Single-direction waterproof plate with copper plated film and preparation method thereof

A waterproof board, copper plating technology, applied in chemical instruments and methods, other household appliances, paper/cardboard layered products, etc., to reduce the direct paste process, reduce material costs, and meet the effect of waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

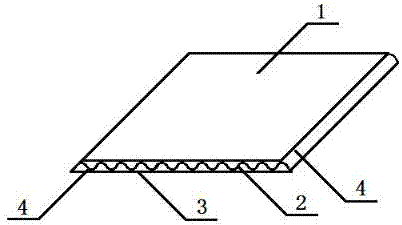

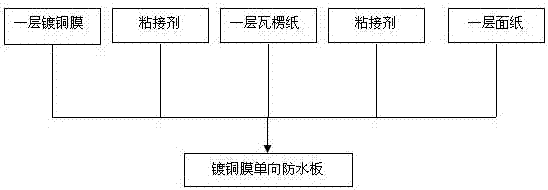

[0011] The following examples further illustrate the process of the preparation method of the present invention: see appendix figure 1 , the present invention can be based on figure 1 The preparation method process implements the production of a copper-plated one-way waterproof board. The specific steps are: use a layer of copper-plated film 1, a layer of corrugated paper 2, a layer of paper 3 and an adhesive 4, place the corrugated paper 2 between a layer of copper-plated film 1 and a layer of paper 3, and use an adhesive 4 Paste the copper-plated film 1, the corrugated paper 2 and the face paper 3 together to form an integral board, that is, make a copper-plated one-way waterproof board, which can be used after drying.

[0012] combine figure 1 and see figure 2 The embodiment of the copper-plated film unidirectional waterproof board and its preparation method can be further elaborated: using a layer of copper-plated film 1, a layer of corrugated paper 2, a layer of paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com