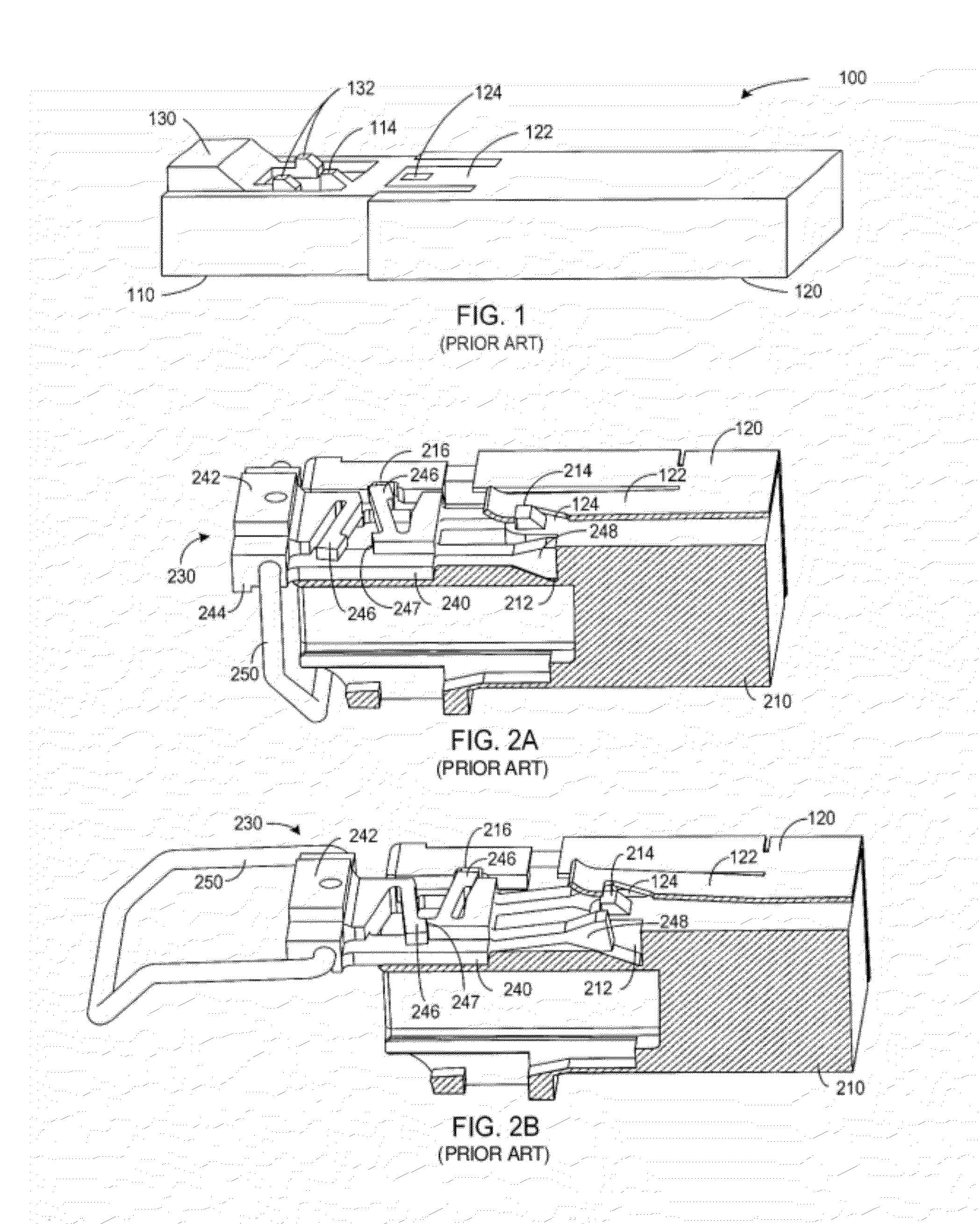

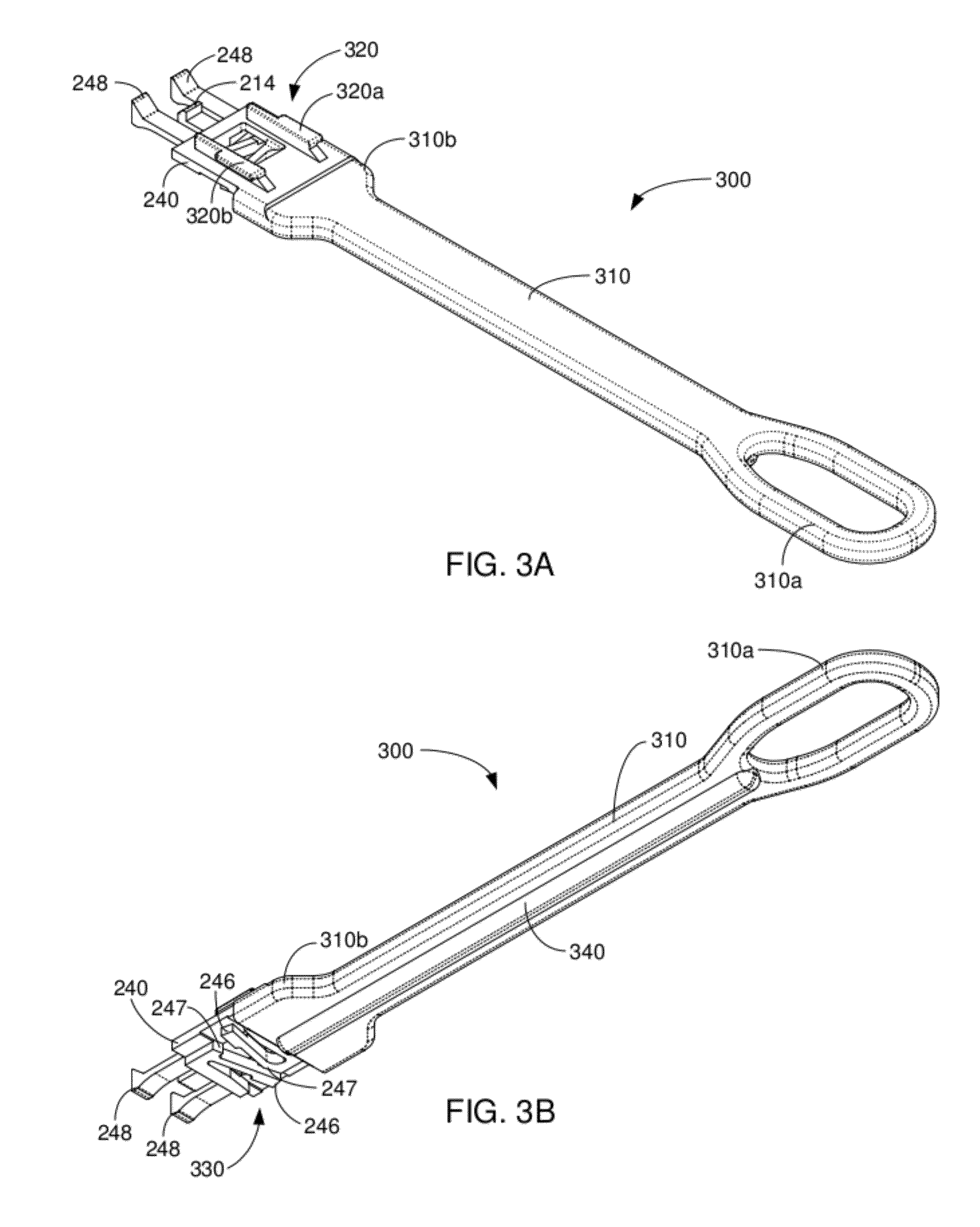

Delatch device having both push and pull operability for use with an optical transceiver module, and a method

ActiveUS20120027362A1Easy to pushRigid structureCoupling light guidesMetal working apparatusPush and pullTransceiver

An optical transceiver module is provided with a delatch device that is configured for pushing and pulling an optical transceiver module into and out of a cage. The delatch device includes an elongated handle having at least one strength member integrally formed therein or secured thereto that provides the handle with a sufficient moment of inertia to prevent the handle from bending or buckling when a force is being applied to the elongated handle to push an optical transceiver module into a cage. The elongated handle allows a module to easily be inserted into a cage by a user without the user having to directly access the front face of the module.

Owner:AVAGO TECH INT SALES PTE LTD

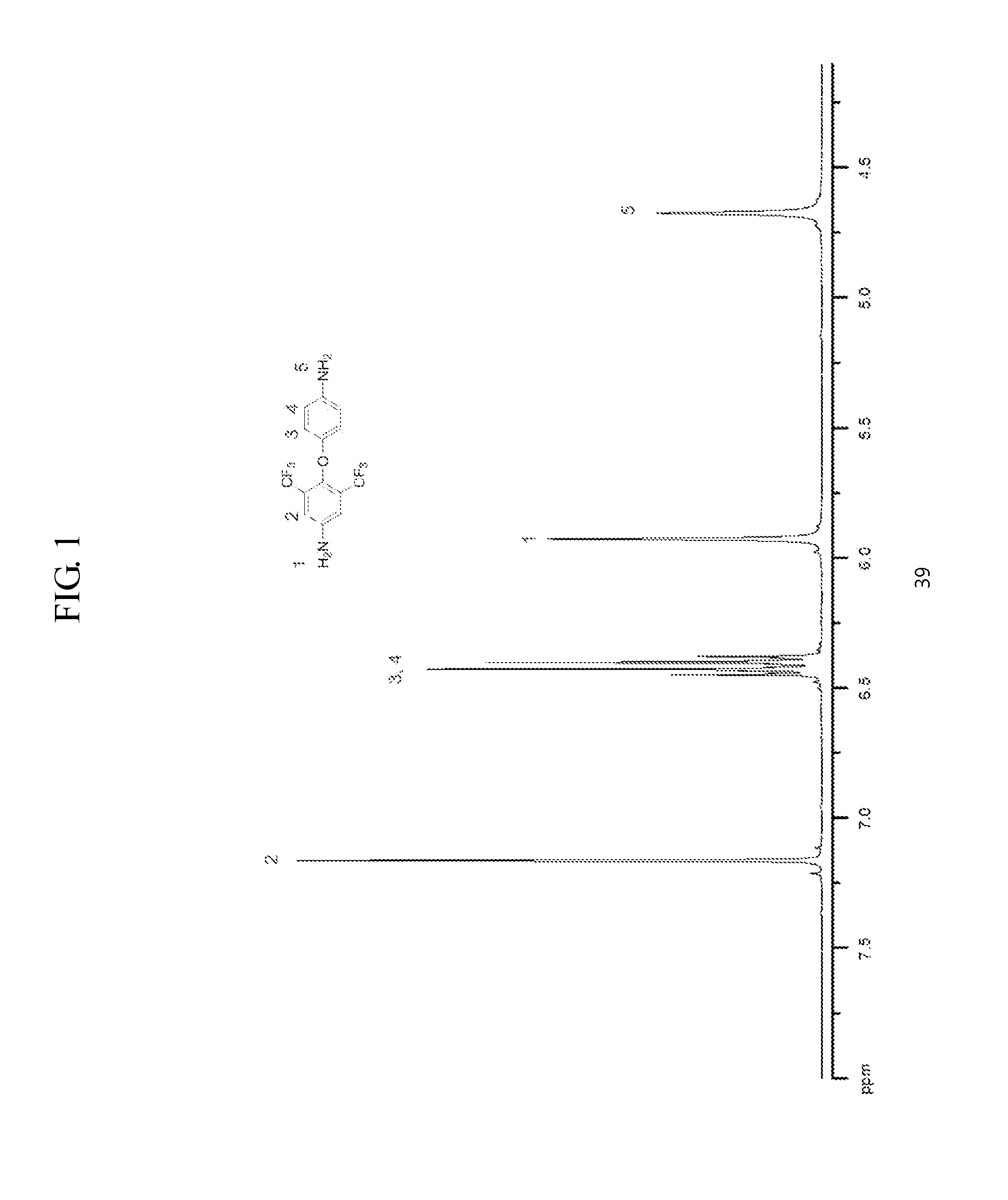

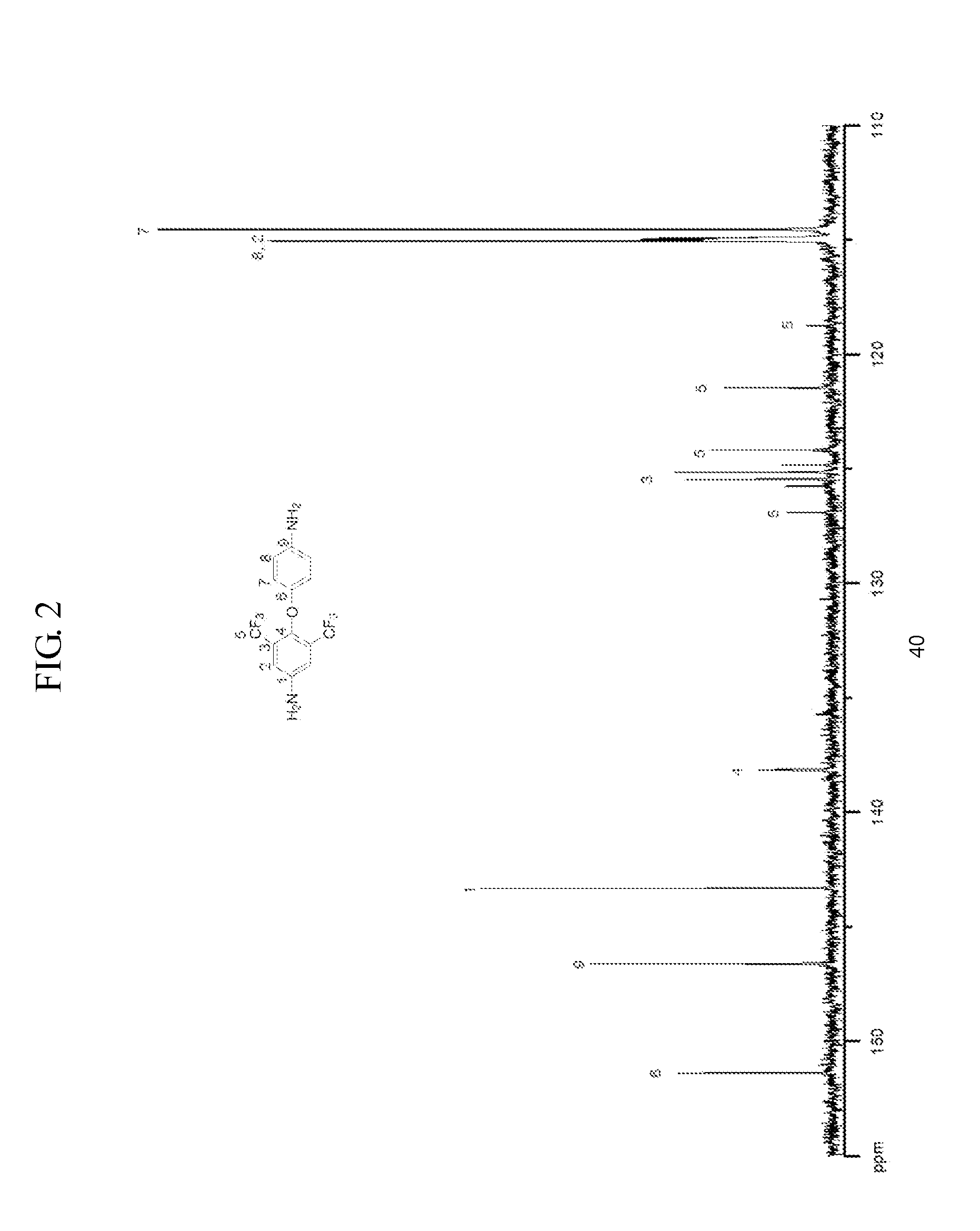

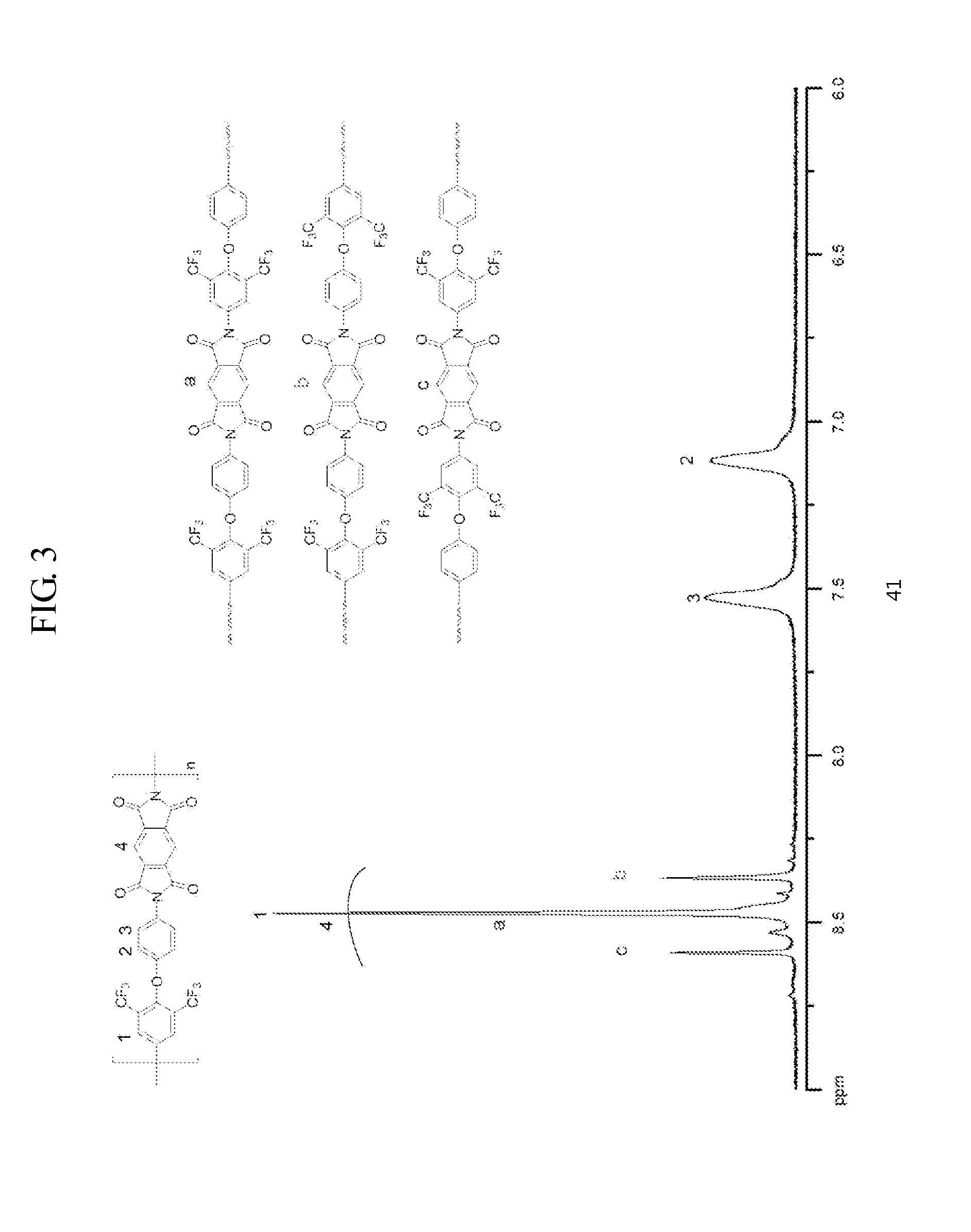

Asymmetric Diamine Compounds Containing Two Functional Groups and Polymers Therefrom

InactiveUS20150045481A1Improve solubilityLow refractive indexPlastic/resin/waxes insulatorsOrganic compound preparationSolubilityOptical property

The present invention relates to a novel diamine compound, wherein two substituents R and R′ are introduced asymmetrically, and a polymer thereof. The polymer may have excellent solubility in the organic solvent and allows for easy processibility after imidization, thus giving proper film maintaining superior properties, such as thermal, mechanical, and optical properties for applications in electrical, electronic, or optical materials.

Owner:KOREA ADVANCED INST OF SCI & TECH

Delatch device having both push and pull operability for use with an optical transceiver module, and a method

An optical transceiver module is provided with a delatch device that is configured for pushing and pulling an optical transceiver module into and out of a cage. The delatch device includes an elongated handle having at least one strength member integrally formed therein or secured thereto that provides the handle with a sufficient moment of inertia to prevent the handle from bending or buckling when a force is being applied to the elongated handle to push an optical transceiver module into a cage. The elongated handle allows a module to easily be inserted into a cage by a user without the user having to directly access the front face of the module.

