Synthetic method of semaglutide

A technology of semaglutide and synthetic method, which is applied in the field of solid phase synthesis of peptides, can solve the problems of difficult control of D-His racemic impurities, unfavorable industrial production, low purity and yield, and reduce production costs and difficulties , The effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

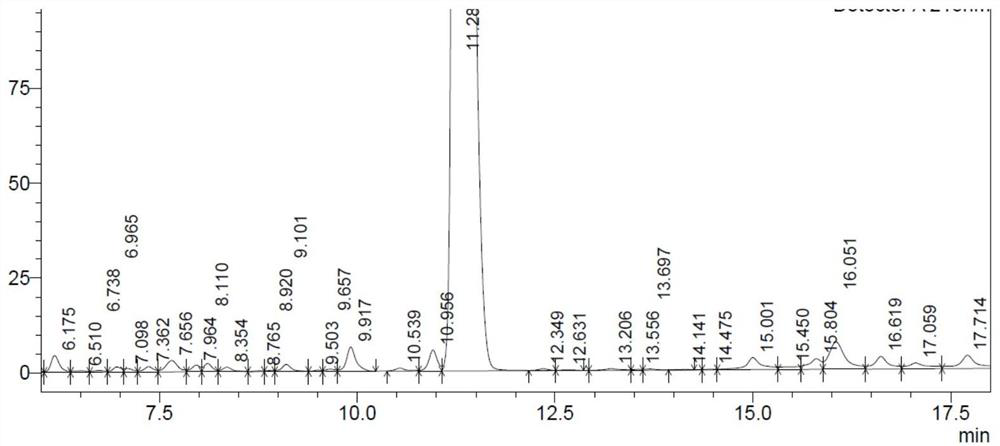

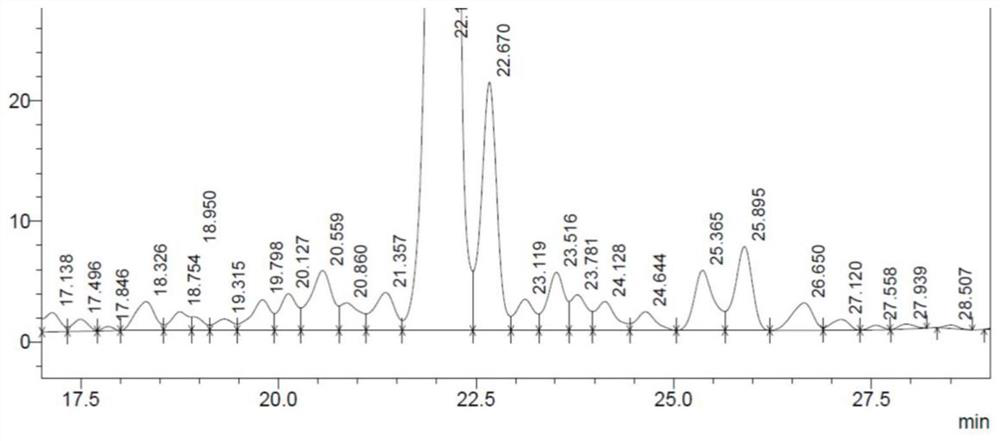

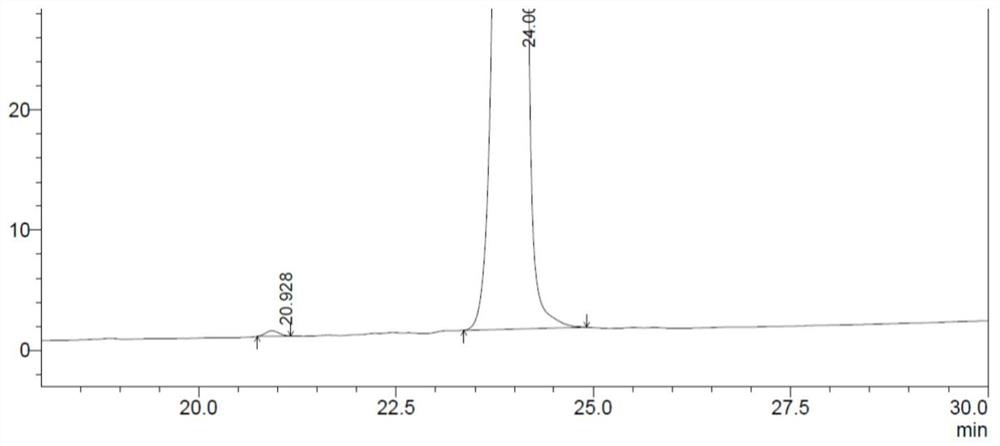

Image

Examples

Embodiment 1

[0043] Embodiment 1 substitution degree is the preparation of the Fmoc-Gly-CTC resin of 0.8mmol / g

[0044] A. Add 10g (13mmol) of 2-CTC resin with a substitution degree of 1.3mmol / g into the reaction kettle, add 100ml of dichloromethane, mix for 2min, filter out the dichloromethane, then add 100ml of dichloromethane, and mix for 40min , filtered off dichloromethane, and finally added 100ml of dichloromethane, mixed for 2 minutes, filtered off dichloromethane, and the resin was set aside.

[0045] B. Weigh 9.81g of Fmoc-Gly-OH and 5.35g of HOBT into a beaker, add 100ml of DMF and 5.46ml of DIEA, stir and activate the solution at 0-10°C for 5min, then pour it into the CTC resin obtained in step A , Mixed for 4h at 20-25°C. After the reaction was finished, 100ml of DMF was added, and the DMF was filtered off. 4 ml of methanol and 5.46 ml of DIEA were added and mixing was continued for 1 h. After the reaction, filter with suction, wash the resin 5 times with DMF, 100ml each tim...

Embodiment 2

[0047] Embodiment 2 substitution degree is the preparation of the Fmoc-Gly-CTC resin of 1.2mmol / g

