Laser-film unidirectional waterproof plate and preparation method thereof

A technology of laser film and waterproof board, applied in chemical instruments and methods, paper/cardboard layered products, lamination, etc., to achieve the effect of satisfying waterproof quality, reducing material cost, and clear steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

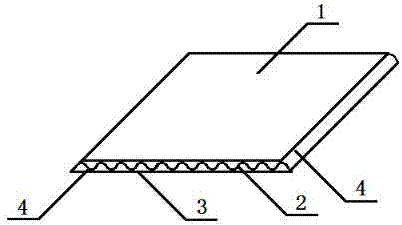

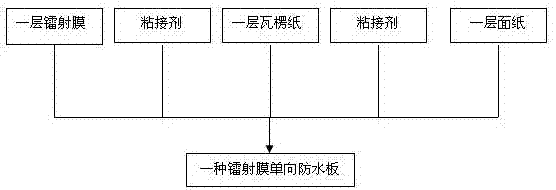

[0011] The following examples further illustrate the process of the preparation method of the present invention: see appendix figure 1 , the present invention can be based on figure 1 The process flow of the preparation method implements the production of a laser film one-way waterproof board. The specific steps are: use one layer of laser film 1, one layer of corrugated paper 2, one layer of paper 3 and adhesive 4, place the corrugated paper 2 between one layer of laser film 1 and one layer of paper 3, and use adhesive 4 to seal Laser film 1, corrugated paper 2 and face paper 3 are pasted together to make it an integral board, that is, a kind of laser film one-way waterproof board is made, which can be used after drying.

[0012] combine figure 1 and see figure 2 The embodiment of the laser film one-way waterproof board and its preparation method can be further described: using a layer of laser film 1, a layer of corrugated paper 2, a layer of paper 3 and adhesive 4 as ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com