Owner:AVAGO TECH INT SALES PTE LTD

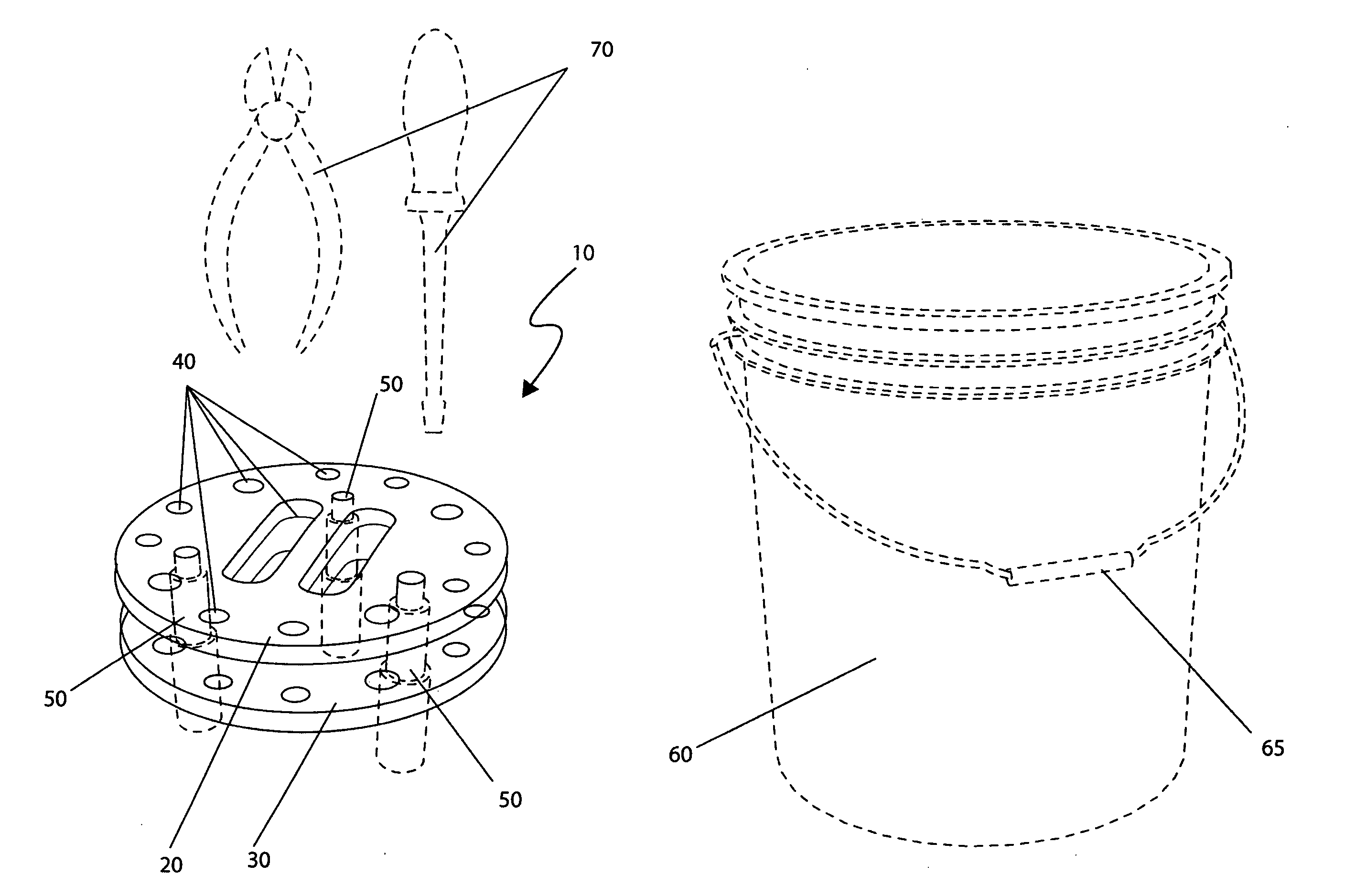

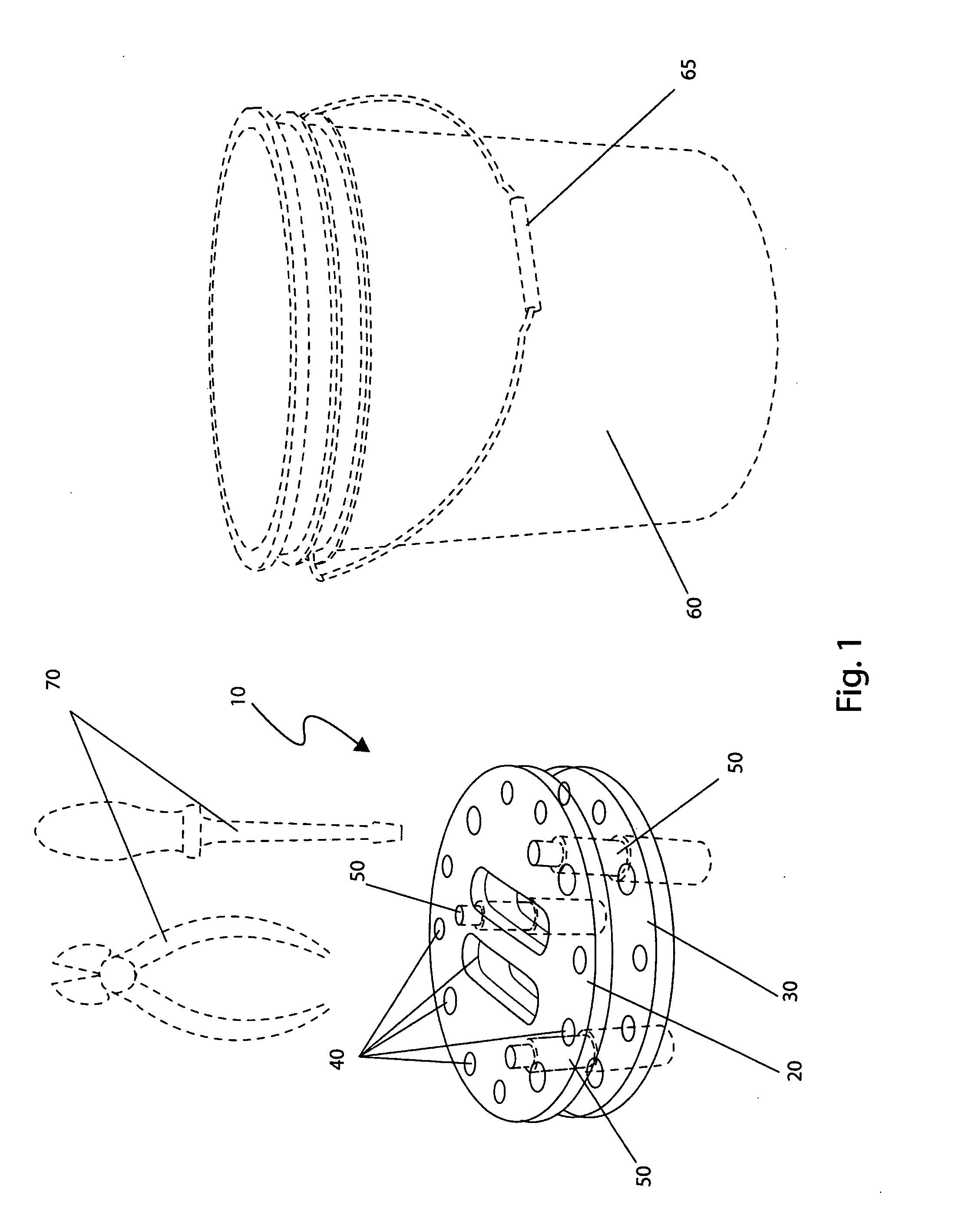

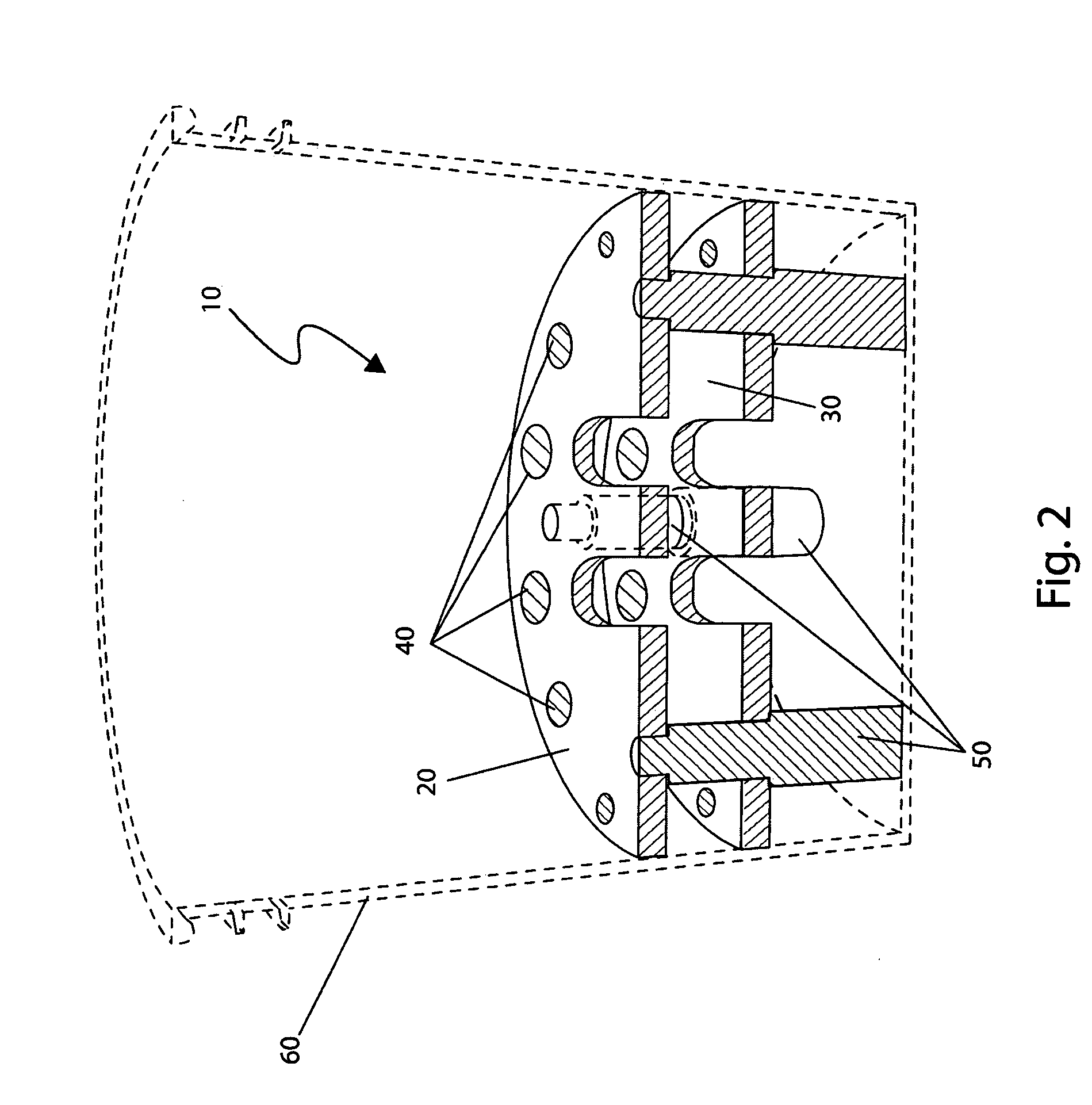

Tool bucket organizer

InactiveUS8127965B1Rigid structureShorten the timeInternal framesOther accessoriesEngineeringSmall hand

An insert for containers designed to store and organize small hand tools comprising two (2) discs, each of a slightly smaller diameter than the interior diameter of the bucket is herein disclosed. Each disc is provided with multiple holes and slots to hold various types of hand tools. The discs are separated a few inches from each other and the lower insert is held off the bottom of the bucket by a set of legs. The insert is designed to hold hand tools such as screwdrivers, pliers, wrenches, hammers, utility knifes and the like. The configuration of the discs allows each tool to stand upright and not fall over, enabling a user to quickly find a desired hand tool.