[0048] A. Add 10g (18mmol) of 2-CTC resin with a substitution degree of 1.8mmol / g into the reaction kettle, add 100ml of dichloromethane, mix for 2min, filter out the dichloromethane, then add 100ml of dichloromethane, and mix for 40min , filtered off dichloromethane, and finally added 100ml of dichloromethane, mixed for 2 minutes, filtered off dichloromethane, and the resin was set aside.

[0049] B. Weigh 9.81g of Fmoc-Gly-OH and 5.35g of HOBT into a beaker, add 100ml of DMF and 5.46ml of DIEA, stir and activate the solution at 0-10°C for 5min, then pour it into the CTC resin obtained in step A , Mixed for 4h at 20-25°C. After the reaction was finished, 100ml of DMF was added, and the DMF was filtered off. 4 ml of methanol and 5.46 ml of DIEA were added and mixing was continued for 1 h. After the reaction, filter with suction, wash the resin 5 times with DMF, 100ml each tim...

Embodiment 3

[0051] Example 3 Preparation of semaglutide S1-S4 peptide resin Boc-His(π-MBom)-Aib-Glu(OtBu)-Gly-CTC resin

[0052] A. Pour all the Fmoc-Gly-CTC resin obtained in Example 1 into the reaction kettle, swell and mix with 100ml DCM for 15min, and then drain it. Add 100 ml of 20% piperidine / DMF solution, mix at 20-30° C. for 5 min, and drain. Add DMF100ml, mix for 5min, and drain. Add 100ml of 20% piperidine / DMF solution, mix at 20-30°C for 10min, and drain. Add DMF100ml, mix for 5min, and drain. Repeat washing with DMF 8 times, 100ml each time, mix 5min each time, and after the seventh washing, test the filtrate with pH test paper, the result shows that the pH is 6.5-7.0 is qualified.

[0053] B. Weigh 8.50g of Fmoc-Glu(OtBu)-OH, 3.03gDIC and 2.7g HOBT in turn in a clean 1L beaker, add 100ml of DMF / DCM solution with a volume ratio of 1:1, place in ice water at 0 Stir and dissolve with a mechanical stirrer at -10°C. After the temperature is constant, continue to maintain the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com