Owner:MILLER KIRK W

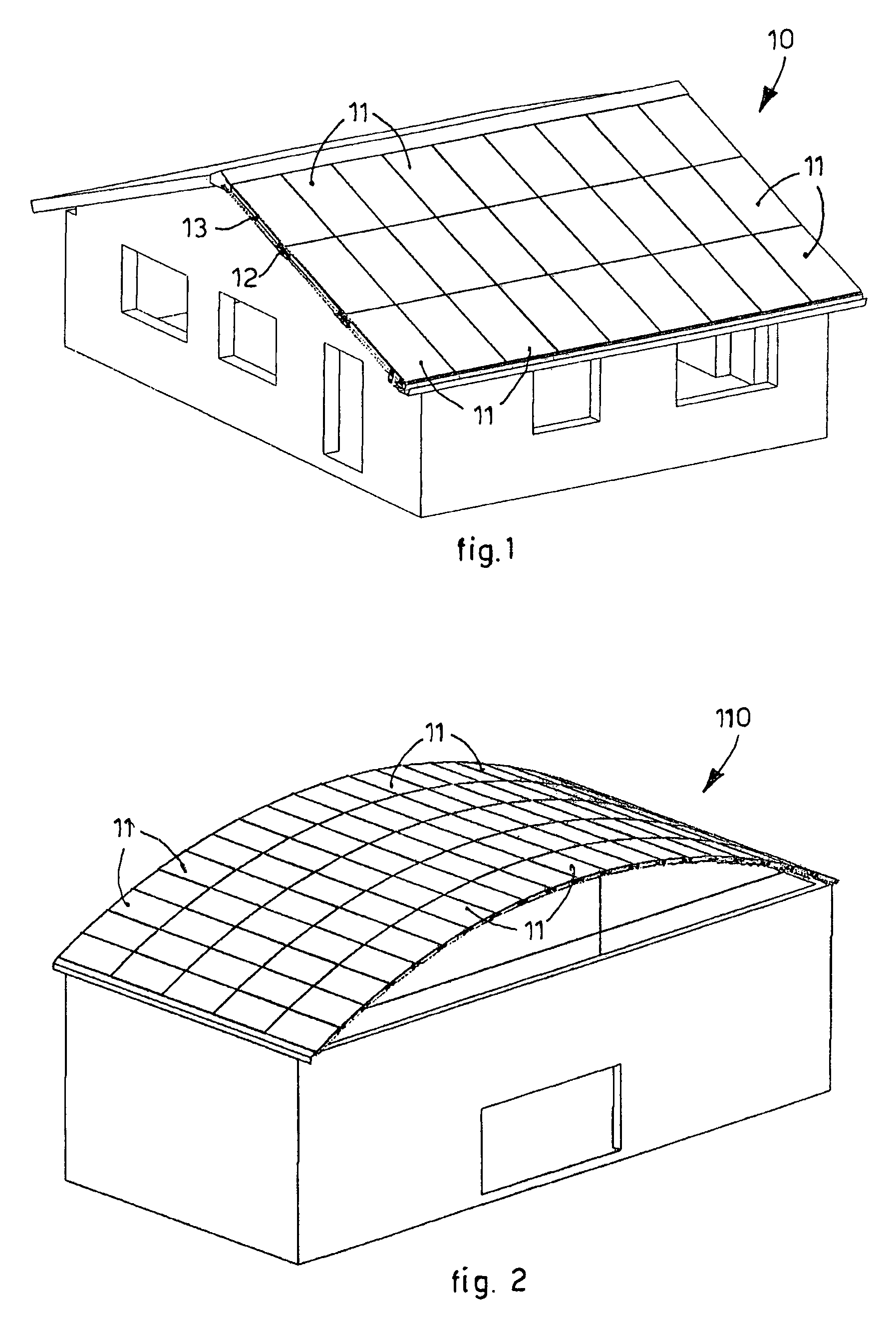

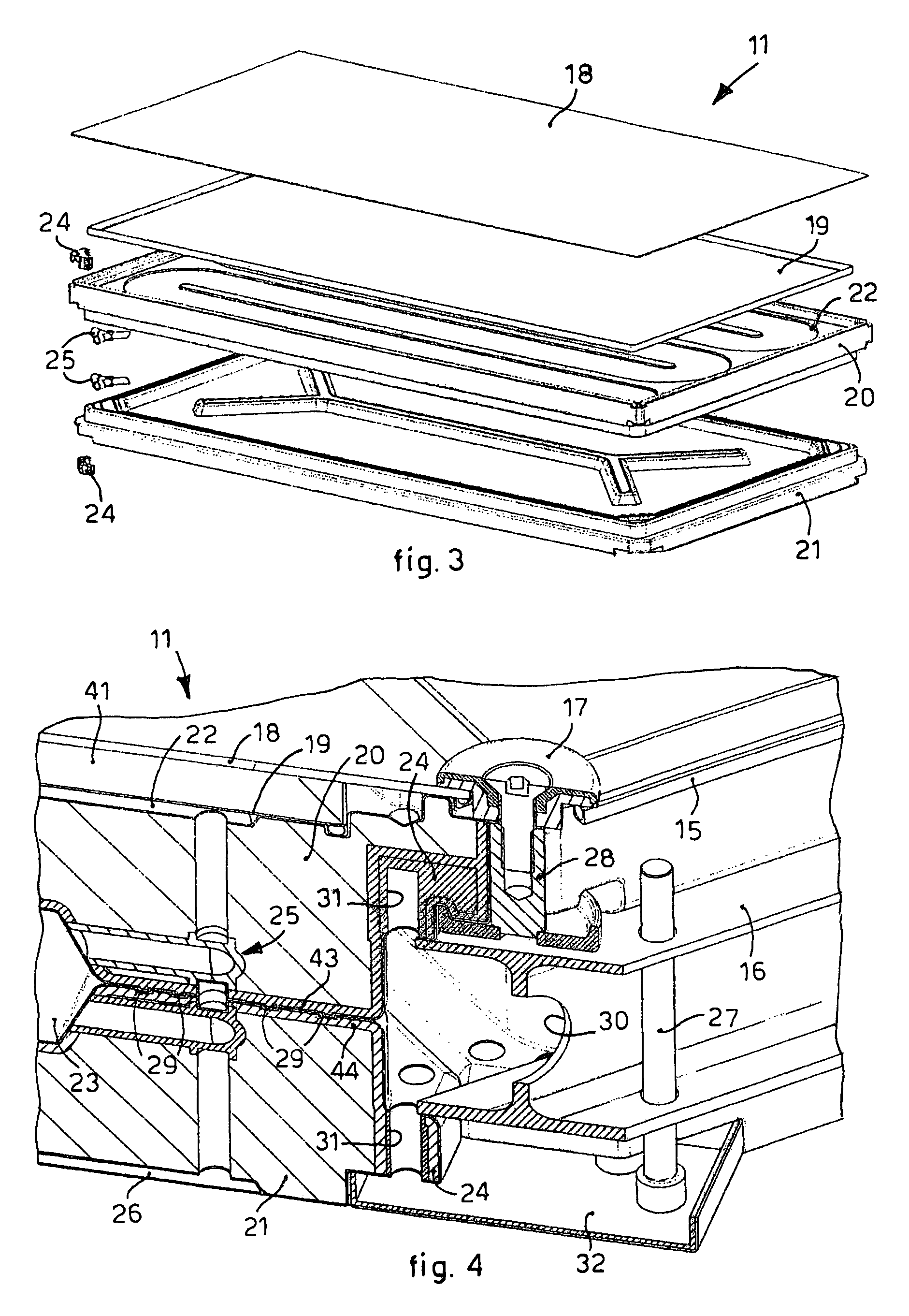

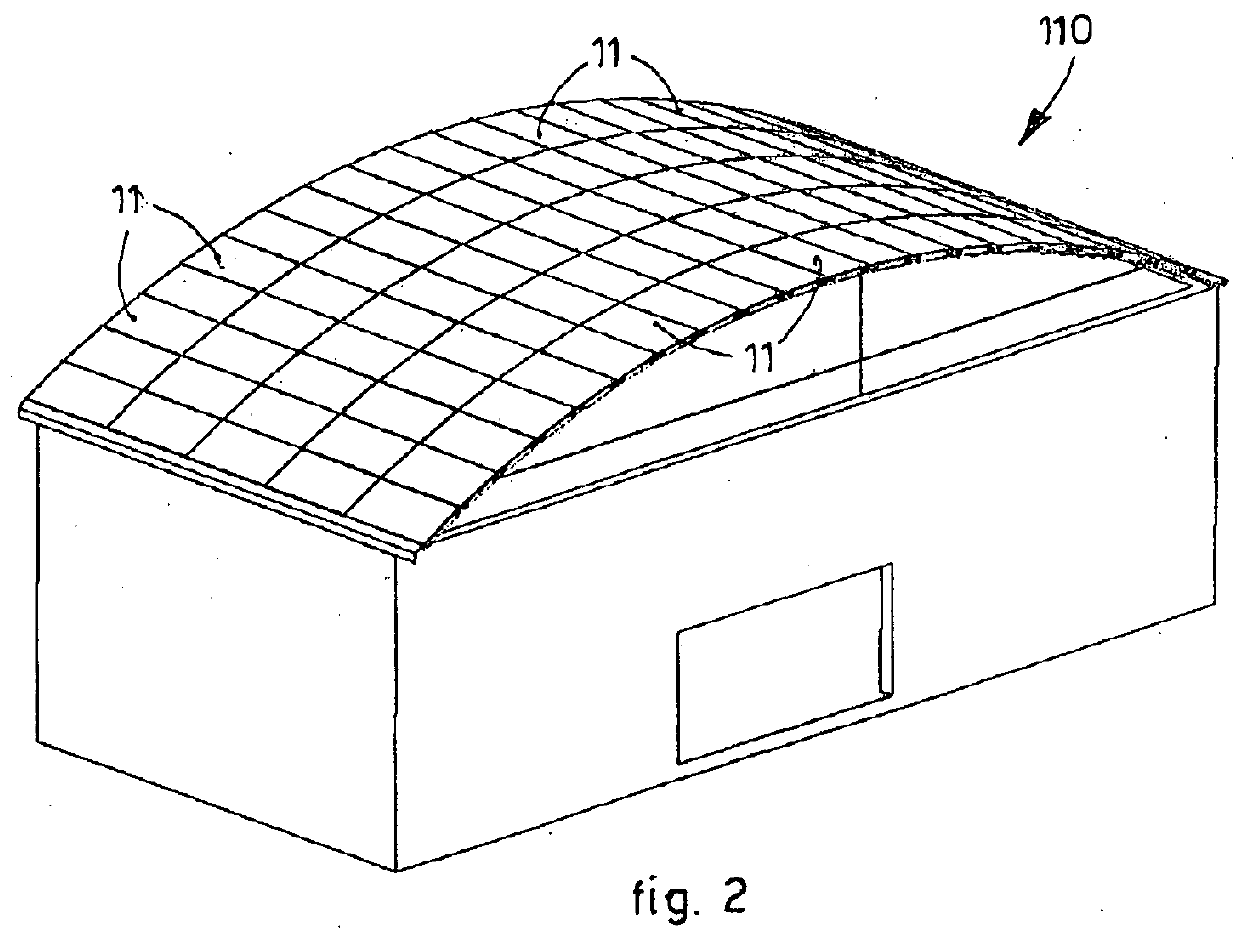

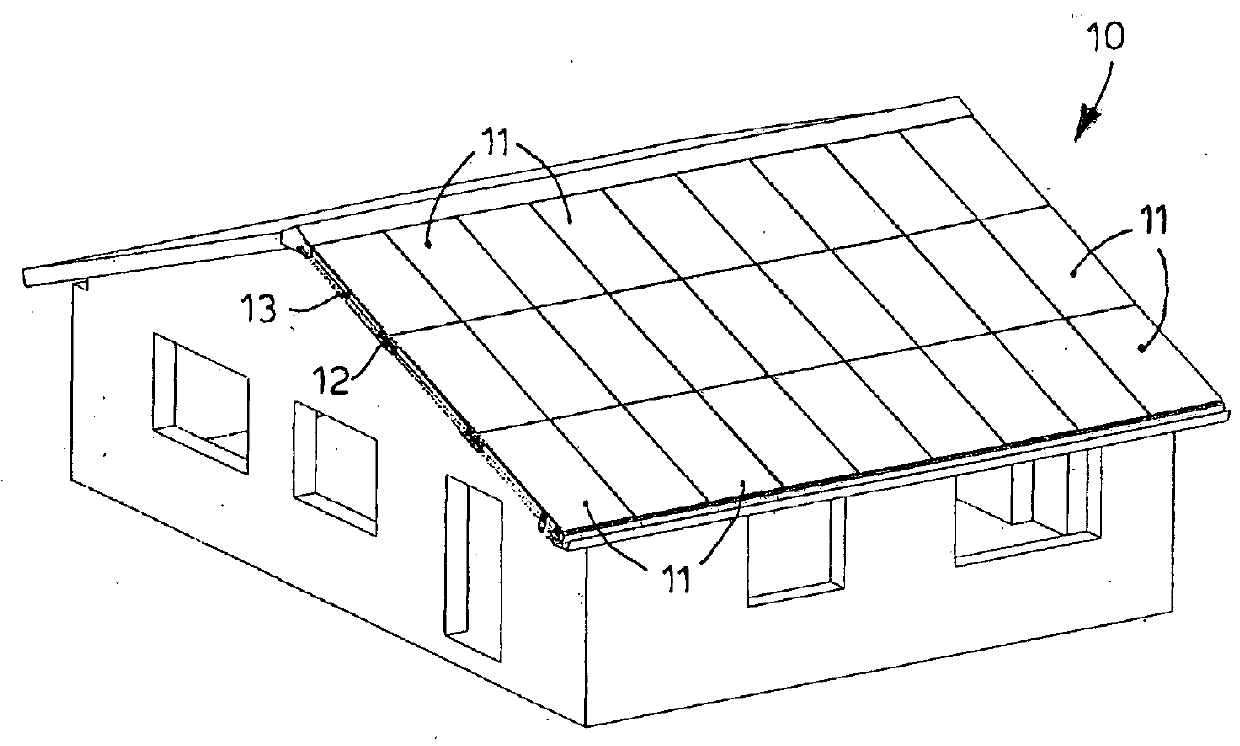

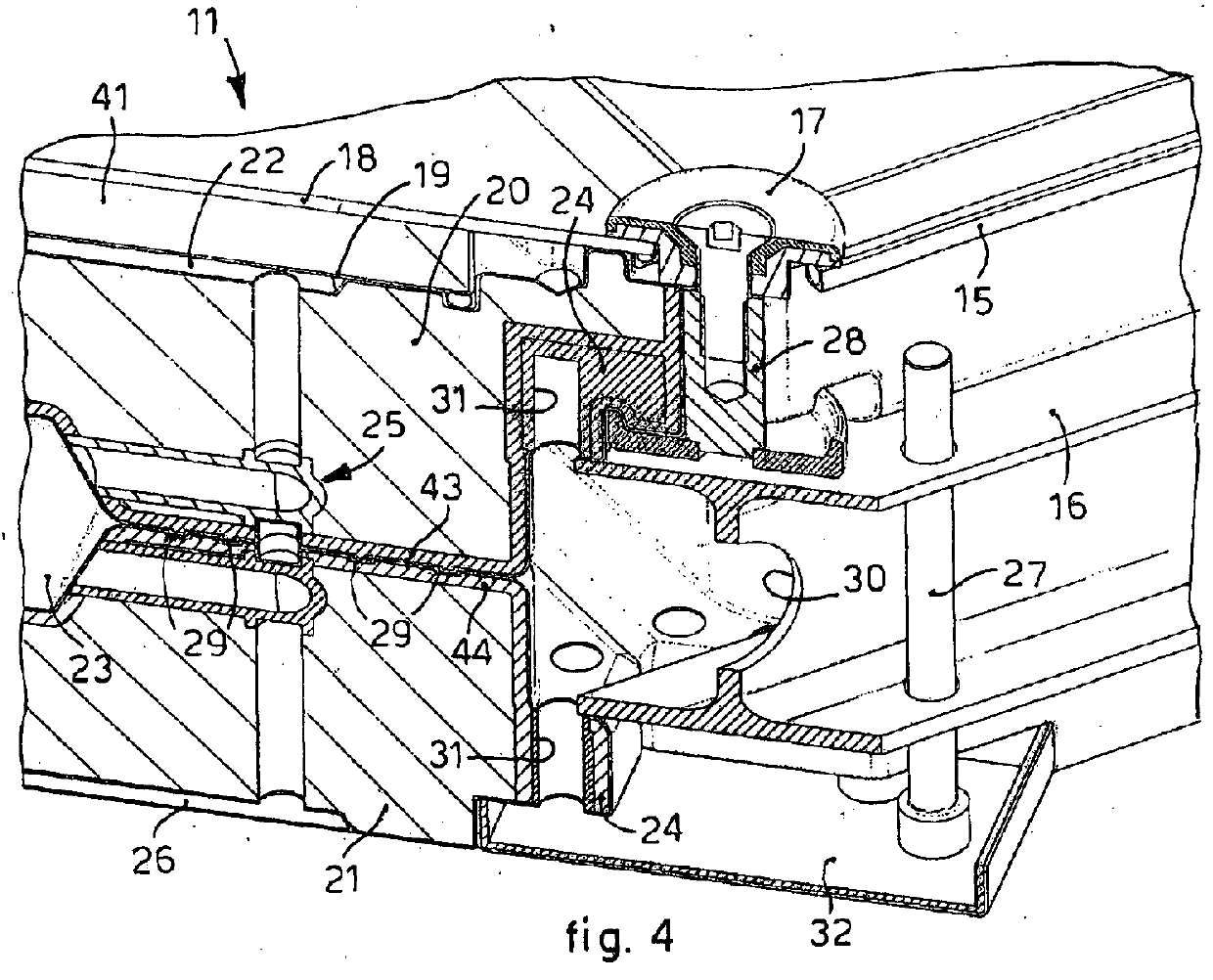

Modular panel for making covering structures for walls, covering structures or walls and method

InactiveUS9010040B2Confer structural rigidityImprove insulation performancePhotovoltaic supportsRoof covering using slabs/sheetsRelative energyPlastic materials

A modular panel to make a roof or a wall of a building comprises an external shell and an internal shell, made of moldable plastic material, coupled with each other to define at least a compartment. The panel integrates in itself means for the capturing and irradiation of energy, and relative energy accumulation means, the capturing and irradiation means being associated, at least partly, with the external shell.

Owner:MAS

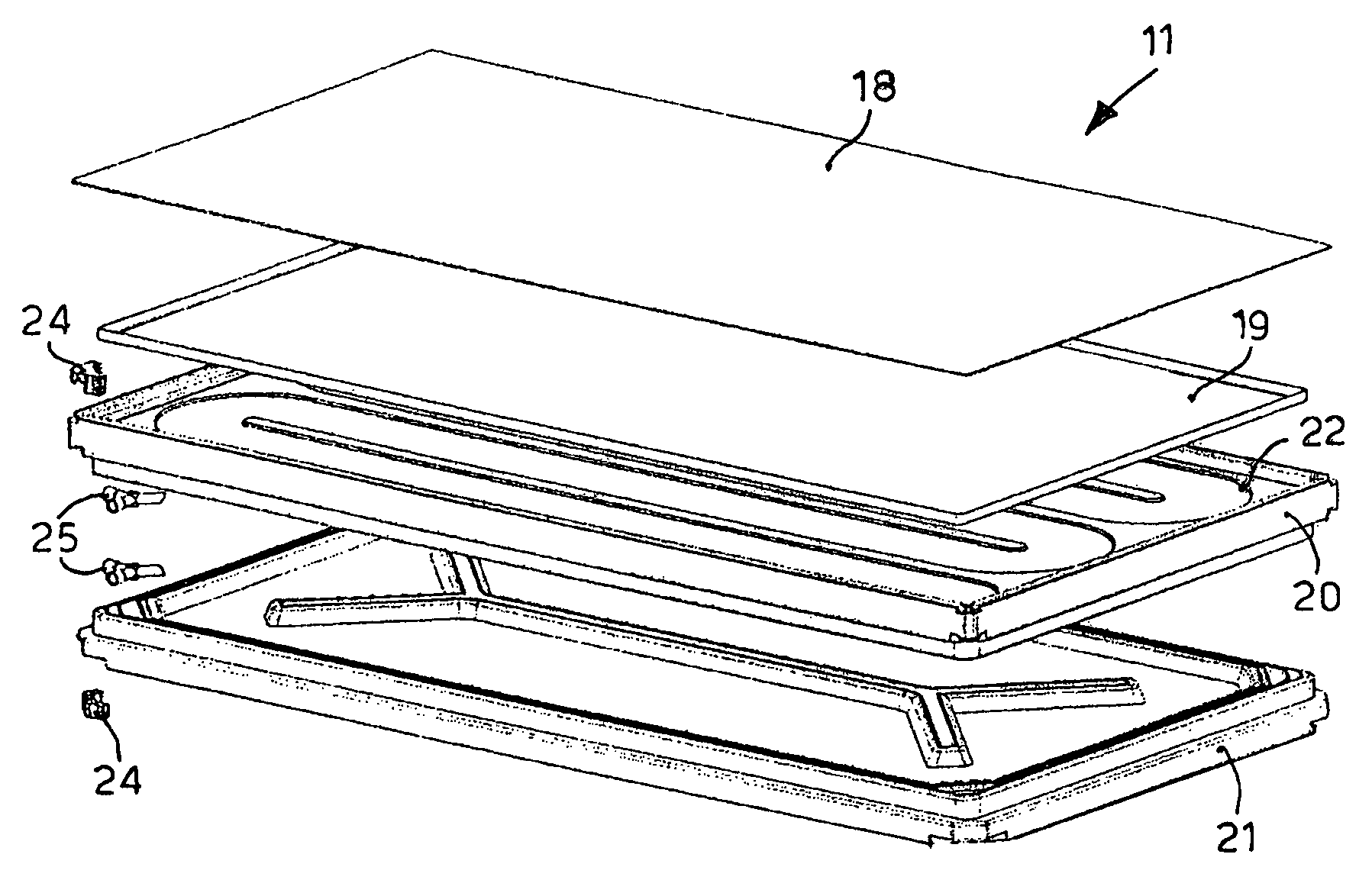

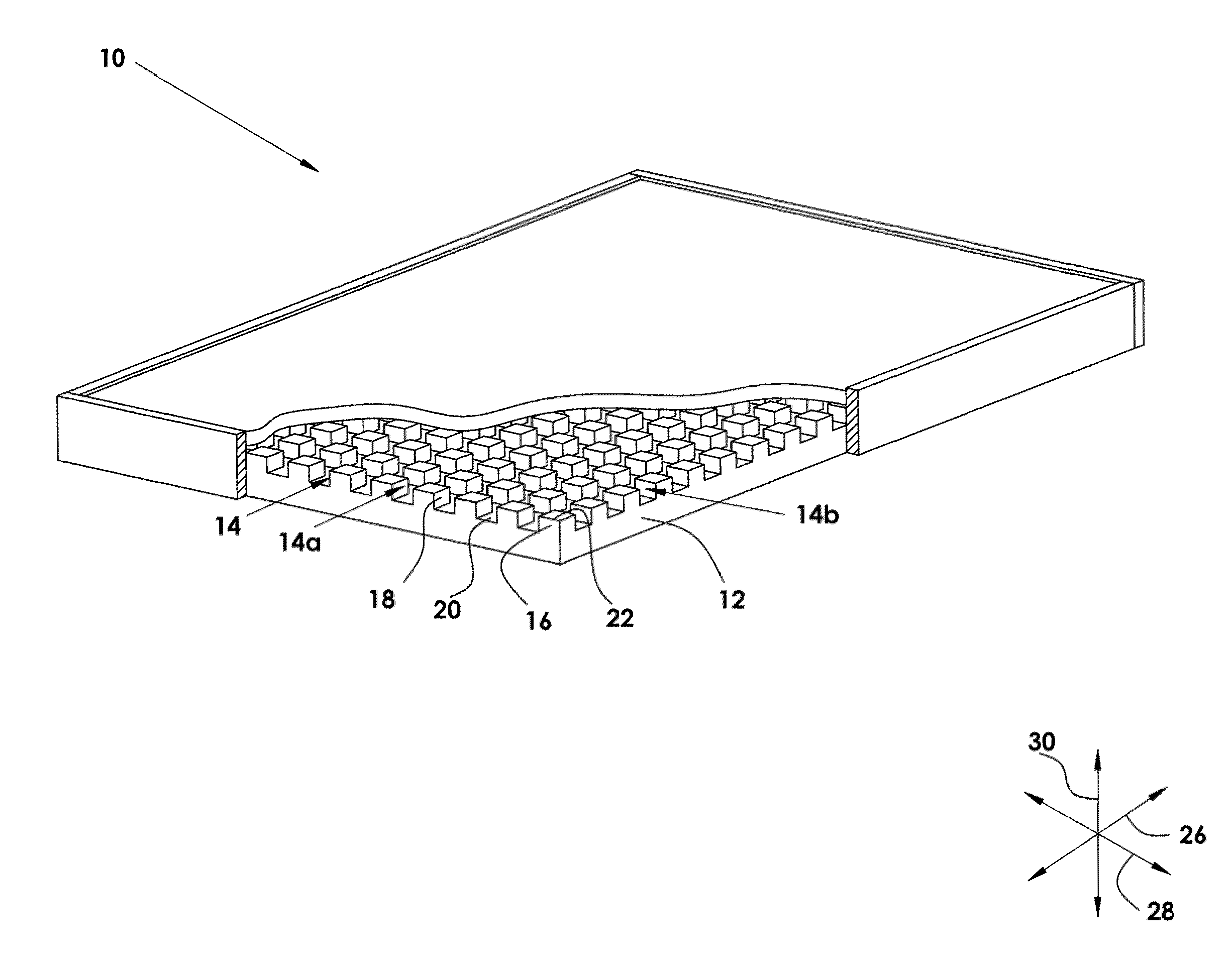

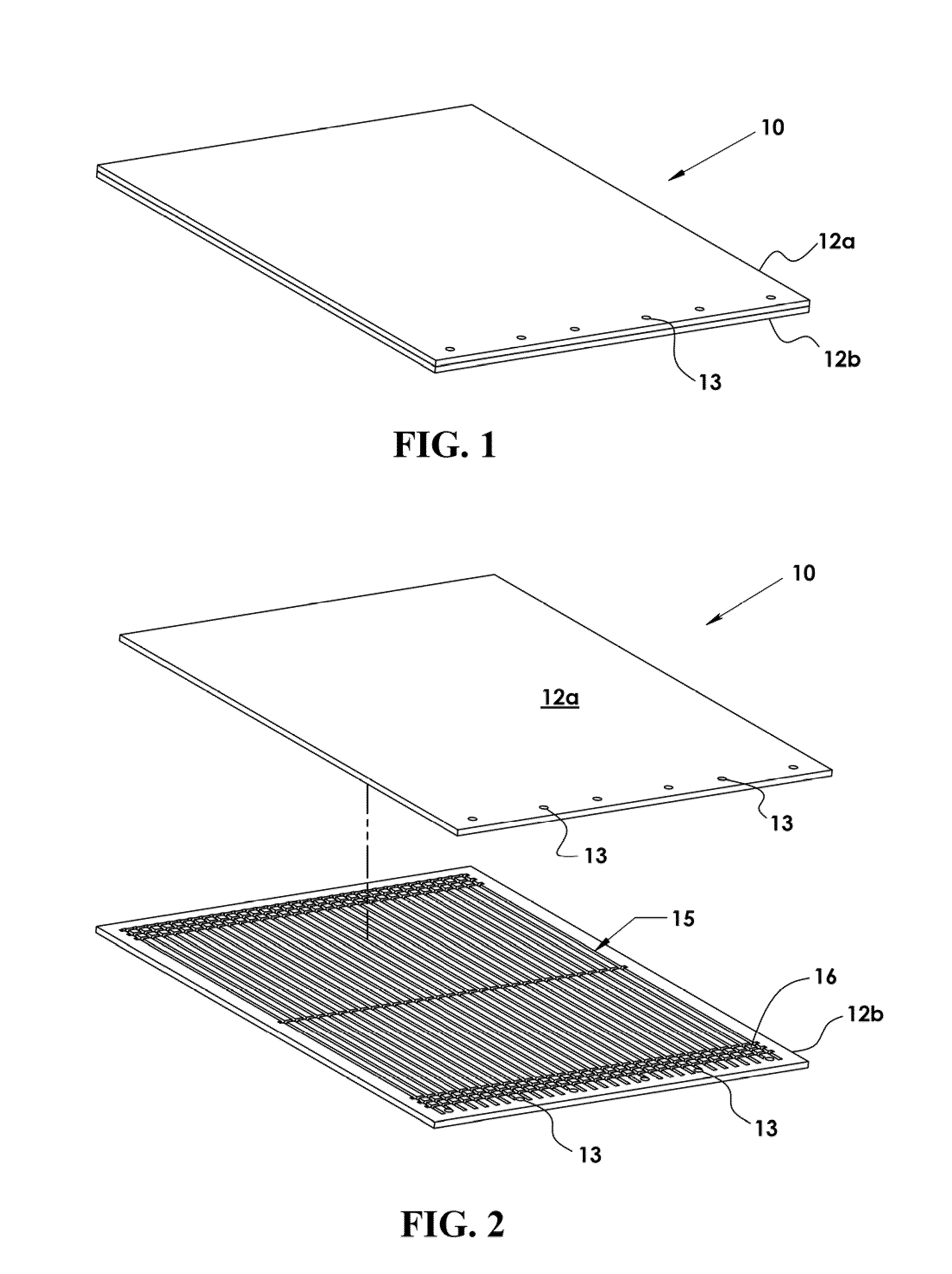

Relieved-channel, bonded heat exchanger

InactiveUS20090250196A1Minimal temperature differentialImprove structural strengthCosmonautic environmental control arrangementIncreasing energy efficiencyPlate heat exchangerEngineering

A panel assembly for exchanging heat with an ambient environment maintains minimal temperature differential by virtue of operation as a heat pipe apparatus. Panels of a composite material having excellent structural strength and structural stiffness but comparatively modest thermal conductivity are machined as mirror images of one another. Two orthogonal arrays of parallel channels are machined in the faces of two panels, each intersection of channels forming and bounded by pedestals having a lower, broader base with a narrower upper portion extending from a shoulder of the base portion of the pedestals. The pedestals, in turn, form the bounds of the channels, each having a deeper and a narrower aspect extending along the bases of all the pedestals. Channels have a broader aspect extending along near the tops of the pedestals.

Owner:UTAH STATE UNIVERSITY

Ruggedized electronics enclosure

InactiveUS20070177348A1Overcomes limitation and disadvantageHigh strength to weight ratioPrinted circuit board receptaclesModifications by conduction heat transferPassive radiatorEngineering

The present invention relates to a ruggedized enclosure for housing and protecting electronic circuits. The enclosure utilizes a top compartment for housing the circuit and a cooling assembly rigidly coupled to the top compartment. The cooling assembly utilizes a passive radiator to form a rigid truss plate structure. The truss plate structure rigidifies the enclosure helping to protect the enclosure and circuit from destructive shock events and destructive vibration events. The cooling assembly further provides an efficient heat exchange for removing heat from the electronic circuit. A method for protecting an electronic circuit utilizing a rigid truss plate structure is also provided.

Owner:KEHRET WILLIAM E +1

Modular Panel For Making Covering Structures For Walls, Covering Structures Or Walls And Method

InactiveUS20120102844A1Considerable recovery efficiencyReduce partPhotovoltaic supportsSolar heating energyRelative energyPlastic materials

A modular panel to make a roof or a wall of a building comprises an external shell and an internal shell, made of moldable plastic material, coupled with each other to define at least a compartment. The panel integrates in itself means for the capturing and irradiation of energy, and relative energy accumulation means, the capturing and irradiation means being associated, at least partly, with the external shell.

Owner:MAS

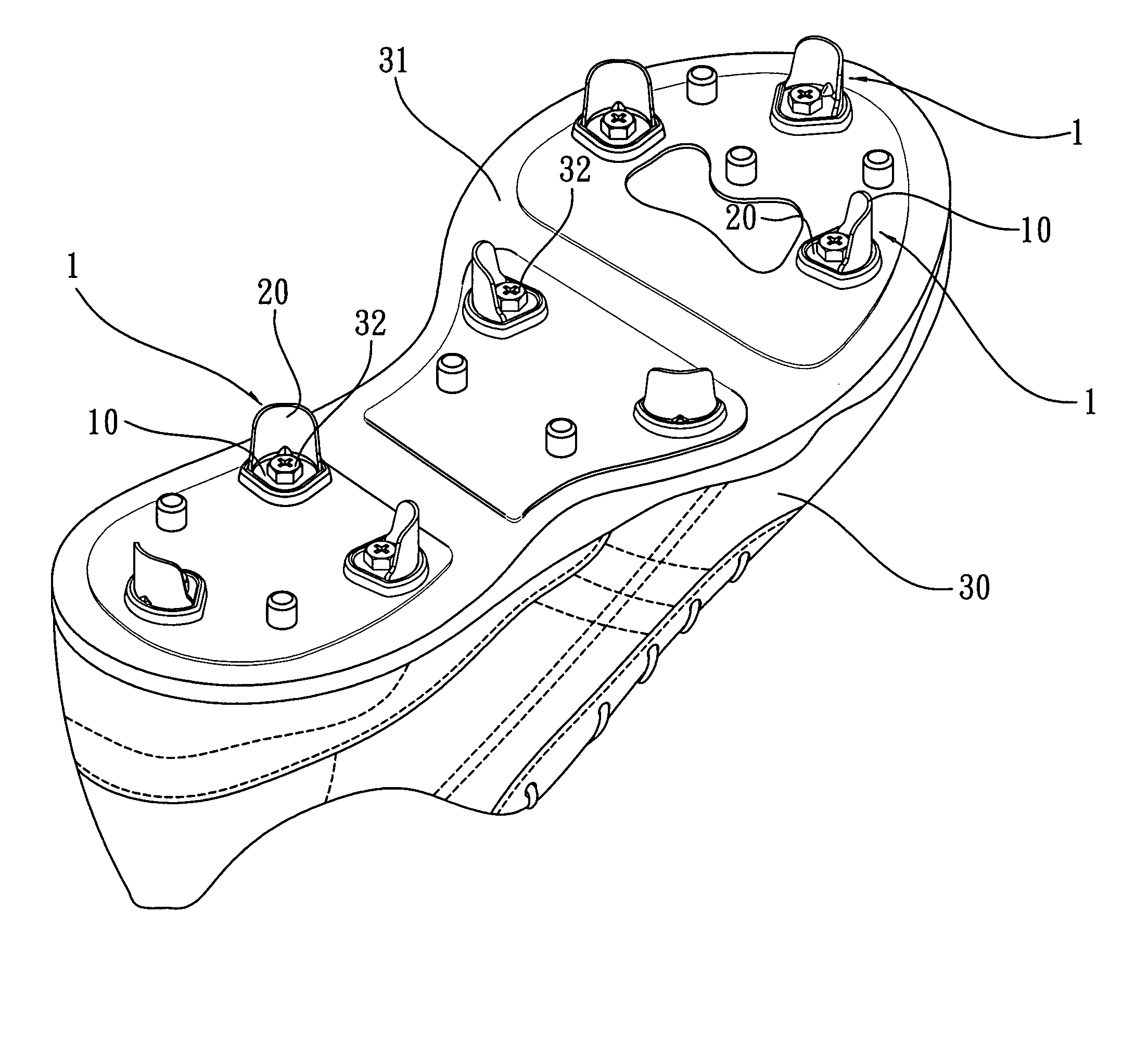

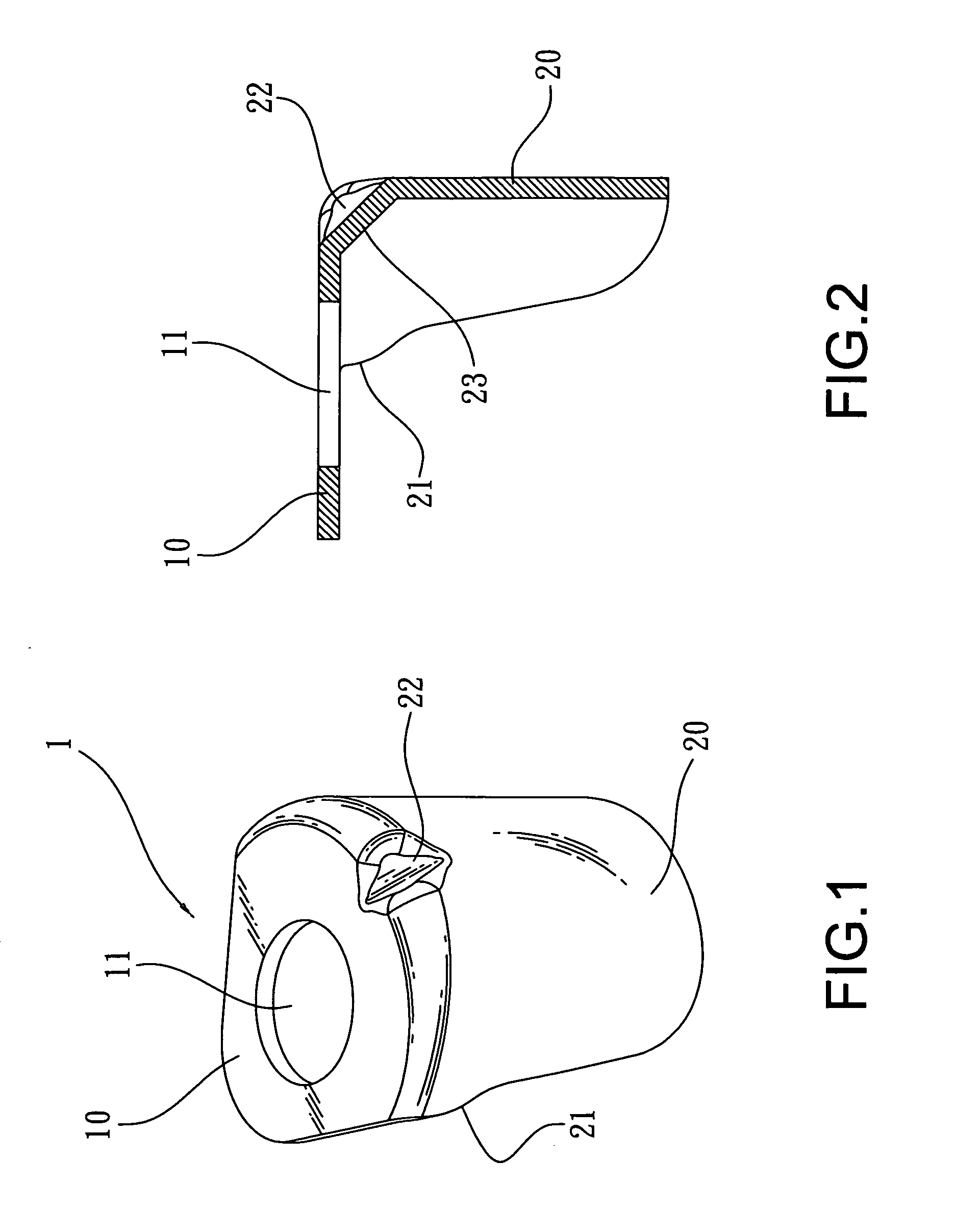

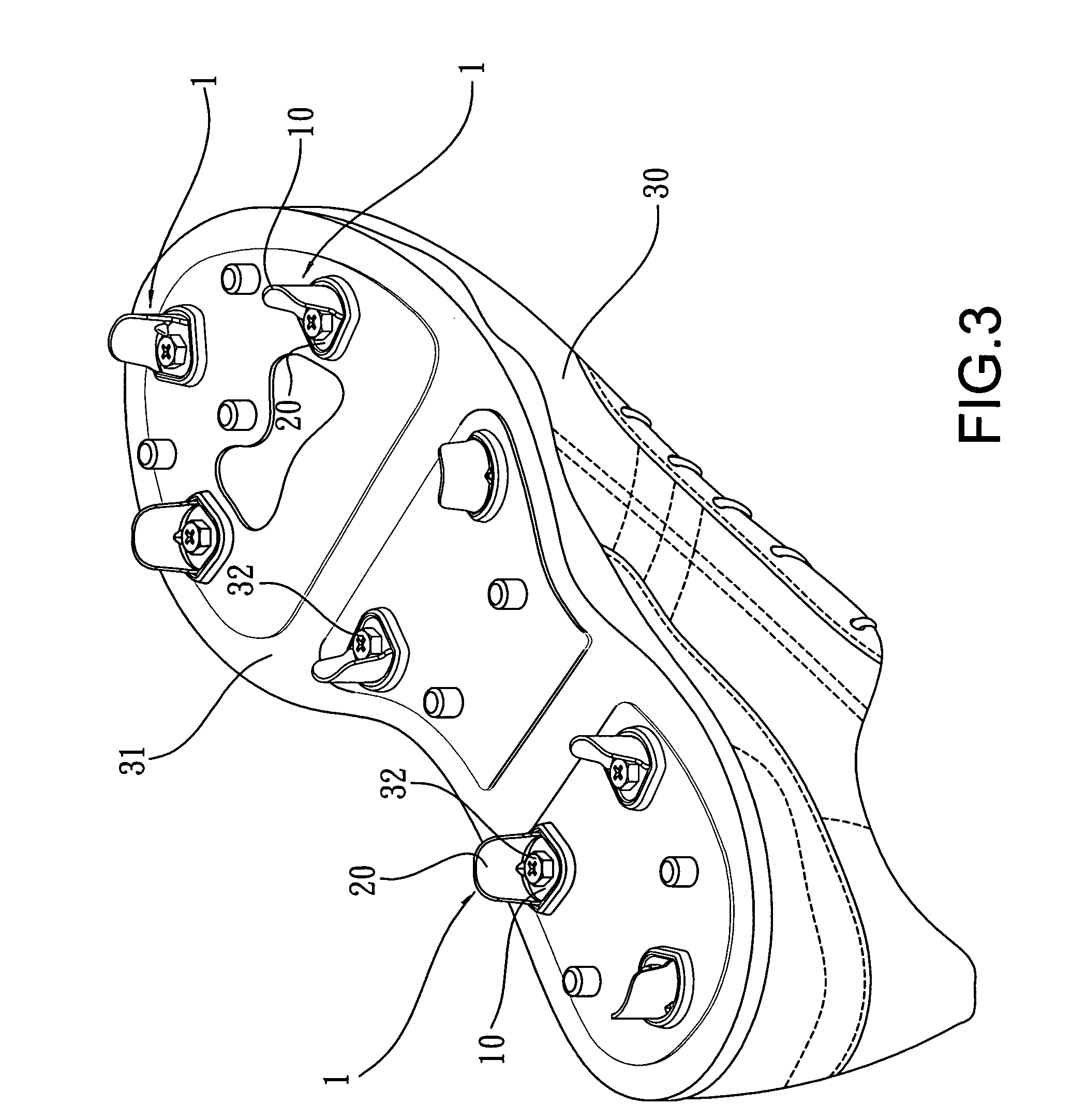

Thin-type spike intensifying structure

A thin-type spike intensifying structure is formed by bending a predetermined plate with a punch finishing work. The thin-type spike includes an assembly part and a spike sheet, wherein the assembly part provides for fixing and assembling the spike at a bottom of a sports shoe, and the spike sheet is disposed at a side of the assembly part and manifests an arc-shape design through bending and protrusion. By the arc-shape structure design, a rigid structure of the spike is intensified, and the spike can be manufactured with a thin metal, such that the spike can be firm and tolerable, and a product can be lighter, in order to improve its practicability and advancement.

Owner:CHANG CHUAN LI

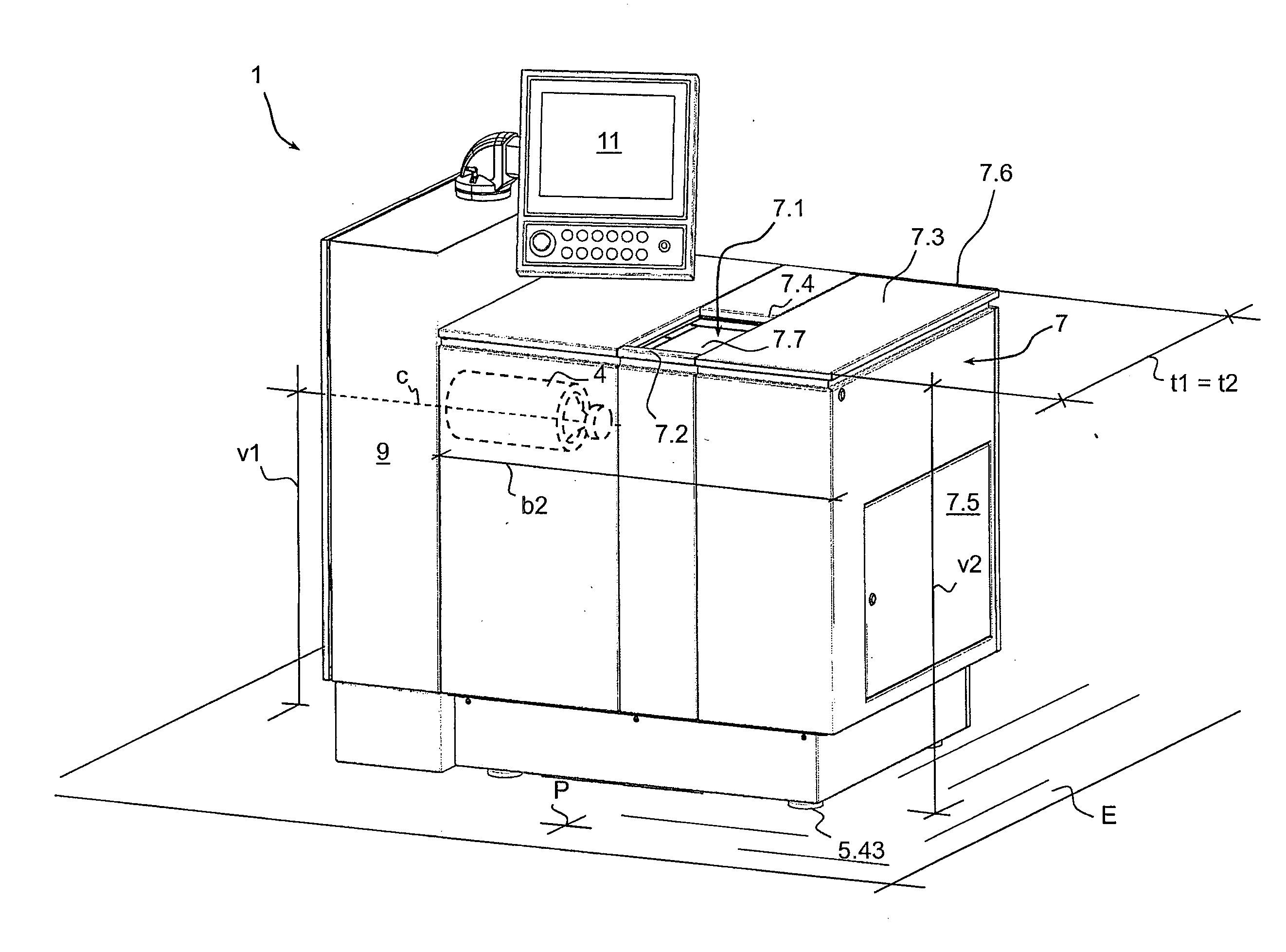

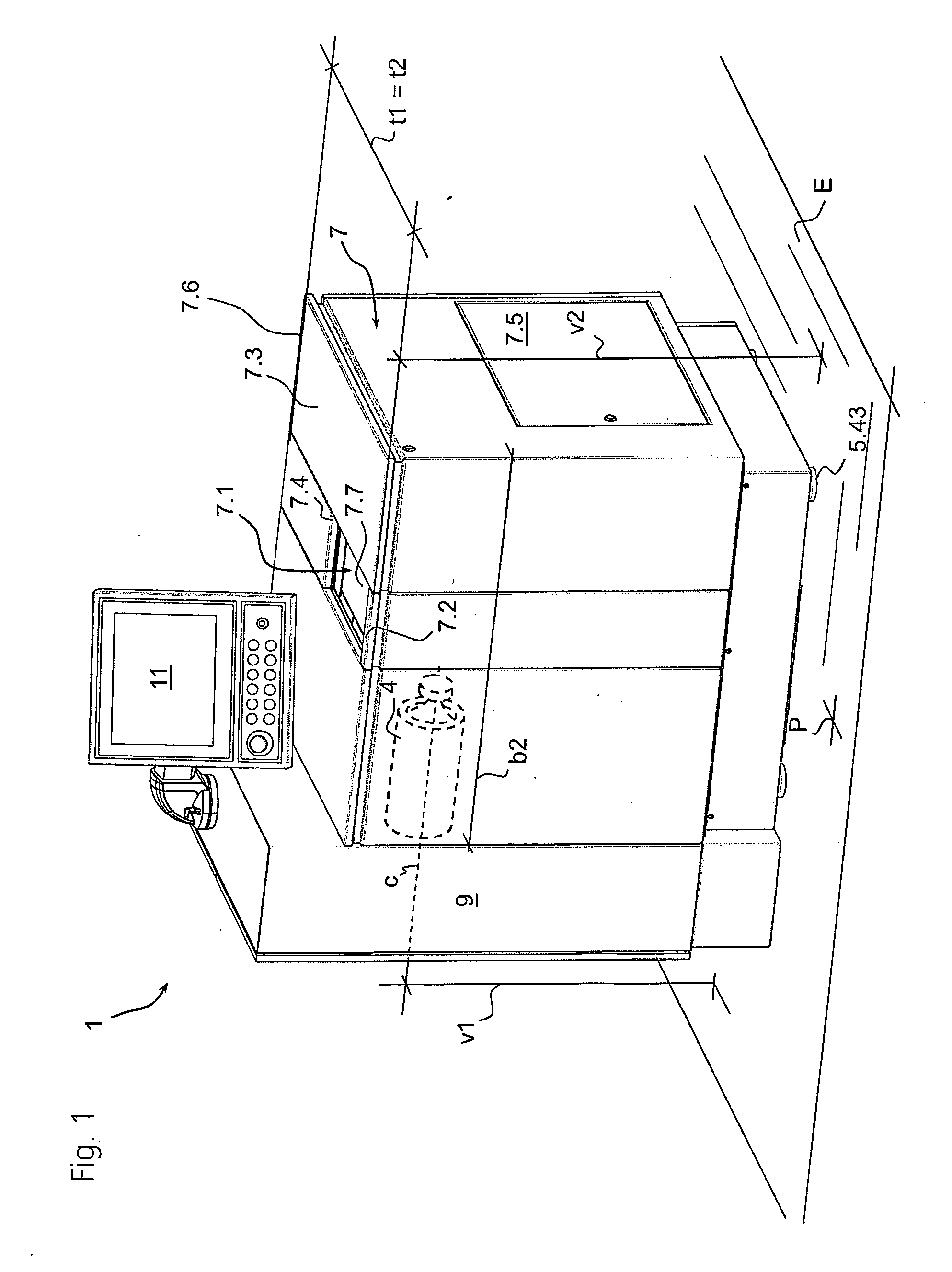

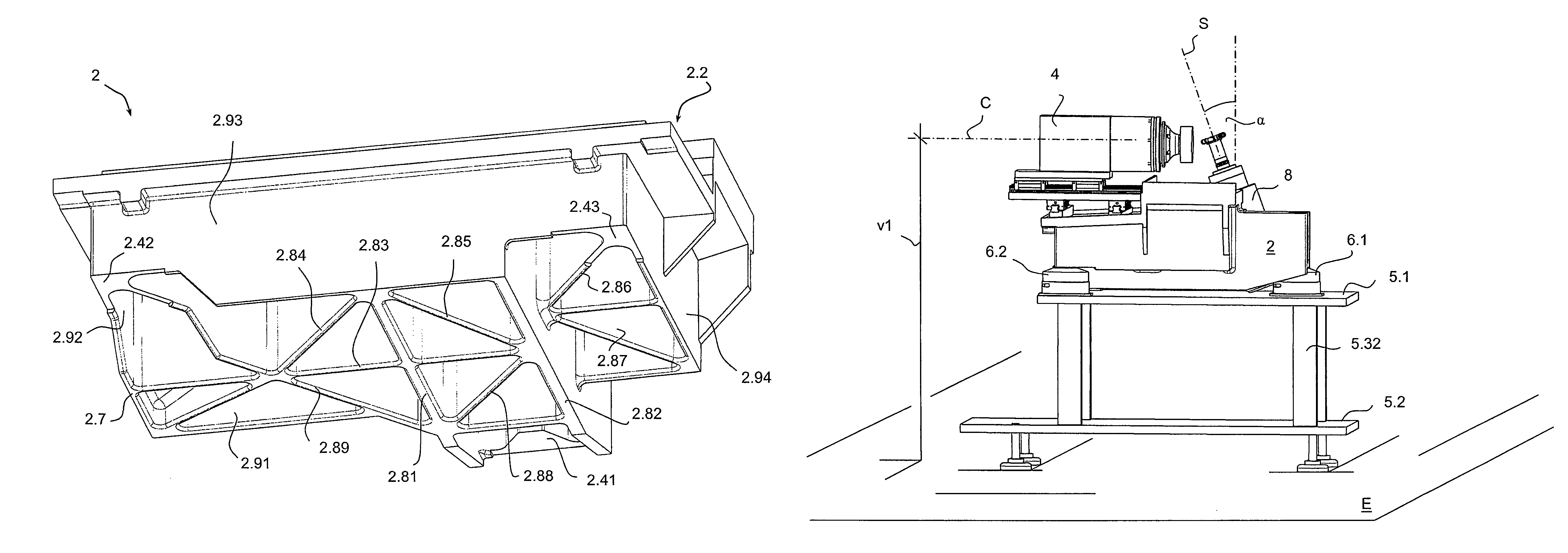

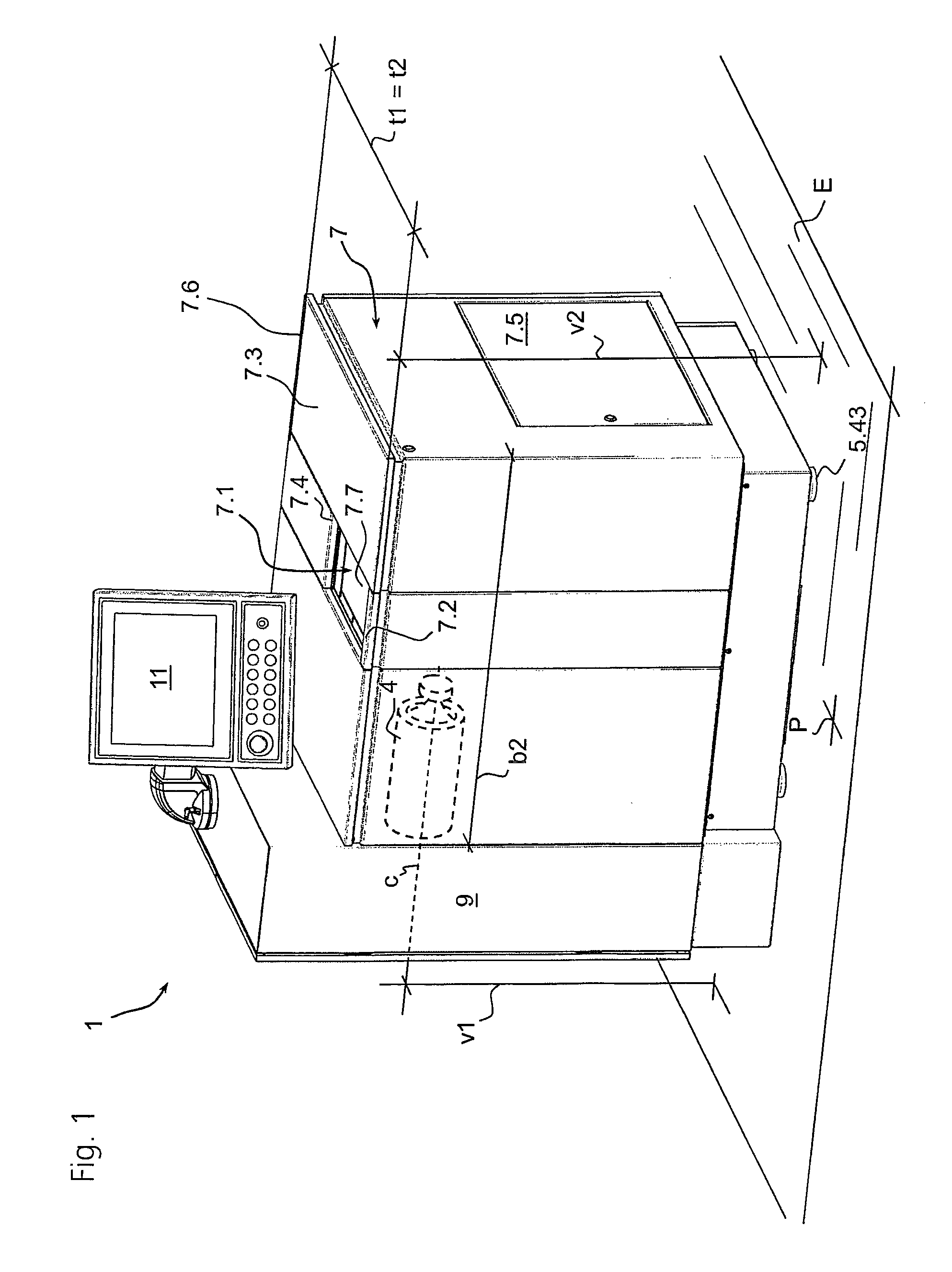

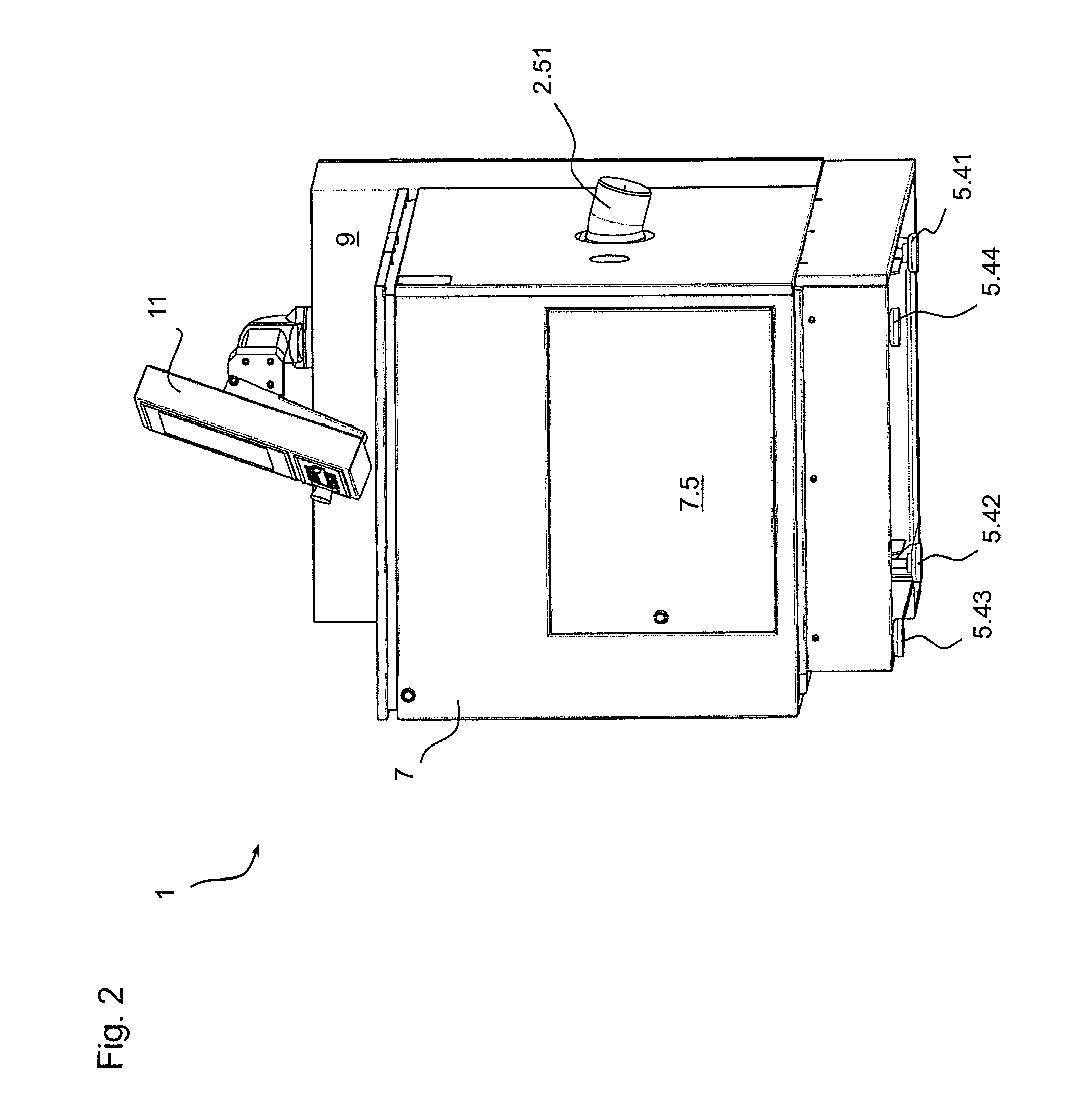

Lathe for manufacturing ophthalmic lenses made of plastic

ActiveUS20100224039A1Reduce quality problemsReduce loadLathesTurning machine accessoriesRotational axisEngineering

A turning machine for producing non rotationally symmetric surfaces of synthetic spectacle lenses, having a support plane E, a machine bed made of cast iron with a width b1 and a mass m1, a linear motor with an actuator comprising a turning tool holder and an oscillation axis Z, a workpiece spindle with a rotational axis C and a movement axis X, wherein the machine bed has at least two bearing surfaces arranged at a distance for the linear motor and for the workpiece spindle, and between the two bearing surfaces, a chip space is provided which is limited at least partially by the machine bed, wherein the linear motor is supported on the first bearing surface and the workpiece spindle is supported on the second bearing surface in relation to the chip space opposite the linear motor, wherein the mass of the machine bed has the maximum value m1, and the value m1 lies between 100 kg and 500 kg, between 150 kg and 300 kg, between 170 kg and 200 kg or 180 kg. A turning machine, in which the ratio of the mass m1 of the machine bed to a moved mass m2 of the linear motor 3 is greater than a quotient Q, wherein the quotient Q is between 1:500 and 1:20, between 1:60 and 1:30 or between 1:140 and 1:100, or 1:40 or 1:120.

Owner:SCHNEIDER GMBH & CO KG

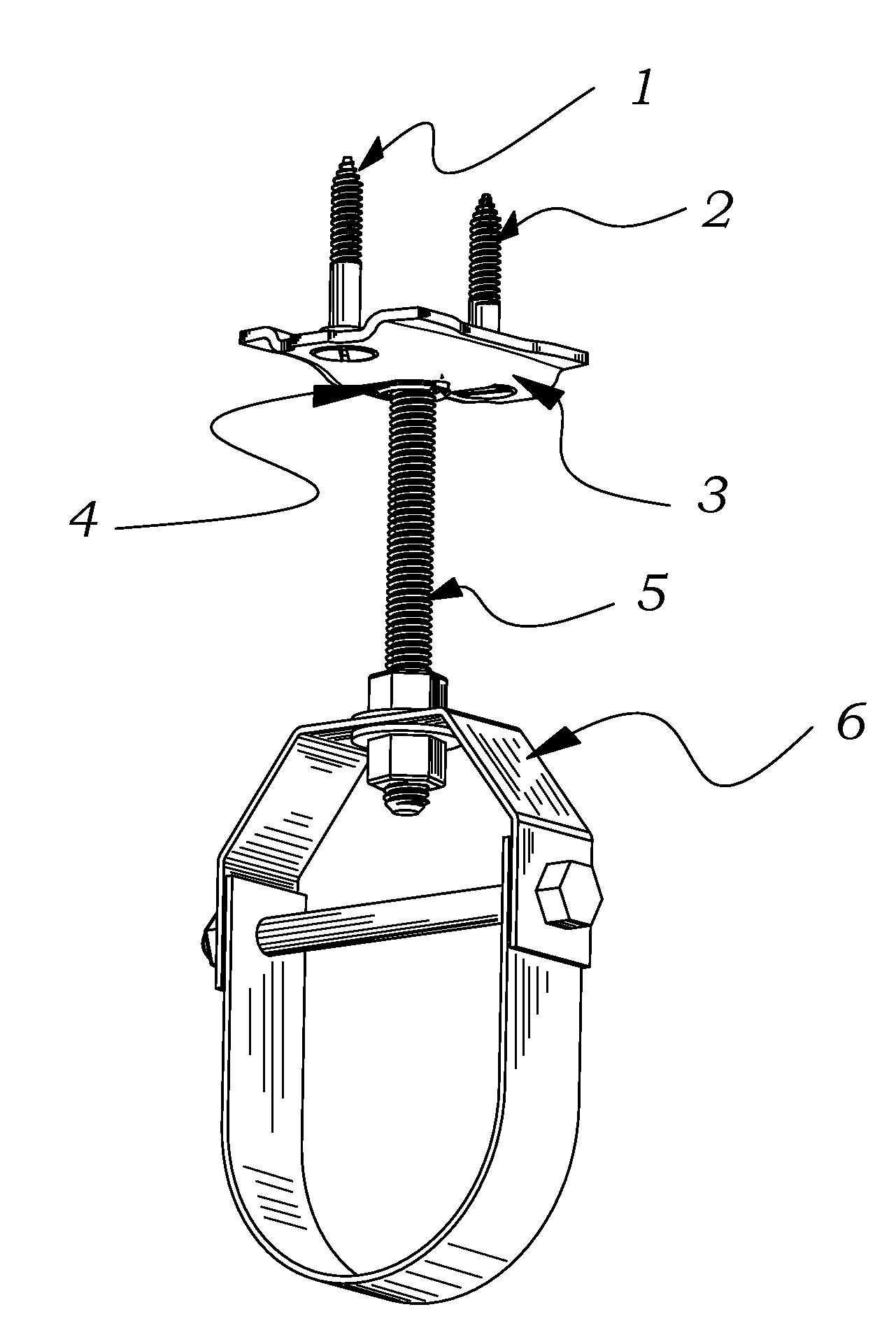

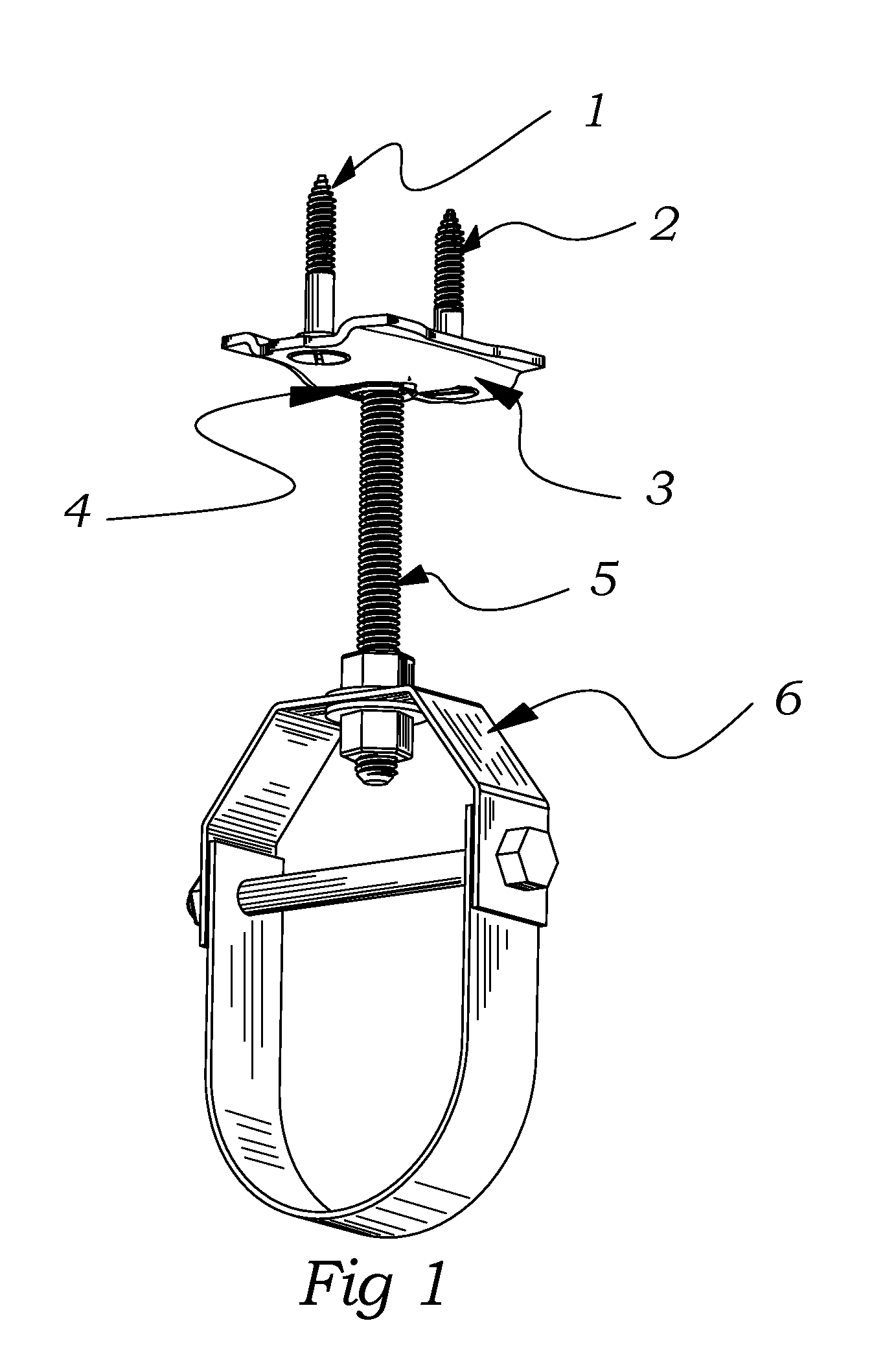

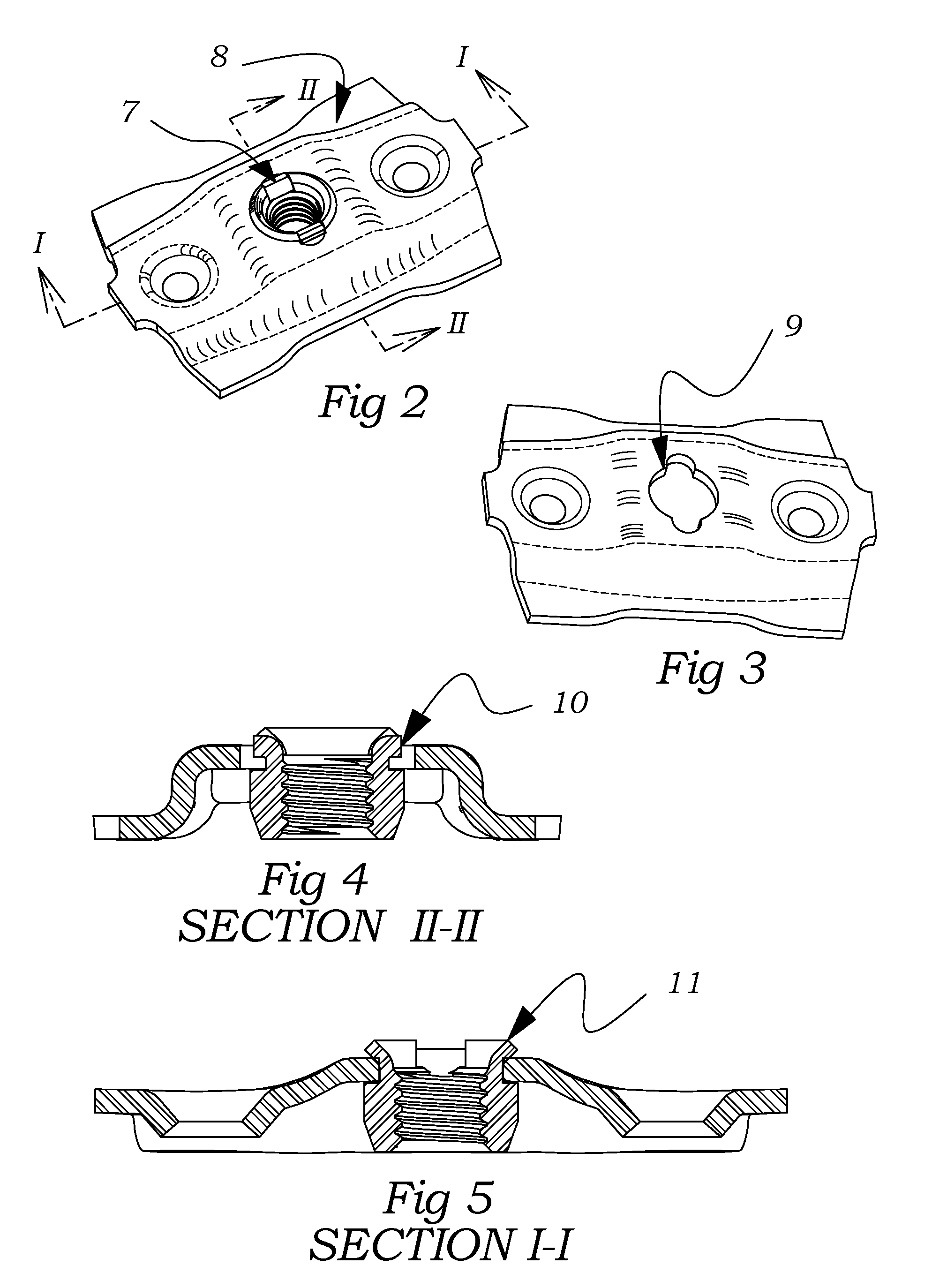

Threaded brackets for hanger rod

InactiveUS20130126681A1Rigid structureIncrease thread connectionPipe supportsMining devicesEngineeringScrew thread

A mounting member for a ceiling or beam utilizes a barrel nut for connection with a hanger rod of a pipe hanging support. A technique of creating a riveted joint with a keyed hole to join the barrel nut and then deforming that portion of the rivet into the key way to provide secure fixation of the nut in the member to prevent rotation of the nut when the hanger rod is turned.

Owner:GREENFIELD MFG

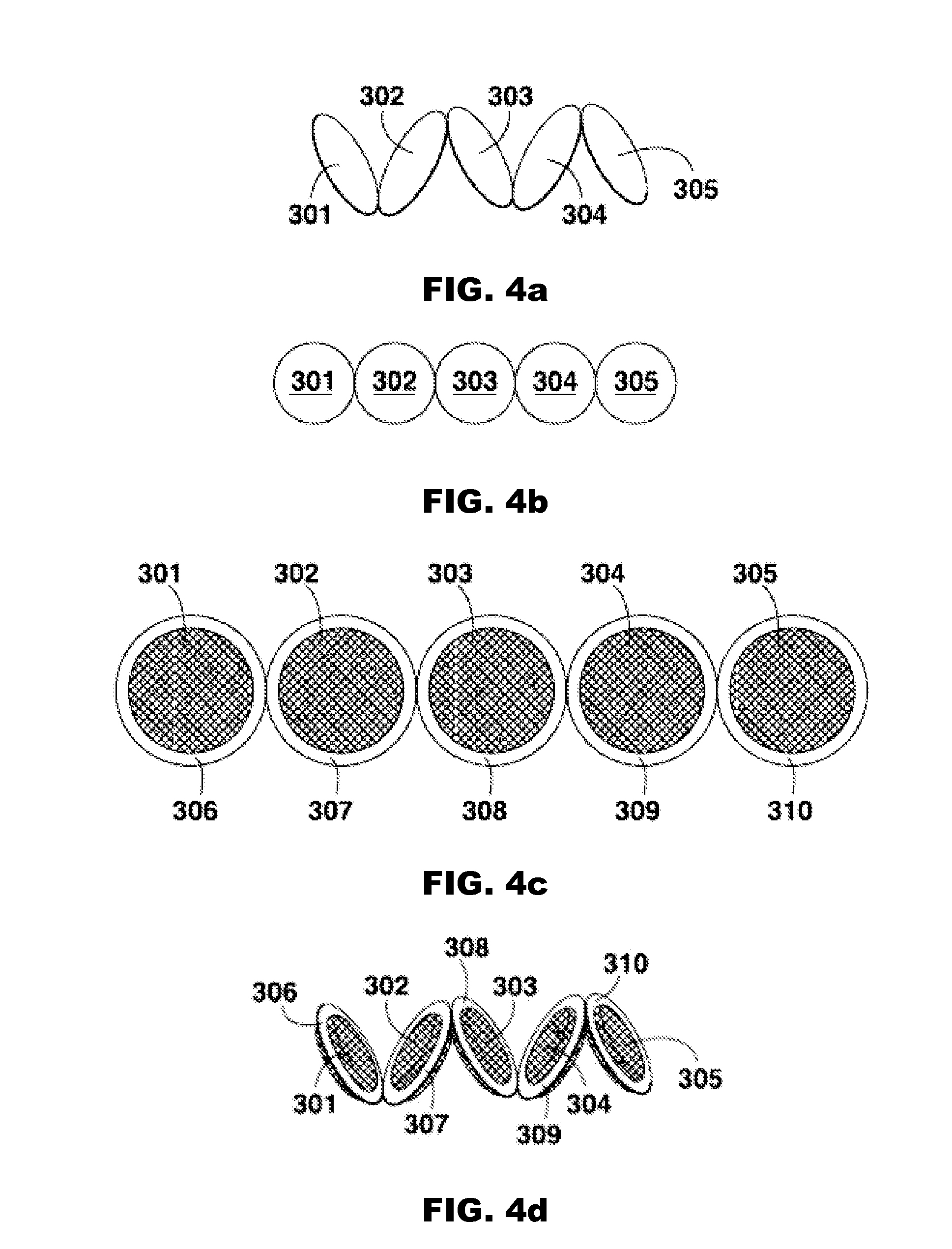

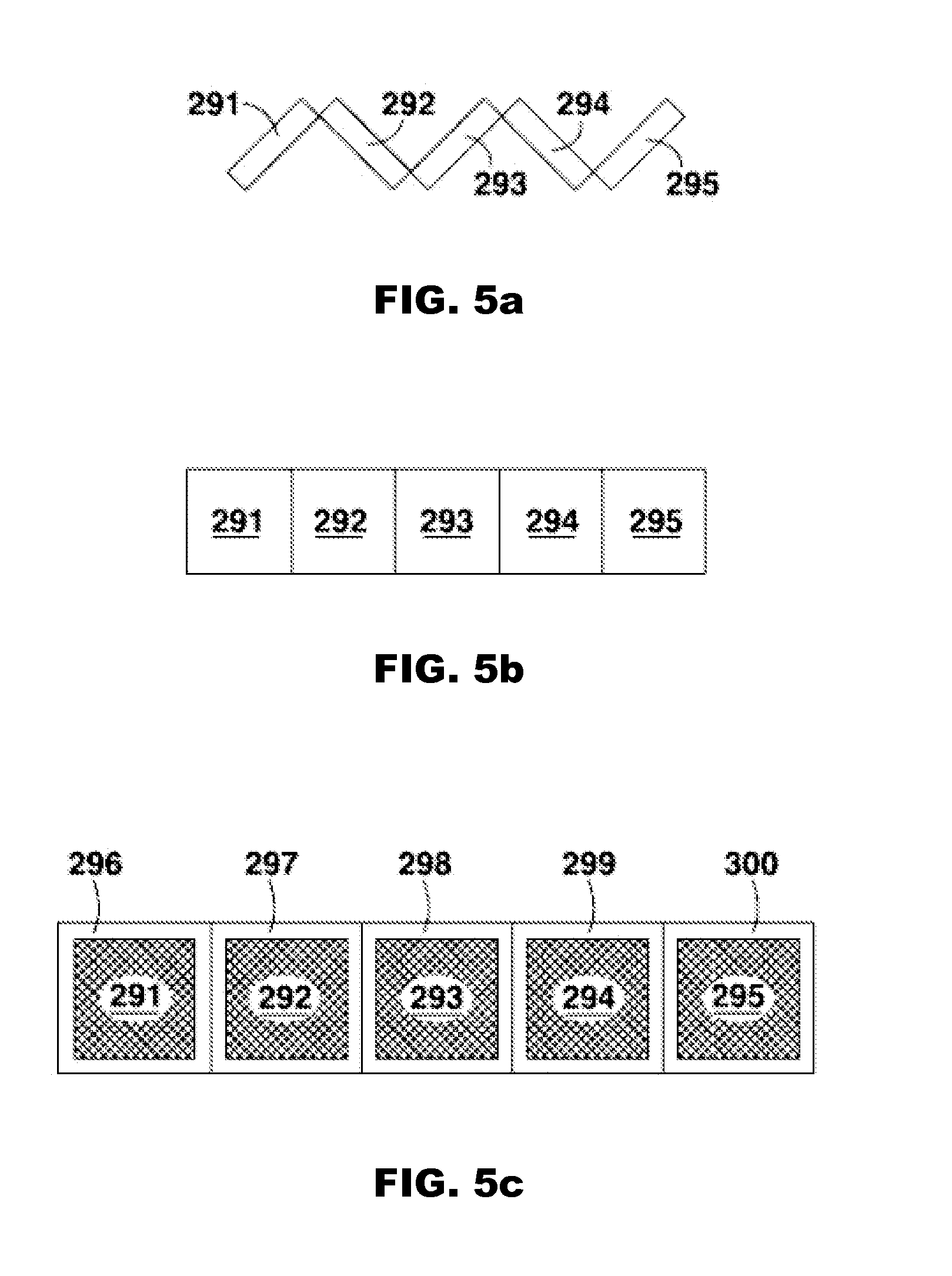

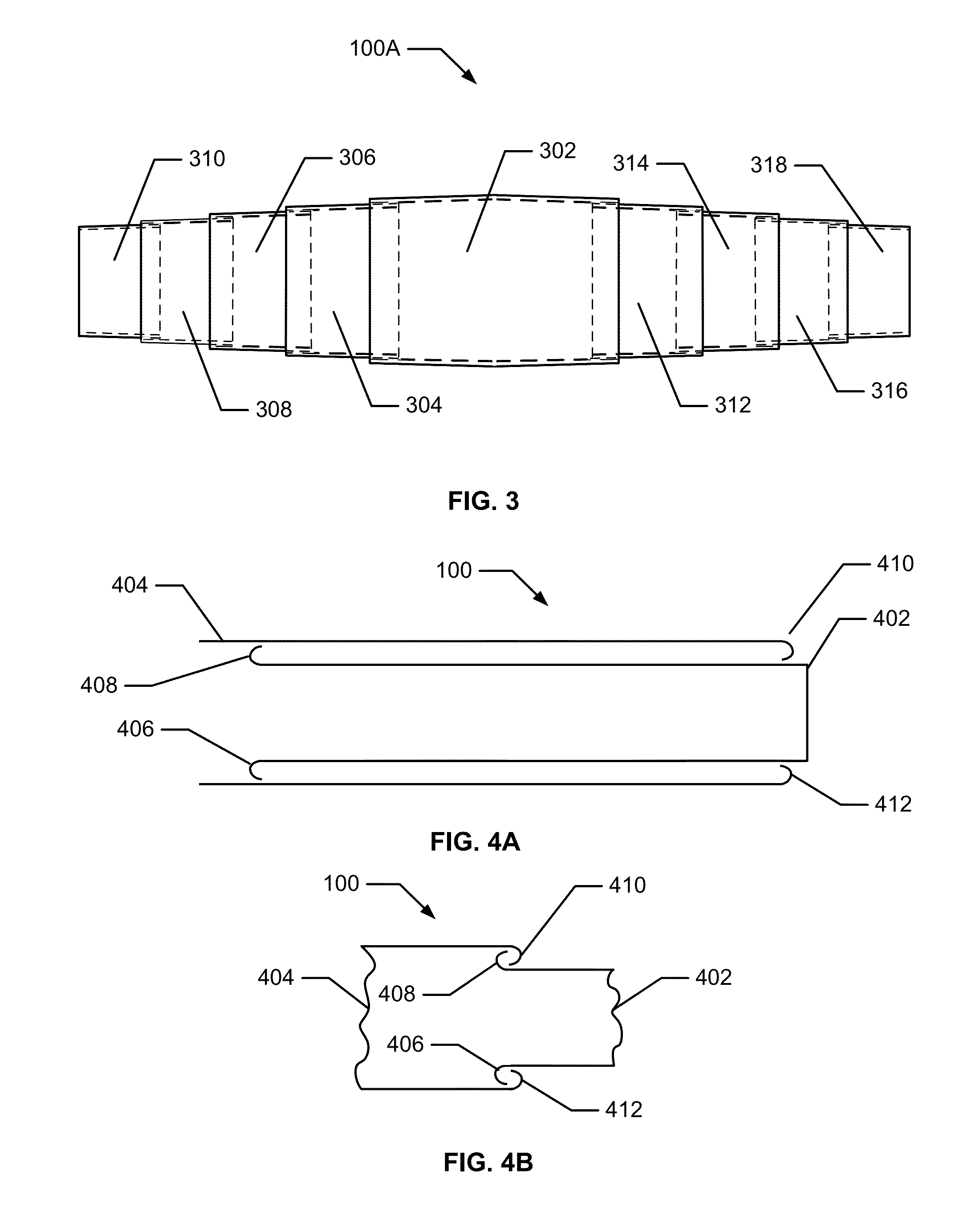

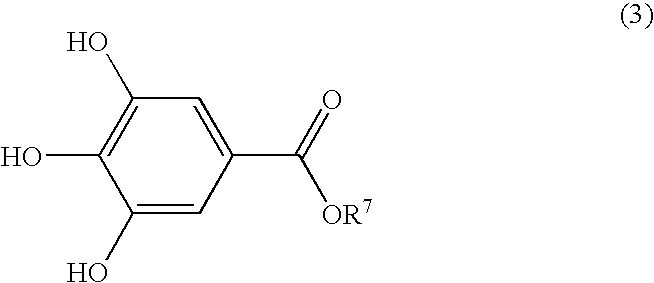

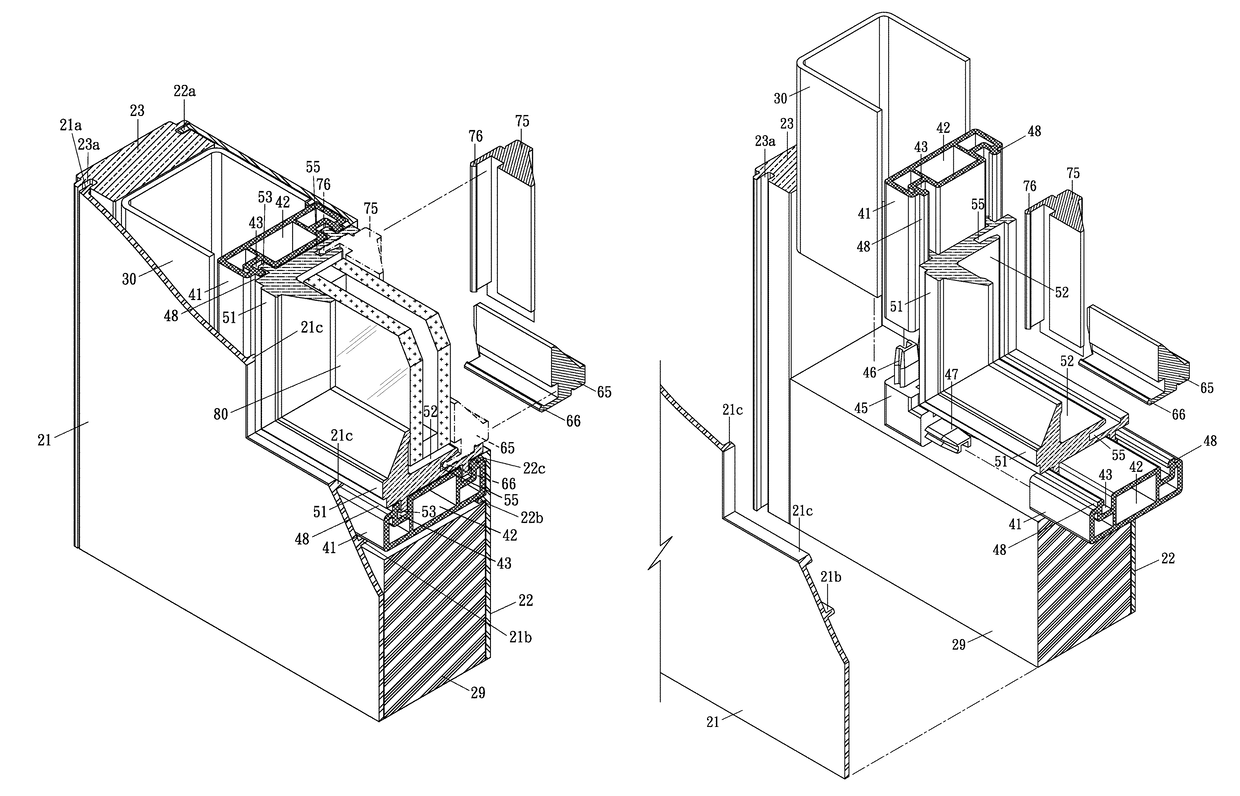

Magnetic Stimulation coils with electrically conducting structures

InactiveUS20110218381A1Improve rigidityTransfer of heatElectrotherapyMagnetotherapy using coils/electromagnetsNon magneticConductor Coil

The present invention introduces a novel apparatus (5) for providing magnetic stimuli to the human brain, the apparatus (5) comprising a casing (4) and at least one coil winding (1) adapted to carry electrical current and enclosed within the casing (4) as well as cooling means (2) situated in thermal connection with the coil (1) and comprising a body made of electrically conductive and non-magnetic material so that the mutual inductance between the coil (1) and the cooling means (2) is essentially zero.

Owner:NEXSTIM

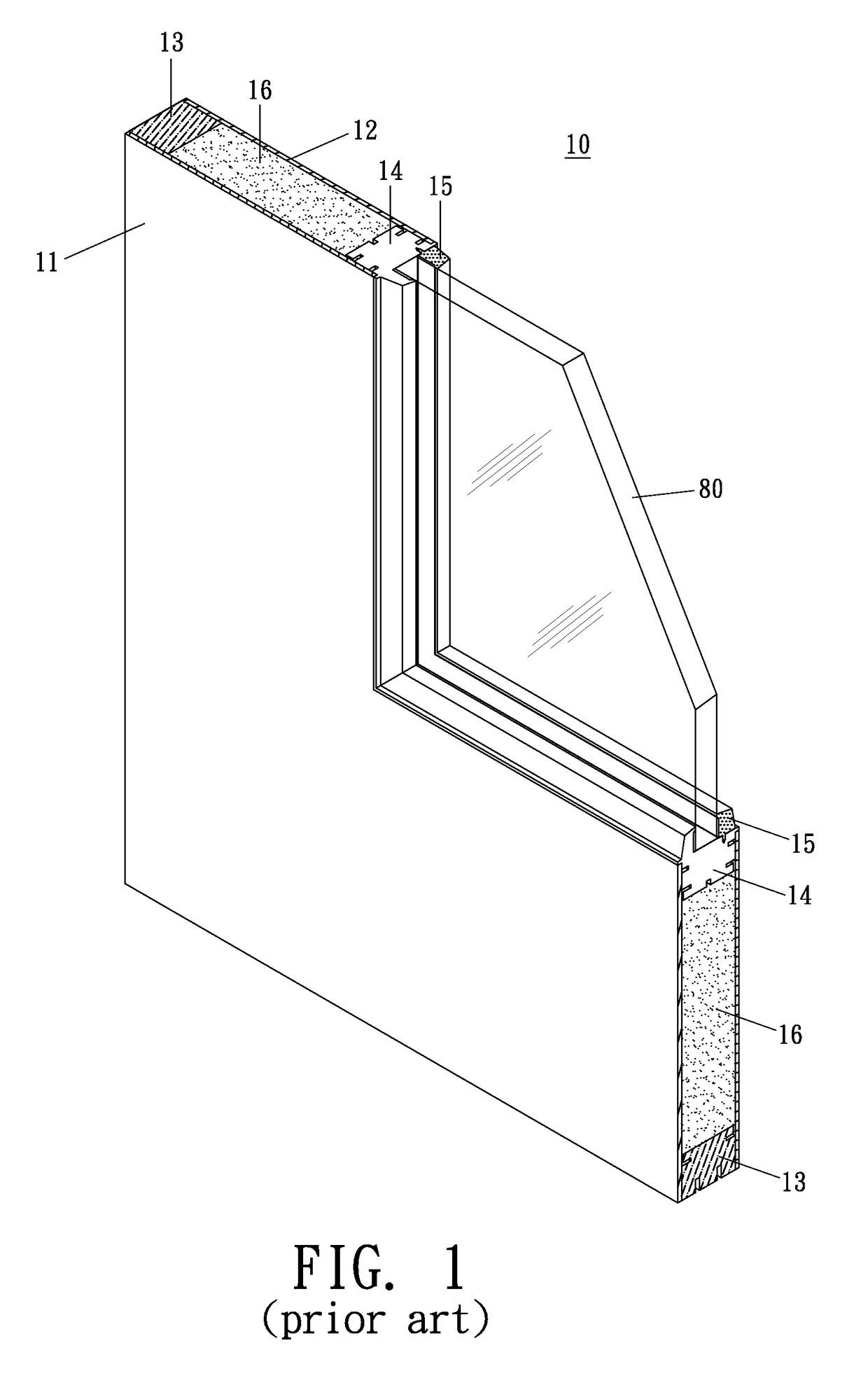

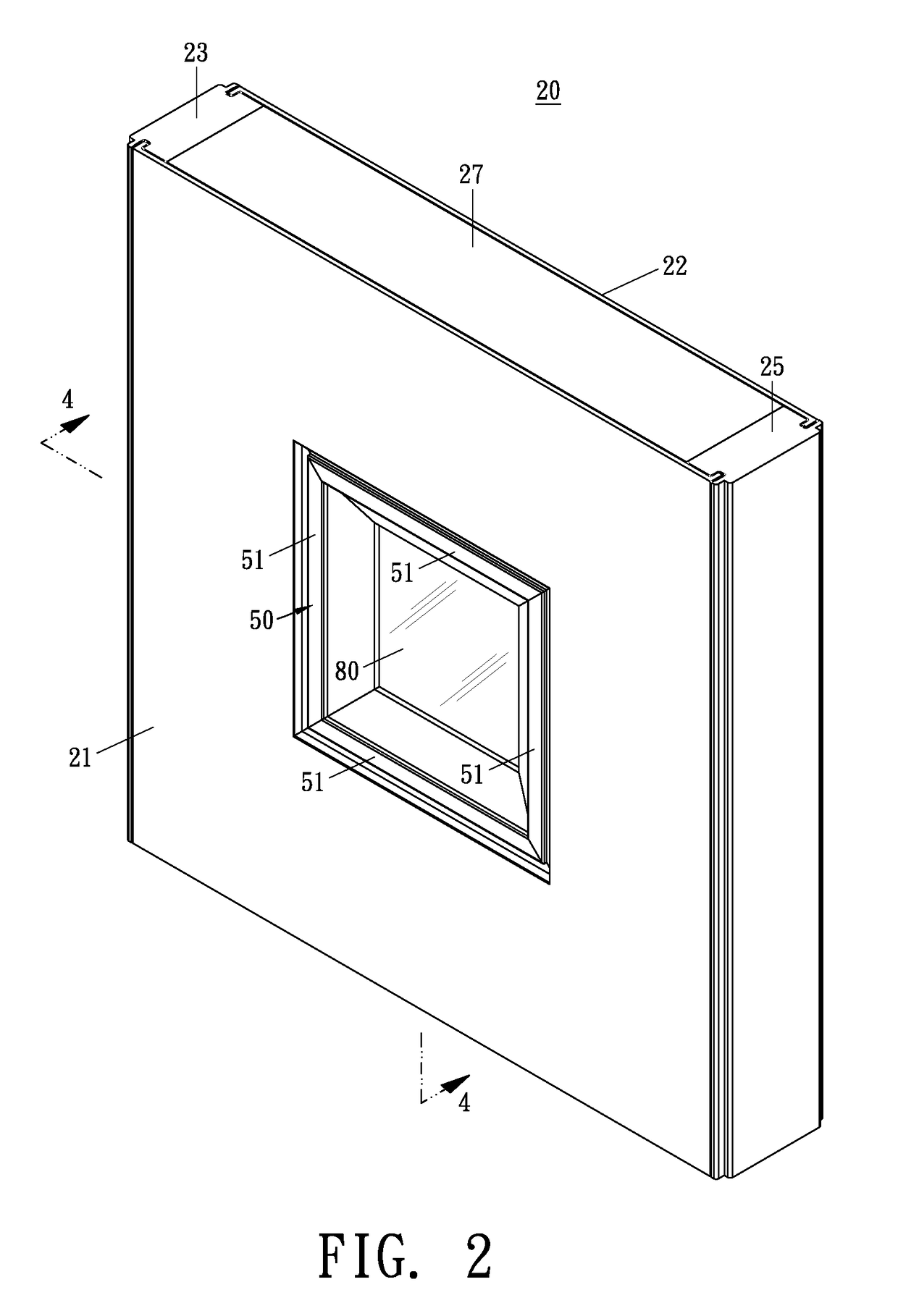

Door structure with glass

A door structure with glass at least comprising a front panel, a rear panel, an inner hollowed-frame assembly, a glass mounted assembly and at least one glass, wherein the front panel and the rear panel are configured with a plurality of positioning protrusions at inner sides for assembling the inner hollowed-frame assembly inside the door structure with glass without using screws; the structure may render the inner hollowed-frame assembly able to support and assemble the glass mounted assembly and the glass with rigidity.

Owner:NANYA PLASTICS CORP

Bases and braces for support poles, such as poles for pavilions and umbrellas

ActiveUS20060081283A1Increase the effective sectionStable structureTents/canopiesStands/trestlesEngineeringSupport surface

Bases are disclosed that comprise a projecting portion designed to receive over it the hollow end of a pole or other elongate member, which may form part of a structure such as a pavilion or umbrella. The projecting portion of the base comprises wedges that move in response to the end of the pole moving over the projecting portion and in so moving, the wedges increase the effective cross section of the projecting portion to engage the inner surface of the end of the pole and to thereby stabilize the structure on a support surface, such as the ground. Braces are also disclosed that pull together adjacent poles of a pavilion to make the structure more rigid.

Owner:JOEN AN MA OLIVER

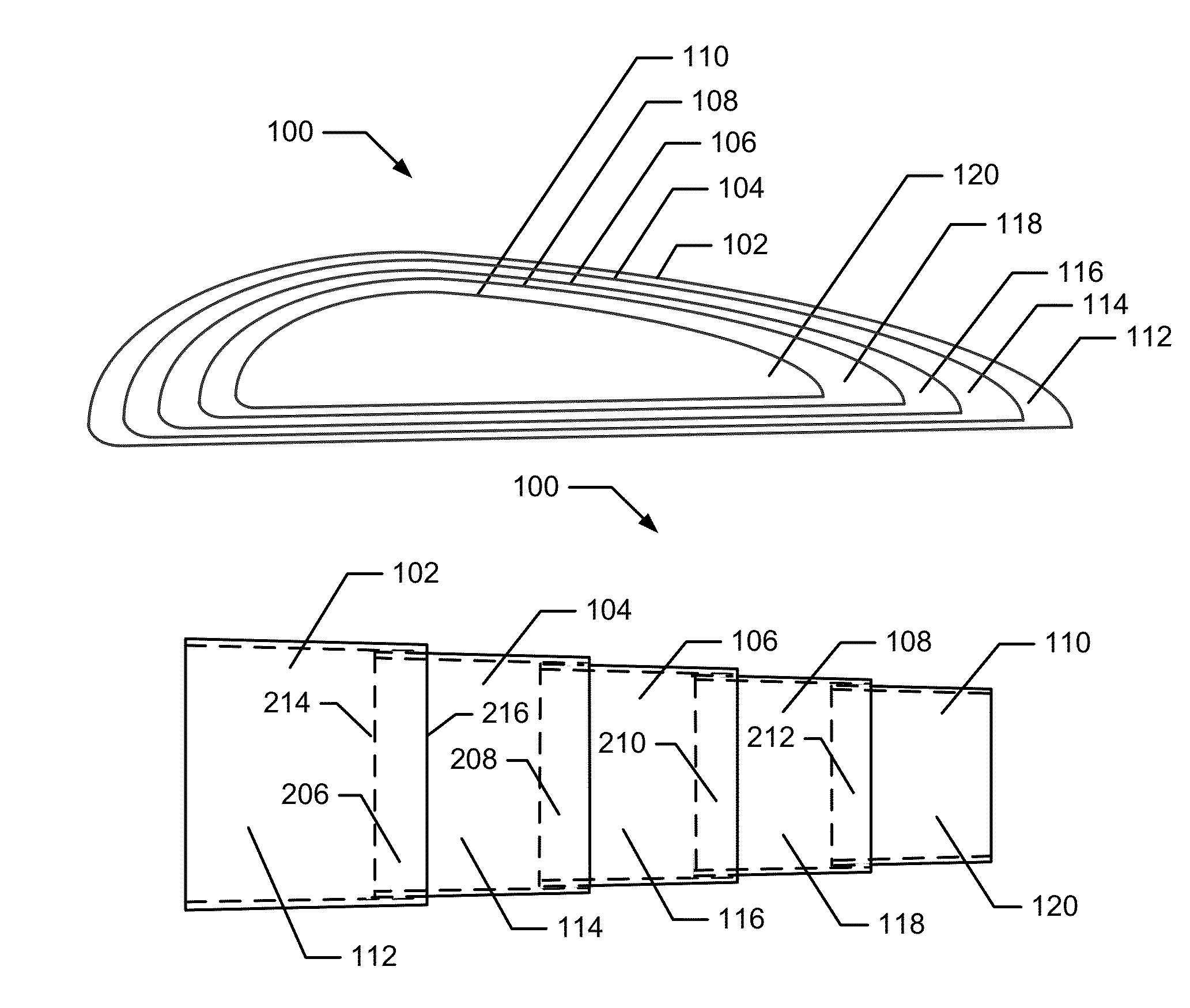

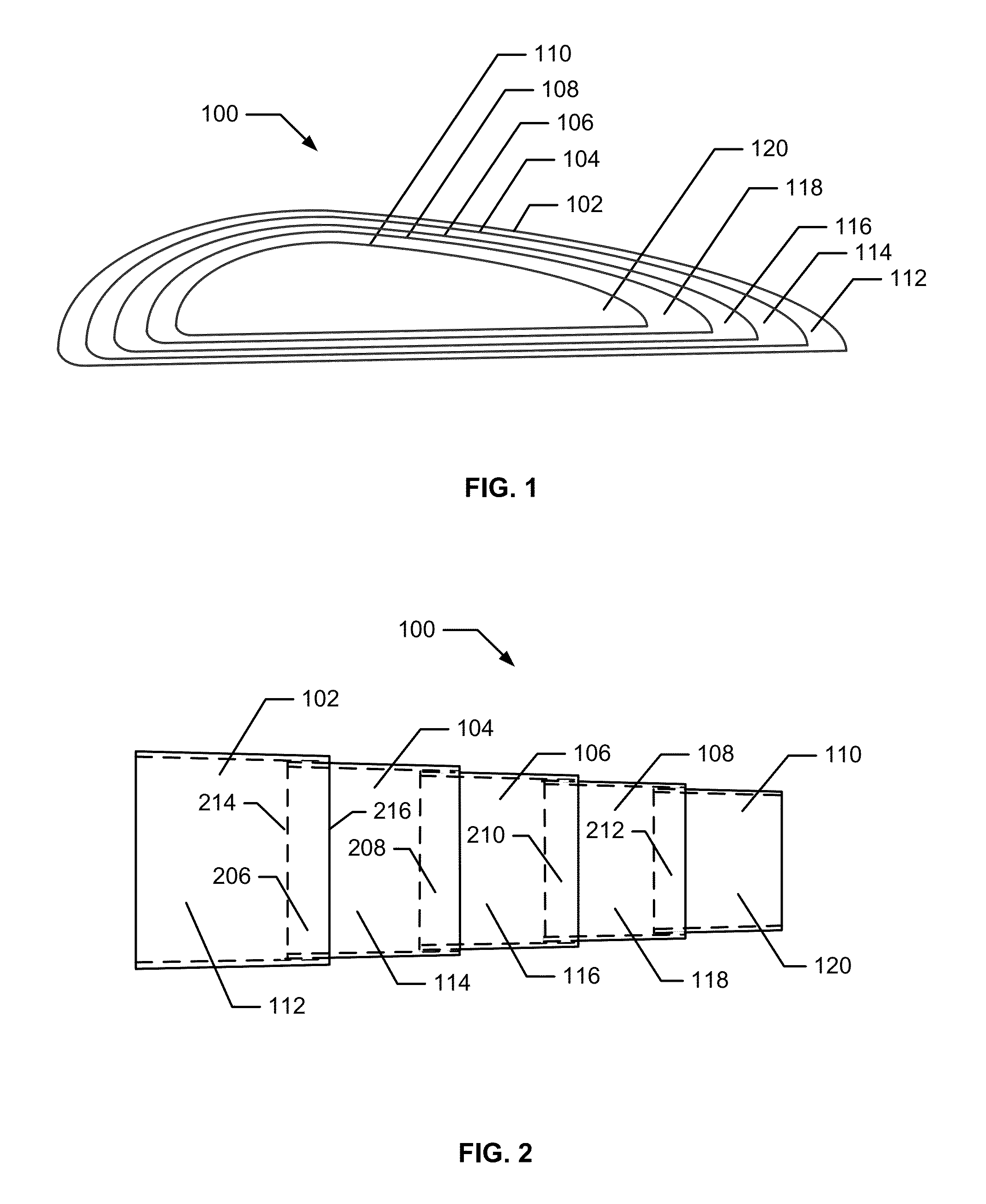

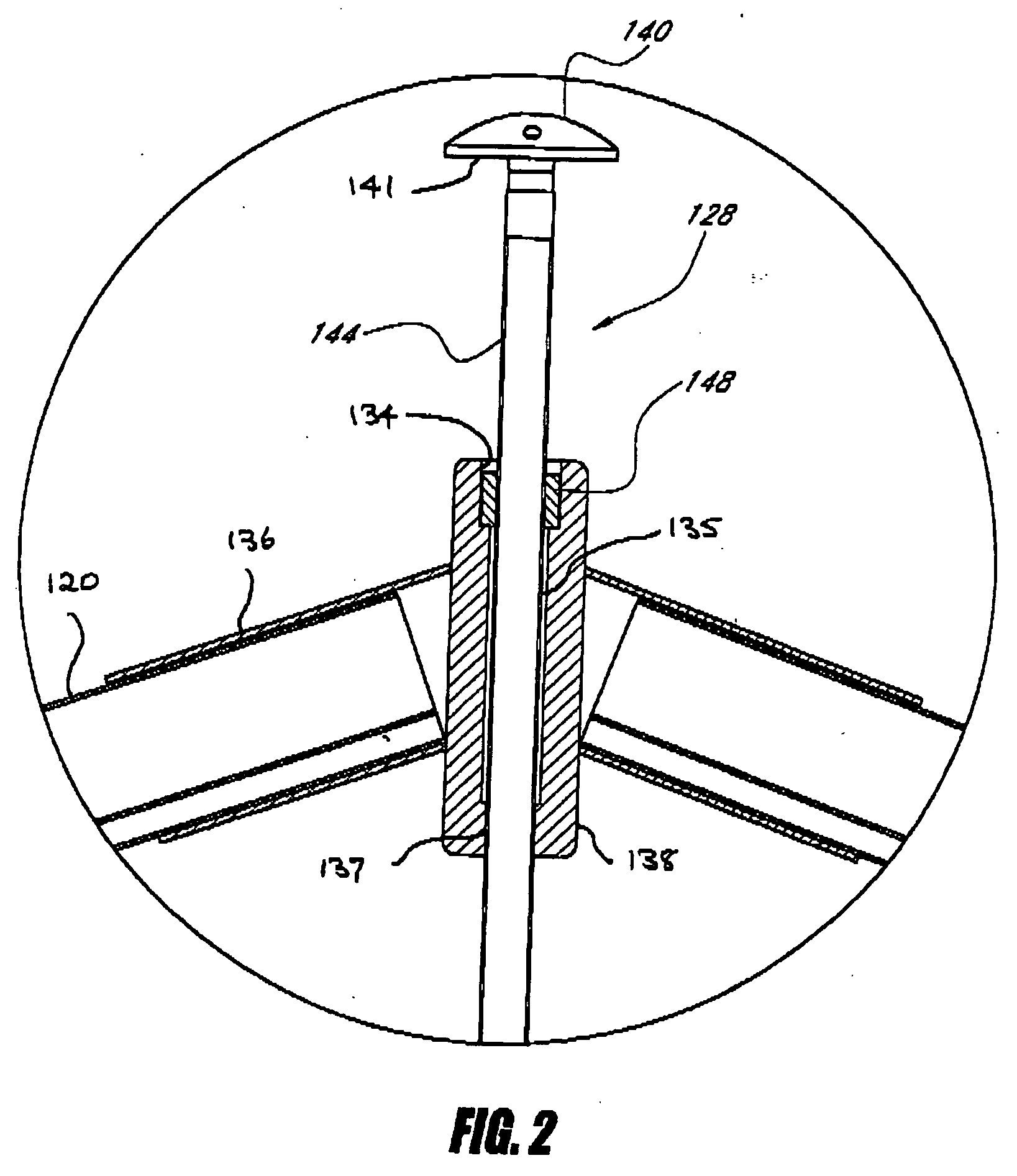

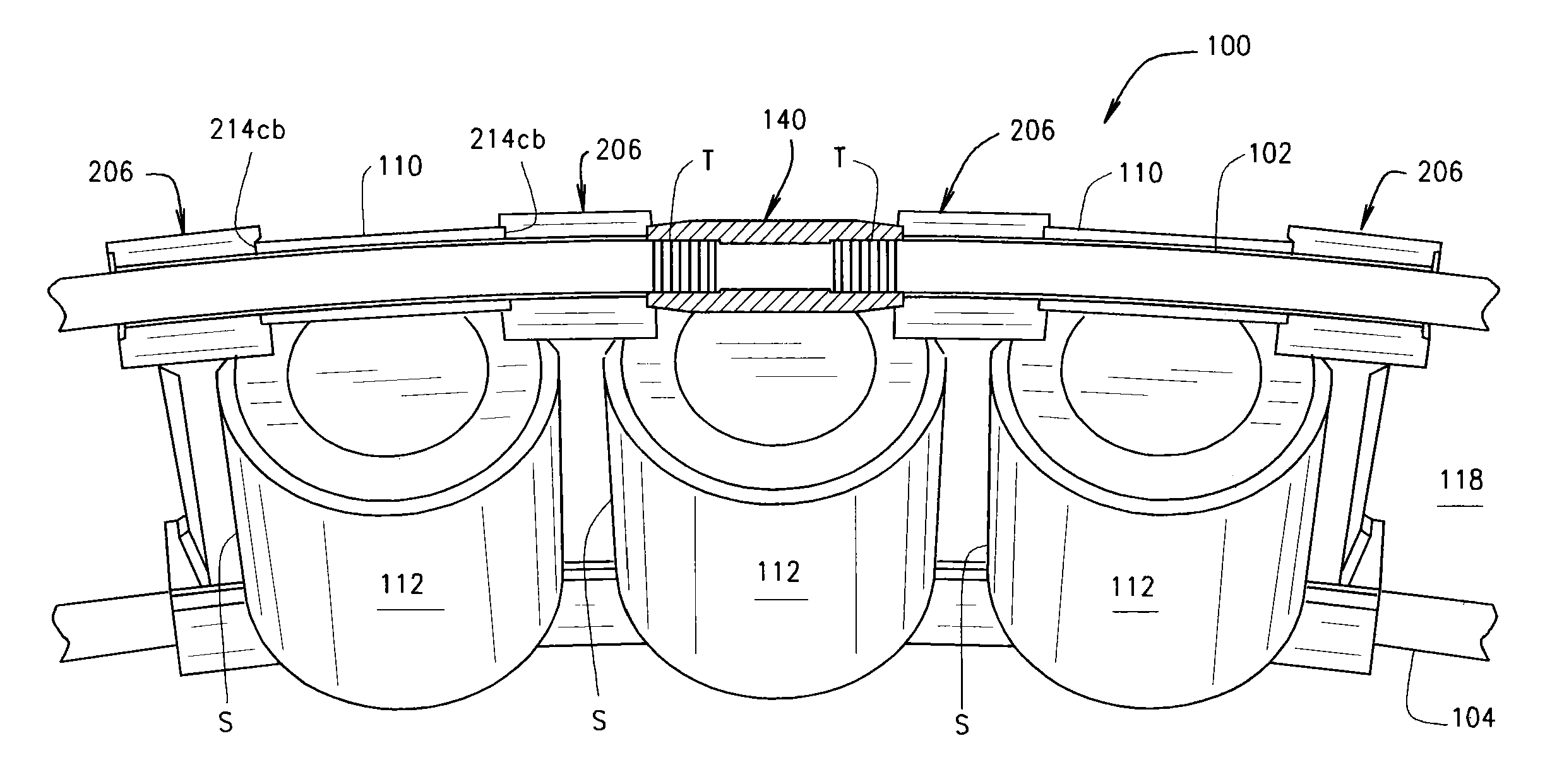

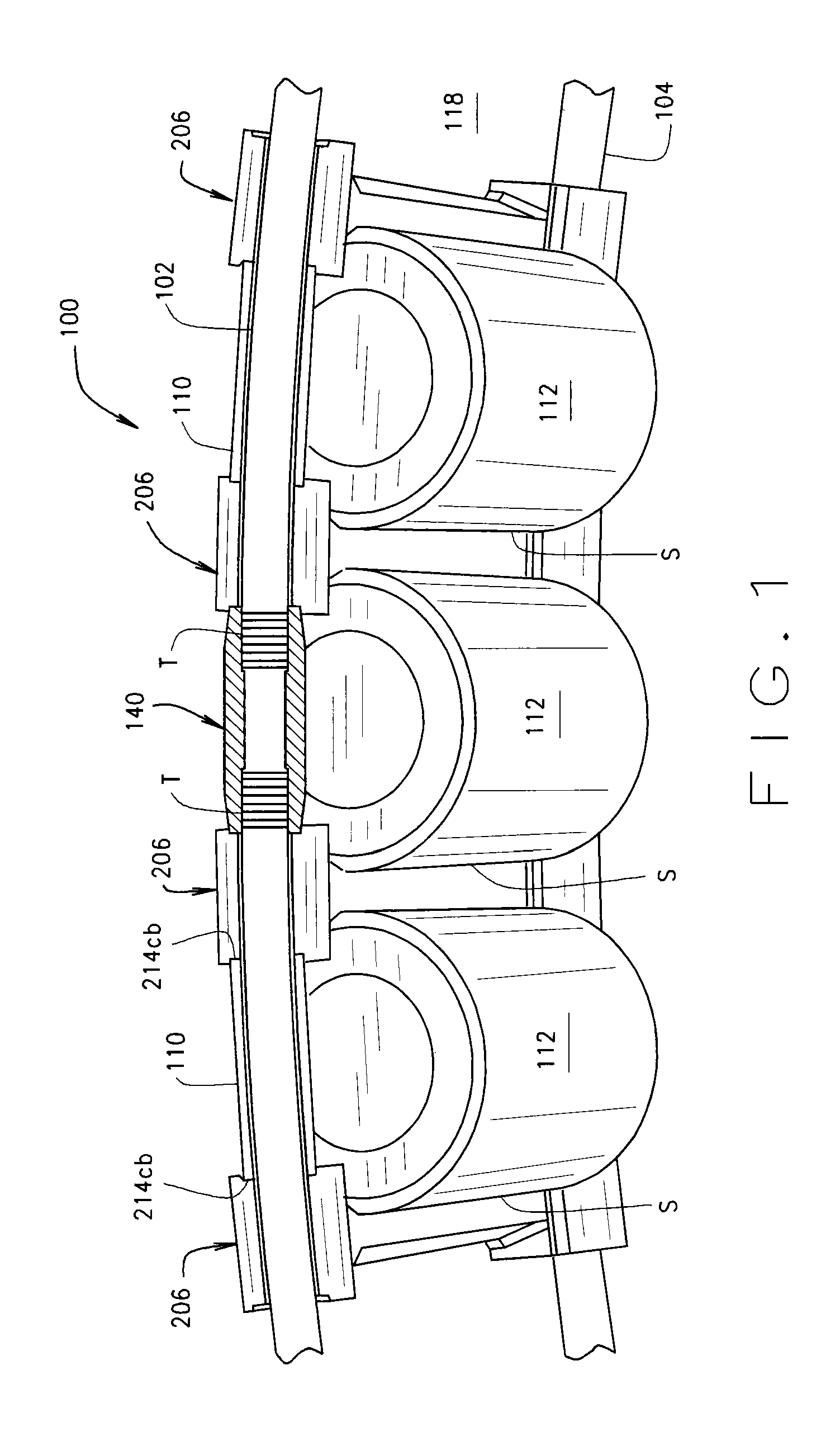

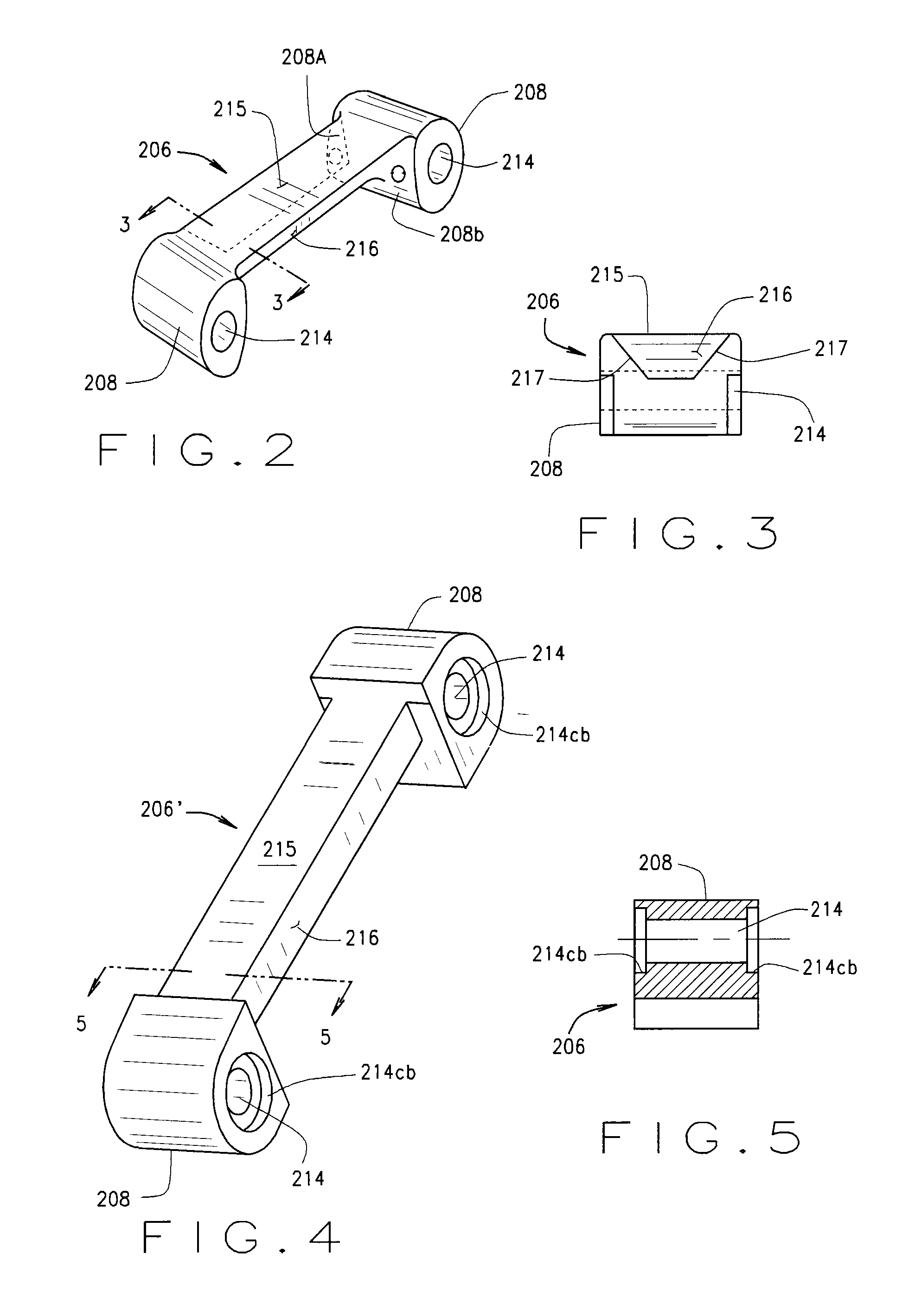

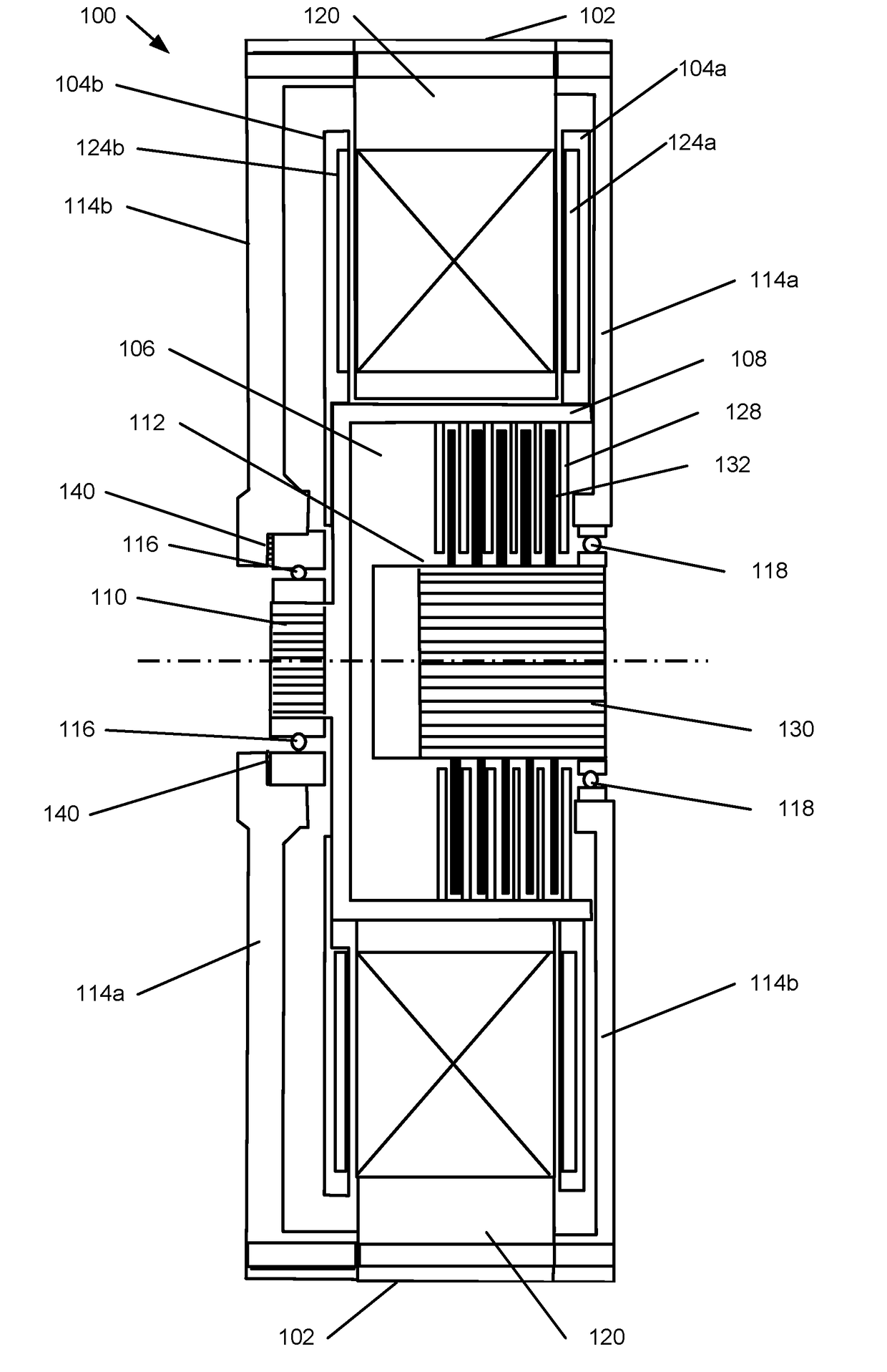

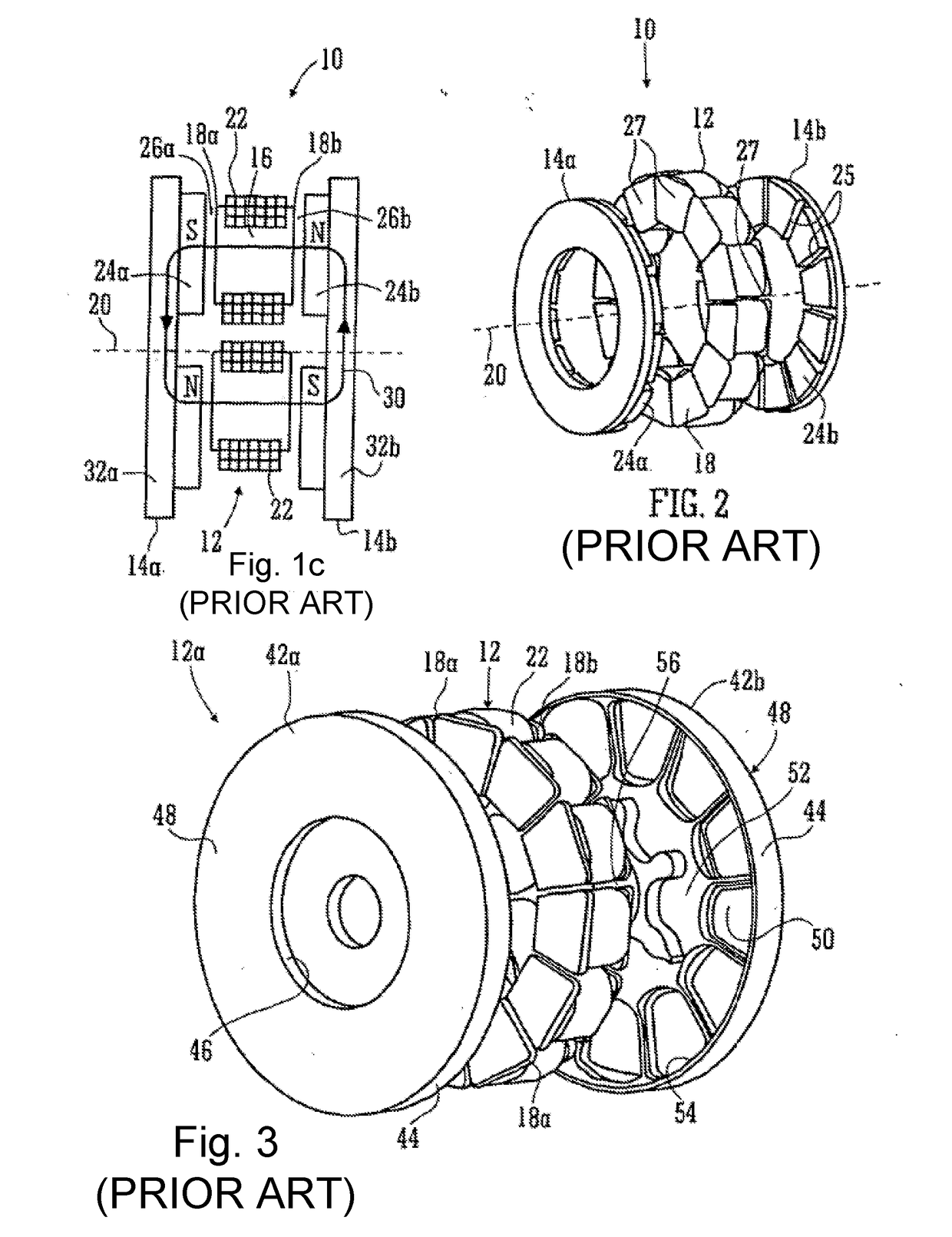

Segmented bearing retainer

A bearing cage assembly (100) comprises a plurality of discrete bridge elements (206) disposed between adjacent rolling elements (112) and coupled between first and second axially spaced cage support wire rings (102, 104) which are appropriately tensioned. Spacers (110) are disposed between adjacent bridge elements and engage the bridge elements in a piloted engagement. The bridge elements maintain a separation between rolling elements, retain the rolling elements within the bearing assembly, and function as a lubrication reservoir for grease lubricated bearings. Profiled surfaces on the bridge elements position the bearing cage assembly on at least one axial end of the rolling elements.

Owner:THE TIMKEN CO

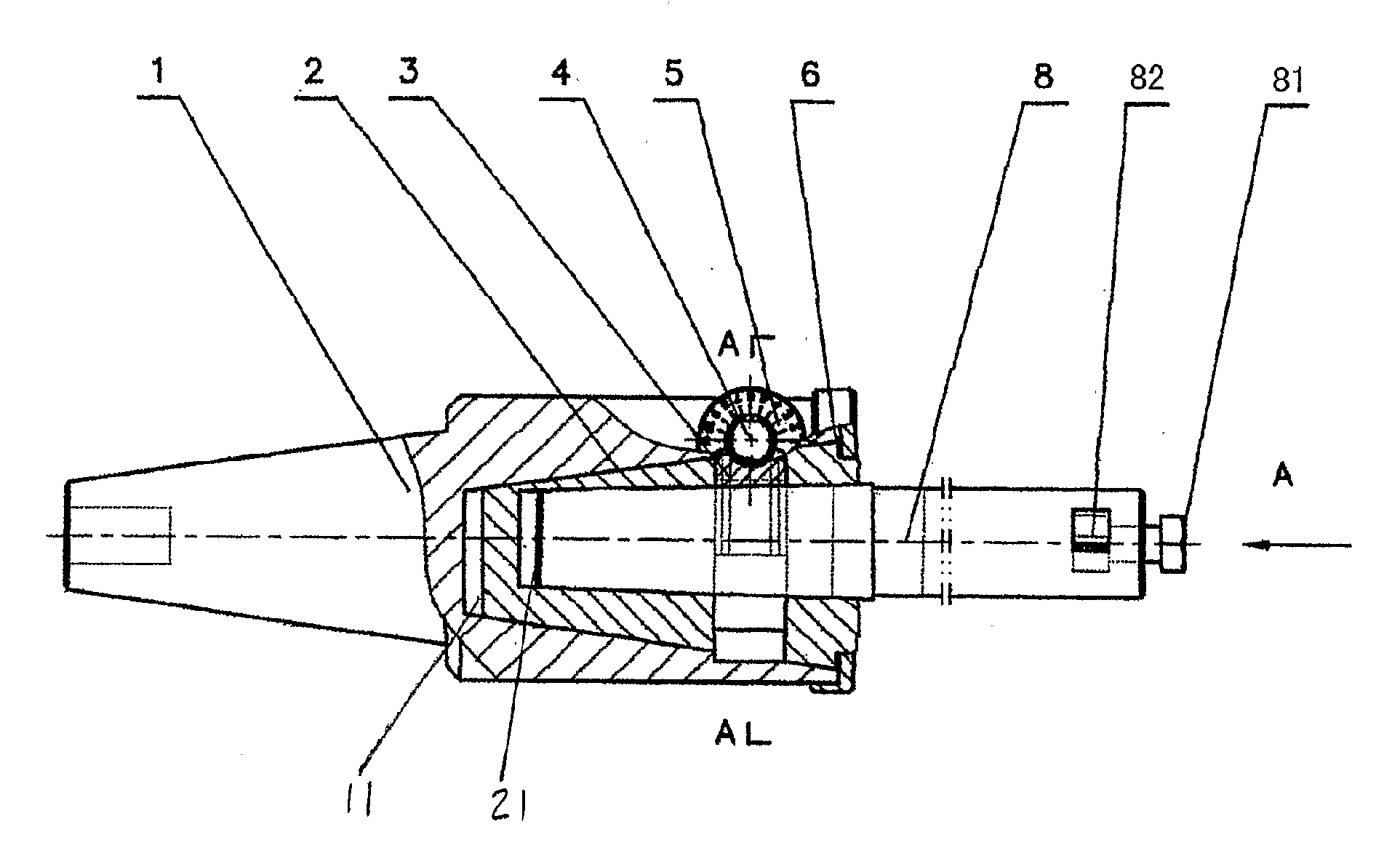

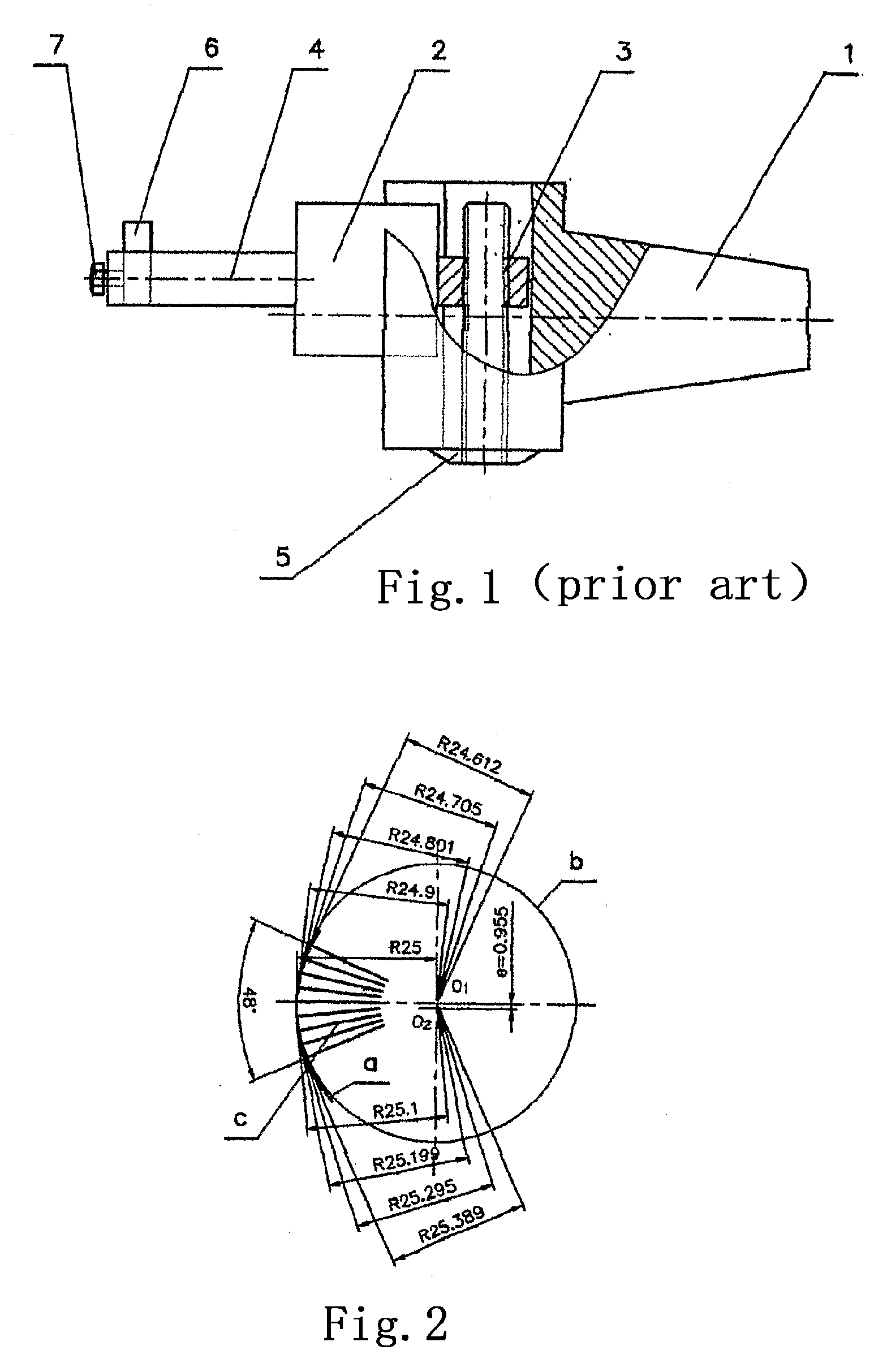

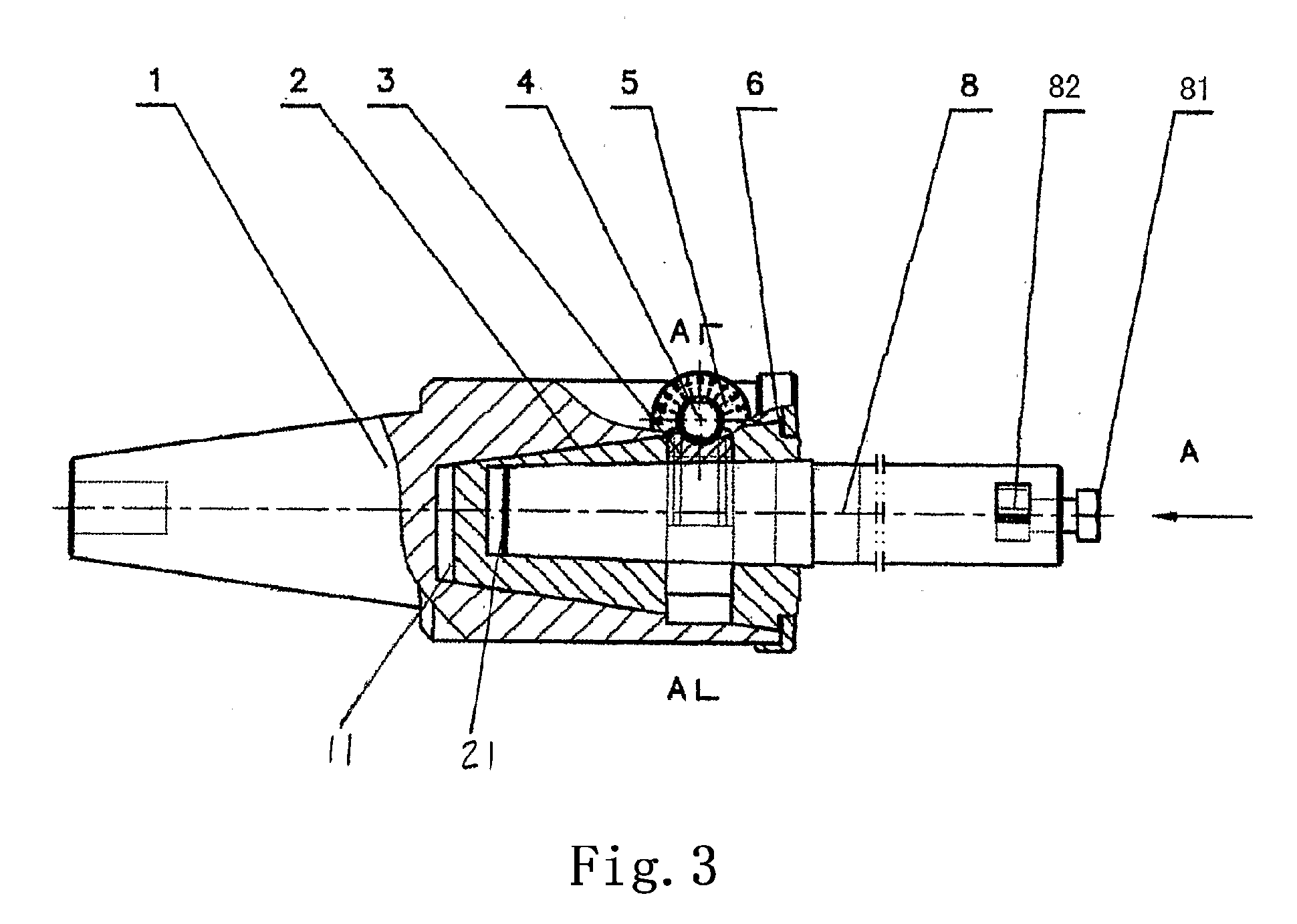

Fine adjusting method of the feed amount of the boring cutter and the adjusting device thereof

InactiveUS20090116916A1Accurate feed amount valueGood linearityProgramme controlThread cutting toolsOffset distanceKnife holder

A fine adjusting method of the feed amount of a boring cutter includes the following steps: a shank body rotates around its axes as the center of a circle to make the cutter tip rotate around its axes as the center of a circle which is apart away from the axes with an offset distance e therebetween so as to change the feed amount. An adjusting device which can achieve the fine adjusting method of the feed amount of the boring cutter includes: a shank body which has a tapered bore, and the axes of the tapered bore is apart away from the axes of the shank body; a rotating cone body which cooperates with the tapered hole; and the rotating cone body is provided with another tapered hole; a changeable cutter holder which is installed in the tapered hole of the rotating cone body; and a drive mechanism which mounts on the shank body and drives the rotating cone body to rotate, therefore makes the changeable cutter holder rotate so as to achieve the micro-feed of the cutter tip.

Owner:ZUO DEJIAN

Lathe for manufacturing ophthalmic lenses made of plastic

ActiveUS8683897B2Easy to operate the machineRigid structureLathesMachine tool componentsRotational axisEngineering

A turning machine for producing non rotationally symmetric surfaces of synthetic spectacle lenses, having a support plane E, a machine bed made of cast iron with a width b1 and a mass m1, a linear motor with an actuator comprising a turning tool holder and an oscillation axis Z, a workpiece spindle with a rotational axis C and a movement axis X, wherein the machine bed has at least two bearing surfaces arranged at a distance for the linear motor and for the workpiece spindle, and between the two bearing surfaces, a chip space is provided which is limited at least partially by the machine bed, wherein the linear motor is supported on the first bearing surface and the workpiece spindle is supported on the second bearing surface in relation to the chip space opposite the linear motor, wherein the mass of the machine bed has the maximum value m1, and the value m1 lies between 100 kg and 500 kg, between 150 kg and 300 kg, between 170 kg and 200 kg or 180 kg. A turning machine, in which the ratio of the mass m1 of the machine bed to a moved mass m2 of the linear motor 3 is greater than a quotient Q, wherein the quotient Q is between 1:500 and 1:20, between 1:60 and 1:30 or between 1:140 and 1:100, or 1:40 or 1:120.

Owner:SCHNEIDER GMBH & CO KG

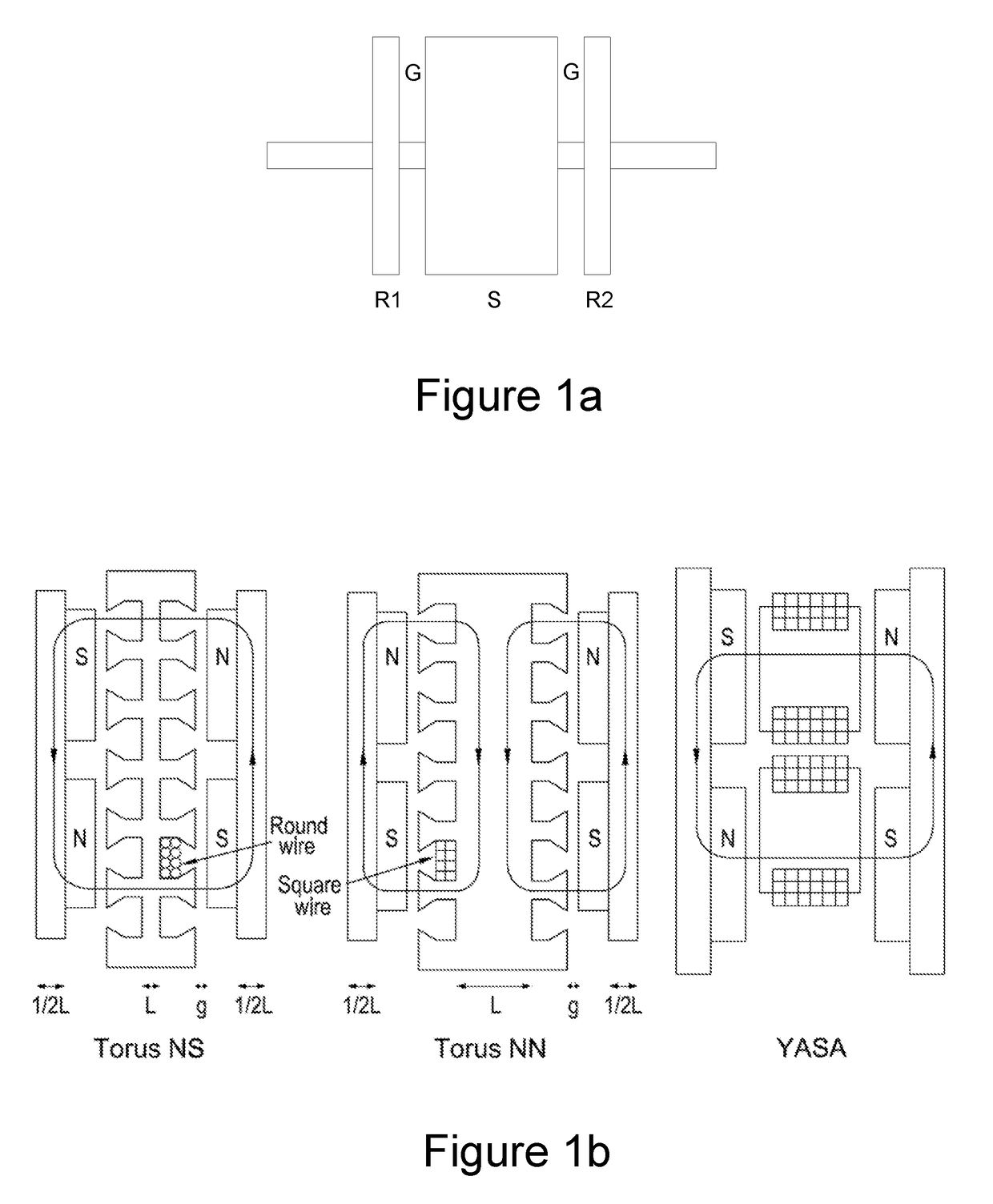

Axial flux machine arrangement

ActiveUS20180323679A1Easy to integratePacked tightlyMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringAxial flux

An axial flux machine is provided with an integrated clutch assembly, which is housed within the bore of an annulus-shaped stator of the machine. First and second rotors, located either side of the stator are attached to the clutch basket of the clutch assembly, and rotate in unison relative to the stator. A machine housing is provided between the stator and an engagement face of the clutch basket, seated on bearings between the clutch basket and machine housing, to provide a rigid structure.

Owner:YASA LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com